Description

CIDER LINE MODULO 250M-45B – The modular cider production line

The modular cider production line kit type CIDER LINE MODULO 250M-45B (in this basic configuration) includes all equipment necessary for the annual production from 1500 to 4500 liters of cider. The actual annual production capacity depends on the selected duration of the production cycle (typically 2-6 months).

This configuration of the CiderLine includes set of fermenting/maturing cylindrical-conical tanks with usable volume 4x 240-300 lt. All the tanks except one are usable for both cider fermentation and maturation process. One tank is used as a buffer tank during the fruit-must cleaning process, carbonation process or bottling process (or filling a cider into other packages like kegs, PET etc.) Simple design with independent devices allows easy assembling of all the cider production line by customer without our specialists.

This configuration doesn´t include an assembly work – a customer ensures it himself according the assembly manual. Optionally we can deliver the CiderLine Modulo including installation work (for an assembling fee and our worker´s team transport and accomodation costs).

For easy manual control of the cider fermenting and maturating process, CCT tanks are equipped with simple PLC temperature controllers.

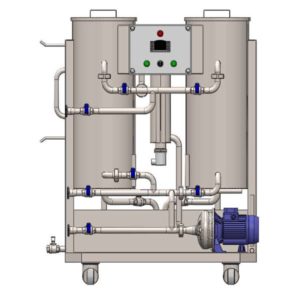

Scheme of the CiderLine MODULO :

Technical parameters :

Production capacity :

- 1500 liters of cider per year – for 6-months production cycle

- 2250 liters of cider per year – for 4-months production cycle

- 3000 liters of cider per year – for 3-months production cycle

- 4500 liters of cider per year – for 2-months production cycle

Raw material :

- Fresh fruit : apple, pears immediately after their collection

- Crushed fruit : The crushed fruit, which is stored in vacuum bags at low temperature (usually from 1 to 4 months max)

- Fruit concentrate : The concentrate of the fruit mash, which is stored in vacuum bags at low temperature (usually from 1 to 9 months max)

- CO2 in pressure bottles (cylindres)

- Washing and sanitizing solutions

Control system :

- Fruit crashing and pressing process – manual control

- Tanks – fermentation, maturation, must purging :

- temperatures – PLC controllers

- timing – manual control

- Washing and sanitation process :

- temperatures – PLC controllers

- pumping, washing – manual control

Required space for building :

- Floor area min : 18 m2

- Room height min : 2.0 m

Electrical connection :

- Electrical socket : 400V 3ph / 50 Hz

- Electrical consumption : 21 kW

Cooling system :

- Cooling of tanks : Each CCT tank is cooled by independent water (optionally glycol) cooler.

- Cooling of room where are FUIC units placed :

- Days with normal temperature – Air ventilation (by windows or ventilator)

- Days with very hot temperature – Air ventilation with air-condition support (it is not part of the CiderLine)

RECOMMENDED OPTIONAL ACCESSORIES :

- CO2 reduction valve + pressure bottles with CO2 gas : The inert gas for pushing of apple cider between tanks and filling of apple cider into packages.

- CIP station : The tank washing and sanitizing unit : The equipment for perfect and easy cleaning and sterilization of all vessels using sanitizing solutions.

- Carbonization stone : Optional accessory for CCT tanks that allows carbonation of apple cider – this equipment is used for production of some types of apple cider.

- Fruit sorting table : The stainless table is using for handy sorting of fruit before its washing in the machine.

- Fruit washer : Fruit is washed in the tub with water without circulation of water. Then fruit drips in the drying tunel equipped with the transportation belt.

- Fruit washer and motorized crusher : Combi machine the fruit washer-dryer-crusher with production performance 1000 kg of fruits per hour.

- Fruit belt press : The belt press is designed for pressing of fruit mass. Fruit mass is placed on the belt which presses it against cylinders.

- Fruit must pump : The equipment for the transport of fruit juice from the fruit press to the fermentation tanks using pump and hoses.

- Flotation machine : Flotation equipment for purging of fruit juices before its fermentation process.

- Mixing-homogenizing tank : Stainless steel tank equipped with side agitator for mixing and homogenizing of must prepared from concentrate.

- Yeast regenerator tanks : Special equipment to regeneration and storage of apple cider yeast.

- Keg washer and filler : The equipment to easy and quick rinsing and sanitizing of stainless steel kegs and to filling of kegs with apple cider.

- Bottle rinsing and filling machine : The equipment to easy and quick cleaning, sanitizing, capping of bottles and filling of apple cider into bottles.

- Filtration equipment : An equipment to mechanical removal of live yeast from the beverage.

- Pasteurizer : An equipment to temperature sterilization of the beverage (killing of remaining organisms)

- Serving tanks : Stainless pressure vessels to storage of finalized apple cider before its bottling or filling into kegs.

- Dispenzing tanks : Stainless pressure vessels to storage of finalized apple cider before its dispenzing into glass in the cider production line.

Reviews

There are no reviews yet.