Description

The semi-automatic bottle washing machine for 15pcs of new or used glass bottles. Working capacity from 400 up to 500 bottles per hour.

The semi-automatic bottle washer is an alternative and affordable solution for beverage producers with low production capacities (farmhouses, family cellars, micro-breweries, small cider producers etc.) This solution offers great versatility to adapt to the most varied needs.

The semi-automatic bottle washer is an alternative and affordable solution for beverage producers with low production capacities (farmhouses, family cellars, micro-breweries, small cider producers etc.) This solution offers great versatility to adapt to the most varied needs.

The bottle washing unit has a compact design, very low consumption and it is practically “maintenance free” as it has almost no mechanical parts. It all combines the features of a traditional bottle washer in a single machine: bottle washing, label removal and final bottle rinsing.

All this while safeguarding the environment and reducing production costs, allowing you to easily recycle and reuse previously “disposable” bottles.

Also, the modular structure of the machine allows to progressively increase its functions and level of automatization as well as the level of sophistication, by inserting optional special washing and / or sanitizing sections.

The “Czech Brewery System” reserves the right to re-confirm this offer upon receipt and evaluation of samples the bottles delivered before production. The machine is designed for use with common bottles, labels and glues used with the bottles, for washing the bottles dirted with common beverages. A producer does not keep guarancee that the machine is able to work with all types of bottles, kind of dirts in the bottles, all kinds of glues on the bottles.

The bottle washer model BWRB-SA15 is designed for cleaning a variety of bottles and can be adjusted to satisfy a number of clients needs and specifications.

The machine has many plus points, namely offering extremely reliable operations, easy and practical use by operator, facilitated cleaning and maintenance and minimum energy consumption.

Main technical parameters :

| Operation capacity with new bottles without glued labels | 450-500 bottles per hour |

| Operation capacity with used bottles without glued labels | 400-450 bottles per hour |

| Operation capacity with used bottles with glued labels | 100-200 bottles per hour |

| Bottle format | Glass, universal (0.1 – 2.0 liters) |

| Number of bottles in one cycle | 15 pcs |

| Recommended detergent | (NaOH 1~3% – 70°C) |

| Electric supply | 3-phase 220-400 Volt – 50 Hz (or other on demand) |

The actual working capacity of the machine may differ from the capacity stated by the manufacturer. It depends on kind and old of dirt in the bottles, type and volume of the bottles, on the chemical composition, concentration, temperature and contamination of the cleaning chemical solution.

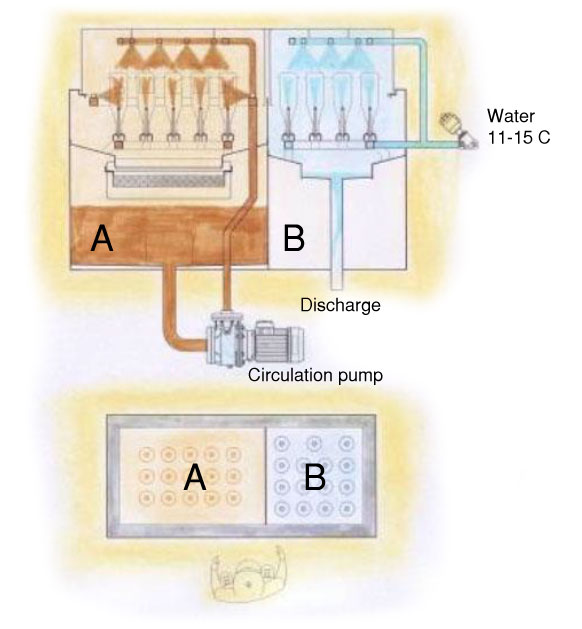

Bottle washing cycle description :

A – Manual loading of the dirty bottles: open the cover and position manually the bottles in the special washing positions in the A-section. The machine is predisposed for 15 dirty bottles.

B – Once the cover is closed, the bottles are rinsed over (internally and externally) with a big flow of warm water with the chemical solution (NaOH 1~3% – 70°C) for effective washing and label removal.

C – Finishing the washing, the operator manually moves the washed bottles from the washing station (A-section) to the rinsing station (B-section), freeing the place for other dirty bottles.

Then places other dirty bottles in the special washing positions (A-section) and, once the cover is closed, it restarts the machine.

D – Finishing the new washing/rinsing cycle, the operator removes rinsed bottles out of the machine, manually moves the washed bottles from the washing station (A-section) to the rinsing station (B-section) and loading the new dirty bottles in the washing positions.

The machine is equipped with:

1 – The machine is in compliance with Machine Directive 2006/42/CE dated May 17 2006.

2 – Frame of the washer is made from steel plates and outlined in stainless steel type Aisi 304. Outside finishing with external micro glass balls.The internal tanks are with inclined bottom for facilitating cleaning, and suitably profiled to equip the structure with greater rigidity and resistance. Ample doors in stainless steel are provided for cleaning the tanks and principal cover in steel glazed stainless steel, hinging at the structure with opening system “easy-open”.

3 – Safety protection (with safety limit switch) positioned on the opening cover. When the operator opens the cover the machine instantly jams the washing operation.

4 – Inside washing system is made with special penetrating nozzles at high pressure. External washing and labels removal made with special nozzles with high flow rate and low head. The water currents are carried through a filter (made of stainless steel) for filtering the detergent solution and for separated the labels.

5 – The pumps are of the monoblock centrifugal type with pump body and impeller in stainless steel type AISI 316. The external showers are of “easy maintenance” because are extremely easy to get off and to clean.Rinsing stations are made with special penetrating nozzles and the external rinsing made through nozzles fed by the net water. On the rinsing alimentation (mains water supply) there is installed an economy valve that interrupts water flow to the machine when it is stopped.

6 – The detergent solution heating block can be furnished, without price variation with :

– heating exchanger (always made in stainless steel ready for steam alimentation, automatically control by an electro-pneumatic valve with respective condensation vents;

– incorporated combustion room (included burner);

– electric heating.

The bottle washing temperature is easily adjustable through a thermostat.

7 – A ball valve for the detergent tank emptying.

8 – Utility connections at a single point.

9 – Electrical circuit (in IP55) with power switchbox in stainless steel installed on the machine. The 24V control panel made of stainless steel is equipped with LED indicators and control switchers for visual monitoring and control of all operations.

10 – Chimney for the vapors spillage from the machine, predisposed for a possible steam extractor application.

11 – Adjustable feet positioned along the sides of the machine.

12 – The User’s/ Maintenance manual in English language version.

Technical features, parameters and requirements :

| 1 | Number of places in the washing section (A-section) | 15 |

| 2 | Number of places in the rinsing section (B-section) | 15 |

| 3 | Bottles total number in the machine | 30 |

| 4 | Bottles that can be washed/rinsed: diameter max./min. – height max./min. (subject to our approval for special shapes). |

Diameter : 125 – 45 mm Height : 400 – 150 mm |

| 5 | Water consumption (the filling tank in the A-section) | ~ 225 liters |

| 6 | Average fresh water consumption at 1,5 bar (rinsing the bottles in the B-section) | ~ 100 liters per hour |

| 7 | Water hardness [F°] | min.7 – max.15 |

| 8 | Water pressure [bar] (Softened and Filtered) | min.1.5 – max.2.5 bar |

| 9 | Water discharge PH | ~ 9 |

| 10 | Water discharge temperature | ~ 35°C |

| 11 | Water consumption per bottle | ~ 0,2/0,7 ml/bottle |

| 12 | Steam pressure [bar] (Filtered & Dried) … to communicate in phase of order will be required the exact pressure of the steam inlet at the bottle washer | min.1 – max.6 bar |

| 13 | Consumption in calories: during machine heating [kcal/h] / at slow running [kcal/h] |

12.500 85 x bottles per hour |

| 14 | Direct heating by burner (gas-oil): during machine heating [lt/h] / at slow running [lt/h] |

1,75 1,25 |

| 15 | Electrical heating – installed heating | 16 kW |

| 16 | Electric power : installed / absorbed | 2 kW / 1,75 kW |

| 17 | Electric alimentation | 3PH+NT 380-420V / 50 Hz |

| 18 | Chemical detergent consumption (NaOH 1~3% – 70°C) | ~ 0,1/0,3 g/bottle |

| 19 | Machine dimensions: length x width (max. encumbrance) x height | 2050 x 1250 x 1300 mm |

| 20 | Empty / Full weight | 525 / 765 kg |

| 21 | Number of adjustable feet | 4 pcs |

| 22 | Average load per each foot | ~ 200 kg |

| 23 | Compressed air [bar] (Filtered & Dried) | 6 bar |

| 24 | Noise | < 85 dB(A) |

Machine working time calculated at 200 bottles per hour :

| 1 | Detergent washing of the bottles (NaOH ~1,5-2,0% – 70°C) | 2 min + 37 sec |

| 2 | Rinsing of the bottles with pure water | 2 min + 37 sec |

| 3 | Exchange of the bottles (manually) | 2 min + 00 sec |

Important information :

Indicated consumption data are calculated using:

* Water temperature at 15°C.

* Bottle temperature at 15°C.

* Bottle temperature at unloading machine 25°C.

* Detergent tank temperature: 70°C.

* Bottle to work in glass.

* Indicative bottle weight: 500 gr.

Consumption data supplied may vary according to individual operating conditions, such as temperature and the quality of industrial water or additives used or the optionals requested.

We would like to underline that the empty bottles shouldn’t contain any foreign materials (such as straws or wires). Remove all foreign objects before bottles enter the machine, thereby avoiding machine malfunctioning.

The producer only uses materials that have been tested and are accompanied by certification.

However, corrosion may occur due to the quality of water used, to some chemical processes in use, or simply by operations not carried out correctly.

The producer will not accept any responsibility in these cases.

N.B.: the mechanical production range refers to the mechanical design of the main washer machine transmission. Treatment times and consumption values refer to nominal production.

The change in loads during the single operating processes (heating, drainage, filling), together with the static behaviour of the floor can cause variations to load that will essentially have an effect on the feet of the machine.

It will be had to have labels of the type not pulping, inks of high quality, glue in non-superior quantity to the 20 g/mq. Temperature and concentration of the detergent will owe the recommendations to be second producer and it must be adding the necessary additives.

Labels must be removed from the bottle within a removal time of maximum 180 seconds. If 180 seconds are exceeded, an increased label carry-over can be considered. The test conditions are defined according to DIN 16524-6.

Price list :

| Description | Price : |

| BWRB-SA15 : The bottle washing machine with a set of parts for one bottle format

• machine made entirely in stainless steel AISI 304 |

On demand |

| MXSG-18CSF : Recommended external steam generator (in the standard version an external steam generator is needed but not included) | MXSG-18CSF : GHIDINI MAXI-24 18kW / 7 bar |

| Options : | |

| BWRB-SA15-ONVF : Non-standard voltage and frequency (EU standard is : 3-phase 400V / 50 Hz) | On demand |

| BWRB-SA15-OTAR : Timer for the automatic regulation of the bottle washing and the bottle rinsing time, easily adjustable by the operator | On demand |

| BWRB-SA15-OPOF : Extra grate for handling each additional bottle format (for different diameter of the bottle) | On demand |

| BWRB-SA15-ODGB : Extra price for direct gas-oil burner (an external steam generator is not needed) | On demand |

| BWRB-SA15-OEHS : Extra price for electric heating 15 kW (an external steam generator is not needed) | On demand |

| BWRB-SA15-OSRS : Safety sensor on the final rinse spray that stops the machine from working in case of lack of water (failed rinsing) | On demand |

| BWRB-SA15-OTID : Thermal insulation for the chemical detergent storage tank (recommended for energy save) | On demand |

| BWRB-SA15-OSSP : Recommended set of spare parts (normally for first 2-3 working years) | On demand |

| BWRB-SA15-PKEU : Packing for on-truck transport to EU countries (wooden pallet / shrink film) / 200×110 x h.125 cm – 525 kg | On demand |

| BWRB-SA15-TREU : On truck transport to EU countries (without over-sea shipping) | On demand |

Reference standards :

The planning/manufacturing of the machine is carried out in compliance with the following rules:

- Planning and manufacturing of the machine:

Machine Directive 2006/42/CE of European Parlament and Council dated 17 May 2006;

- Electric installation:

– Low-tension Directive 2006/95/CEE;

– Electromagnetic compatibility Directive 2004/108/CEE;

- The electric installation of our supply complies with the following regulations:

– European regulations: EN 60204-1;

– International regulations: IEC 204-1

- Steam heating system:

Directive 97/23/CE PED

- Piping thermal insulation:

EN 563;

- Operator safety guards:

Machine Directive 2006/42/CE of European Parlament and Council dated 17 May 2006;

- Machine not suitable to be installed in premises with explosion risk:

Directive 99/92/CE Atex

General technical features of the supplier :

| (1) | Machine efficiency as DIN 8782 | 95% |

| (2) | Grid voltage | 230 Volt Volt ±4% |

| (3) | Grid frequency | 50 Hertz ±0,5% |

| (4) | Distribution | 3F + N + T |

| (5) | Distribution system | T – N separate |

| (6) | Auxiliary circuits voltage | 24 Volt DC |

| (7) | Instrumentation voltage | 24 Volt DC – 240 Volt AC |

| (8) | Plant IP degree | IP 54 |

| (9) | Motors IP degree | IP 55 |

| (10) | Noisiness | < 85 dB(A) |

| (11) | Humidity | min. 20% – max. 80% |

| (12) | Temperature | min. 5°C – max. 40°C |

| (13) | Maximal altitude | 750 metri m asl |

| (14) | Harmful gases presence | NO |

| (15) | Ambient light level | min. 100 Lux. |

| (16) | Water hardness | min.7 – max.15 F° |

| (17) | Water pressure | min.1.5 – max.2.5 bar. |

| (18) | Air pressure | 6 bar. |

| (19) | Steam pressure [bar] (to communicate in phase of order the exact pressure of the steam at the bottle washer) | min.1 – max.6 |

Reviews

There are no reviews yet.