Description

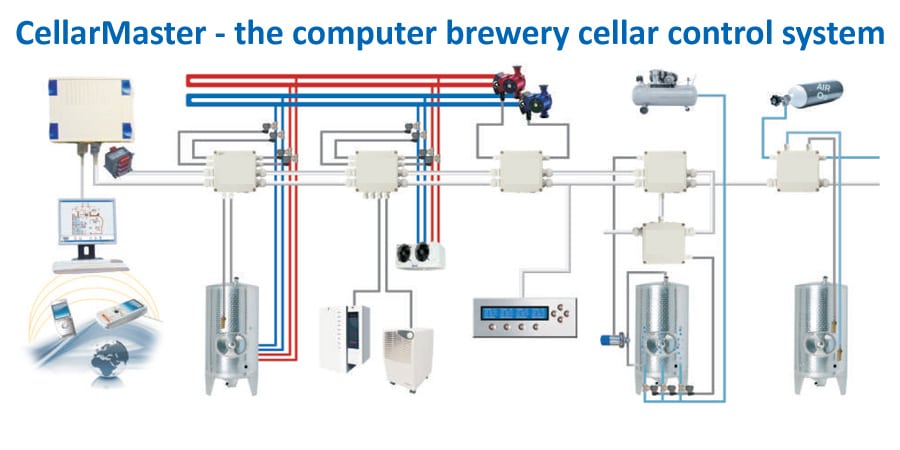

The CellarMaster hardware-software package includes the PC terminal server , Windows OS, WinInfo single licence and USB converter. Complete pre-installed including cellar plan (tanks layout). PC-screen, mouse and keyboard not included . The CellarMaster is a complete, modular, system for controlling and logging many operations in your winery, brewery or ciderline from your computer. It is truly unique and the most flexible, affordable system on the market.

The WinInfo software – in connection with the server – enables you to systematically manage and control the complete course of fermentation and maturation processes and units managed through WinInfo software. The temperature controller FermCont and the control cabinet CTTCS can also be managed through WinInfo software in the foreground. The software is available in seven operation languages.

The main screen can be designed to display your own cellar plan. The position of the tanks, the different halls and units positioning corresponds to their actual location, providing you with a convenient orientation pertaining the location of your fermentation, maturation and storage tanks and of all other units controlled by the WinInfo software, e.g.: tanks, pumps, cooling room air-condition units.

The main screen can be designed to display your own cellar plan. The position of the tanks, the different halls and units positioning corresponds to their actual location, providing you with a convenient orientation pertaining the location of your fermentation, maturation and storage tanks and of all other units controlled by the WinInfo software, e.g.: tanks, pumps, cooling room air-condition units.

Each element is represented by a particular symbol. All important information is available anytime over the software. The objects’ current state can be noted at a glance. By moving the mouse on an object, A ‘quickinfo’ window is opened with it’s parameters. By clicking on the desired object, further information is displayed,

You can Control:

- Cooling and heating: interacts with tank controllers and logs data. opens glycol valves to allow flow as needed.

- Glycol recirculation Pumps: Pumps activated only when needed

- Micro or Macro Oxygenation: We also have a portable micro oxygenation system, but you can build it as tank specific unit for half the cost. All the same features as the Oxyboy

- Room temperature through control of fan unit connected to your glycol system

- Humidity Control: With the added humidity sensor you can control your humidification system through the software.

- Air injection into tank to disrupt cap in red fermentation (we order Speidel tanks with air jets in place)

- CO2 Measurement: which measures the off gassing CO2 allowing you to set how long you want the fermentation to last. For example if you want a slow fermenation in which you have skin contact for 12 days you set the program for 12 days and the CO2 is monitored and the tank temperature changed to maintain a 12 day fermentation.

- Pump Over: if you want to pump over you can control your pump with the control system allowing you to do a pump over at anytime.

- Carbodioxide injection process – control of injection carbodioxide into tank during the beer secondary fermentation using the candle with the porous stone to injection. Time and duration control is included.

Besides, changes in the regulation parameters can be made easily and quickly. Whether you would like to determine the fermentation pace of a single tank for the next few days or you wish to set a clock timer, you can carry out these tasks with only a few clicks.

The software provides easy and quick analysis of the measured data, including graphic presentation, entering data, recalling data, saving and printing information.

For instance, if you would like to have a look at the fermentation process of a particular tank, you could enter and save directly in the charts, which also shows instances when the process was intervened by the winemaker, added comments and additional information. To round off the analysis and data interpretation, graphic analysis is easily and quickly created with a few mouse clicks. Various zoom and print options are also available. For assistance – call up the help texts anytime.

With the WinInfo software, all the records regarding the fermentation process, such as relevant events, process parameters, measured values, and relevant information are kept without gaps (completely, no information loss). The saved list of completed fermentation processes can be retrieved and sorted according to year, grape variety, tank number, etc.

Note : Price does not insclude all possible items but only the basic set of hardware and software for average configuration of a cellar equipment. Actual price will be calculated according to an individual project.

Reviews

There are no reviews yet.