![]()

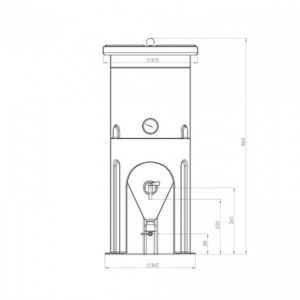

Non-insulated fermentation tanks are either simplified single-jacketed fermenters without insulation intended to be cooled with ambient air or double-jacketed fermenters without insulation intended to be cooled with a liquid.

Their main advantage is low price.

Main disadvantage of non-insulated single-jacketed fermenters is problematic control of the fermentation process because cooling with air is not as efficient as cooling with liquid and it is impossible to accuracy and fastly regulate temperature of fermenting beverage in the tank. This is the main reason why the single-jacketed non-insulated fermenters are not suitable for the main fermentation of beverages when yeast is still very active.

Main disadvantage of non-insulated double-jacketed fermenters is low efficiency of their cooling due big thermal loses to ambient air. It is possible to use them for both phases of the fermentation process but with high consumption of energy.

The second problem is the extreme condensation of water on the surface of the fermenters, which can cause the emergence and spread of bacterial infection.

The non-insulated fermenters are suitable mainly for the secondary fermentation (the beer lagering process, natural carbonation of cider, wine or kombucha etc.) or for storage of finalized drinks in the tanks before their bottling or serving into jars.