Description

BREWORX CLASSIC-ECO 300 : Compact industrial brewhouse for small restaurants

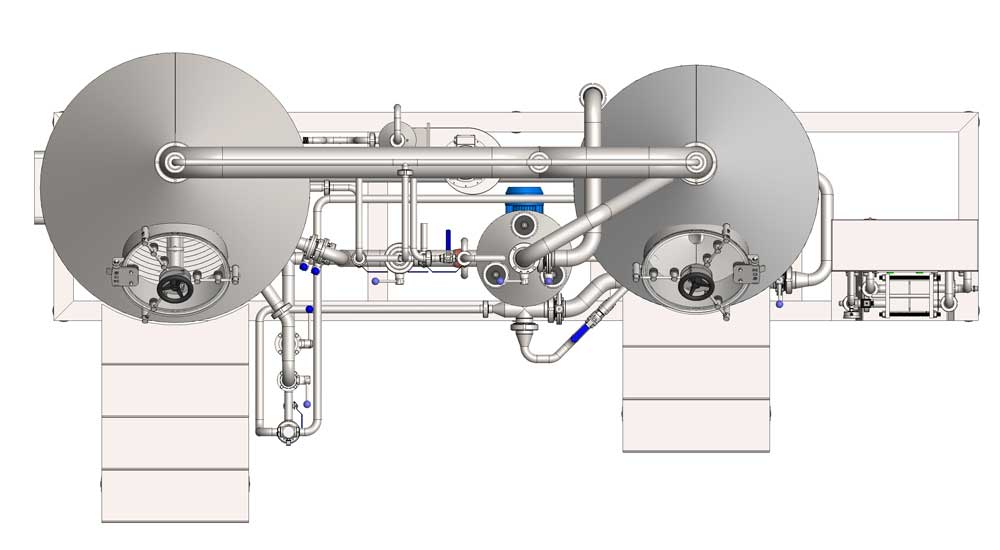

The BREWORX CLASSIC-ECO 300 wort brew machine is a compact food machine which includes all necessary equipment to produce 330 liters of wort (for production approximately 300 liters of beer) in one batch from malt, water and hops. Alternatively is possible to produce wort from malt extract or wort concentrate (so called beer concentrates). A simplified industrial design of the machine allows effective work during entire wort production process using simple step PLC controller for heating of the vessels, semi-automatic system or fully automatized system. Transfer of heat from the electric heating spirals to water, mash or wort ensures oil.

This wort brew machine is a main equipment of the BREWORX CLASSIC-ECO 300 breweries, MODULO CLASSIC 300 breweries, but it can be use also with other type breweries too.

Fully equipped compact wort brew machine BREWORX CLASSIC-ECO 300 :

(The vapor condenser and the integrated wort cooler/aerator are optional parts that are not included in a basic price … )

Technical description and features :

The brewhouse wort machine is a food equipment for the production of wort (intermedia product in a beer production). A construction of the brewhouse allows the wort production using both infusion and decoction methods of the mashing process.

All components are firmly connected to a compact self-supporting frame.

The cooking set is transported in assembled state including all electric wiring and pipelines, valves, sensors and other equipment. Only several parts are dismounted to easy transport and they are simply and quickly assembled by customer on a place using our assembling instructions.

The wort brew machine consists of the following components:

Functional tanks :

1. Mash tank / Wort boiling tank / Whirlpool tank – Multifunction vessel for the mashing of malt grains in watert and for the boiling of wort with hops. The tank is equipped with the tangential inlet for the final centrifugal separation of hops from wort.

2. Filtering tank – the tank wit special sieve to separation of malt rests from wort before boiling wort with hops.

3. Heating tank – tank equipped with electric heating elements and the oil heat exchanger serves to the heating of water, mash and wort.

Basic equipment :

- Main frame for easy transport of pre-assembled machine

- Removable stairs for easy access to the tanks and control elements

- Pipe system with valves, filters, sightglasses a control elements, DN 25 / DN 40

- Centrifugal pump.

- Heating system for mixing and boiling of wort based on oil as a heat transfering medium with the electric heating elements

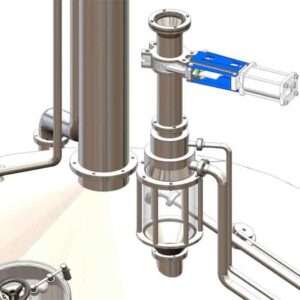

- Integrated wort cooler (optional accessory) with the aeration candle

- Electric switchboard

- Electric system for measuring and manual or automatic control of the wort brewing process

- Control panel with touch display (only semi-automatic and fully-automatic version)

Optional equipment (for surcharge) :

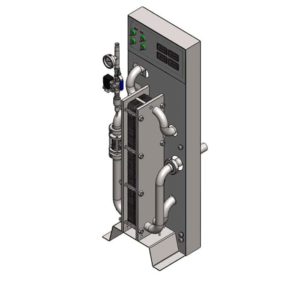

- Condenser of vapors from the wortbrewing process with the stainless steel ventilator and regulation system (optional accessory)

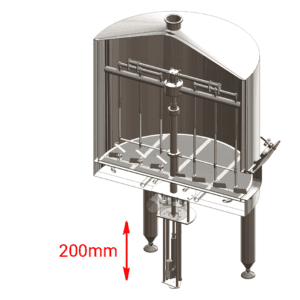

- Lift mechanism of the stirrer in the filtering tank (optional accessory)

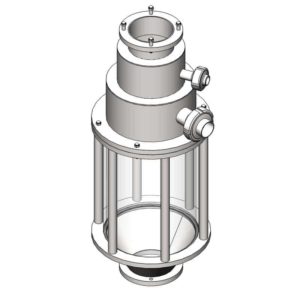

- Malt humidifier (optional accessory)

- Special centrifugal pump EBARA DWO 150 designed for high temperatures up to 115°C with the cooling system of the shaft seal with very long lifetime and liquid anti-leak protection (optional accessory)

- Increasing heating power by 6kw – the special heating elments (optional accessory)

- Electric switchboard cabined made of stainless steel (optional)

- Induction flowmeter (only for the semi-automatic and fully automatic versions)

Specifications and technical parameters :

1. Stainless steel base frame with auxiliary stairs

The frame is made of stainless steel AISI 304. There are 8 adjustable support feet 0-40 mm on the frame.

The frame surface is brushed – matt finish.

The frame includes removable stairs.

2. Combi tank for the mashing, wort boiling, wort whirlpooling

Stainless steel vertical double-walled vessel insulated with NOBASIL mineral wool.

The combi tank serves for mixing of malt in water, mashing, boiling of wort with hops and wort whirlpooling.

This vessel has a top eccentric hat with a steamer interconnected with a filtering tank to remove of vapors and elimination of pressure surges.

| Material | Stainless steel AISI 304 / 1.43.01 |

| Internal and outer surface finish | 2b Ra 08/ SB |

| Outer diameter | 1000 mm |

| Weldings | In argon protective atmosphere / grinded and polished |

| Volume effective / total | 330 / 550 liters |

| Insulation | NOBASIL mineral wool |

| Weight netto / brutto | 179kg / 509kg |

| Maximal working pressure | 0.1bar |

3. Filtering tank for the separation of malt grains from wort

Stainless steel vertical double-walled vessel insulated with the NOBASIL mineral wool

The vessel serves to separate solid malt particles from wort before the boiling of wort with hops

The vessel has a top eccentric hat with a steamer connected to the mash vessel which eliminates pressure surges affected the quality of the wort produced

The filtering tank has the possibility of the wort filtering both using gravity (pump-free) and vacuum-controlled filtering using the PID controller.

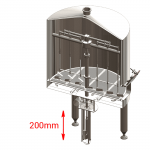

Part of the filtering tank is a knife stirrer and the wort ejector. The knife stirrer can be lifted from height 5mm above the screen up to a height of 205mm above the screen.

A change of the rotation direction causes the change of function between the knife stirrer to the wort ejector.

| Material | Stainless steel AISI 304 / 1.43.01 |

| Internal and outer surface finish | 2b Ra 08/ SB |

| Outer diameter | 1010 mm |

| Weldings | In argon protective atmosphere / grinded and polished |

| Volume effective / total | 330 / 572 liters |

| Insulation | NOBASIL mineral wool 50 mm |

| Weight netto / brutto | 179kg / 509kg |

| Maximal working pressure | 0.1bar |

3. Heating tank for the heating of water, mash and wort

Stainless steel vertical double-walled vessel insulated with NOBASIL mineral wool.

Oil tank filled with glycelin oil. The advantage of the external exchanger is that the oil is not pumped and thus its oxidation does not take place. Temperature low losses are also imprortant advantage of this system. Temperature hysterezion is very low because oil not stay in the heating tank when the heating up is stoped.

This system also allows the decoction to be increased during the wort boiling up to 12% of total volume thanks to the system of circulation and spraying up of the overheated wort. Thanks to spraying up the wort, the foam formed precipitates back into the wort and there is no overflow of foam from the container, which prevents hop loss in the overflowed foam.

| Material | Stainless steel AISI 304 / 1.43.01 |

| Internal and outer surface finish | 2b Ra 08/ SB |

| Outer diameter | 400 mm |

| Weldings | In argon protective atmosphere / grinded and polished |

| Volume of oil : effective / total | 39 / 43 liters |

| Insulation | NOBASIL mineral wool 60 mm |

| Weight netto / brutto | 165kg / 146kg |

| Maximal working pressure | 0.5bar |

Available control systems :

We offer this wort brew machine equipped with one of these levels of the control system :

MC : manual control system

In the manual version, all fittings are manually operated.

- The temperature steps are controlled by a PID controller which ensures an accurate heating gradient in cooperation with the pump so that the temperature rise gradient does not exceed the allowed limits.

- Each temperature has to be entered manually and it is not possible to program several steps in advance. The pump speed is controlled either manually by a frequency converter or by a PID controller according to the selected process.

- This variant is not equipped with the PLC and touch panel.

- This variant does not have an induction flow meter.

SA : semi-automatic control system

In the semi-automatic version, the water fittings are pneumatically operated and as a result some steps can be automatized :

- Filling of tanks with water according to required target volume.

- Mashing process – automatization the temperature steps and times within of the whole mashing process, including regulation of heating gradient.

- Filtering – the whole process is operated automatically. It allows both methods : Gravity and vacuum filtering.

- Pumping of cooled wort – automatic regulation of flow rate according to wort temperature measured on the output of the heat exchanger.

- Start / stop of the vapor condenser. – automatic according to the pressure of the vapors in the tanks.

- This variant is equipped with a PLC and a touch screen, all automatic valves are controlled by a pneumatic elements.

AC : fully-automatic control system

In the fully automatic variant, all steps are controlled by PLC and they can proceed fully automatically. The fully-automatic control system includes all features and equipment as the semi-automatic system … and also some more :

- All valves are fitted with pneumatic actuators.

- Remote control is available via the Android or iOS mobile devices

- Induction flowmeter

- Sensors of empty pipes

- Electronic control of the height of the knife stirrer with a positioner

- Electronic turbidity meter on filtering sight glass

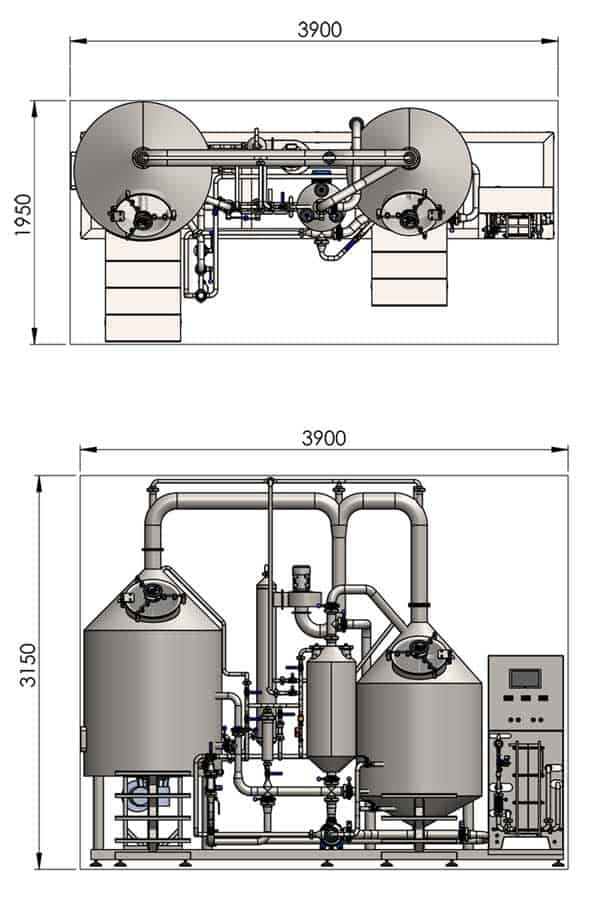

Dimensions

All dimensions are in milimeters.

Optional accessories :

| Recommended options and additional equipment for improvement of the wort brew machine Breworx CLASSIC-ECO 300 | Prices (EUR) |

|---|---|

| ELS : Electric lift of the knife-stirrer in the filtering tank (lifting up to 200mm) | ELS : Electric lift of the knife-stirrer in the filtering tank (lifting up to 200mm)

This customization of the wort brew machine allows you very variable setting position of the knife-stirrer inside the filtering tank. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. The lifting of the knife-stirrer ensures you to speed up the process of souring wort. This is important to avoid excessive oxidation of the wort during the filtering process. |

|

| WCA : Integrated wort cooler and aerator with flow capacity up to 300 liters per hour | WCA : Integrated wort cooler and aerator with flow capacity up to 300 liters per hour

The integration of the compact cooler and aerator to the wort brew machine allows the cooling and aeration of wort without use of external devices. It allows also the measuring and precise regulation of output temperature of wort on the end of the wort production cycle, before start of the beer fermentation, using the automatic control system of the brewhouse. |

|

| BVP : Integrated waste vapor condenser with the stainless steel ventilator and the automatic regulation | BVP : Integrated waste vapor condenser with the stainless steel ventilator and the automatic regulation

This equipment is used for condensation and removal of waste vapors generated in the tanks during the wort brewing process.The vapor condenser allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger may be collected in the hot water tank for later use. |

|

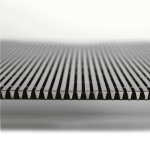

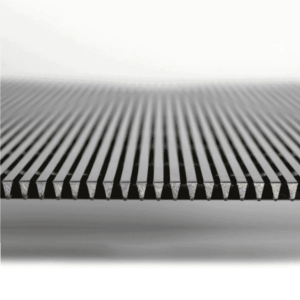

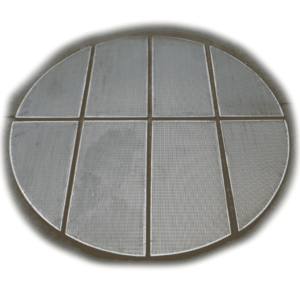

| WSF : Wire sieve to acceleration process filtering of wort | WSF : Wire sieve to acceleration process filtering of wort

Special wire sieve to filtering wort during the wort brew process has by 30% bigger filtering area in comparation with the classic filtering sieves where the holes are cut using a profiled knife. The main benefit is faster filtering of wort through the malt sediment layer. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. It is important to avoid excessive oxidation of the wort during the filtering process. |

|

| MHU : Malt humidifier | MHU : Malt humidifier

The malt humidifier is intended to continually moistening the crushed malt grains during their pouring from the screw conveyor into the mashing tank. It is made of AISI 304 steel and tempered sight glass with a diameter of 215 mm, thickness 8 mm. Part of the system is the Delmatic water mixing system to accurate temperature and water flow measurement, which counts towards the total water volume measurement system for the mashing cycle. Maximum water flow 40 l / min. |

|

Special centrifugal pump – Special pump designed for high temperatures up to 115°C with the cooling system of the shaft seal with very long lifetime and liquid anti-leak protection (optional accessory) Special centrifugal pump – Special pump designed for high temperatures up to 115°C with the cooling system of the shaft seal with very long lifetime and liquid anti-leak protection (optional accessory) |

2643 |

Increasing of heating power by 6kw – the special heating elments with higher heating power ensure the speeding of the wort brewing process. Very useful if you plan to produce more than only one batch of wort per day. Shorter time of each batch of wort saves your time and work. Increasing of heating power by 6kw – the special heating elments with higher heating power ensure the speeding of the wort brewing process. Very useful if you plan to produce more than only one batch of wort per day. Shorter time of each batch of wort saves your time and work. |

528 |

Reviews

There are no reviews yet.