Description

The PCH-360 chamber water-shower pasteuriser is an ideal equipment for pasteurising of filled and closed bottles or cans, whether they contain fruit juice, vinegar, cider, conserves and even canned fruit or vegetables. Pasteurization capacity : up to 360 pcs of the 1L, 506 pcs of the 0.50L standard cans, up to 668 pcs of the 0.33L pcs of the SLEEK cans, up to 786 pcs of the 0.20L SLIM cans (or bottles) in one batch.

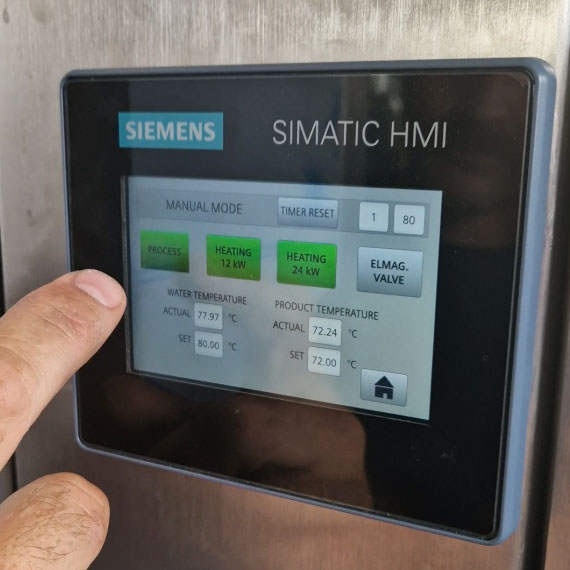

The cabinet-pasteurisers for beverages offer safe and easy use, they are controlled via a digital panel for an adjusting of heating temperature and the cooling time. Filled and closed bottles or cans are placed into the pasteuriser, beverage does not flow through the pasteurizer parts, therefore the need for cleaning of the equipment is drastically reduced.

Filled and closed bottles or cans are placed into the cabinet, the temperature level and duration can be programmed via a digital control pannel and heating time and cooling time can both be adjusted. Pasteurisation time is normally one hour after which the process shuts down automatically. The PCH-360 cabinet pasteurizer is ideally suited for the small to medium producers requiring an efficient in-bottle pasteurisation method

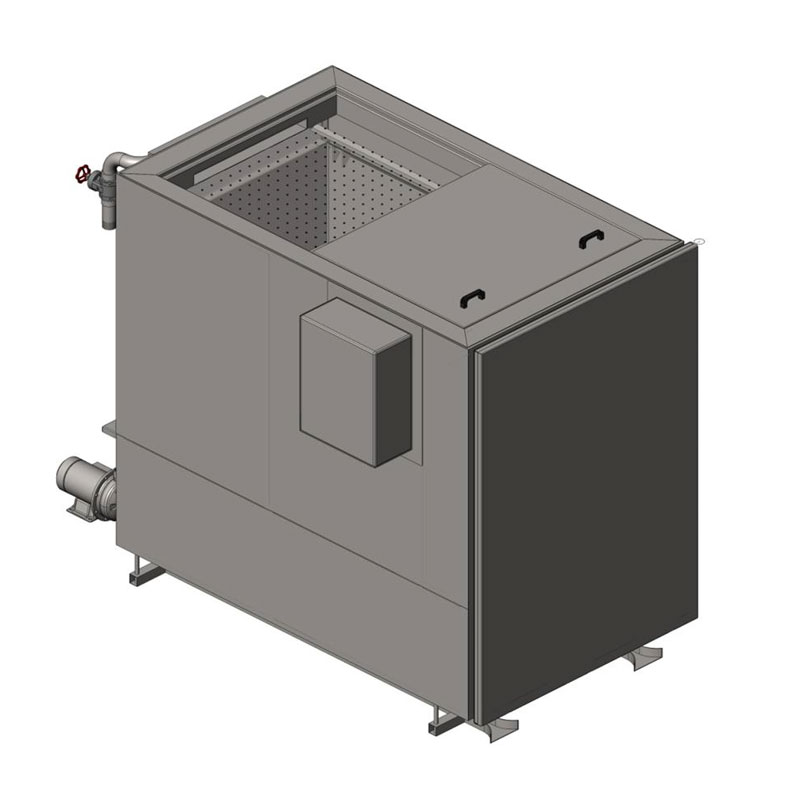

Equipment for easy pasteurisation of beverages. Very simple pasteurizer designed as a stainless steel cabinet. This pasteurizer has advantage that also bottles or cans are well cleaned from outside during the pasteurizing process. The pasteuriser is an integral part of the beer or other beverage production process. Keeping the right method of pasteurisation is incredibly important for managing of beverage product quality and achieving low production costs.

Note :

If this water-shower pasteurizer is used to pasteurize beverages that have defined a specific number of pasteurization units (e.g. beer), we recommend using only one layer (grid) with bottles/cans in the cart. When using both layers (on both grids), it cannot be guaranteed that the beverages on both layers will be exposed to the same number of pasteurization units.

Key Features:

- Large capacity – up to 360 pcs of the 1L, 506 pcs of the 0.50L standard cans, up to 668 pcs of the 0.33L SLEEK cans, up to 786 0.20L SLIM cans (or bottles) in one batch

- Stainless steel construction with an insulated stainless steel cabinet

- Electronic temperature and time control

- Capable of pasteurising a wide range of products

- Automatic temperature control with individual sensors for water and product temperature

- Suitable for use with a wide range of product types and packaging sizes

- Any external heating is not needed – 3pcs of 12 kW electric heating elements are included.

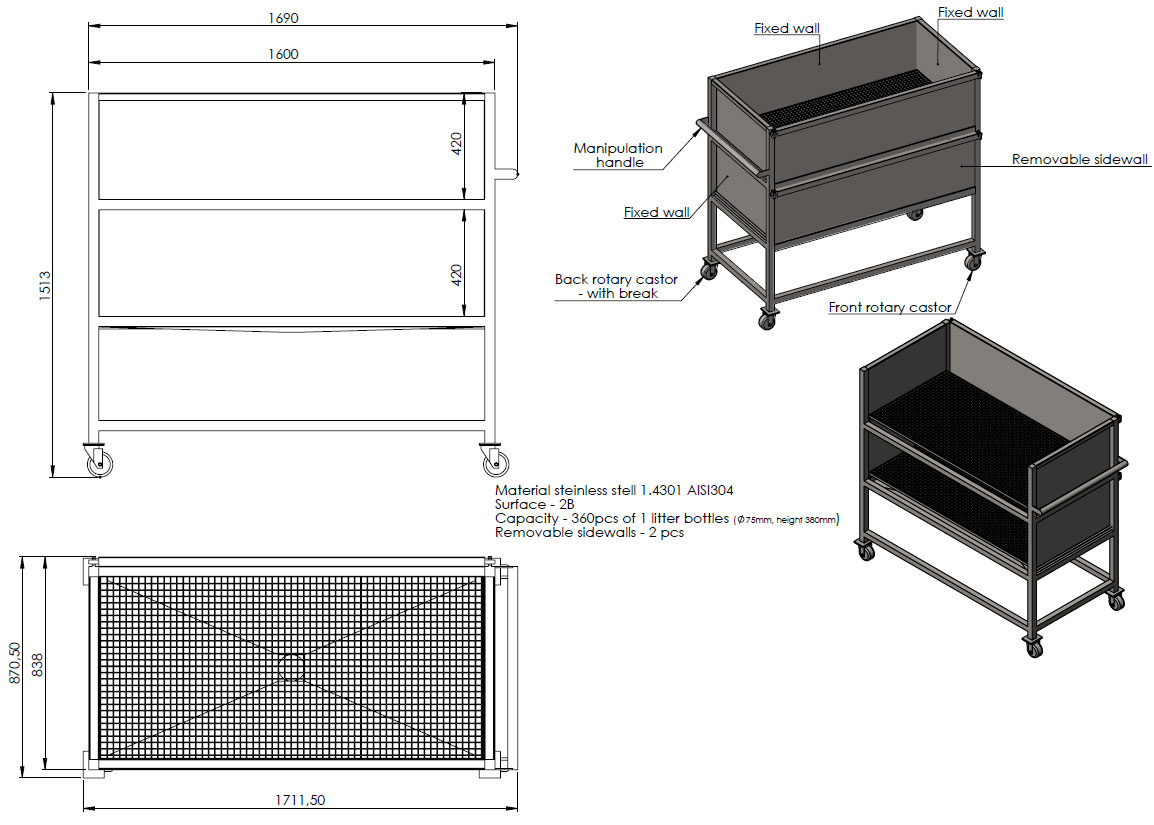

- One bottle trolley with capacity approximally 500 pcs of 0.33L bottles or cans is included.

- It is possible to order a secondary bottle trolley for higher production capacity.

Technical Specification

| Model | PCH-360WE |

| The principle of pasteurization | Showering beverage containers with hot water at a set temperature for a set time – temperatures and times can be programmed in a few steps. The water is heated by integrated heating elements directly inside the pasteurizer. |

| Capacity | up to 360 pcs of the 1L, 506 pcs of the 0.50L standard cans, up to 668 pcs of the 0.33L pcs of the SLEEK cans, up to 786 pcs of the 0.20L SLIM cans (or bottles) in one batch |

| Heating power ** | integrated (3x 12 kW) electric heating elements / possibility of switching to 3×4 kW or 3×8 kW |

| Electrical supply (without electric heating) | 3-phase 400V 50 Hz / 16A fusing / 1.5 kW |

| Electrical supply (with electric heating) | 3-phase 400V 50 Hz / 63A fusing / 40.0 kW |

| Control system | Automatic control system, based on the PLC Siemens S7-1500 / HMI Siemens |

| Water supply | BSP 1″ male / or DIN 11851 DN25 male |

| Water drain (sewage) | BSP 2″ male / or DIN 11851 DN50 male |

| Material | Standard version : Stainless steel AISI 304 / Optionally : AISI 316L (for surcharge 20%) |

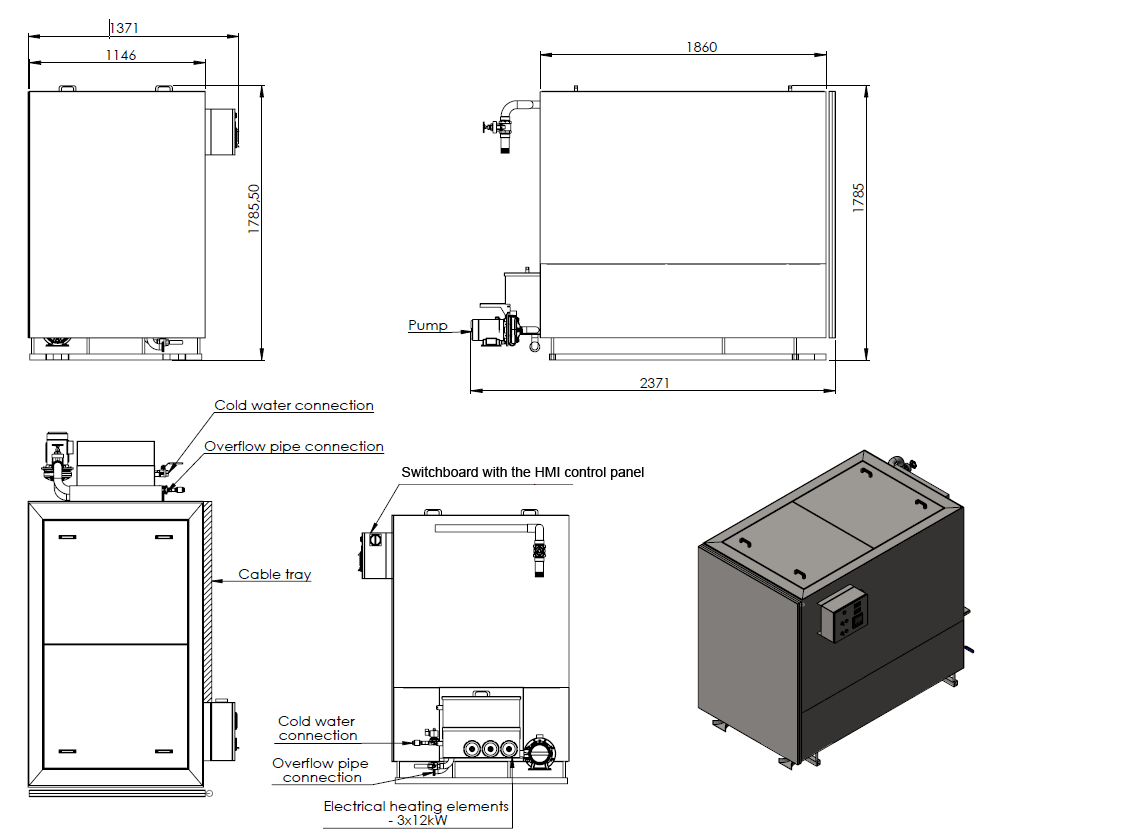

| Space required (mm) | Machine : L x W x H : 2300 x 1400 x 1787 mm

Recommended space (floor plan) :L x W x H : 4500 x 3000 x 1900 mm (1400 mm before front door) Absolutely flat floor under the paster with no slope. |

| Weight | Floor load | 700 kg | 250 kg/m3 |

** Only version with integrated heating system

Dimensions, connections :

Recommended optional equipment :

| Code | Description | Price |

| PCH-360BT | Additional bottle trolley for the PCH-360 chamber pasteurizer | On demand |

| PCH-360DR | Drying of the bottles with the air after the pasteurization | On demand |

| PCH-360DV | Electric system equipment different than 3-phase 380-420V 50 Hz (EU standard) | On demand |

Additional bottle trolley for the PCH-360 chamber pasteurizer………….. for next 360 – 786 bottles or cans

Reviews

There are no reviews yet.