Description

The MFS-2B4C is an universal mechanic filter with two housings for bag filtration elements and four housings for filtration elements in the candle shape intended for 2-stage up to 6-stage filtration of water, beer, cider, wine, kombucha or other beverages. The filtration very extends lifetime of the beverages. Filtration capacity is up to 1200 liters per hour.

This filter is a full-fledged replacement for diatomaceous earth filtration. If the filter is fitted with micro-filter candle elements, it can also be used for micro-filtration of drinks.

Mechanical filtration consists of two high-capacity filter housings in which are placed bag filtration elements for coarse filtration and four candle filter housings in which are placed special polypropylene filtration elements with permeable surface at the level of microfiltration.

In standard configuration we deliver the filter with two high-capacity filtration bags with porosity of 50μm, two candle filtration elements with porosity of 5.0 μm (to remove rests of the yeast) and two candle filtration elements with porosity of 2.4 μm (to remove the proteins).

The entire mechanical filtration set is mounted on a mobile stainless steel frame made of AISI 304 material.

Delivered with one set of the filtration elements (see bellow)

A special polypropylene microfilter meets all the requirements for food production in the EU (1935/2004 / EC) and the USA (CFR Title 21).

Main technical parameters :

- Number positions for the bag filtration elements : 2

- Number positions for the candle micro-filtration elements : 4

- Recommended bag filtration elements for the primary beverage filtration : 50 μm (coarse filtration)

- Recommended candle microfiltration elements for the secondary beverage filtration : 5.0 μm (removing rests of yeast) + 2.4 μm (removing of proteins)

- Connections for beverage (inlet / outlet) : 2x DN32 / 2x NW32 DIN 11851 “Dairy Coupling” (optionally DIN 32676 “TriClamp” )

- Connections for CIP (inlet) : 2x DN20 / 2x NW20 DIN 11851 “Dairy Coupling” (optionally DIN 32676 “TriClamp” )

- Connections for gas (inlet) : 2x DN20 / 2x NW20 DIN 11851 “Dairy Coupling” (optionally DIN 32676 “TriClamp” )

- Maximal flow capacity : up to 1200 liters per hour

- Dimensions (LxWxH) :1250 x 1750 x 1400 (h) mm

- Weight : 160 kg

Optional accessories :

| Code | Description | Price |

| MFS-2B4C-AES | Aseptic equipment set for the basic equipment of the filter (aseptic manometers, aseptic valves, aseptic seals) | € 1556,- |

| MFS24-E1122N | Non-aseptic expansion accessory kit for the 1-1-2-2 configuration (Non-aseptic valves, seals and pressure gauges) | € 1174,- |

| MFS24-E1122A | Aseptic extension kit of accessories for 1-1-2-2 configuration (aseptic valves, seals and pressure gauges) | € 2075,- |

| MFS24-E222N | Non-aseptic expansion accessory kit for the 2-2-2 configuration (Non-aseptic valves, seals and pressure gauges) | € 1174,- |

| MFS24-E222A | Aseptic expansion accessory kit for 2-2-2 configuration (aseptic valves, seals and pressure gauges) | € 2075,- |

| MFS24-E114N | Non-aseptic expansion accessory kit for the 1-1-4 configuration (Non-aseptic valves, seals and pressure gauges) | € 1174,- |

| MFS24-E114A | Aseptic expansion accessory kit for 1-1-4 configuration (aseptic valves, seals and pressure gauges) | € 2075,- |

| MFS24-E24N | Non-aseptic expansion accessory kit for the 2-4 configuration (Non-aseptic valves, seals and pressure gauges) | € 1174,- |

| MFS24-E24A | Aseptic expansion accessory kit for 2-4 configuration (aseptic valves, seals and pressure gauges) | € 2075,- |

Recommended configurations :

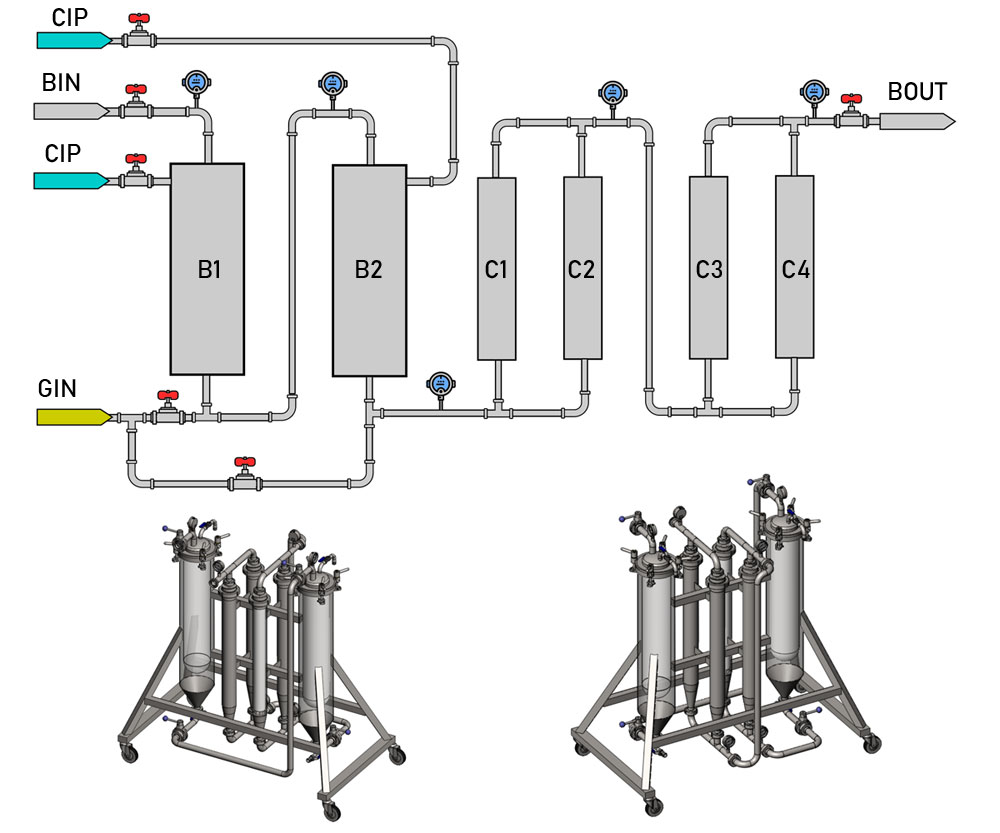

Description :

CIP : Input for the CIP chemical cleaning

BIN : Bevarage input (non-filtered drink)

BOUT : Bevarage output (filtered drink)

GIN : Gas input (pushing air from the filter before start of the filtration process)

Configuration 1-1-2-2 :

| Coarse filtration (optical purification of beverages) | |||

|---|---|---|---|

| Position | Filter element |

Description | Porosity |

| B1 | FMB30-B100U | 1st stage of coarse filtration (30″ bag filter) – removal of coarse sludge (remains of hops and cereal grains, remains of fruit pulp) | 100 μm |

| B2 | FMB30-B050U | 2nd stage of coarse filtration (30″ bag filter) – removal of fine sludge (small mechanical impurities in the drink causing optical turbidity) | 50 μm |

| Coarse filtration + microfiltration (biological stabilization of beverages) / 99.98% efficiency for capture of defined particles | |||

| Position | Low-Cost Filter Element / High-Quality Filter Element | Description | Porosity |

| B1 | FMB30-B010U / FMS30-BPG000 | 1st stage of microfiltration (30″ bag filter) – removal of yeast from primary fermentation | 10 μm |

| B2 | FMB30-B005U / FMS30-BFS500 | 2nd stage of microfiltration (30″ bag filter) – removal of yeast from secondary fermentation | 5 μm |

| C1 | FMS30-L0100U / FMS30-BFS500 | 3rd stage of microfiltration (30″ candle filtration element) – protein removal | 1 μm |

| C2 | FMS30-L0100U / FMS30-BFS500 | 3rd stage of microfiltration (30″ candle filtration element) – protein removal | 1 μm |

| C3 | FMS30-L0022U / FMS30-BFS030 | 4th stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 – 0.45 μm |

| C4 | FMS30-L0022U / FMS30-BFS030 | 4th stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 – 0.45 μm |

| Microfiltration (biological stabilization of beverages) / 100% efficiency for capture of defined particles (with the final membran filter) | |||

| Position | High-Quality Filter Element | Description | Porosity |

| B1 | FMB30-B005U | 1st stage of microfiltration (30″ bag filter) – reduction of yeast | 5 μm |

| B2 | FMB30-B001U | 2nd stage of microfiltration (30″ bag filter) – reduction of yeast and protein | 1 μm |

| C1 | FMS30-BFS050 | 3rd stage of microfiltration (30″ candle filtration element) – protein and bacteria removal 99.00% / the candle pre-filter | 0.50 μm |

| C2 | FMS30-BFS050 | 3rd stage of microfiltration (30″ candle filtration element) – protein and bacteria removal 99.00% / the candle pre-filter | 0.50 μm |

| C3 | FMS30-BPS045 | 4th stage of microfiltration (30″ candle filtration element) – yeast, protein and bacteria removal 100% / the candle membran filter | 0.45 μm |

| C4 | FMS30-BPS045 | 4th stage of microfiltration (30″ candle filtration element) – yeast, protein and bacteria removal 100% / the candle membran filter | 0.45 μm |

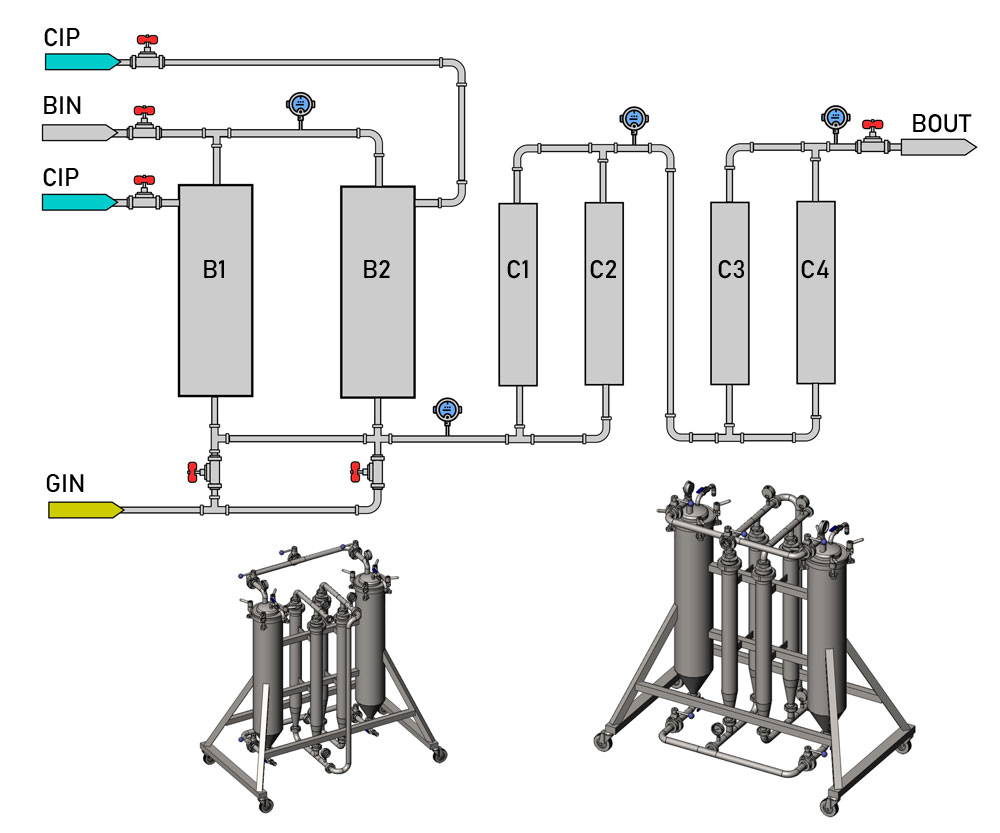

Configuration 2-2-2 :

| Coarse filtration (optical purification of beverages) | |||

|---|---|---|---|

| Position | Filter element | Description | Porosity |

| B1 | FMB30-B050U | 1st stage of coarse filtration (30″ bag filter) – removal of fine sludge (small mechanical impurities in the drink causing optical turbidity) | 50 μm |

| B2 | FMB30-B050U | 1st stage of coarse filtration (30″ bag filter) – removal of fine sludge (small mechanical impurities in the drink causing optical turbidity) | 50 μm |

| Coarse filtration + microfiltration (biological stabilization of beverages) / 99.98% efficiency for capture of defined particles | |||

| Position | Low-Cost Filter Element / High-Quality Filter Element | Description | Porosity |

| B1 | FMB30-B005U | 1st stage of microfiltration (30″ bag filter) – removal of yeast from primary and secondary fermentation | 5 μm |

| B2 | FMB30-B005U | 1st stage of microfiltration (30″ bag filter) – removal of yeast from primary and secondary fermentation | 5 μm |

| C1 | FMS30-L0100U / FMS30-BPG100 | 2nd stage of microfiltration (30″ candle filtration element) – protein removal | 1 μm |

| C2 | FMS30-L0100U / FMS30-BPG100 | 2nd stage of microfiltration (30″ candle filtration element) – protein removal | 1 μm |

| C3 | FMS30-L0022U / FMS30-BPG030 | 3rd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 – 0.45 μm |

| C4 | FMS30-L0022U / FMS30-BPG030 | 3rd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 – 0.45 μm |

| Microfiltration (biological stabilization of beverages) / 100% efficiency for capture of defined particles (with the final membran filter) | |||

| Position | High-Quality Filter Element | Description | Porosity |

| B1 | FMB30-B001U | 1st stage of microfiltration (30″ bag filter) – removal of yeast and protein 99.98% / the candle pre-filter | 1 μm |

| B2 | FMB30-B001U | 1st stage of microfiltration (30″ bag filter) – removal of yeast and protein 99.98% / the candle pre-filter | 1 μm |

| C1 | FMS30-BFS050 | 2nd stage of microfiltration (30″ candle filtration element) – bacteria removal 99.98% / the candle pre-filter | 0.50 μm |

| C2 | FMS30-BFS050 | 2nd stage of microfiltration (30″ candle filtration element) – bacteria removal 99.98% / the candle pre-filter | 0.50 μm |

| C3 | FMS30-BPS045 | 3rd stage of microfiltration (30″ candle filtration element) – yeast, protein and bacteria removal 100% / the candle membran filter | 0.45 μm |

| C4 | FMS30-BPS045 | 3rd stage of microfiltration (30″ candle filtration element) – yeast, protein and bacteria removal 100% / the candle membran filter | 0.45 μm |

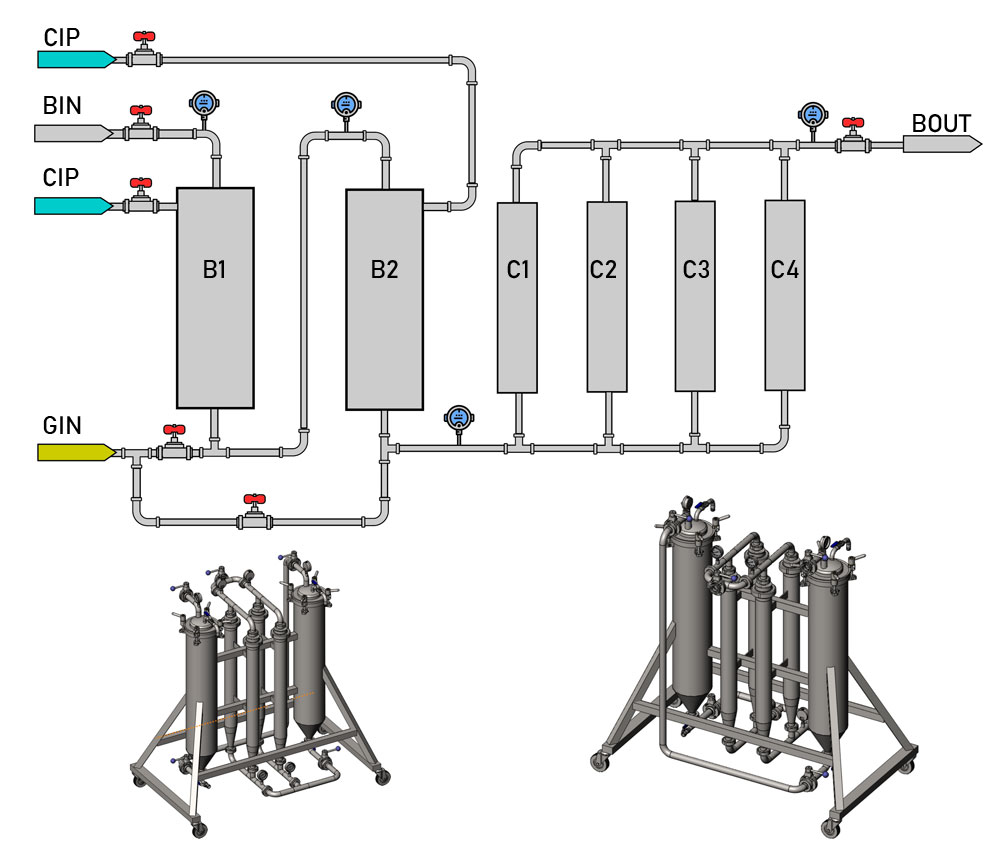

Configuration 1-1-4 :

| Coarse filtration (optical purification of beverages) | |||

|---|---|---|---|

| Position | Filter element | Description | Porosity |

| B1 | FMB30-B050U | 1st stage of coarse filtration (30″ bag filter) – removal of fine sludge (small mechanical impurities in the drink causing optical turbidity) | 50 μm |

| B2 | FMB30-B025U | 2nd stage of coarse filtration (30″ bag filter) – removal of yeast from primary fermentation | 25 μm |

| Coarse filtration + microfiltration (biological stabilization of beverages) | |||

| Position | Low-Cost Filter Element / High-Quality Filter Element | Description | Porosity |

| B1 | FMB30-B005U | 1st stage of microfiltration (30″ bag filter) – removal of yeast from secondary fermentation | 5 μm |

| B2 | FMB30-B001U | 2nd stage of microfiltration (30″ bag filter) – protein removal | 1 μm |

| C1 | FMS30-L0022U | 3rd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

| C2 | FMS30-L0022U | 3rd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

| C3 | FMS30-L0022U | 3rd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

| C4 | FMS30-L0022U | 3rd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

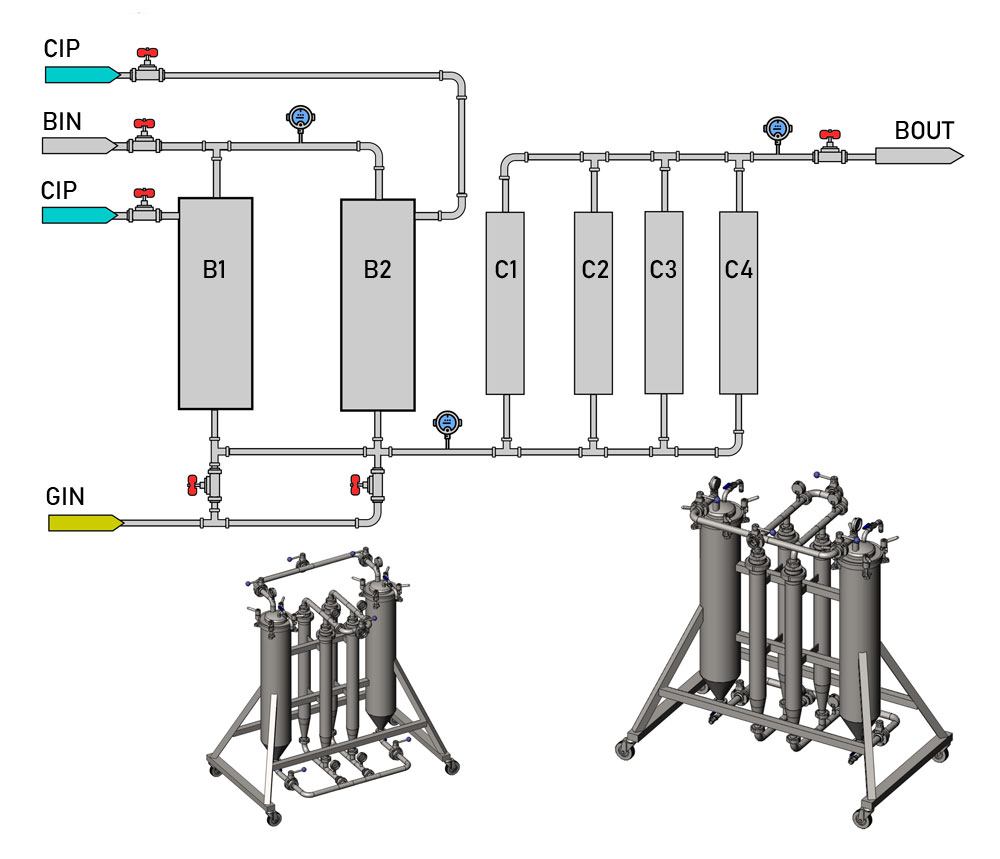

Configuration 2-4 :

| Coarse filtration (optical purification of beverages) | |||

|---|---|---|---|

| Position | Filter element | Description | Porosity |

| B1 | FMB30-B025U | 1st stage of coarse filtration (30″ bag filter) – removal of all yeast from primary and secondary fermentation | 25 μm |

| B2 | FMB30-B025U | 1st stage of coarse filtration (30″ bag filter) – removal of all yeast from primary and secondary fermentation | 25 μm |

| Coarse filtration + microfiltration (biological stabilization of beverages) | |||

| Position | Low-Cost Filter Element / High-Quality Filter Element | Description | Porosity |

| B1 | FMB30-B001U | 1st stage of microfiltration (30″ bag filter) – all yeast and protein removal | 1 μm |

| B2 | FMB30-B001U | 1st stage of microfiltration (30″ bag filter) – all yeast and protein removal | 1 μm |

| C1 | FMS30-L0022U | 2nd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

| C2 | FMS30-L0022U | 2nd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

| C3 | FMS30-L0022U | 2nd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

| C4 | FMS30-L0022U | 2nd stage of microfiltration (30″ candle filtration element) – bacteria removal | 0.22 μm |

Frequently asked questions:

How long is lifetime of the filtration material (filtering candles) ?

- If you will use only chemical sanitizing and you will not use hot steam then lifetime of the filtration elements is appoximally 1000 sanitizing cycles.

- Number of the filtration cycles is not limited.

How to do the cleaning, sanitizing and sterilizing of the filtration candles and the filter ?

- You need use a CIP station for the chemical cleaning and sanitizing of the filter. We produce this CIP station that fully suits this purpose :

Description of sanitizing cycle :

- Rinsing of candles with filtered water

- Sanitation in the direction of filtration with alkalic and acidic solution.

- Desinfection with Peristil (remove the filtration elements from the housings and put them to the Peristil solution, let them there up to next use).

Filtration scheme (two options):

- Only with overpressure – without a pump: source tank with higher pressure > filter > target tank with lower pressure (or stainless steel keg)

- No overpressure – using a pump: source tank > pump > filter > target tank (or stainless steel keg)

Does the filter clog during the filtration process and what is the procedure for cleaning the filter?

- The clogging rate of the filtering candles and the length of the filtering cycle depend on the amount of yeast in the beverage.

- If this does not help then the cleaning and sanitation with a CIP station, an alkaline and acidic sanitizing solution, is necessary to do, and sterilize them with Peristil.

What are loses of the beverage product when is filtered ?

- Product losses are almost zero. It depends on the amount of yeast in the tank from which it is filtered.

Is there a problem with the loss of CO2 after the filtration of the beverage, or is it necessary to saturate the beverage?

- Beverage is filtered almost no loss – with overpressure – the pump can also be used.

Delivery time : 7 weeks

We recommend you to purchase also :

FCSH-30C7 : Stainless steel housing for sterile storing 30/3″ filtration cartridge

Reviews

There are no reviews yet.