Description

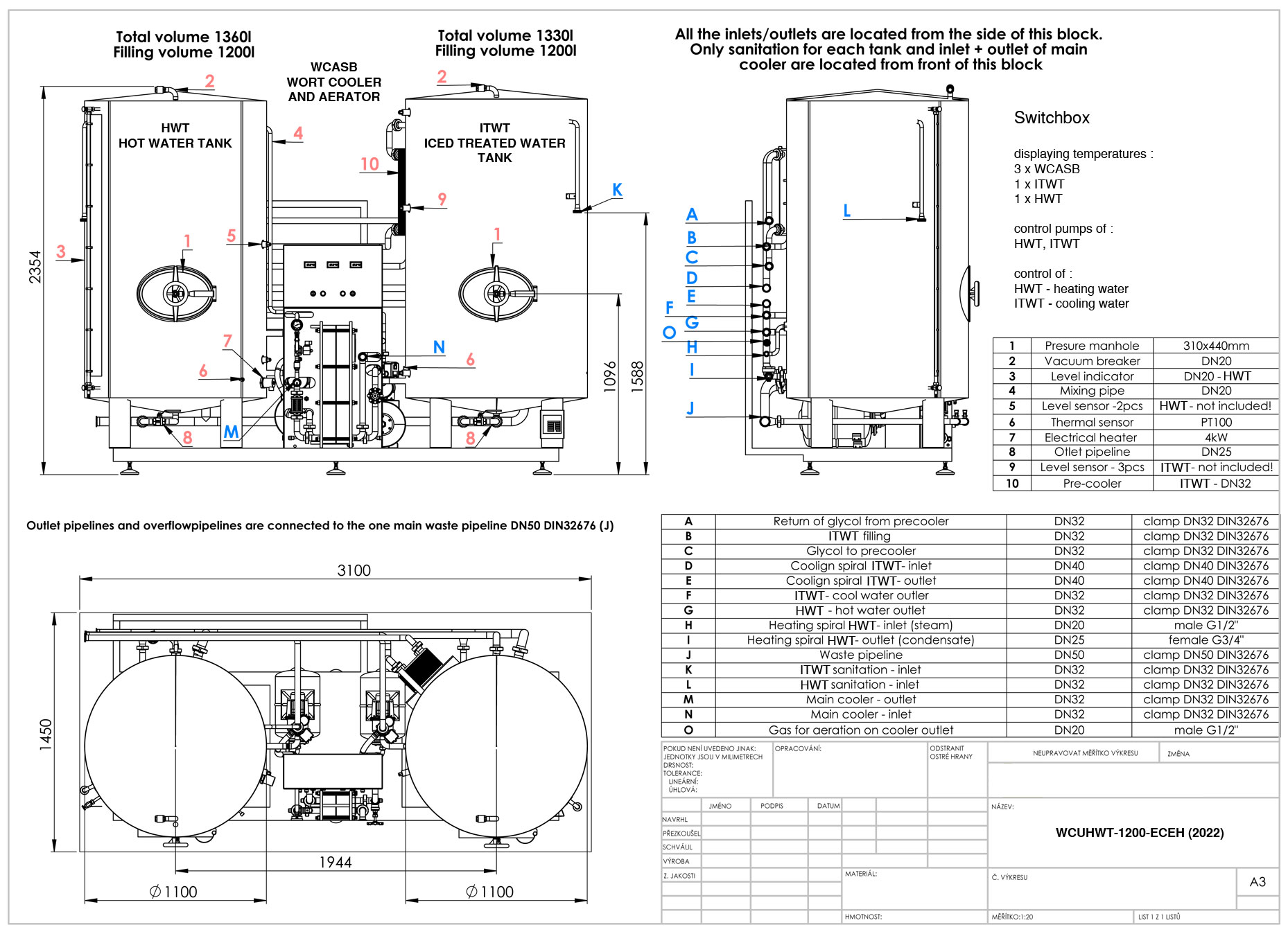

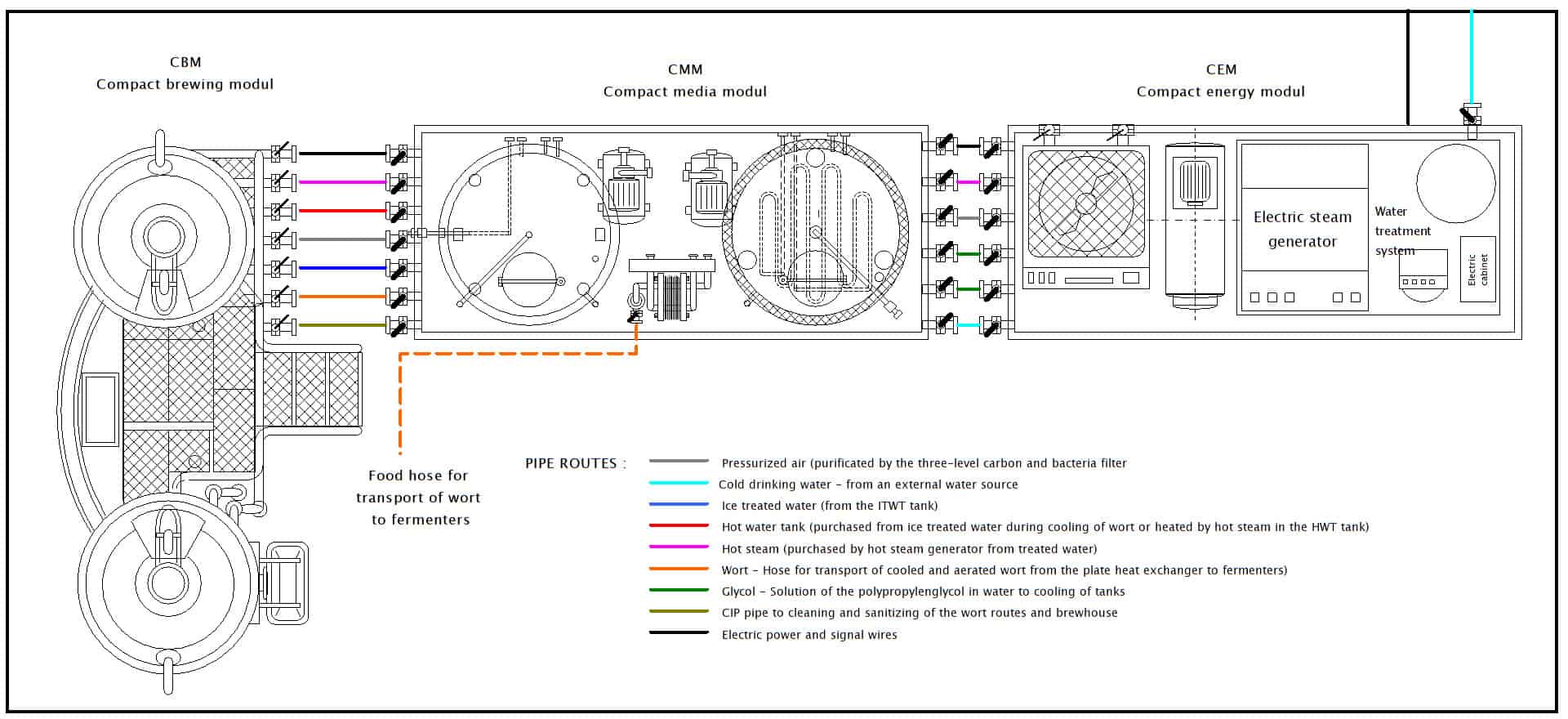

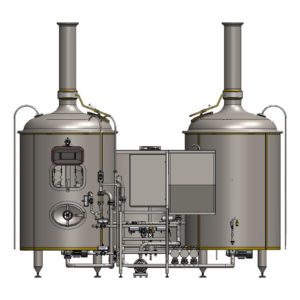

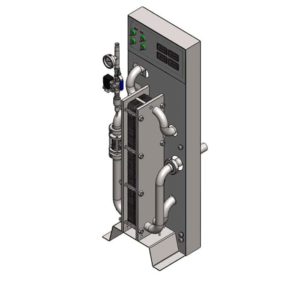

Special CMM module (The compact system wort cooling and the water management) which integrates the unit for cooling of the wort consists of heat exchanger, cold water tank 1200 liters and independent water cooler for cooling of the wort , stone for aeration of the wort and the hot water tank 1200 liters on a shared frame with the adjustable feet. Hot water that we receive from cooling of the wort in the first stage of cooling (in the plate heat exchanger integrated in the brewhouse) is collected in a stainless steel insulated tank and is ready for use. Most often brewers use the hot water for preparing the next batch of brewing, but also when washing and sanitizing other equipment in microbrewery. This recuperation of waste heat from wort cooling contributes to substantial savings in production costs.

The WCUHWT-1200 unit contains :

The WCUHWT-1200 unit contains :

1) Isolated container ITWT-1200 for cooling and storage 1200 liters of cold treated water. The circulation pump for keeping the same temperature in entire volume of water is also part of the tank.

2) Isolated container HWT-1200 for the heating and storage 1200 liters of hot water. This tanks is equipped with electric heating elements for preparation of hot water. If the wort brew system is equipped with the hot steam generator then the tank may include the steam pipe heat exchanger instead electric heating elements. The circulation pump for keeping the same temperature in entire volume of water is also part of the tank.

3) Compact glycol chiller which ensures cooling of water in the ice water tank up to temperature 1°-3° C from the initial temperature of about 15 ° C within 10-20 hours. If the Modulo wort brewing system includes also dedicated power modul then the compact cooler may be placed on this external module.

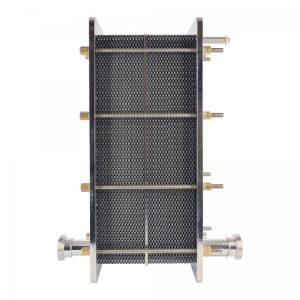

4) Plate heat exchanger, ensuring effective transfer of the cold from ice water into wort. The compact block is equipped with numeric displays to indication of temperatures of all media flowing through the exchanger.

5) Wort aeration candle with stainless steel stone for aeration of wort before start of fermentation process.

6) Centrifugal pump for ensuring the necessary flow of ice water through the plate heat exchanger to cooling of wort.

7) Centrifugal pump for creating a pressure in the hot water pipes.

8) Valves and flanges for connection of all hoses or stainless steel pipes with other modules of the Modulo wort brewing system.

9) Chassis with the adjustable feet for easy transport of the unit and safe positioning on uneven ground.

10) Fully equipped system of measuring and regulation of temperature.

Compact design and easy installation …

Possible design of the WCUHWT-1200-ECEH module – with the external steam heating (a steam generator is not included) and the external cooling (a water cooler is not included)

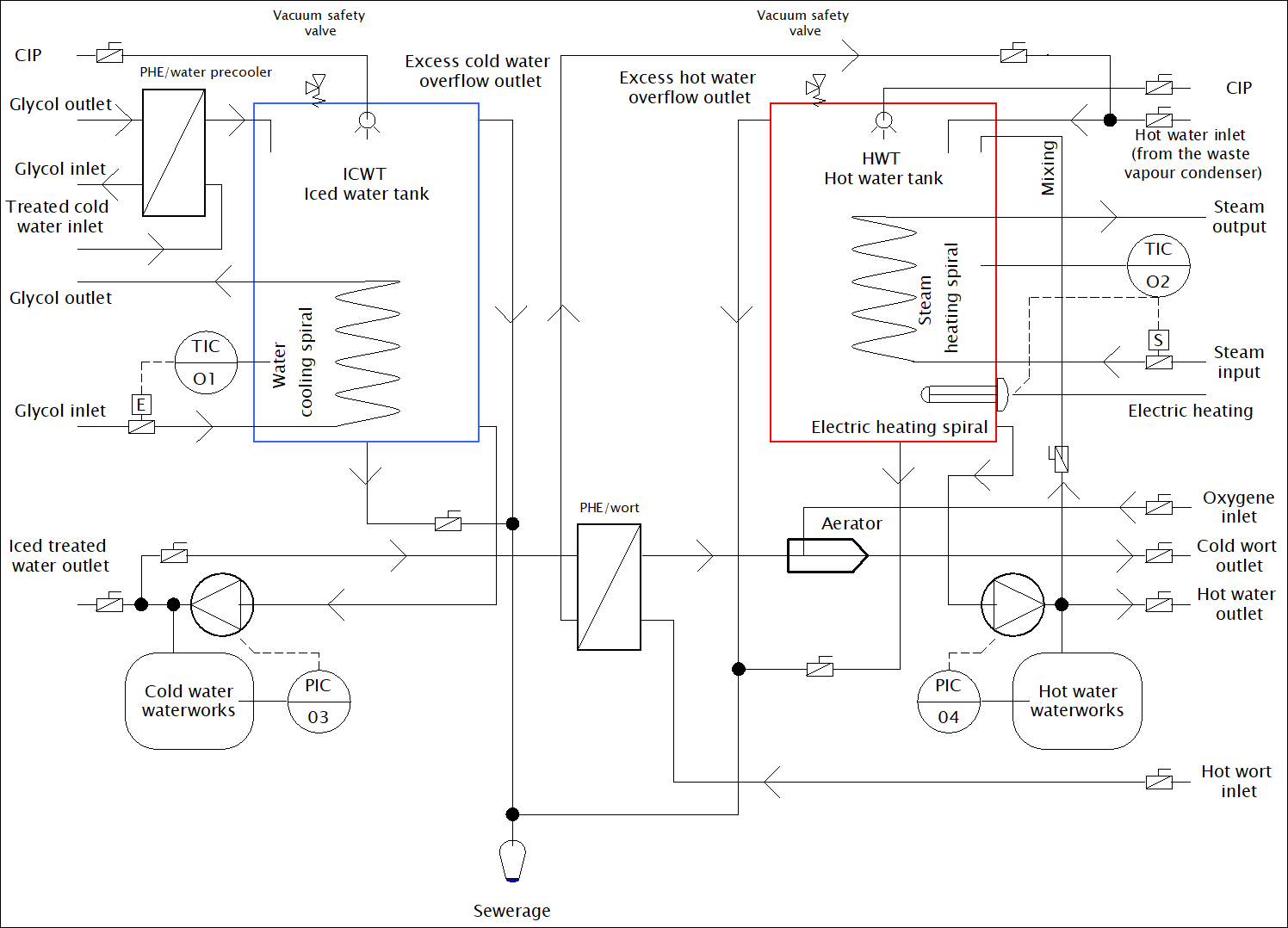

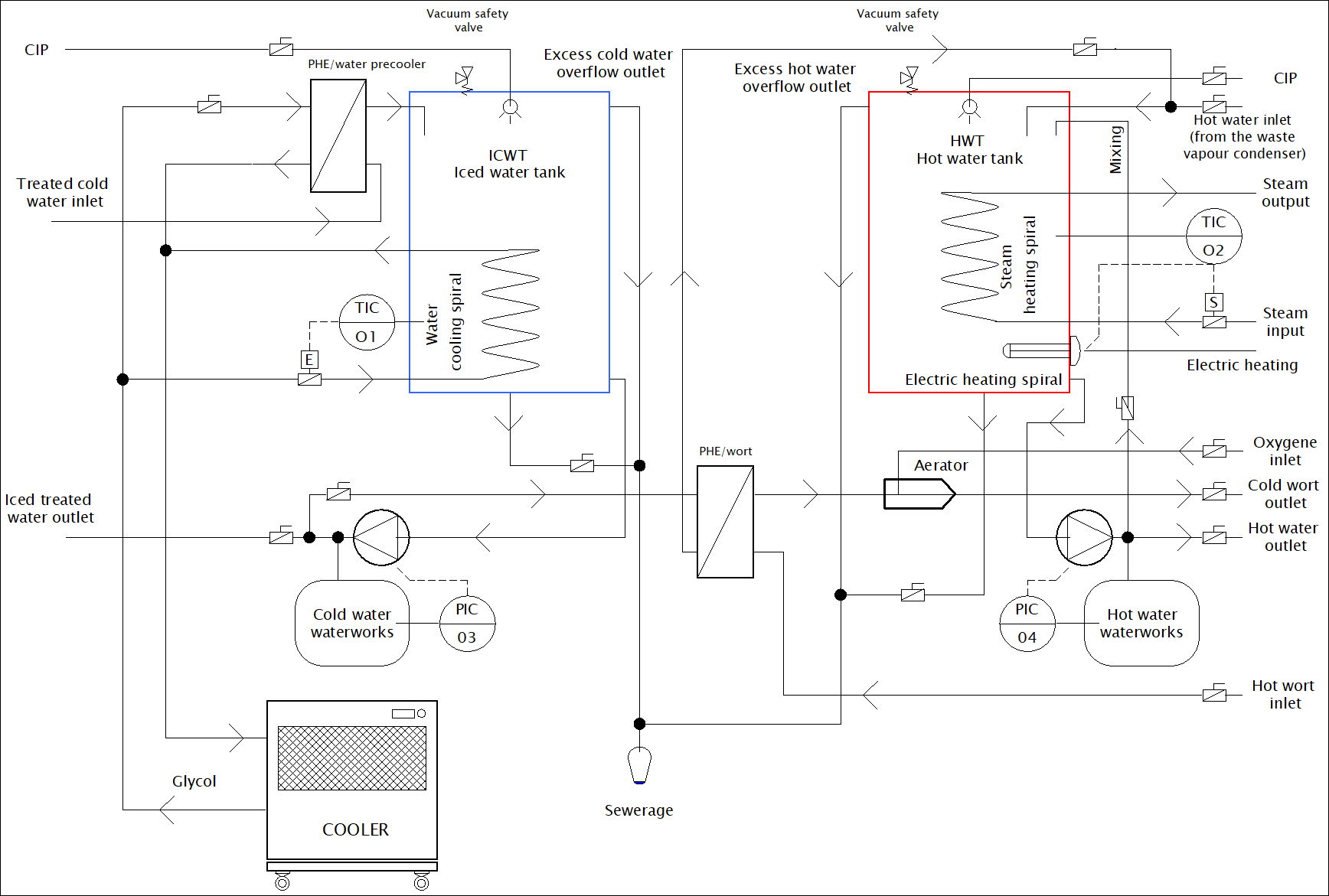

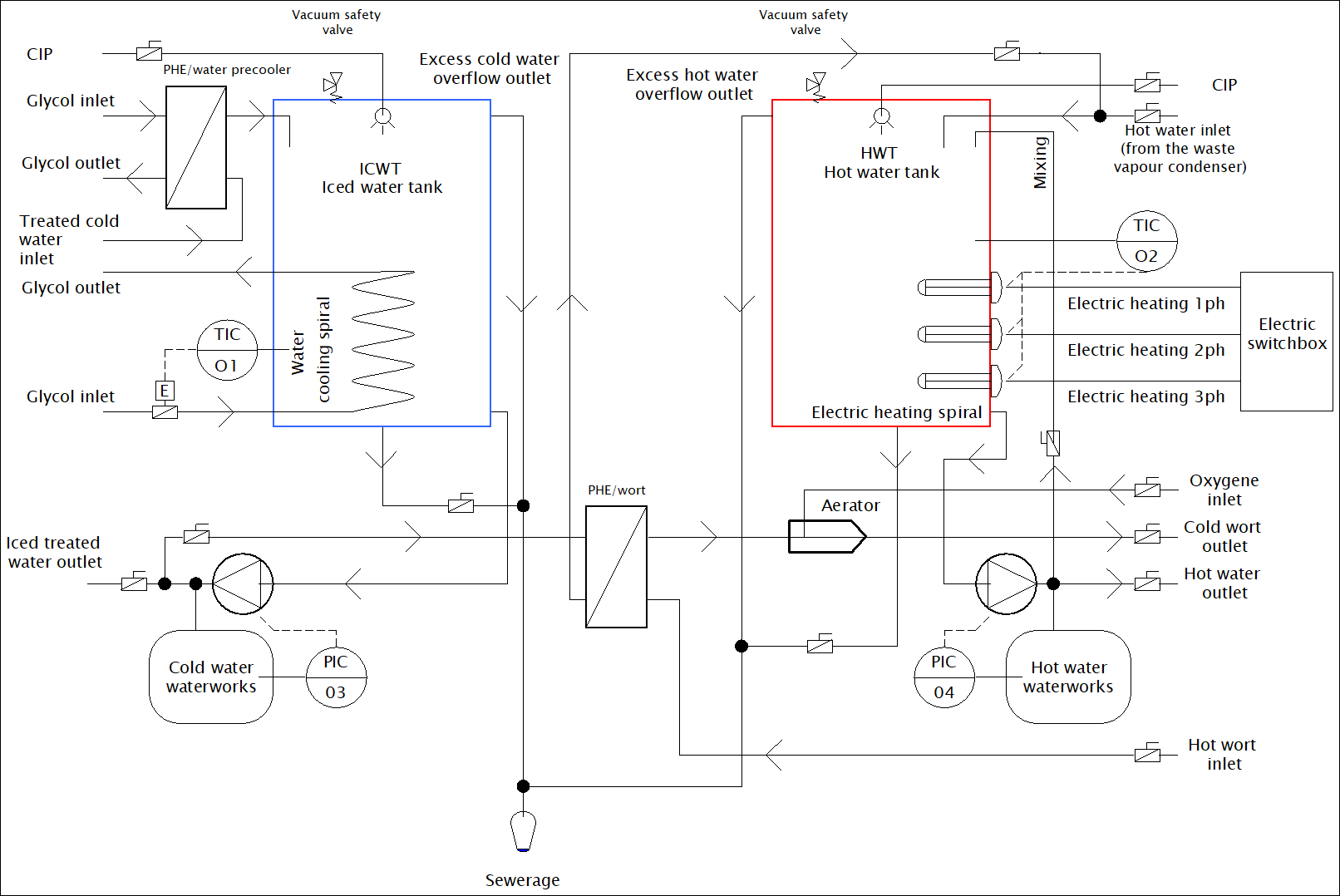

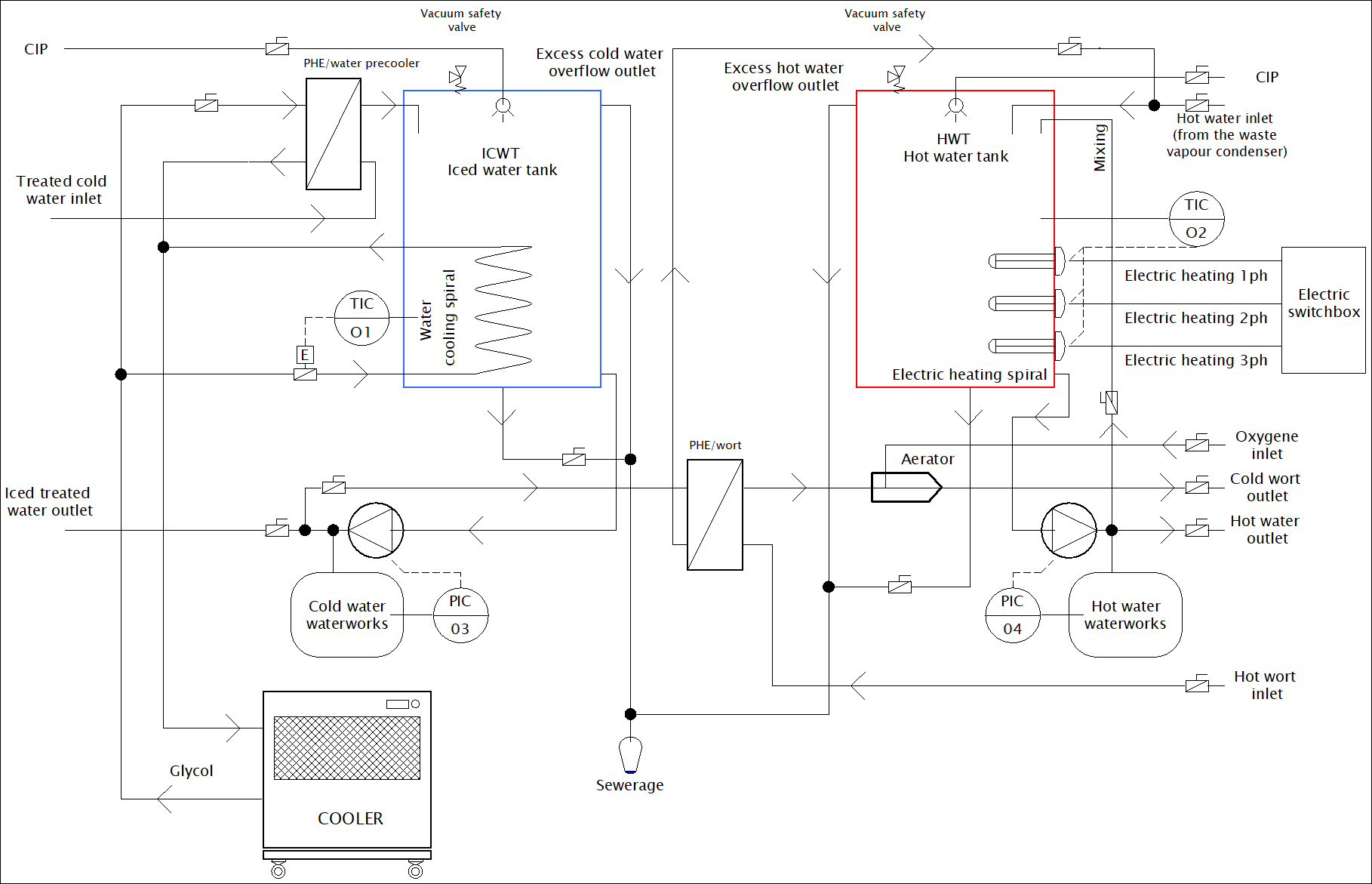

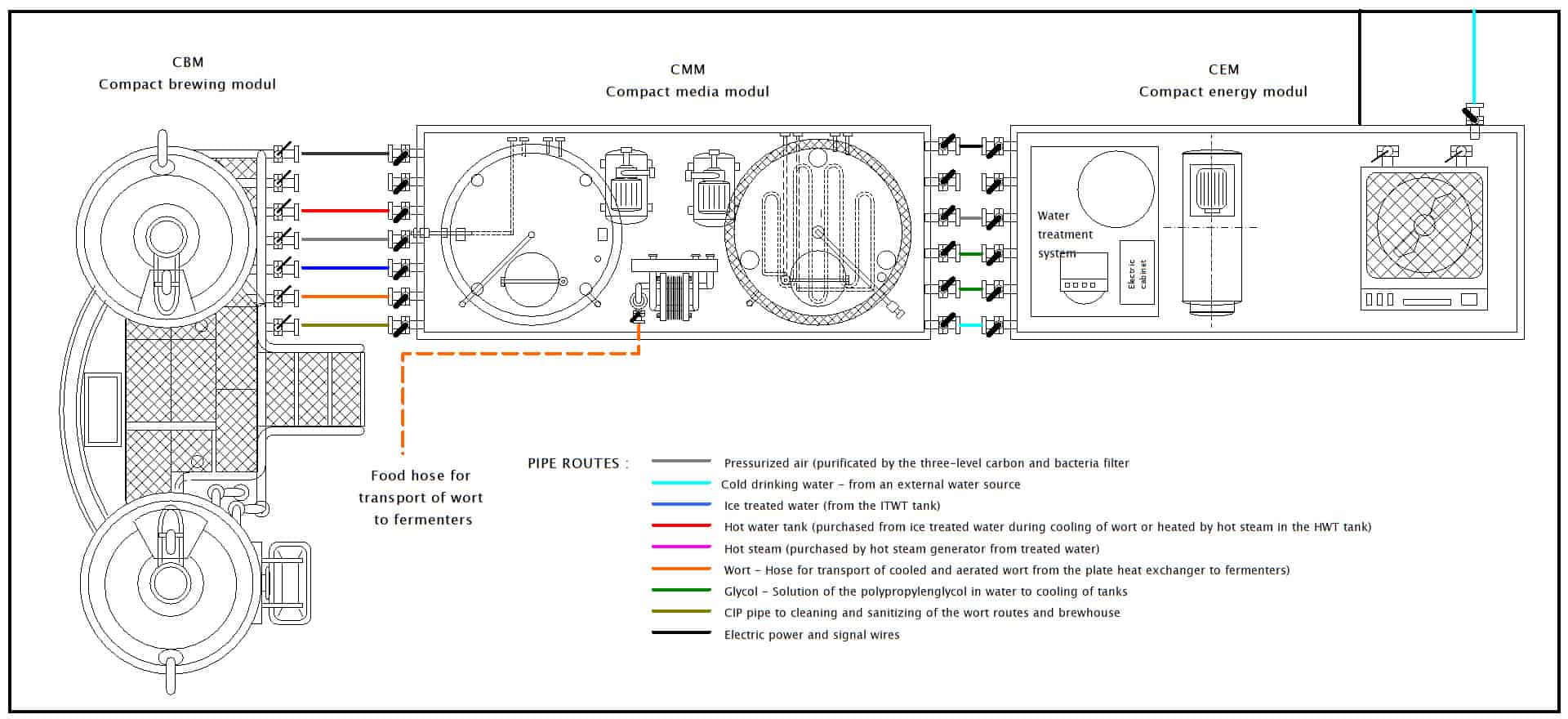

Technological scheme :

1. Version ECEH : external cooling (external glycol chiller) + external heating (external steam generator)

2. Version ICEH : integrated cooling (glycol chiller) + external heating (external steam generator)

3. Version ECIH : external cooling (external glycol chiller) + integrated heating (electric heating spirals)

4. Version ICIH : integrated cooling (glycol chiller) + integrated heating (electric heating spirals)

Heat recovery and utilization of hot water with the WCUHWT unit

The WCUHWT unit in the brewery without hot water tank allows recovery to 95% of the heat , produced during wort cooling – resulting hot water is collected in full volume in the tank for hot water. Hot water will be used for the next cycle of subsequent wort boiling, or for washing and sanitizing of brewhouse, tanks and other equipment in the brewery.

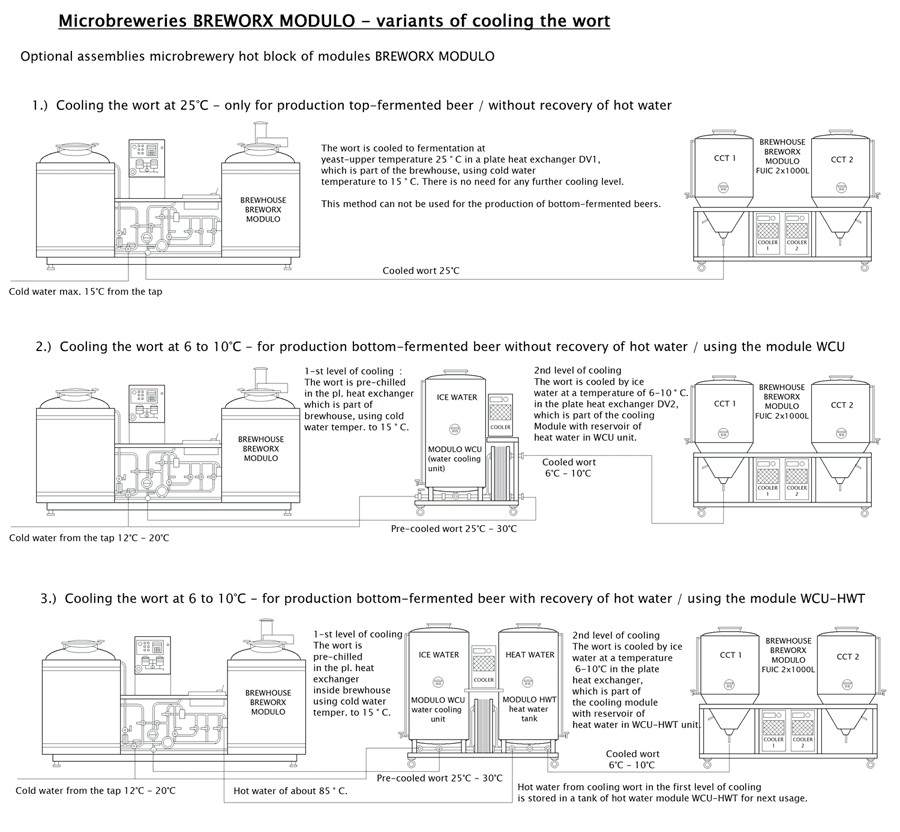

Scheme of the recommended Modulo wort brew systems :

I. SH – Steam heating system (click on the picture to enlarge)

II. Electric-oil heating system (click on the picture to enlarge)

Reviews

There are no reviews yet.