Description

The PCH-960 Chamber steam pasteuriser is ideal equipment for pasteurising of filled and closed glass bottles or aluminium cans, whether they contain fruit juice, vinegar, cider, conserves or chutney, and even canned fruit or vegetables.

The cabinet-pasteurisers for beverages offer safe and easy use, they are controlled via a digital panel for an adjusting of heating temperature and the cooling time. Filled and closed bottles or cans are placed into the pasteuriser, beverage does not flow through the pasteurizer parts, therefore the need for cleaning of the equipment is drastically reduced.

Filled and closed bottles or cans are placed into the cabinet, the temperature level and duration can be programmed via a digital control pannel and heating time and cooling time can both be adjusted. Pasteurisation time is normally one hour after which the process shuts down automatically. With capacity of 960 litres, the PCH-960 range of cabinet pasteurisers are ideally suited for the small to medium producer requiring an efficient in-bottle pasteurisation method.

Key Features:

- Large capacity – up to 960-2400 bottles or cans per hour (more for smaller containers)

- Stainless steel construction with insulated housing

- Electronic temperature and time control

- Capable of pasteurising a wide range of products

- Automatic temperature control with individual sensors for water and product temperature

- Suitable for use with a wide range of product types and packaging sizes

- Air circulation by high effective stainless steel air blower

- Steam injection in the air channel for opimal steam mixing

- Pneumatically actuated steam valve

- Condensate outlet on the bottom of the Chamber DN 70

- 4 pcs of adjustable feet

- Steam consumption: approx.:. 180-300 kg / hr at 1 bar pressure

- Pressure air consumption : approx.:. 50-120 litres / hr at 5 bar pressure

- Electric power consumption: 5.5kW/ 16A / 3-phase / 400V

Technical specifications

| Model | PCH-960ST / with direct steam heating |

| The principle of pasteurization | Blowing hot steam into the interior of the pasteurizer, where bottles or cans of beverages are stored on a pallet in plastic or metal transport baskets. The temperature is measured by a thermoprobe, which is placed inside the fake bottle between the other bottles with drinks. Steam is generated by an external steam generator (which is not included in price of the pasteurizer), inside the pasteurizer the steam circulates using a fan. This achieves almost the same temperature in the entire space of the pasteurizer. |

| Capacity | Up to 960 pcs of the 1L, up to 1600 pcs of the 0.50L, up to 2400 pcs of the 0.33L cans/bottles in one batch

Inner space inside the pasteurizer : 1300 x 1800 x 1800 (L x W x H) Maximally 80 packages 400 x 300 x 300 with bottles or cans on the Europalette |

| Heating power | Minimal power capacity of the external steam generator is of 120kW. Recommended capacity of 120-200 kW (180-300 kg of steam per hour at 1-2 bar) |

| Electrical supply | 400V / 16A / 5.5 kW (without an external steam generator) |

| External steam generator | Required : Electric steam generator, Gas steam generator, Diesel steam generator / 180-300 kg of steam per hour at 1-2 bar |

| External air compressor | Required : External air compressor / 120 litres per hour at 5 bar (activation of the steam valve) |

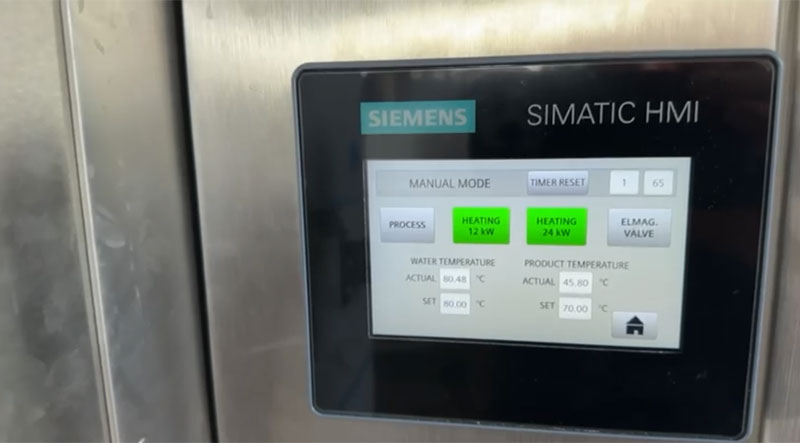

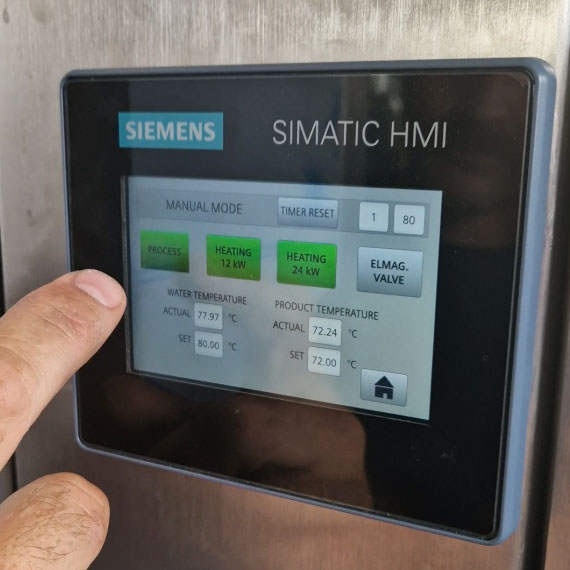

| Control system | Automatic control system, based on the PLC Siemens S7-1500 / HMI Siemens |

| Material | Standard version : Stainless steel AISI 304 / Optionally : AISI 316L (for surcharge 20%) |

| Space required (mm) | length 1800 width 2200 height 2000 |

| Weight | 1300 kg |

How the steam chamber pasteurizer works :

There is another chamber behind the main chamber for bottles or cans where the air fan is located. Steam from the steam generator is blown into this space under pressure and the steam at a temperature of approximately 110°C mixes with the air and heats this air, condensing into small drops of water.

This heated air is blown into the space with the bottles or cans using 4 flaps, where 4 temperature sensors are located and the flaps open and close according to the set required temperature. Furthermore, when the required temperature is exceeded, the steam valve immediately closes.

In this way, this way the required air temperature is regulated very precisely in the entire space of the steam pasteurizer (usualy between 60-90°C according to a food or beverage product).

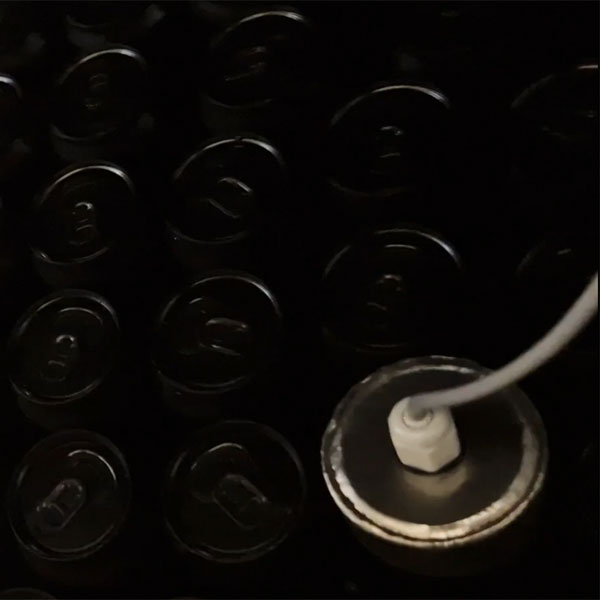

Another temperature sensor is placed in the fake bottle, which is between the real bottles or cans. This sensor is used to measure the temperature inside the bottle and to calculate the exposure of the pasteurization units.

If you do not want to use standard plastic crates for bottles for pasteurizing beverages in cans, we can make a special cage with several levels (demountable in individual levels), which you place on a pallet and thus optimally use the pasteurizer space for the maximum number of cans.

Accurate measuring of temperature directly in a can/bottle.:

Automatic control system based on the PLC Siemens S7-1500 / HMI Siemens

Recommended steam generators :

An external hot steam generator with minimal capacity 180-300 kg of steam per hour is needed … this equipment is not included in price.

Model |

Picture |

Description |

Electric steam generators : |

||

MXSG-120 |

|

Electric steam generator GHIDINI MAXI-120 120kW / 180kg/hr | pressure max 4.5 barAutomatic electric hot steam-generator with capacity of 120 kW (180 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

MXSG-180 |

|

Electric steam generator GHIDINI MAXI-180 180kW / 240kg/hr | pressure max 4.5 barAutomatic electric hot steam-generator with capacity of 180 kW (240 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

MXSG-120CSF |

|

Electric steam generator GHIDINI MAXI-120 120kW / 180kg/hr | pressure max 4.5 bar | Complete system on the frameAutomatic electric hot steam-generator – the complete system on the frame with capacity of 120 kW (180 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included) The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use. This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

MXSG-180CSF |

|

Electric steam generator GHIDINI MAXI-180 180kW / 240kg/hr | pressure max 4.5 bar | Complete system on the frameAutomatic electric hot steam-generator – the complete system on the frame with capacity of 180 kW (240 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included) The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use. This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

Gas steam generators : |

||

GSG-200 |

|

Gas steam-generator 151 kW | 200kg/hr | 5 barAutomatic gas steam-generator, available power 151 kW – The production capacity from 100 to 200 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar. This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations. + WTS-MX180 : Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) …€ 1190,- |

GSG-300 |

|

Gas steam-generator 227 kW | 300kg/hr | 5 barAutomatic gas steam-generator, available power 227 kW – The production capacity from 150 to 300 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar. This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations. + WTS-MX180 : Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) …€ 1190,- |

Optional equipment :

- Electric system equipment which is designed for power supply system different than 3-phase 400V / 50 Hz (The UL/CSA certificate is not available) … On demand

Reviews

There are no reviews yet.