Tanks for the production of fermented beverages :

Beverage production tanks are special vessels. They are intended for the production, fermentation, maturation, carbonization, final flavoration, filtration, temporary storage, bottling and sale of beer, cider, sparkling wine and all the similar alcoholic fermented and carbonated beverages.

The tanks are made of certificated stainless steel (AISI 304 or AISI 316 – by their purpose) or polyethylene recommended for production of beverages and safe contact with food and beverages.

We produce and offer these kinds of fermented beverage production vessels :

I. Primary fermentation (main fermentation phase) – primary fermentors

FET : Tanks for the primary fermentation – pressure or non-pressure vessels intended only for the primary fermentation of beer, cider or wine. Only covered tanks are equipped with the fermentation lock or special armature with the manometer and adjustable pressure valve.

- OFV : Opened fermentation tanks – non-covered vessels for the primary fermentation of beer. The main fermentation process of wort takes place in the opened containers. This is a traditional technology for production of typical Czech lager beer.

- CFT : Closed cylindrical fermentation tanks – non-pressure simplified cylindrical vessels without the cone bottom. Closed tanks allow the fermentation of more kinds beer in the same room without risc of contamination with other yeast.

- PFV : Plastic fermentation vessels – Plastic non-pressure vessels for the primary fermentation of small volumes alcoholic beverages like beer, cider or wine. The fermentors are made of food-safe polyethylene.

- HCFT : Simple fermentors for home brewing – simple non-insulated fermentors with small volumes intended mainly for home brewing

II. Secondary fermentation (maturation, carbonization, conditioning phase) – secondary fermentors

BMF : Tanks for the secondary fermentation – pressure vessels intended only to the secondary fermentation (maturation) of beer, cider, wine – the conditioning, natural carbonation under pressure in low temperature. They are equipped with fermentation lock and the special armature with the manometer and adjustable pressure valve.

- MBTVI : Cylindrical pressure fermentors vertical, insulated (for the maturation, lagering, conditioning) – Cylindrical fermentors for the secondary fermentation (maturation, carbonation) of alcoholic beverages, with vertical orientation, with the PUR insulation, cooled by water or glycol.

- MBTVN : Cylindrical pressure fermentors vertical, non-insulated (for the maturation, lagering, conditioning) – Cylindrical fermentors for the secondary fermentation (maturation, carbonation) of alcoholic beverages, with vertical orientation, without the insulation, cooled by air.

- MBTHI : Cylindrical pressure fermentors horizontal, insulated (for the maturation, lagering, conditioning) – Cylindrical fermentors for the secondary fermentation (maturation, carbonation) of alcoholic beverages, with horizontal orientation, with the PUR insulation, cooled by water or glycol.

- MBTHN : Cylindrical pressure fermentors horizontal, non-insulated (for the maturation, lagering, conditioning) – Cylindrical fermentors for the secondary fermentation (maturation, carbonation) of alcoholic beverages, with horizontal orientation, without the insulation, cooled by air.

- PFK : Pressure fermentation kegs – Simple small pressure vessels for the secondary fermentation small volumes of beer or cider under pressure.

III. Both the primary and secondary fermentation in the same tank – universal fermentors and sets

Universal tanks for both primary and secondary fermentation of beer, cider, wine in the same vessel without the pumping beverage between two tanks. Compact units and fermenting sets with fully equipped fermenation system.

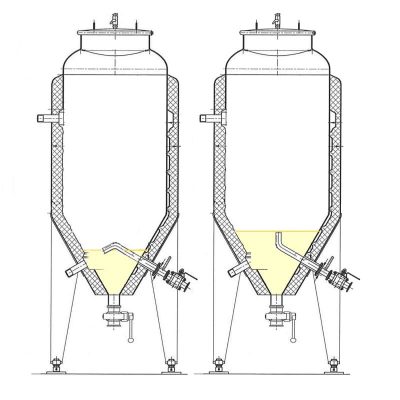

- CCT : Cylindrically-conical fermentation tanks – universal pressurizable tank intended for both primary and secondary fermentation of beer, cider, wine in the same vessel without the pumping beverage between two tanks. Available for all kinds of fermenting beverages. The cone bottom allows easy separation of yeast from beverage to later use.

- FUIC : Compact fermentation units – the compact devides that include all what is needed for both the primary and secondary fermentation of beer, cider, wine. One, two, three or four cylindrically-conical fermentors, cooling unit, temperature control system, frame.

- CFS : Complete fermentation sets – Fully equipped sets for the fermentation and maturation of alcoholic beverages under pressure (beer, wine, cider) that are equipped with classical cylindrical-conical tanks and all equipment that is needed for controlled cooling of the tanks with fermenting beverage.

IV. Final conditioning (temporary storage and final operations with beverages)

BBT “Bright beer tanks” – they are pressure cylindrical vessels intended for temporary storage and the final conditioning (carbonation, filtering, pasteurization, flavorization …) of carbonated alcoholic beverages like beer or cider before their filling into kegs, bottles and cans.

- BBTVI : Cylindrical pressure storage tanks vertical, insulated (for the maturation, lagering, conditioning) – Insulated pressure vessels for the storage, carbonization, filtering of drinks (beer, cider, wine) under pressure, with vertical orientation, with the PUR insulation, cooled by water or glycol.

- BBTVN : Cylindrical pressure storage tanks vertical, non-insulated (for the maturation, lagering, conditioning) – Insulated pressure vessels for the storage, carbonization, filtering of drinks (beer, cider, wine) under pressure, with vertical orientation, without the insulation, cooled by air.

- BBTHI : Cylindrical pressure storage tanks horizontal, insulated (for the maturation, lagering, conditioning) – Insulated pressure vessels for the storage, carbonization, filtering of drinks (beer, cider, wine) under pressure, with horizontal orientation, with the PUR insulation, cooled by water or glycol.

- BBTHN : Cylindrical pressure storage tanks horizontal, non-insulated (for the maturation, lagering, conditioning) – Insulated pressure vessels for the storage, carbonization, filtering of drinks (beer, cider, wine) under pressure, with horizontal orientation, without the insulation, cooled by air.