Description

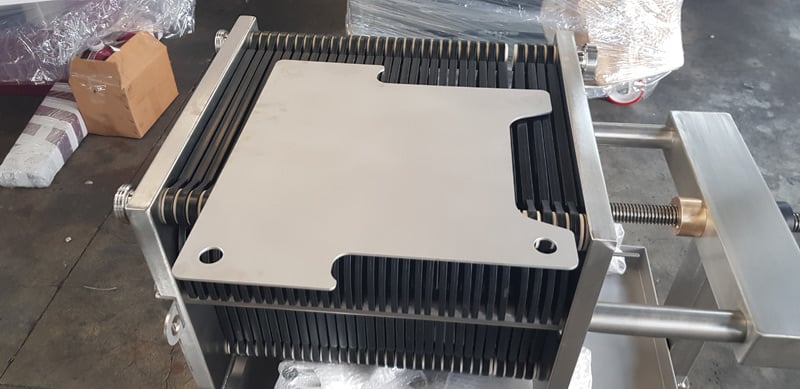

Plate filter 400×400 mm with stainless steel plates and a pump. Available with 11, 19, 29 or 39 pcs of stainless steel plates (frames) for filtration cartons 400×400 mm.

This filtration system involves the use of filter layers “cartons” which are interposed between the plates with frames made of stainless steel. It can be used for a primary and secondary filtration of beer, wine or cider before the bottling process. Sterilizable with hot steam. With a set for the double filtration – the double filtration kit. Can be delivered with SST filter plate holders for double filtration (optionaly).

The plate filters 400×400 mm are intended for professional wine makers and brewers. With their greater surface area they have not only a much higher capacity tham filters 200×200 mm in litres/hour but also a greater operational time (number of litres that can be filtered before the plates have to be cleaned /changed). The table below gives an indication of the capacity (depending on the filter plates used) of the various models.

The beverage plate filters produced in four variants have the following characteristics:

1. Filter 400×400/11 with 11 pcs of stainless steel plates – maximal flow rate 600-1200 L/hr (wine) / 200-300 L/hr (beer)

Filtration surface : 1.7 m²

Dimensions : 1250x700xh920 mm

2. Filter 400×400/19 with 19 pcs of stainless steel plates – maximal flow rate 1000-2000 L/hr (wine) / 350-500 L/hr (beer)

Filtration surface : 2.9 m²

Dimensions : 1450x700xh920 mm

3. Filter 400×400/29 with 29 pcs of stainless steel plates – maximal flow rate 1600-3000 L/hr (wine) / 500-800 L/hr (beer)

Filtration surface : 4.5 m²

Dimensions : 1700x700xh920 mm

4. Filter 400×400/39 with 39 pcs of stainless steel plates – maximal flow rate 2000-4000 L/hr (wine) / 700-1100 L/hr (beer)

Filtration surface : 5.5 m²

Dimensions : 2000x700xh920 mm

Technical description :

These plate filters can be equipped with the separator plate for double filtration. By using this plate you can simultaneously carry out pre-filtration and fine filtration! With double filtration, it is better to use cardboard filter plates and the operational time is frequently greater than with simple filtration.

By using the noryl filter plate holders and the special rubber seals, the plate filter can be steam sterilised at 120°C.

Components :

E = inlet for the liquid to be filtered

U = outlet for the filtered liquid

UII = outlet for liquid filtered by double filtration

ESV = steam inlet (only with steam sterilisation)

USV = steam outlet (only with steam sterilisation)

1 + 3 = header filter plate holders (only with double filtration)

2 = stainless steel plate for double filtration

4 = sealing cap for steam sterilisation gear

5 = sight-glass

6 = bleed valve + test cock

7 = manometer inlet + outlet

8 = filter plate holders

9 = header of the filter plate holders

Tips for use :

• After assembling the cardboard filter plates and before using the complete filter and cardboard filter plates, first flush with clean water for 10 – 20 minutes then disinfect, preferably with steam or hot water at a maximum of 120 °C (inlet and outlet : see components) for 20 minutes, or by pumping through a disinfectant liquid such as pure alcohol or a permitted disinfectant for 10 – 20 minutes. Once again, flush through thoroughly with clean water to wash out any remnants.

• At the beginning of the filtration process, the first few litres of wine/beer are diluted with the remains of the flushing water. If desired, you can pour this wine/beer back into the tank of unfiltered liquid. You can see through the sight glass when the wine/beer is coming out undiluted.

• Depending on the head, the pump body may need to be primed. An unscrewable sealing cap is provided for the purpose. Obviously you must close it again and start the pump after filling.

• With double filtration it is difficult to determine the ratio of pre-filters to fine-filters. Experience will tell. We recommend a ratio of 1/3 pre-filters to 2/3 fine-filters. However, this is only an indication.

• With large batches you can, after a period of time, also back flush the filter discs with clean water in order to increase their operational time.

• After filtering, clean and flush out the entire unit thoroughly with clear water and let everything dry properly. Allow the pump body to discharge via the outlet at its base. Leave both the filling opening and the outlet open for a while so that all moisture can evaporate from the pump body. In this way you will avoid the growth of fungi in the pump body. Also leave the ball valves in the ‘open’ position.

Stainless steel frames

Stainless steel plate frames are a professional solution for the beverage filtration – they are sanitable chemically with hot steam sterilization, usable for double filtration (coarse filtration + micro filtration)

Properties of all types :

- AISI 304 stainless steel filter frame

- Input/output fittings DN40

Standard accessories :

- Pipe sight glass

- Centrifugal pump

Optional accessories :

Spare plate – noryl 400 x 400 mm … € 49,- / pc

Rubber ring plateholder head/end … € 15,-

PLATE KIT FOR DOUBLE FILTERING

The double filtration kit it is intended to divide the plate array to two parts. On one hand the customer will put a filtering cartons of one type (basic filtration) and on the other side it will put a filtering carton of another type (fine filtration).

Why choose a plate filter for the beverage filtration ?

Beverage filtration through a plate filter is the cheapest and easiest way to get rid of most live yeast in beer or cider. It is used in microbreweries of a small and medium size, for which the cost of the equipment is a primary decision parameter.

These filters are made from stainless steel therefore resist to extent aggressive substances. They consist of two end steel plates ,one of which is slidable on guide pins , controlled by the pressure screw or hydraulic element. Among them there are stainless steel frames with filter cellulose pads (cartons) of the choosed porousity and number of the plates according to the required purity and overall flow capacity of the filtered liquid.

During passage of beverage through the filtration plates the impurities contained in the beverage are captured. The flow rate gradually decreases, depending on the saturation of the filter plates by the impurities (yeasts).

Plate filter is mobile on castors and it is equipped with a control pressure gauges, air-outlet valve and flow taps made of stainless steel. The filter allows continuous filtering and dual filtering with different purity grade using two types of cartons in one pass through the filter body . It is a convenient way especially in terms of lower workload of beverage and easier to easy work.

Advantages of a plate filter:

- Low cost of purchasing

- Easy to use

- Using both primary and secondary filtration – choice of filter elements

Disadvantages of a plate filter:

- Higher cost of consumables in comparation with the kieselguhr filters – the filter cartons are intended only for several use

- It is necessary to disassembly entire filter after its every use, to remove the filter plates and also to do the full cleaning and sanitizing of the filter

Reviews

There are no reviews yet.