Cylindrically-conical fermentation tanks with the CRAFT design

CCT/CCF : Universal pressure tanks with a professional equipment optimized to both primary and secondary fermentation and conditioning of craft beer or cider in the same fermentor

CCF cylindrically-conical fermenters, CCT cylindrically-conical tanks, the most commonly used brewery fermentation vessels, with classical design and equipment – for the most of breweries, microbreweries and producers of alcoholic carbonated cider. Insulated tanks cooled by water (or glycol). They are equipped with double-jacket for efficient cooling and temperature control during all fermentation process.

The CRAFT version of the tanks allows the beer production using traditional methods and final conditioning of beer in the tank like flavoring with natural hops, carbonization with carbon dioxide etc.

The CRAFT version of the fermentor has bigger total inner volume than the CLASSIC version because stronger craft beer creates more foam during the fermentation.

Designed to use with beer, cider, sparkling wine.

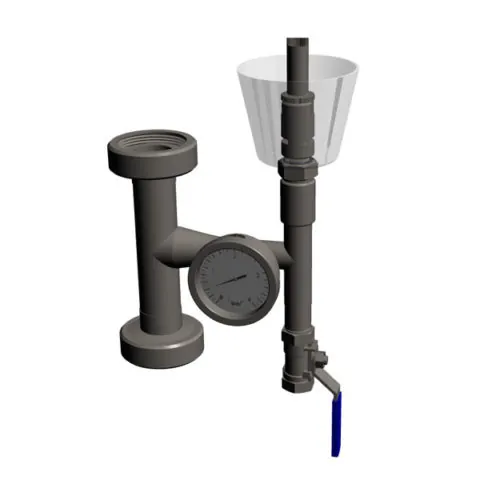

All the tanks are equipped with the fermentation control mechanism for fine adjusting of pressure in the tanks. Temperature may to be easily regulated with the local or central control system.