Description

Special accessory for all Breworx brewhouse machines – intended for the brewhouses with production capacities from 250 up to 6000 liters per batch of wort :

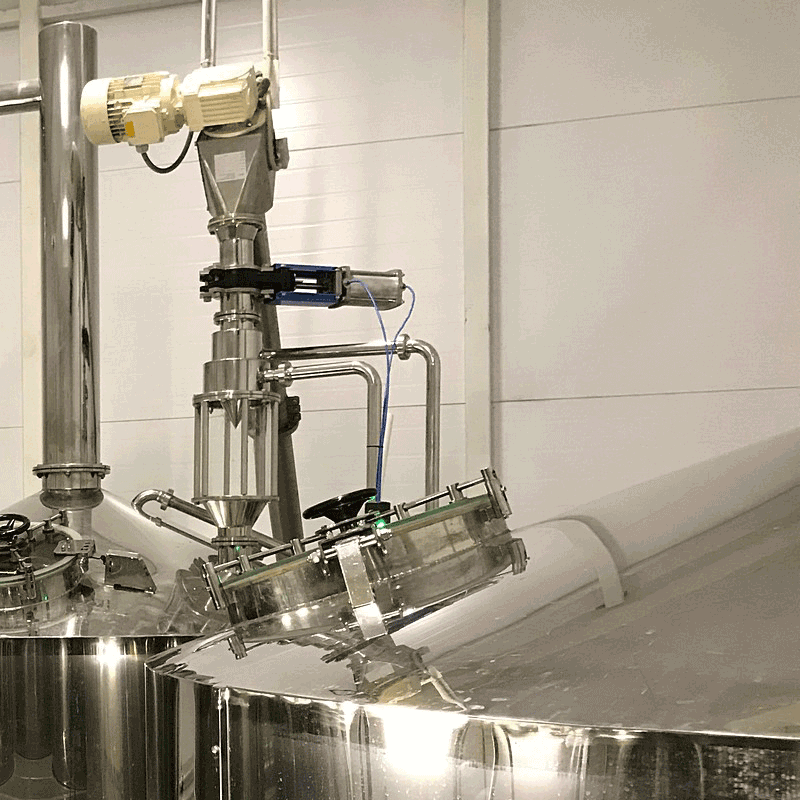

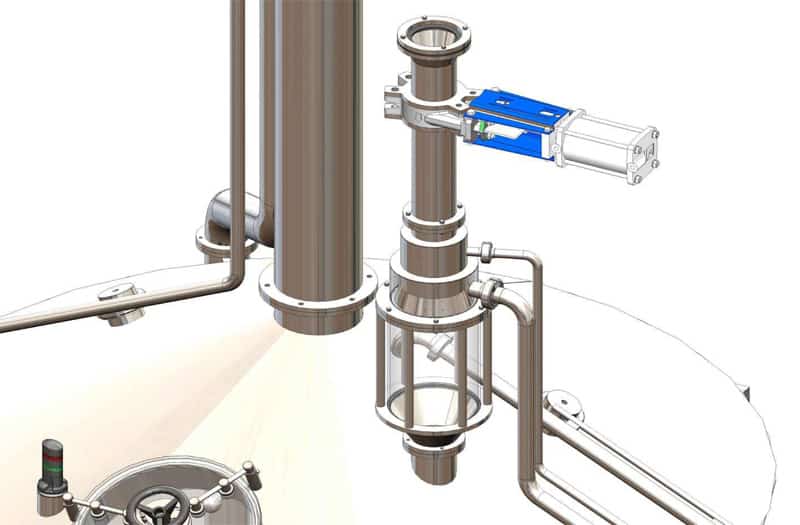

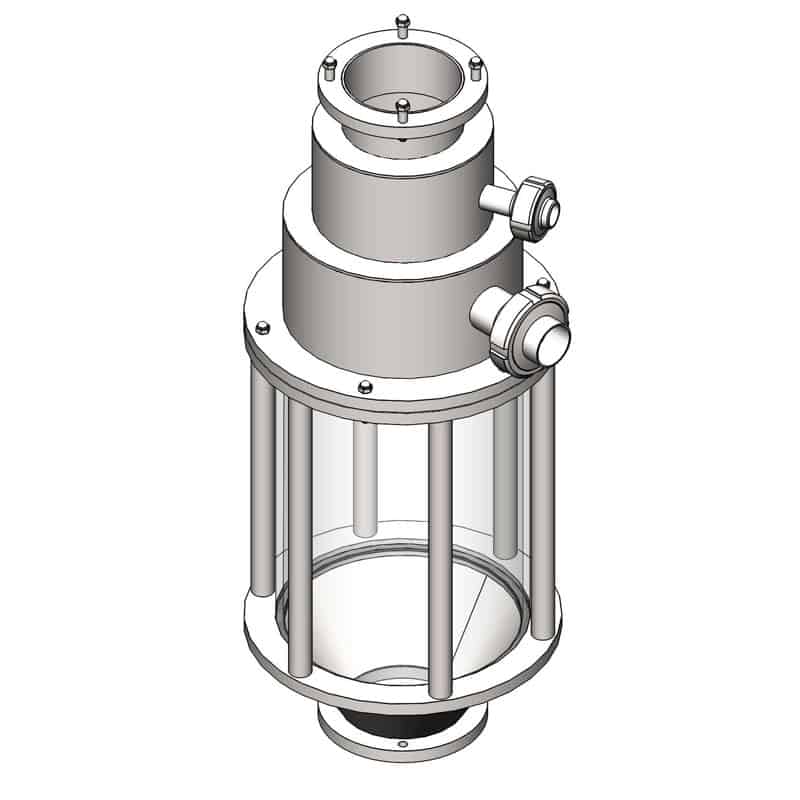

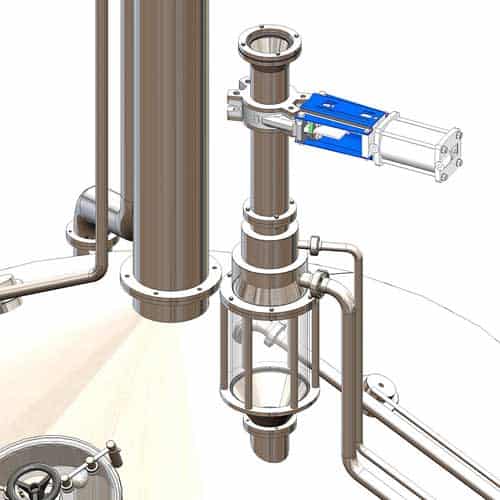

PREMASHER – The malt humidifier is intended to continually moistening the crushed malt grains during their pouring from the screw conveyor into the mashing tank. It is made of AISI 304 steel and tempered sight glass with a diameter of 215 mm, thickness 8 mm.

The malt humidifier is fitted with a 50mm sanitary shower connected to the brewhouse machine CIP sanitation system. Maximum water flow 40 l / min.

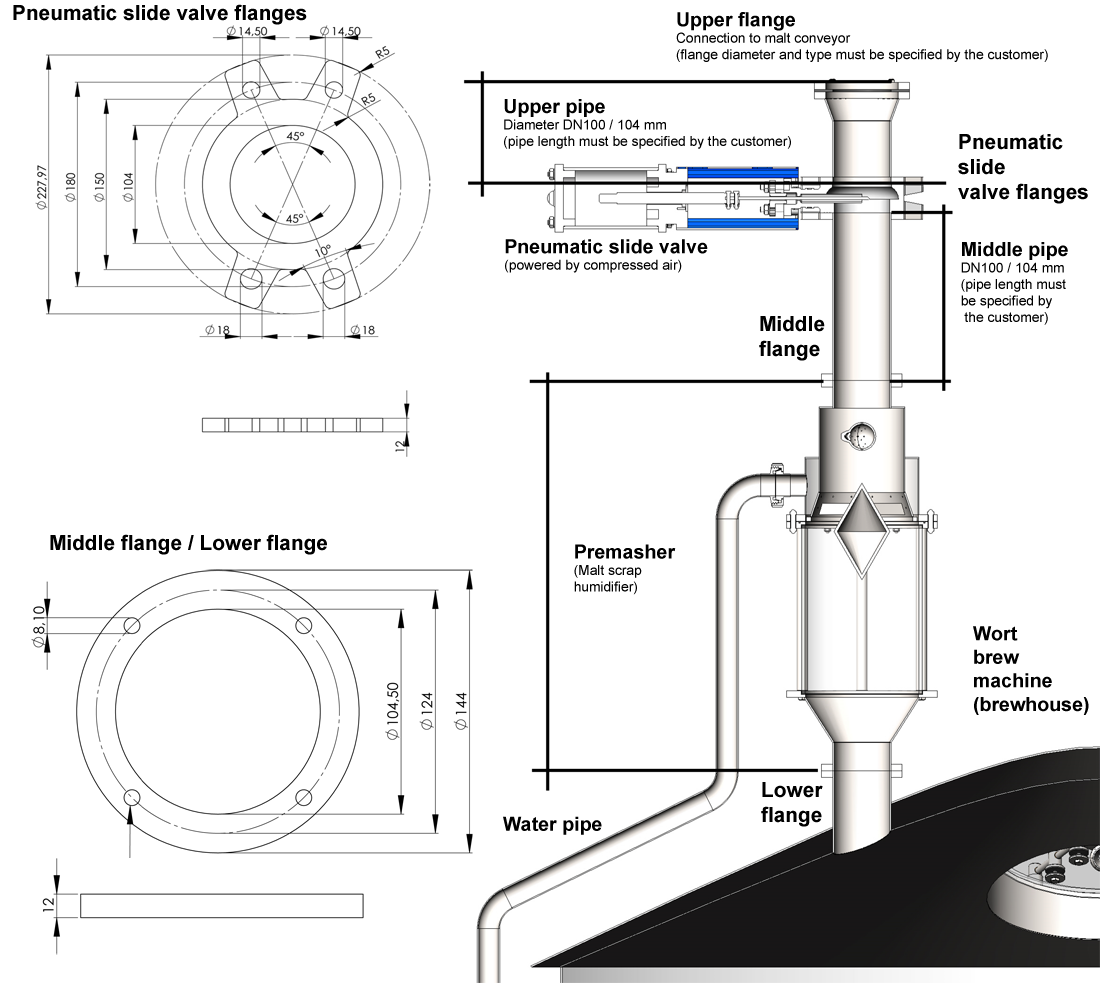

The inlet can be optionally equipped with the pneumatic gate valve DN 125 AISI 304 operated from the central PLC control system.

Description :

- Inlet for dry malt scrap – the connection flange DN 100 with screw holes

- Output of humidified malt scrap – the connection flange DN 100 with screw holes

- Sightglass – transparent glass tube Ø 215mm

- Sanitation input DIN 11851 female/male DN 20

- Sprinkling water input DIN 11851 female/male DN 40

Why do we recommend a malt humidifier?

Three ways for the mixing of malt scrap in water before the mashing process

During a mixing of the grinded malt grains (malt scrap) in water before the mashing process at the prescribed temperature, there must be no formation of lumps and damage to the malt enzymes. For achieve of that the blade stirrer and the PREMASHER (malt humidifier) are used.

There are 3 ways of the mixing the malt scrap in water before the mashing process :

1.) Cold procesure :

Pouring the malt scrap into water with temperature of 20°C. So called mash water represents 2/3 of water. After addition of mash water hot water of 80°C is added, represents 1/3 of the total water content. By mixing of both parts of water temperature of water grows its temperature up to 35-38°C

2.) Warm procedure :

Pouring the malt scrap into water with temperature a little higher than 35–38 °C (maximaly 40–42 °C). After mixing, a temperature of 35-38°C is achieved. This way is used for poorly decomposed malts, in order not to damage the enzymes by adding boiling water.

3) Hot procedure :

Pouring the malt scrap into water with temperature of 62-65 ° C.

Water at temperature 62-65 ° C is used. It is recommended for very decomposed malt. By exceeding 52°C, protein breakdown is prevented and a fuller taste, better foaming of beer and increased colloidal stability of beer are achieved.

Lighter malt mash is usualy prepared for brewing of light beers – from 5 to 6 hl of water is added per 100 kg of grinded malt grains.

Denser malt mash with is usualy prepared for brewing of dark beers – from 4 to 5 hl of water is added per 100 kg of grinded malt grains.

Mashing in usually carried out at the slurry temperature of 35–37 ° C. It is carried out in a mashing tank equipped with a stirrer, a hatch, a water inlet and a malt humidifier (PREMASHER) in which the malt scrap is humidified before pouring into the mashing tank (malt humidification).

The third way is possible to be used only when the wort brew machine is equipped with the malt humidifier

Options :

1. Pneumatic slide valve DN 125 AISI 304 … € 906,-

- Is to be operated from the central PLC control system.

2. Upper pipe – for connection to a malt conveyor … € 61,-

- Diameter DN 100 / 104mm – Type of the upper flange and length of the pipe must be specified by customer

3. Middle pipe – between the premasher and the pneumatic slide valve … € 56,-

- Diameter DN 100 / 104mm – Length must be specified by customer

4. Connection flanges – between the premasher, the malt conveyor and the pneumatic slide valve … € 56,-

- Other type of the connecting flanges – Types and dimensions must be specified by customer

Reviews

There are no reviews yet.