Description

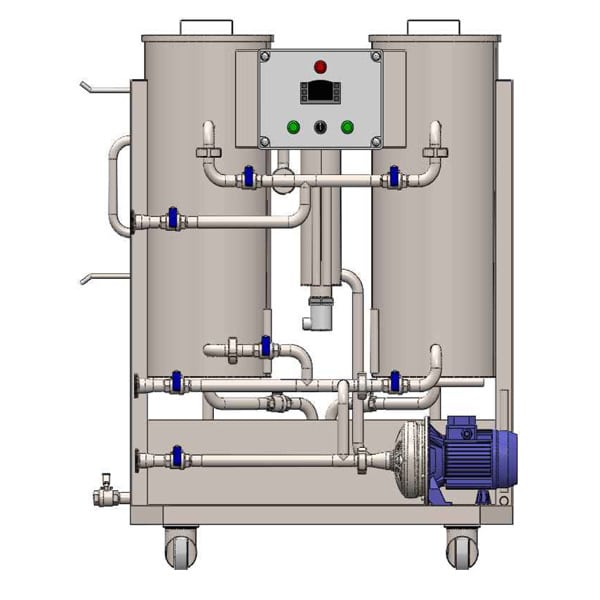

Mobile CIP station 2×50 liters | Cleaning-In-Place machine

Equipment to the cleaning and sanitizing of vessels, hoses and piping routes in breweries and other food production plants, with two tanks 50 liters, pump and heating

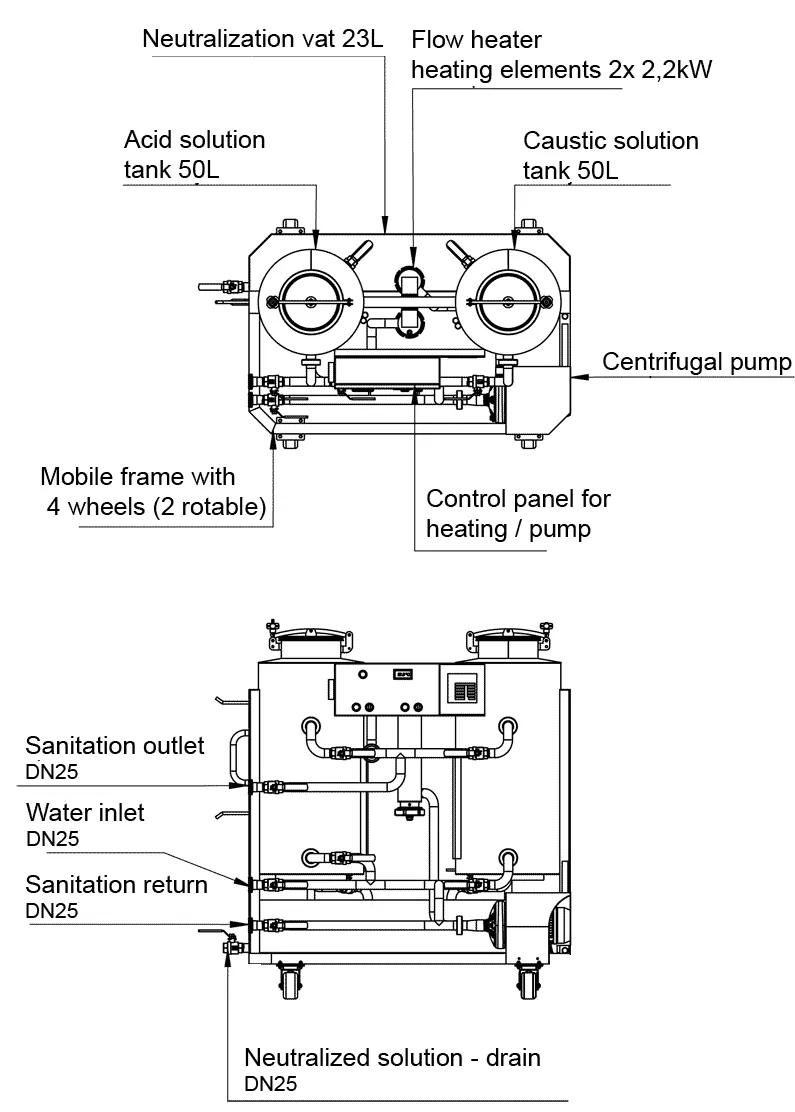

CIP unit with cleaning solutions in two 50L tanks and a 23L neutralizing vessel

A principe of the cleaning and sanitizing process is based on circulation of an alkaline or acid solution through a sanitary shower spraying it onto vessel walls and into its space. It is equipped also with a flowheater with digital regulation of temperatures ranging from 0°C to 80°C.

The CIP consists of two main tanks for alkaline and acid solution and one vessel used for a neutralization of the solutions. The circulation of the sanitary solutions is provided by a pump and a system of connecting hoses.

Functions of the vessels (3):

- Alkaline vessel for alkaline cleaning-sanitation of all brewery equipment

- Acid vessel for acid cleaning-sanitation of all brewery equipment

- Neutralizing vessel for a neutralization of acid and alkaline solutions before they pour into the drain

The equipment CIP-52 is installed in a rigid frame provided by lockable wheels. Used material is stainless steel 1.4301 (AISI 304). Containers (vessels): not equipped with insulation.

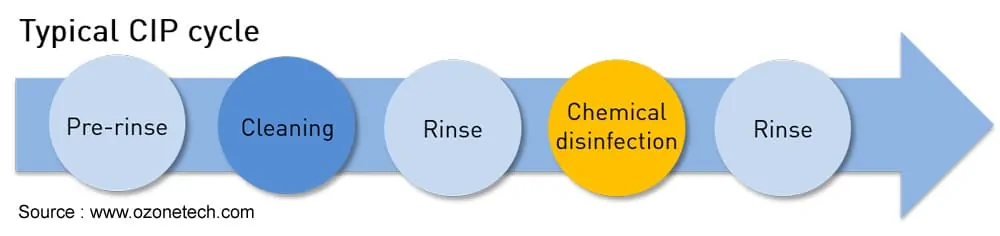

Description of the cleaning-sanitizing cycle

The cleaning-sanitizing cycle usually consists of these steps :

- Pre-rinsing – rinsing of the production equipment using cold or hot water.

- Cleaning – cleaning of the production equipment using circulated hot water.

- Rinsing – thorough rinsing of the production equipment using cold or hot water.

- Chemical disinfection (sanitation) – washing of technology using alkaline and then acid sanitizing solution at the desired concentration.

- Rinsing – thorough rinsing of the production equipment using cold or hot water.

- Neutralization – is performed after the finish of several cleaning and sanitizing cycles – mixing alkaline and then acidic sanitizing solution to achieve neutral pH of the solution and their discharge to the channel.

More informations : All about the process Cleaning-In-Place

Parameters

Parameters

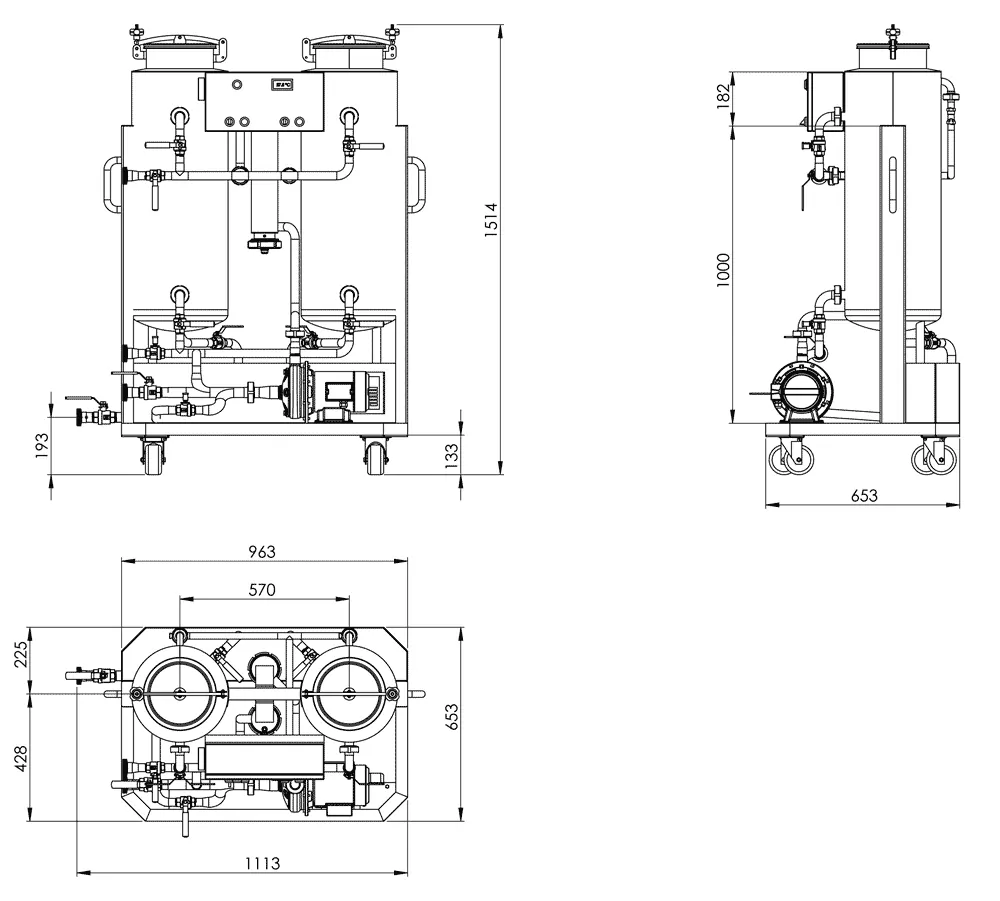

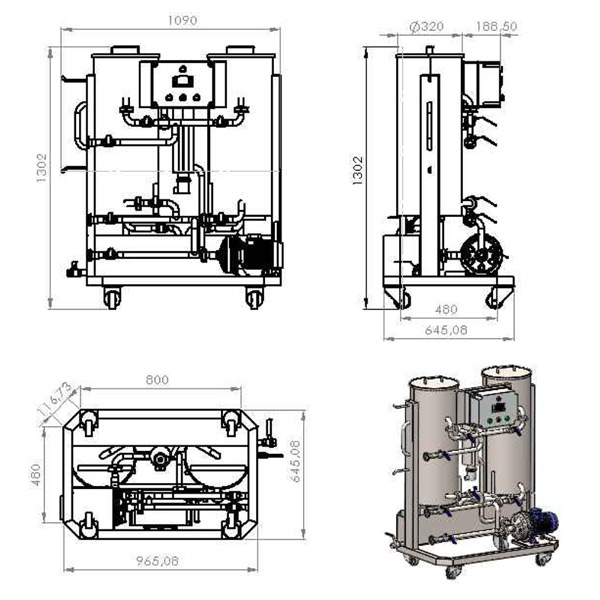

- Width 1 090 mm

- Height 1 302 mm

- Depth 645 mm

- Container with NAOH 50 l

- Container with H2SO4 50 l

- Boiler 12 l

- Heating elements 2x 2200 W

- Neutralization vessel 23 l

- Distribution piping DN 25

- Armatures (outputs / inputs) DN 40, 1.4301

- Centrifugal pump, type EBARA CD 70/05 0.37 kW 80 l/min, 230V/50Hz (AISI 316L)

- Pump discharge 21 m

- Electric switchboard

- Main electrical connection 3*400V/50Hz 16A

- Circuit breaker 230V 16A

- Digital regulator Dixel XR 10 D

- Contactor of heating 230V 16A

- Motor starter 230V

- Probe NTC 6 mm

- Cable 5x 1.5 5m

Warranty

- Equipment CIP 50 36 months

- Electric installation 24 months

- Pump 24 months

Pipe connections :

(Standard version – all connections may be different type by the customer´s requirements)

| Description | Version DC : DIN 11851 (Dairy couplers) | Version TC : DIN 32676 (TriClamp couplers) |

| Water inlet | DIN 11851 / DN 40 (external thread) | DIN 32676 / TriClamp 1,5 ” DN 40 |

| CIP chemical solution outlet | DIN 11851 / DN 40 (external thread) | DIN 32676 / TriClamp 1,5 ” DN 40 |

| CIP chemical solution inlet (return) | DIN 11851 / DN 40 (external thread) | DIN 32676 / TriClamp 1,5 ” DN 40 |

| Tank overflow outlet (discharge into the neutralizing container) | DN 25 pipe (without a pipe coupler) | DN 25 pipe (without a pipe coupler) |

| Tank draining (discharge into the neutralizing container) | DN 25 pipe / BSP G 1″ (without a pipe coupler) | DN 25 pipe / BSP G 1″ (without a pipe coupler) |

| Draining the neutralizing container | DIN 11851 / DN 25 (external thread) | DIN 32676 / TriClamp 1,5 ” DN 25 |

Material

- Version CIP-52-304 : Pump inner parts and heating chambers are made from stainless steel AISI 316. Pipes, fittings, frame and tanks are made from stainless steel AISI 304.

- Version CIP-52-316 : All parts are made from stainless steel AISI 316.

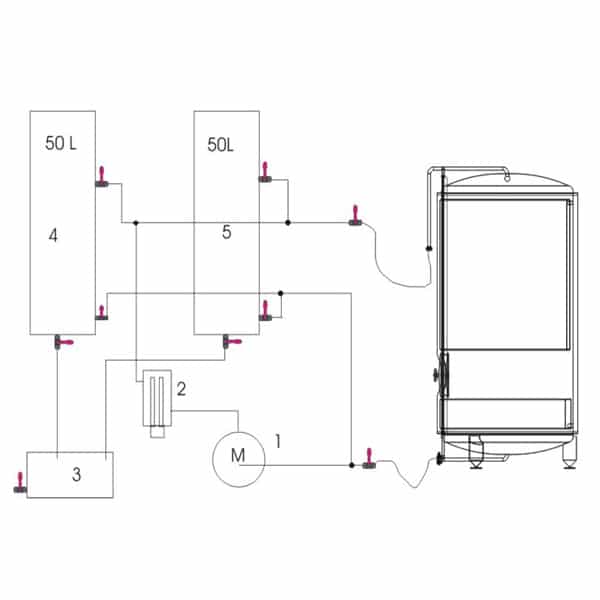

Technological scheme of the CIP-52 station connected with an external tank to be cleaned and sanitized

- Black marked – standard equipment of the CIP station

- Blue marked – optional self-cleaning kit (usable for the self-cleaning of the CIP station)

- Orange marked – optional hose cleaning kit (usable for the cleaning the hoses and pipes)

Standard equipment (black marked):

- Tank A : Alkaline vessel for alkalic cleaning-sanitation of all brewery equipment

- Tank B : Acid vessel for acidic cleaning-sanitation of all brewery equipment

- Tank C: Neutralizing vessel for a neutralization of acid and alkaline solutions before they pour into the drain

- Pump : Circulation pump EBARA

- Heaters : Electric heating elements in separate chambers

- F1 : Fitting-armature to connection of hose for the sanitizing solution inlet (return from the sanitized tank)

- F2 : Fitting-armature to connection of hose for the sanitizing solution outlet (spraying of the sanitized tank)

- F4 : Fitting-armature to connection of hose for the filling the CIP with water

- V11: Valve to filling the tank A

- V12: Valve to filling the tank B

- V21: Valve to suction of sanitizing solution from the Tank A to the pump

- V22: Valve to suction of sanitizing solution from the Tank B to the pump

- V31: Valve to draining of the Tank A

- V32: Valve to draining of the Tank B

- V1: Valve to open/close of the sanitizing solution inlet (cleaning of the tank)

- V2: Valve to open/close of the sanitizing solution outlet (cleaning of the tank or hose or pipe)

- V4: Valve to open/close of the water inlet

- V6: Valve to draining of the Tank C

Self cleaning kit (optional equipment) :

- V12: Valve to suction of sanitizing solution from the Tank C to the pump

- V51 : Valve to cleaning of the Tank A

- V52 : Valve to cleaning of the Tank B

- The spraying ball in the tank A

- The spraying ball in the tank B

Hose cleaning hit (optional equipment) :

- F2 : Fitting-armature to connection of hose for the sanitizing solution outlet (cleaning of hose or pipe)

- F3 : Fitting-armature to connection of hose for the sanitizing solution inlet (return from the sanitized hose or pipe)

- V2: Valve to open/close of the sanitizing solution inlet (cleaning of the hose or pipe)

- V3: Valve to open/close of the sanitizing solution outlet (cleaning of the hose or pipe)

- V5: Separation valve to use for the cleaning of the hoses and pipes

Optional equipment – prices :

Maximal temperature of chemical solutions :

- Temperature of chemical solutions is maximally 60°C … included in basic price

- Temperature of chemical solutions is maximally 80°C … surcharge for a special pump seal … 290 Eur

Insulation of the tanks (to save energy of heated solutions)

- Insulation of the tanks with mineral wool and outer jacket made of AISI 304 ….. 620 Eur (1 tank) / 1117 Eur (2 tanks)

- Insulation of the tanks with mineral wool and outer jacket made of AISI 316 ….. 825 Eur (1 tank) / 1485 Eur (2 tanks)

Self-cleaning packet (the blue elements on the CIP scheme)

- Self-cleaning packet made of AISI 304 … 812 Eur

- Self-cleaning packet made of AISI 316 … 1056 Eur

- Rotating spray heads (instead the static spray heads) … 279 Eur

Hose cleaning set (the orange elements on the CIP scheme)

- Hose cleaning packet made of AISI 304 … 659 Eur

- Hose cleaning packet made of AISI 316 … 857 Eur

Flow speed regulation :

- Frequency controller for the pump speed regulation (without measure of the flow speed) … 794 Eur

- Frequency controller for the pump speed regulation with measure of the flow speed – setting of desired stabil flow speed is possible … 2119 Eur

Conductivity meter :

- Conductivity meter : Mettler Toledo EasySense77 conductivity sensor (0.2 – 400mS/cm) with the Transmitter M200 numeric display unit … 3874 Eur

Dimensions

Why to use the CIP for cleaning and sanitation of the brewery equipment ?

- Less preparatory work: Sanitizing solutions are always prepared in the CIP containers and they are available in the desired dilution for several cleaning and sanitizing cycles. Their preparation before each cleaning and sanitizing cycle is not needed.

- Increasing work safety: Limiting the frequency of manipulation with sanitizing solutions reduces the likelihood of burns the operator when handling concentrated acids and alkalis.

- Saving of time and energy: Continuous heating of cleaning and sanitizing solution during the cleaning and sanitizing cycles and keeping them at a prescribed temperature increase considerably the efficiency of cleaning and sanitation, resulting in time saving operation of the equipment and saving of electricity consumption. All cleaning process, pump operations, heating of sanitizing solutions and water, they all take significantly less time, require less human work and electric energy.

- High efficiency of cleaning and sanitation: Compared with the cleaning and sanitizing of the food processing equipment by simple circulation pump there is still the same temperature of the sanitizing solutions during all time of the CIP cycle, if our CIP unit is used for this operation. Cleaning and sanitation with hot water and disinfectant solutions is definitely more effective than the same procedure with cold solutions, and therefore containers and equipment are perfectly clean after disinfection and washing cycles and are also free of organic and other impurities, which is desirable not only in the brewing industry but also in any other beverage or food production process. This is a prerequisite for compliance with legal hygiene requirements.

- Simple and efficient neutralization of acid and alkaline solutions after use: Neutralizing vessel (part of the CIP station) allows easy, safely and completely neutralize the used acid and alkaline sanitizing solution before pouring into the channel. It fully meets the requirements of laws to protect the environment and prevents damage to sewerage systems and other building components. Furthermore, this increases the safety when handling used washing and sanitization solution.

How the machine works ?

Self-Sanitation process – Sanitizing of the container 1

- Empty the container no.1 into the container no.3 by opening the G valve.

- Open the valve A and the valve D and start the pump. The sanitation solution from the container 2 will wash the container 1 thrue the sanitation ball inside the container 1.

- After transfering all of the solution from the container 2 into the container 1 turn off the pump and close the valves A and D.

- Transfer the solution from the container 1 back into the container 2. Open the valve C and valve H and start the pump.

- After transfering all of the solution from the container 1 into the container 2 turn off the pump and close the valves C and H.

- Transfer the solution from the container 3 back into to container 1. Open the Valve E and valve I and start the pump.

- After transfering all of the solution from the container 3 into the container 1 turn off the pump and close the valves E and I.

Self-Sanitation process – Sanitizing of the container 2

- Empty the container no.2 into the container no.3 by opening the F valve.

- Open the valve B and the valve C and start the pump. The sanitation solution from the container 2 will wash the container 1 thrue the sanitation ball inside the container 1.

- After transfering all of the solution from the container 1 into the container 2 turn off the pump and close the valves B and C.

- Transfer the solution from the container 2 back into the container 1. Open the valve D and valve I and start the pump.

- After transfering all of the solution from the container 2 into the container 1 turn off the pump and close the valves D and I.

- Transfer the solution from the container 3 back into to container 2. Open the Valve E and valve H and start the pump.

- After transfering all of the solution from the container 3 into the container 1 turn off the pump and close the valves E and H.

Parameters

Parameters