Description

Compact fully automatic bottle (optionally cans) counter pressure filling and capping machine with two integrated units

- fully automatic isobaric filling the glass bottles (optionally aluminium cans) – 6 electronic valves

- fully automatic pneumatic capping the bottles with crown caps (optionally screwed caps, ROPP caps, mushroom corks) – 1 capping head

- optionally fully automatic pneumatic welding the aluminium cans – 1 welding head

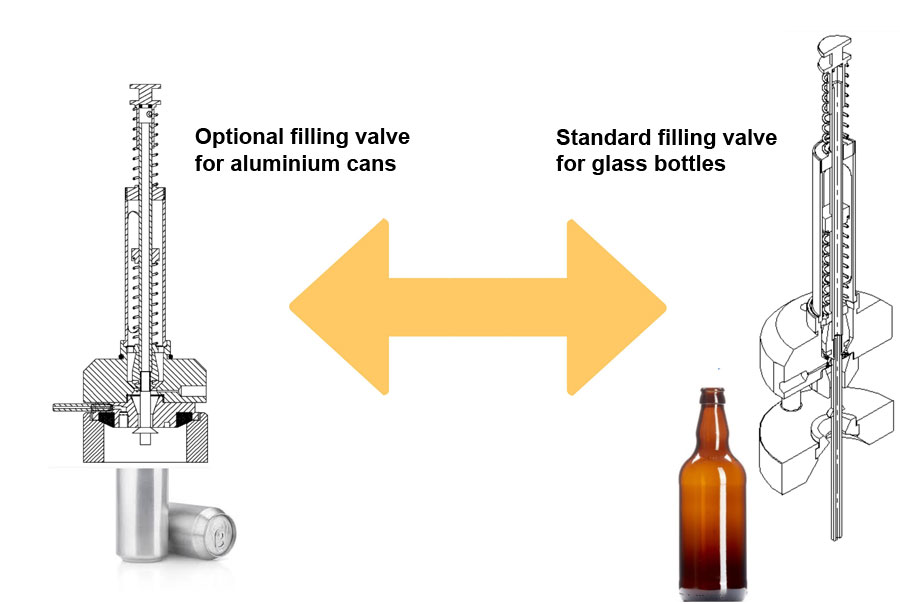

with electronic valves, optionally adaptable for aluminium cans, screwed caps, ROPP caps, mushroom corks.

Production speed : up to 850 bottles or cans per hour (depending on the operator, product, temperature, foamicity, pressure)

Special optional equipment allows the filling beverages into aluminium cans.

Technical parameters

| Maximal operation capacity : 330ml bottles | up to 850 bottles per hour if only filling and degassing is used, up to 640 bottles per hour with double oxygen pre evacuation (depending on the operator, product, temperature, foamicity, pressure) |

| Maximal operation capacity : 500ml bottles | up to 750 bottles per hour if only filling and degassing is used, up to 590 bottles per hour with double oxygen pre evacuation (depending on the operator, product, temperature, foamicity, pressure) |

| Maximal operation capacity : 750ml bottles | up to 650 bottles per hour if only filling and degassing is used, up to 540 bottles per hour with double oxygen pre evacuation (depending on the operator, product, temperature, foamicity, pressure) |

| Number of : filling valves/capping heads | 6/1 |

| Height of the worktable | 1150 mm +/- 50 mm |

| Min. bottles size : diameter / height | 55mm / 110mm |

| Max. bottles size : diameter / height | 110mm / 350mm |

| Max. cans size : diameter / height | 70mm /180mm |

| Power connection | 380-420V 50/60 Hz three phases |

| Electrical consumption | 3.0 kW/h 7 Amp |

| Max filler tank pressure | 5 bar/72 psi(tested on 9 bar/130 psi ) |

| Compressed air consumption | 120 lt/min 7 bar |

| Beverage product pipe connection | DIN 32676 TRICLAMP D=51mm (other types on request) |

| CO2/N2 connection | John Guest 8mm or Female G 3/8” gas |

| Compressed air connection | John Guest 8mm or Female G 3/8” gas |

| Sterile water connection | Female G 1/2” / 3.5 bar |

| Maximum cleaning temperature | 60°C / 140°F (on request 85°C / 185°F) |

| Filler tank material | AISI 304 (filling valves AISI 316) |

| Beverage products | Beer, sparkling water, wine, soft drinks |

| Crown caps type | 26 mm or 29 mm |

| Cans type | All common types defined by customer (available only with an optional adaptation kit) |

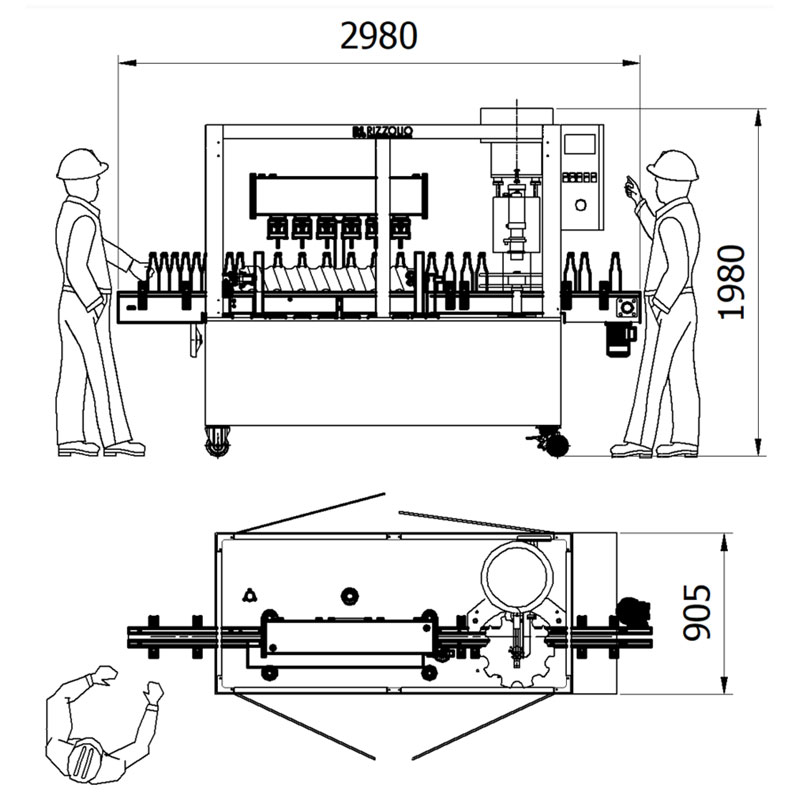

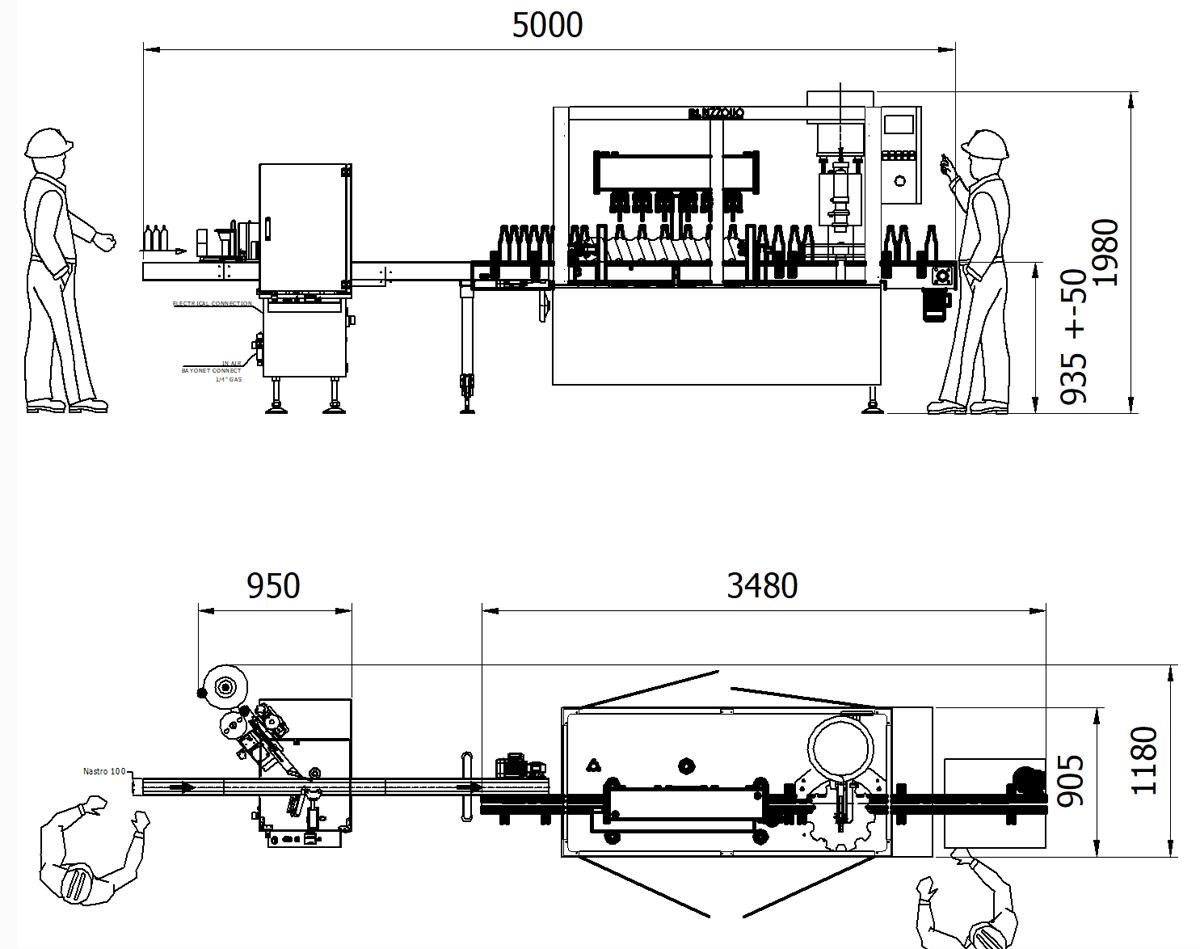

| Dimensions | WxDxH : 2980 x 905 x 1980 mm |

| Weight Net | 950 kg |

Description :

The machine is manufactured of stainless steel and food-friendly plasts of different thicknesses.

Construction is on four lockable wheels for easy transport of the machine.

This double-block machine has been designed to assist in filling carbonated or non-carbonated beverages in glass bottles with crown caps. Two units in one compact block with a steel base on wheels. Filling the bottles + capping the bottles with crown caps

Special optional equipment for the filling beverages into aluminium cans :

1st section : filling the bottles (or cans)

First the single or double pre-evacuation of oxygen is carried out inside the empty bottles, by means of an external high vacuum pump.

A purge of CO2 blow out quickly the oxygen from the bottles. The filling process starts automatically by gradual balanced the pressure from tank to bottles.

The second pre-evacuation of oxygen is preceded by a CO2 injection, in order to move the rest of oxygen up to the upper part of the bottle.

This system guarantees an excellent result in terms content of dissolved oxygen in the beverage :

<28ppb for bottles

<50ppb for cans

At the end of the pre-filling process, the pressure compensation occurs between the bottle and the isobaric tank.

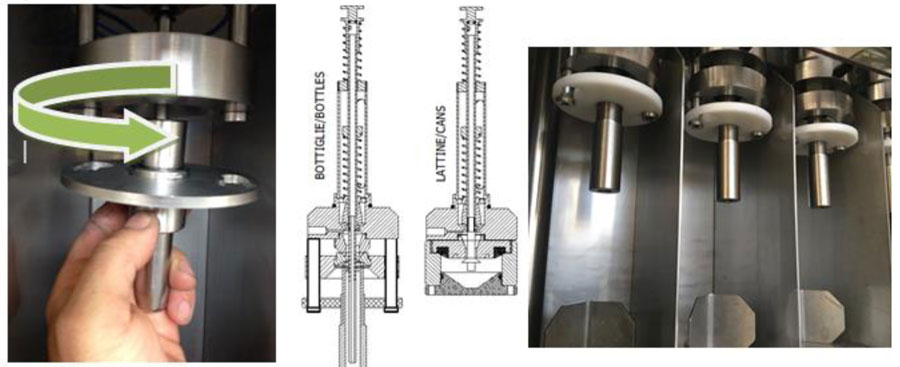

The type of deflector installed determines the correct flow of the product along inner surface of the bottles.

The final level of product inside the bottles is determined by the interchangeable devices depending on the capacity of the bottle and the filling level required.

The last phase, the bottles will be de-pressurized, controlled by an opening and closing timer in order to gently release the pressure in the bottles with creation of foam in the bottle throat.

The creation of a foam ensures that the oxygen cannot enter in the bottles before they are closed.

By modifying the depressurization times, the operator can set more or less foam before the capping of the bottles.

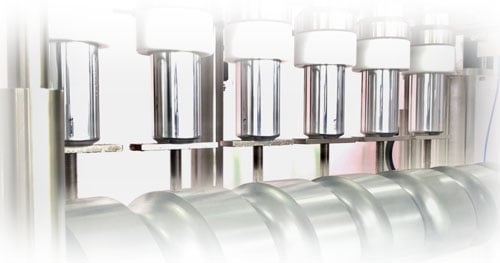

- Six filling positions

- Isobaric filling of carbonated beverage into six bottles in the same time (in standard)

- Gravity filling of non-carbonated beverage into six bottles in the same time (in standard)

- Filling beverages into glass bottles (in standard)

- Filling beverages into aluminium cans (only with optional equipment)

- The filling process takes place automatically, the operator only has to place all the bottles on the input conveyor belt and remove them in the end of the process from the output conveyor belt.

- Pre-evacuation (only with optional equipment) : First the single or double pre-evacuation of oxygen is carried out inside the empty bottles, by means of an external vacuum pump

- The second pre-evacuation of oxygen is preceded by a CO2 injection, in order to lift the rest of oxygen to the upper part of the bottle.

- This system guarantees an excellent result in terms of dissolved oxygen – less than 28 PPB is reached in beverage in the bottles.

- At the end of the bottle filling process, the pressure compensation occurs between the bottle and the isobaric tank, and the beverage flowes up to the level of the level devices.

- The type of deflector installed determines the correct flow while measures a level through the walls of the bottle.

- The level of product inside the bottles is determined by the interchangeable devices depending on the capacity of the bottle and the level height required.

- In the last phase, the bottles are de-pressurized, controlled by an opening and closing timer in order to gently release the pressure and avoid extremely foaming.

- The controlled creation of a foam avoid entering of the oxygen in the bottles before they are closed.

- By modifying the depressurization times, the operator can set more or less foam.

a) Filling the glass bottles

b) Filling the aluminium cans

2nd section : capping the bottles

The purpose of the automatic capper machine, is to close the glass bottles with crown caps of the with diameters 26mm and/or 29mm.

The closing system is usable just for one size: 26 or 29mm diameter.

If both sizes are required then it will be supplied an additional unit with the other format.

The capping head is made of hardened steel and it doesn’t lose its strength in the time.

The capping unit has also a feeder for each size of caps. It is made of INOX 304 stainless steel. The caps are orientated automatically before the bottle capping.

The closure unit captures the cap from the feeder and inserts it in the closing head.

- Single automatic capping head with a crown caps sorter & with automatic feed of crown caps to the capping head

- Closing the bottles with steel crown caps (in standard version)

- Closing the bottles with plastic or aluminium screw caps (in optional version)

- Closing the aluminium cans with aluminium lids (only with optional equipment or in optional version)

Operating cycle:

- Manual loading the bottles on the input conveyor belt – the input convecor belt can be connected on the output conveyor belt of other machine (for example bottle rinsing machine, bottle labelling machine etc.)

- Automatic moving the bottles to the filling positions.

- The bottles are lifted pneumatically under the filling valve.

- The vacuum system sucks air out of the bottle.

- The machine fills bottles with carbon dioxide from the external CO2 pressure bottle (not from a filling tank).

- The vacuum system sucks air out of the bottle.

- The machine fills the bottles with carbon dioxide from the external CO2 pressure bottle (not from the filling tank)

- The vacuum system sucks air out of the bottle.

- The machine achieves pressure stability and starts the filling beverage into the bottles.

- The machine lowers the level of pressure.

- The bottles are moved down from the filling valves.

- The the bottles are moved autoatically to the bottle capping unit

- The bottles are closed with crown caps automatically using a pneumatically driven capping head.

- Manual unloading the bottles from the output conveyor belt – the output convecor belt can be connected to the intput conveyor belt of other machine (for example machine for the bottle outside rinsing, bottle labelling machine etc.)

BFA-MB061 machine consists of :

| DESCRIPTION | EURO |

|---|---|

| Main equipment |

|

| BFA-MB061-CRW Automatic 6-1 filling and capping machine for bottles (counter pressure filling, capping the bottles with crown caps) | price on demand |

| BFA-MB061-SCR Automatic 6-1 filling and capping machine for bottles (counter pressure filling, capping the bottles with screw caps) | price on demand |

| BFA-MB0611-CSC Automatic 6-1-1 filling and capping machine for bottles (counter pressure filling, capping the bottles with crown caps, capping the bottles with screw caps) | price on demand |

| BFA-MB0611-COR Automatic 6-1-1 filling and capping machine for bottles (counter pressure filling, capping the bottles with mushroom corks, fixing with wire hoods) | price on demand |

| BFA-MB0611-CRC Automatic 6-1-1 filling and capping machine for bottles and cans (counter pressure filling, capping the bottles with crown caps, can seamer) | price on demand |

| Optional equipment |

|

| I. Optional equipment for the filling unit |

|

| Single pre-evacuation of air from the bottles with external vacuum pump | price on demand |

| Double pre-evacuation of air from the bottles with external vacuum pump | price on demand |

| Set of parts made of AISI 316 stainless steel for cleaning in temperature up to 85°C | price on demand |

| Dummy bottles with continuous flow – Special CIP system for high level cleaning process and chemical solution return exhaust to your CIP unit | price on demand |

| Non-return valve with TriClamp 1 inch connections | price on demand |

| CIP collector for chemical solutions – hose manifold (see a scheme bellow) | price on demand |

| Set of accessories for filling the cans | price on demand |

| Complete set of replaceable seals for all 6 filling valves | price on demand |

| Additional filling tubes, for different types of the bottles | price on demand |

| Product loading kit AISI 304 – Pneumatic diagphragm pump AISI 304 with connections TriClamp 1 inch | price on demand |

| Product loading kit AISI 316 – Pneumatic diagphragm pump AISI 304 with connections TriClamp 1 inch | price on demand |

| Additional feeding screw for the bottle filling unit (for different bottle size) – price for one type of bottles | price on demand |

| Beverage product hose sterilizable with hot steam (TriClamp connectors) | price on demand |

| Construction parts in contact with the beverage product made of AISI 316 (necessary for cider) | price on demand |

| 50 liters tank AISI 304 with all pipe and hose connections to filling machine | price on demand |

| III. Optional equipment for the capping unit |

|

| Parts for change between capping with 29 or 26 mm crown caps | price on demand |

| Vibrating hopper for the crown caps 26 or 29 mm | included |

| Additional head for different screw caps | price on demand |

| Bottle format change for the wire hood fixing unit | price on demand |

| Format change of the cans welding unit for different body cans with the same lids | price on demand |

| Protective door with plexi glass 8mm with automatic operation cycle for closure (In accordation with the CE standard) | included |

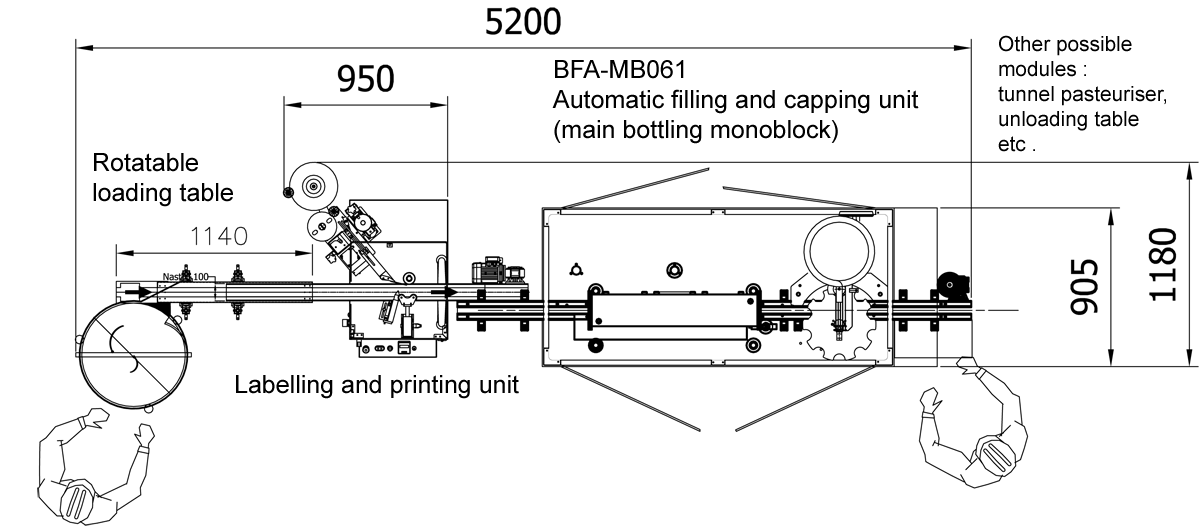

| IV. Expanding modules |

|

| Bottle labelling unit | price on demand |

| Thermal printer (date, batch number, expiration date …) | price on demand |

| Incoming bottle loading table (rotatable) | price on demand |

| Outgoing bottle unloading table (non-rotatable) | price on demand |

| Outgoing bottle unloading table (rotatable) | price on demand |

| V. Optional equipment and services – others |

|

| Supplement for machine equipped for remote support service (remote service hours will be invoiced 55€/hour) | price on demand |

| Shipping cost including packing | not included |

| Special voltage including UL conformity electronic parts (American market) | price on demand |

| Installation work provided by our specialist – each day (does not include hotel/dinner/lounch and travel expenses) | price on demand |

| Packing costs – wooden crate with chemical protection for transport over sea | price on demand |

| Packing costs – wooden crate (normal, transport to EU area) | price on demand |

| Packing costs – wooden crate when more devices will be packaged | price on demand |

| Delivery & insurance (only Europe) | price on demand |

| TOTAL – (for Europe) | price on demand |

I. CIP setup – cleaning and sanitizing of the compact bottling machine

Description :

- Compact bottle filling machine

- Bottle with pressure carbon dioxide and reduction valve

- CIP station – we recommend use the machine CIP-52 or CIP-53

- CIP collector for chemical solutions (see optional equipment table)

- Hoses for connection between the CIP station and the compact bottle filling machine

II. Dummy bottles setup for CIP (in motion)

III. Dummy bottles – set for high pressure CIP operation (in motion)

Connections :

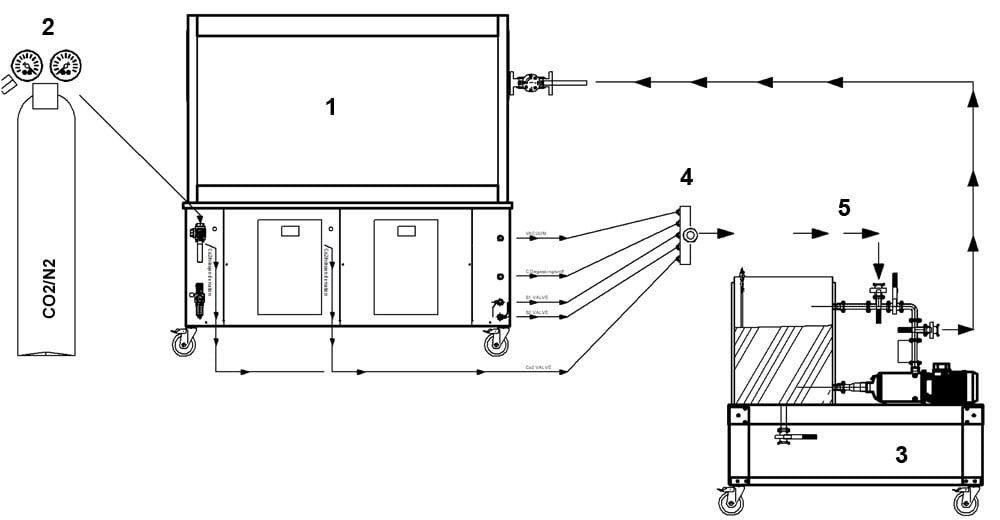

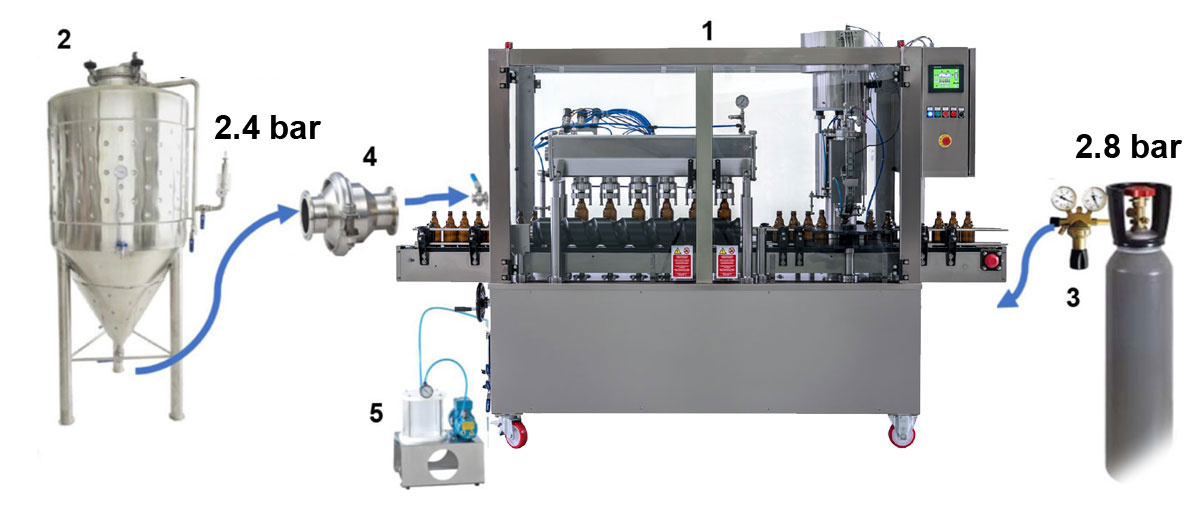

I. Filling carbonated beverages from a pressure tank

Description :

- BFA-MB bottling machine

- Pressure tank with carbonated beverage

- Pressure bottle with carbon dioxide and reduction valve

- Non-return valve

- Vacuum pump

- Blue lines – pressure hoses

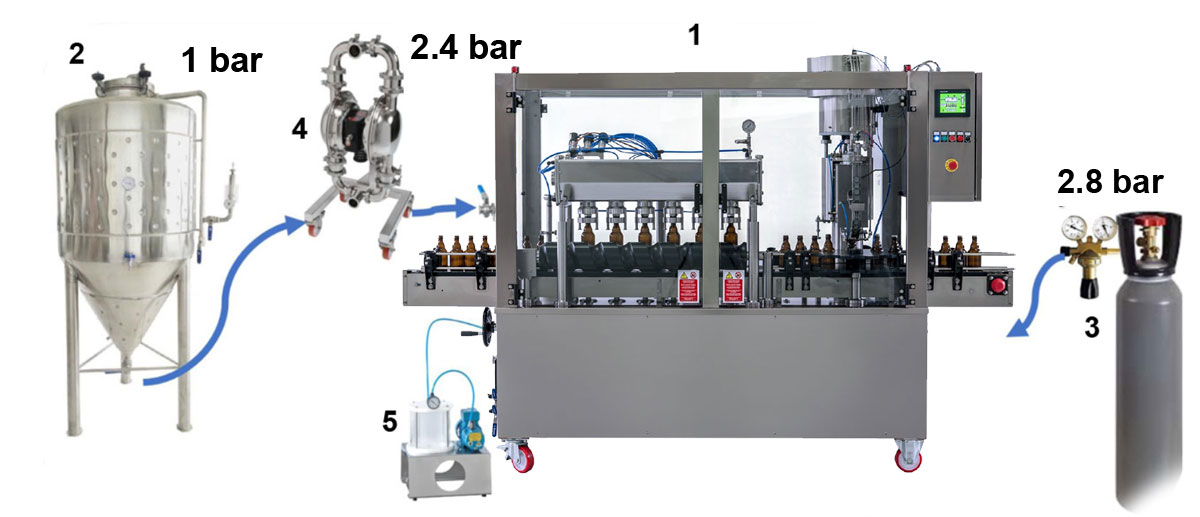

II. Filling non-carbonated beverages from a non-pressure tank

Description :

- BFA-MB bottling machine

- Pressure tank with non-carbonated beverage

- Pressure bottle with carbon dioxide and reduction valve

- Pneumatic diagphragm pump

- Vacuum pump

- Blue lines – pressure hoses

Automatic control system :

From the Touch screen you can easily monitor, control and adjust all the operations of the filling and capping process :

Available modes and their settings

I. Bottle rinsing mode :

- Injection timer – editable timing of the automatic valves

II. Bottle filling mode :

- Standard

- Single pre evacuation with CO2 injection timer adjustable

- Double pre evacuation with double CO2 injection timer adjustable

- CO2 purge for remove the oxygen in the bottles or cans before the capping cycle

- You can change the time of the pre-evacuation, time of CO2 injection, time of the degassing

III. Bottle capping mode :

- Time of the bottle capping operation is adjustable

IV. CIP mode :

- Opening all valves for the cleaning and sanitizing the machine using a CIP station

V. Degassing mode :

- Opening and closing the valves when decompressing according on timer setting in two or more steps.

VI. Schematic page:

On the synoptic page, you can see all the steps of the bottle filling and capping process in simple graphics screen.

Optional expanding modules :

Bottle labelling unit

Labelling the bottles with self-adhesive paper labels

Thermal printer (date, batch number, expiration date …)

Marking the bottles with variable informations

Rotatable loading table

Manual loading the bottles/cans onto rotatable table which serves as input stack for empty bottles/cans.

Rotatable unloading table

Manual unloading the bottles/cans from the rotatable table which serves as output stack for full bottles/cans.

Video 1:

Video 2: