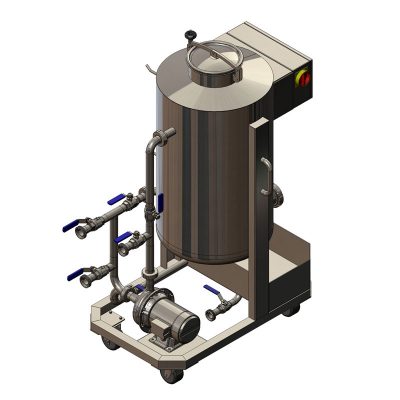

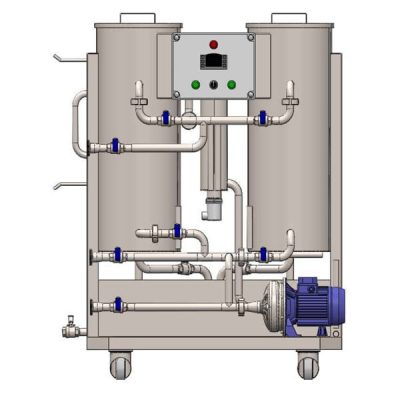

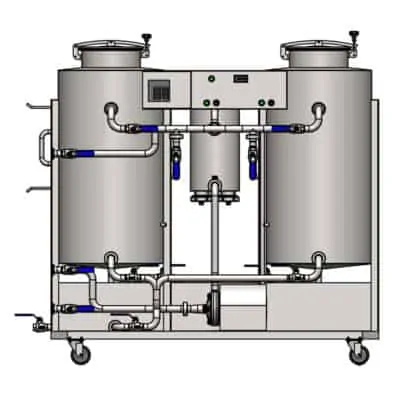

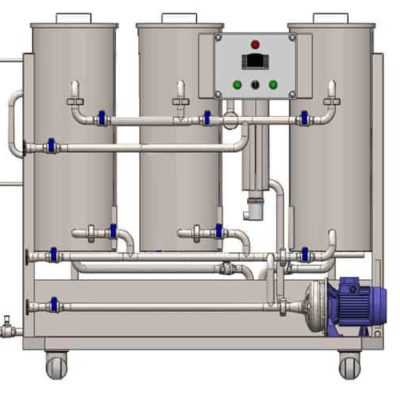

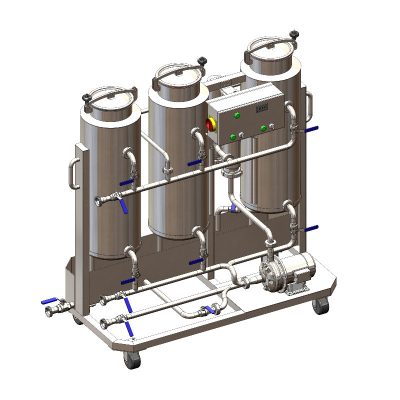

The CIP machines with the Clean-In-Place technology

Professional equipment for a chemical cleaning of all tanks, machines and pipe routes which came in contact with food and beverages

The CIP stations are mobile or static machines to the chemical cleaning, sanitation and sterilization of the tanks and all piping routes. This is a fully equipped system for breweries and other food production devices : Clean-In-Place technology. The CIP equipment provides heating and circulation of alkaline and acid chemical cleaning solutions using a pump through pipe system, hoses and sanitary shower that sprays sanitary solution on interior walls of the sanitized vessel and removes all dirt and deposits from inside the pipelines, fittings, tanks and also from all other equipment that come in contact with food and beverages.

Without regular care of the cleanliness of all equipment brewery is not possible to produce quality drinks. Our CIP stations are equipped with all components that are necessary for easy and efficient cleaning and sanitizing of all brewery equipment like wort production machines, pipe routes, fermentation tanks, beverage maturation tanks, other beverage tanks, filters, water storage containers etc. They ensures all cleaning procesures in the manual or fully automatic mode according to the model of the CIP station choosed.

More about the clean-in-place (CIP) process