Description

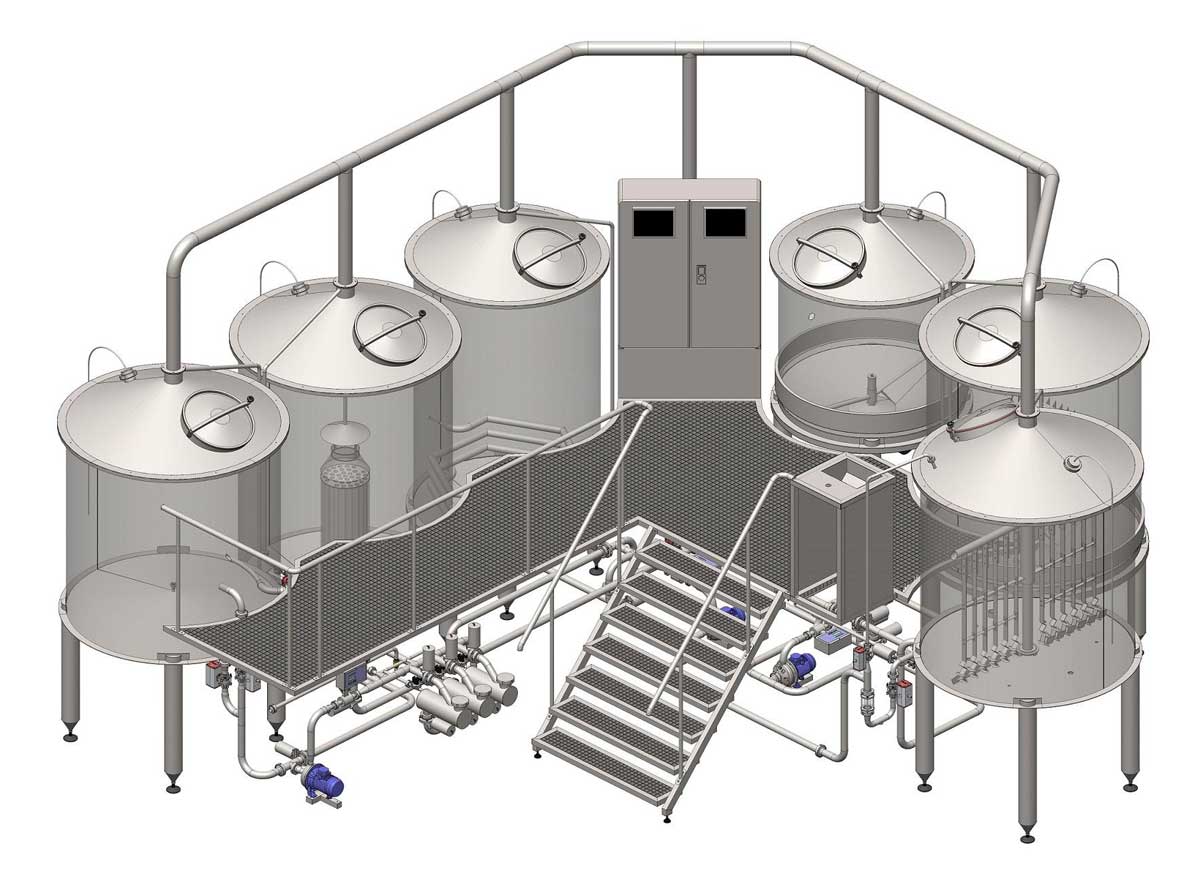

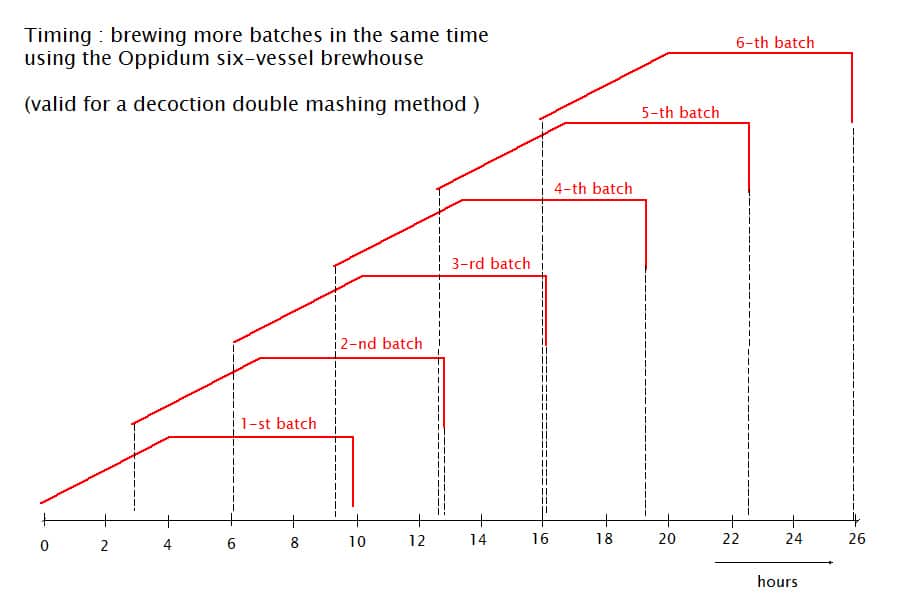

The wort brew machine OPPIDUM 3000 is a powerful professional compact equipment with industrial design which includes all necessary equipment to produce 3450 liters of wort in one batch from malt (or malt extract or wort concentrate), hops and water. The compact machine for preparation of wort includes six special vessels to maximize of production capacity. Thanks to parallel production method this machine is able to produce from one to six batches of wort per day – (from 3540 up to 21240 liters of wort per day). The wort production machine is the main functional component of the brewery BREWORX OPPIDUM 3000 . It is a food machine whose primary function is the production of wort. The wort is an intermediate product which is result of a first phase during production beer. The next phase of the production cycle is fermentation and maturation of this wort in fermentation tanks. The resulting product of this production process is a tasty refreshing low-alcoholic beverage – beer.

The wort brew machine OPPIDUM 3000 is a powerful professional compact equipment with industrial design which includes all necessary equipment to produce 3450 liters of wort in one batch from malt (or malt extract or wort concentrate), hops and water. The compact machine for preparation of wort includes six special vessels to maximize of production capacity. Thanks to parallel production method this machine is able to produce from one to six batches of wort per day – (from 3540 up to 21240 liters of wort per day). The wort production machine is the main functional component of the brewery BREWORX OPPIDUM 3000 . It is a food machine whose primary function is the production of wort. The wort is an intermediate product which is result of a first phase during production beer. The next phase of the production cycle is fermentation and maturation of this wort in fermentation tanks. The resulting product of this production process is a tasty refreshing low-alcoholic beverage – beer.

The compact wort production machine BREWORX OPPIDUM 3000 is a compact industrial machine which includes all necessary equipment to produce 3540 liters of wort in one batch. It is a industrial device equipped with six special vessels wherein containers are connected by pipes and electric wires and operated from the central stainless steel platform. This way we have achieved extremely efective functionality of the brewing machine while we retained the traditional design of industrial type Czech brewery which is optimalized for producing of world-famous Czech type beer, althought this machine is able to produce also all other known types beer always with a maximal production effectivity of this great machine. Thanks to that this machine enables the production up to six batches (21240 liters of wort) per day

The wort brew machine BREWORX OPPIDUM 3000 includes in standard version :

- mash kettle 3000 liters – vessel for mixing of grinded malt grains with warm water and splitting starch to form a sugar solution

- mash kettle 1500 liters – vessel for boiling and for cleave the starch to form a sugar solution

- filtration tank – (wort filtration tank) – vessel with a special sieve for filtering of wort

- wort storage tank – vessel for temporary storage of hot wort and keeping its temperature

- wort boiling tank – vessel for boiling of wort with hops

- whirlpool tank – for centrifugal separation of hop dregs from wort

- laboratory sink for tests of wort

- control panel with all control elements

- platform with stairs

- all needed pipes and wires connections

- all needed mechanically and automatically controlled valves and armatures

- electric switchboard cabinet

- industrial computer for control of wort brewing process (only version with automatic control system)

Options and properties

Two kinds of a raw material for production of wort :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

Six production capacities of the brewhouse :

- 3540 liters of wort per day – one batch during 12 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 7080 liters of wort per day – two batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 10620 liters of wort per day – three batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 14160 liters of wort per day – four batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 17700 liters of wort per day – five batches during 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 21240 liters of wort per day – six batches during 26 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

Practical design :

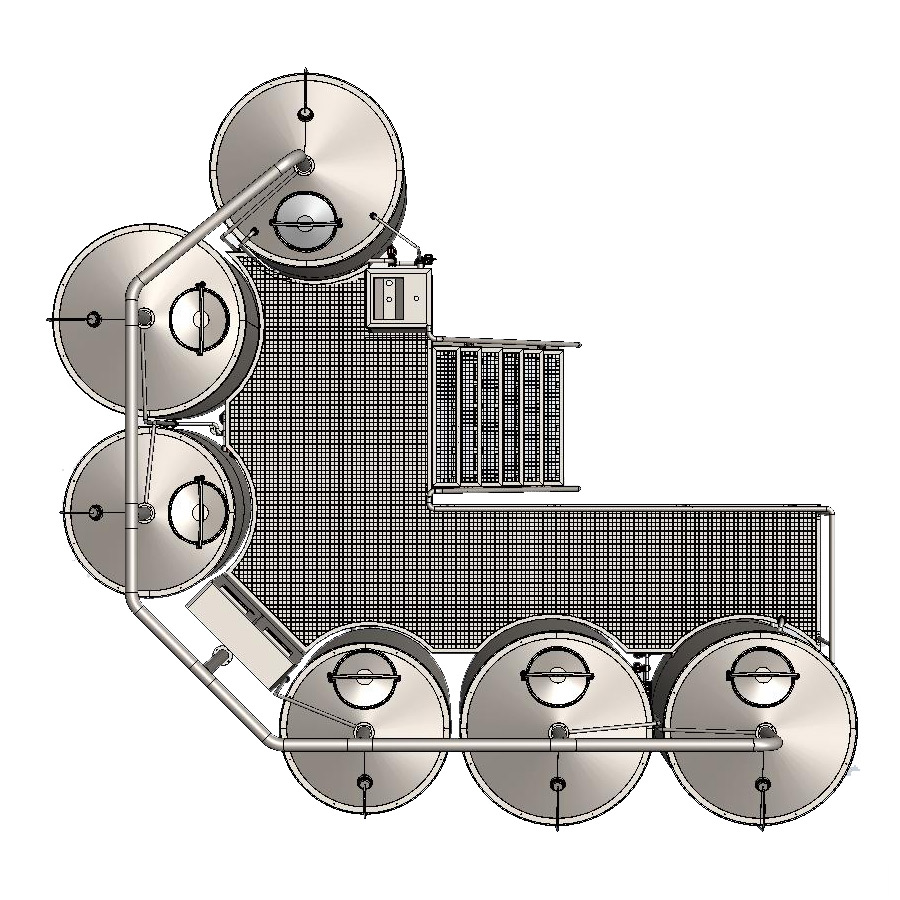

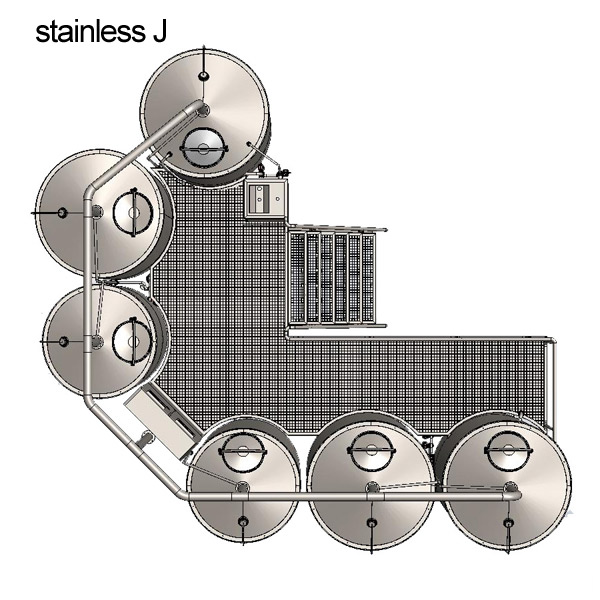

- SJ : Stainless steel / J-shape – all tanks are fully made of stainless steel AISI 304, arrangement of containers into the J-shaped

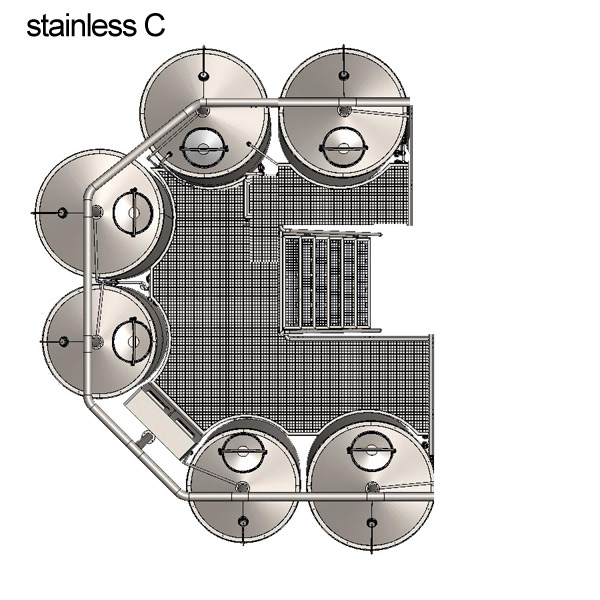

- SC : Stainless steel / C-shape – all tanks are fully made of stainless steel AISI 304, arrangement of containers into the C-shaped

- BLMS – Brewlock quick door-lock system – simple BLMS system allows very quick locking and unlocking of all upper doors of the tanks by only one hand (with the glass door design)

Powerful heating system :

- SH – Steam heating – the heating of the tank kettles is performed by hot steam produced by the steam-generator. Heating by hot steam significantly speeds up the boiling process. This is the best and very safety system for the heating of wort without danger caramelization of malt. This system requires a connection of the brewhouse to electric, gas or pellet steam-generator that is not included in the wort brew machine (see an optional accessories).

Automatic control system for automatization of entire wort production process :

- AC – Automatic control system – wort brew machine equipped with a computer support – the automatically controlled process of infusion or decoction – fully automatized management of the entire processes of production wort.

Why only the automatic control system for this wort brew machine is available ?

The OPPIDUM machine produces several batches of wort at the same time. This is extremelly demanding of attention, concentration and speed of brewer work as well as rapid and concurrent monitoring and evaluation of rapidly changing data from many sensors . Only sophistical system with a computer and many electronic sensors of the automatic control system are able to provide the properly timing of all brewing phases, the right temperatures in the right time, the right speed of pumps and motors, without damage of wort, it all controlled continuously during up to six paralelly worked production processes.

There are also other good reasons why use the automatic control system :

There are also other good reasons why use the automatic control system :

- Elimination of human errors – machine accurately and timely perform necessary tasks

- Costs saving for owner – only one worker is necessary for manipulating in the brewery

- Minimization the number of error conditions in the brewery – everything is still under control of the computer

- Monitoring and registration– all statuses and operations of the wort production process are stored in the computer memory

- Minimization of requirements – this system does not require extremelly attention of human operator – There is always ensured an early reaction of machine

- Stable quality of beer – standard manufacturing procedures are always observed in order to ensure always the same maximum possible quality of beer

- Six pre-programmed recipes – for production of the most known types of beer : Pils, Lager, Black, Weissenbeer, Ale, Special

- Manual brewing mode – for production of all other different types of beer that pre-programed system does not know

- Special sanitation mode – for automatic cleaning, sanitizing and sterilization of all tanks, pipes, armatures and other brewery equipment

Technical specification

This type of the stainless steel wort boiling machine OPPIDUM 3000 consists of:

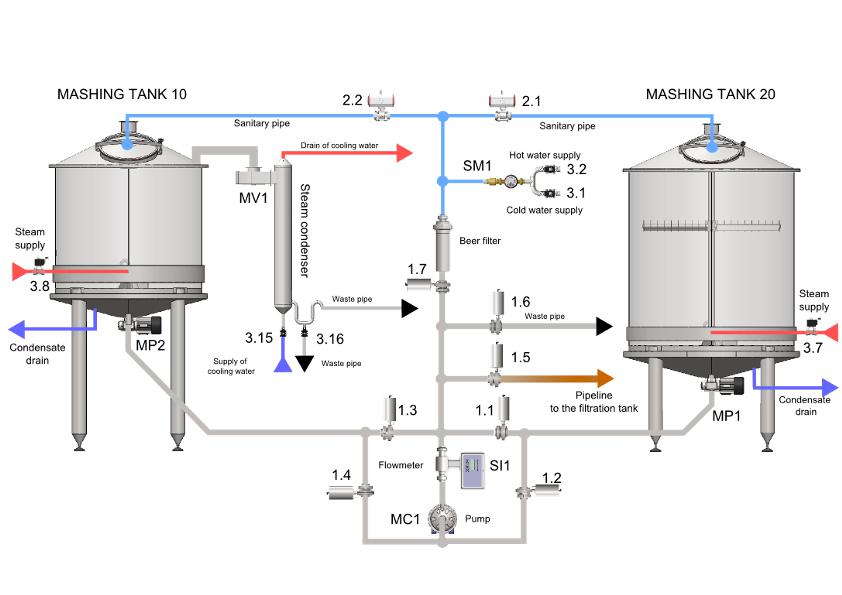

1. Mash kettle 3000 liters

Vertical, double-walled stainless steel vessel with a spherical or conical upper bottom, designed for mixing malt meal with warm water and splitting starch to form a sugar solution. Internal surface of tank: Cold rolling to a thickness of 4 mm and hot-rolling from a thickness of 5 mm, surface treatment 2B, seams polished to Ra<0.3 micrometers.

- Usable capacity 4 019 liters

- Dimensions Ø 1 600 mm, height 2 000 mm

- Steam-heated bottom area 1.85 m2

- Steam-heated cylindrical area 2.50 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 15

- Four-arm agitator with gearbox, output power 650 Nm, input power 2.2 kW

- Lighting 24V 100W

- Service manhole with a glassed door Ø 510 mm

- Hopper for crushed malt DN 100

- 2x Sanitary rotating shower DN 20

- Steam outgoing pipe DN 100, 3x spraying device

- Gearbox LBC 110/50 615 Nm sf 1.1

- Agitator blades 4 pcs

- Double jacketed bottom with a slope of 12° , heating area 2.50 m2 50 mm entrance

- External jacketing stainless steel 1.5 mm

- Top cover in stainless steel, welded seams and polished to Ra 0.1-0.3 micrometers

- Steam outlet to the central air exchanger DN 100

2. Mash kettle 1500 liters

Vertical, double-walled stainless steel vessel with a spherical or conical upper bottom, designed to cleave the starch to form a sugar solution.

- Usable capacity 2 308 liters

- Dimensions Ø 1 400 mm, height 1 500 mm

- Steam-heated bottom area 1.40 m2

- Steam-heated cylindrical area 1.62 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 25

- Four-arm agitator with gearbox, output power 450 Nm, input power 2.2 kW

- Lighting 12V 35W

- Service manhole with a glassed door Ø 410 mm

- 2x Sanitary rotating shower DN 20

- Steam outgoing pipe DN 100, 3x spraying device

- Gearbox LBC87/50 430Nm sf 1.1

- Agitator blades 2 pcs

- External jacketing stainless steel 1.5 mm

- Top cover in stainless steel, welded seams and polished to Ra 0.1-0.3 micrometers

- Steam outlet to the central air exchanger DN 100

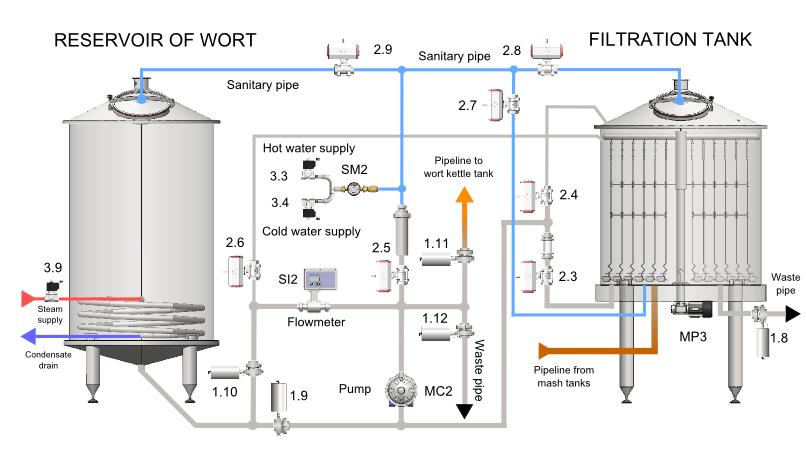

3. Filtering tank (wort filtration tank)

Stainless steel vessel with a special sieve for filtering of wort, with a spherical or conical upper bottom.

- Usable capacity 3 179 liters

- Dimensions Ø 1 800 mm, height 1 250 mm

- Filtration bottom 8 segments with 18% permeability

- Nozzles for rinsing under wire 6 pcs

- Stirrer 2 arms, 18 blades

- Gearbox LBC 130/100 820 Nm 2200 W

- Lighting 12V 35W

- Mechanical temperature indicator 0-120ºC stainless steel

- 2x Sanitary rotating shower DN 25

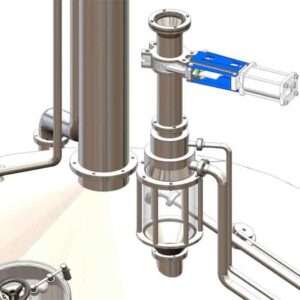

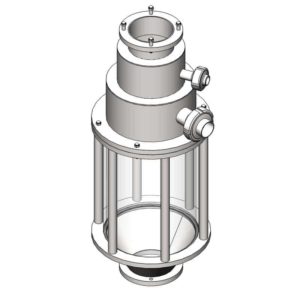

- Three-way setting valve with sight glass DN 80

- Brewer’s grains discharge 420*540

- Equipment for automatic grains discharge

- Insulation 50 mm plasticized cotton,

- external jacketing stainless steel 1 mm

- Top cover in stainless steel

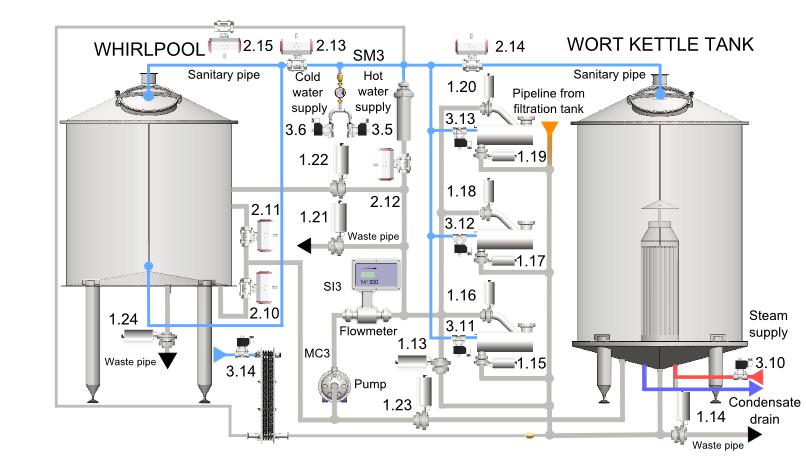

4. Wort kettle

Vertical, stainless steel tank with a spherical or conical upper bottom. Steam heating is secured by coil, located inside the container.

- Usable capacity 3 533 liters

- Dimensions Ø 1 500 mm, height 2 000 mm

- Steam-heated bottom area 1.50 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 25

- Lighting 12V 35W

- Service manhole with a glassed door Ø 410 mm

- 2x Sanitary rotating shower DN 20

- Steam outgoing pipe DN 100, 3x spraying device

- Insulation 50 mm plasticized cotton,

- external jacketing stainless steel 1 mm

- Top cover in stainless steel

5. Wort storage tank

Vertical, stainless steel tank with a spherical cap for storage of wort and keeping its temperature. Steam heating is secured by coil, located inside the container.

- Usable capacity 4 537 liters

- Dimensions Ø 1 700 mm, height 2 000 mm

- Steam-heated cylindrical area 2.90 m2

- Steam valve ASCO jucomatik DN 15

- Steam condensate discharge DN 25

- Lighting 12V 35W

- Service manhole with a glassed door Ø 510 mm

- Sanitary rotating shower DN 25

- Steam outgoing pipe DN 100, 3x spraying device

- Insulation 50 mm plasticized cotton,

- external jacketing stainless steel 1 mm

- Top cover in stainless steel

6. Whirlpool tank

Stainless steel vessel for centrifugal separation of hop dregs from wort, with a spherical or conical upper bottom.

- Usable capacity 3 857 liters

- Dimensions Ø 1 700 mm, height 1 700 mm

- Service manhole with a glassed door Ø 510 mm

- 2x Sanitary rotating shower DN 60

- Tangential nozzle DN 40

- Filling level indicator DN 40

- Fermenting valve 1x DN 40, 1x DN 50

- Insulation 50 mm plasticized cotton,

- External jacketing stainless steel 1 mm

Piping, armatures

- Primary line DN 60, 5x flap valve DN 60

- Drain line DN 60, 3x flap valve DN 60

- Sanitary line DN 32, 4x valve DN 32

- Water supply and additional lines DN 32, 5x valve DN 32

- Beer wort filter 2xDN 32, 1xDN 40 4 000 l/h

- Mashing /fermentation pump DWO 150 Ebara

- Input power 1.400 W

- H max. 2.2 bar

- pump controlled by frequency converter Fronic 2.2 kW

Electric installation

- Main switch 3x 25A with central stop button

- Motor starter 3x 2,5-4A

- 1x Frequency converter Fronic mini 1.5 kW

- 2x Frequency converter Fronic mini 0.75 kW

- Digital temperature regulator of mash kettle Dixel XR20D

- Digital regulator of wort output temperature Dixel XR20D

- Circuit breaker 6A 230V

- Circuit breaker 10A 230V

- Circuit breaker 4A 230V

- Plastic DIN switchboard, 36 modules

- Wiring

- 5*1,5 18 m

- 5*2,5 10 m

- 3*1 48 m

Connections:

- Wort discharge pipe DN 32

- Cold water supply DN 32

- Hot water supply DN 32

- Drain line DN 60

- Electro 5*2,5 18 000 W

Auxiliaries:

- Wash basin with combined lever taps assembly

- Cooling device for samples

- Flow meter DN 32 of water supply

- Water filter

Main technical data:

- Total weight 4 600 kg

- Minimum height 3 600 mm

- Width 8 600 mm

- Depth 8 000 mm

Transport

This equipment is usually shipped in assembled state with exception for stainless steel covers, steamer for steam condensation, steps of service bridge and electric switchboard.

Warranty:

- Boiling equipment OPPIDUM 36 months

- Pump 24 months

- Electrical components 24 months

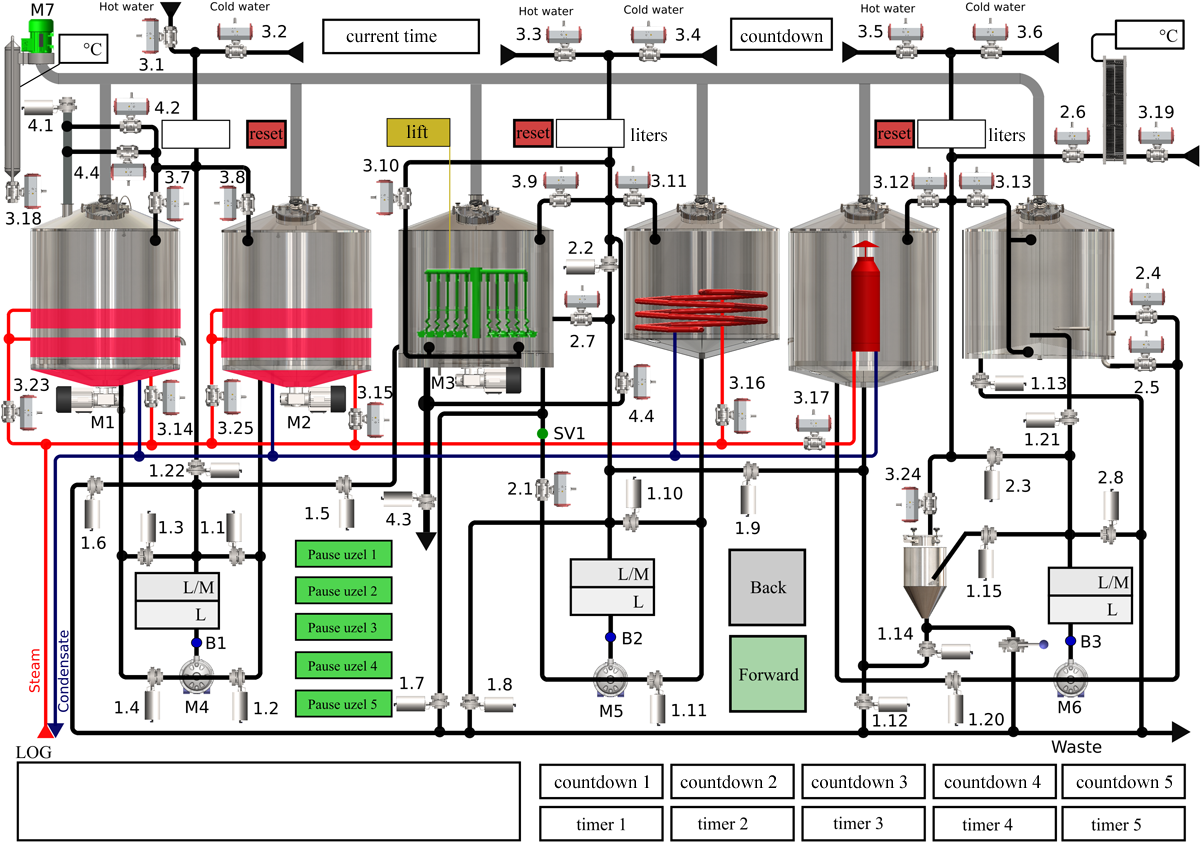

The automatic control system for the OPPIDUM – technical description

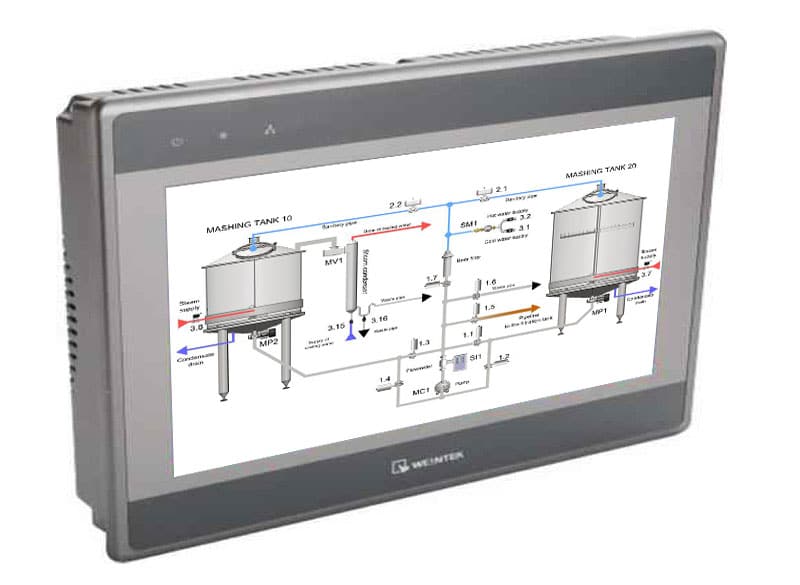

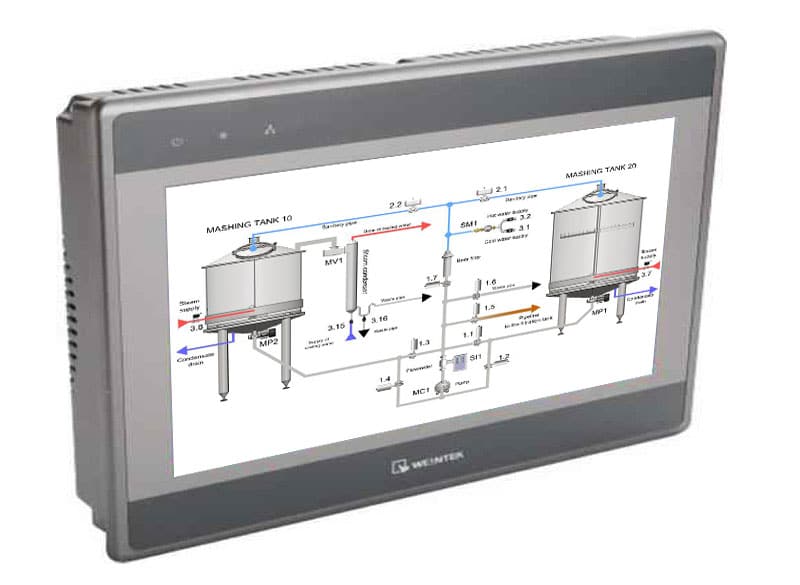

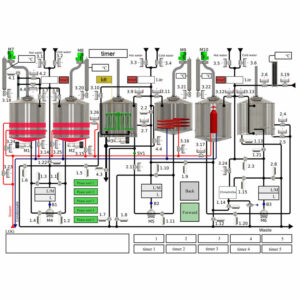

The BHAC3 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel.

The BHAC3 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel.

This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 5000 liters of wort per one batch.

BHAC3 automatic control system for the brewery includes:

- Automatically controlled hot process of brewing – fully automatized management of the entire processes of production wort

- Automatic system for time-control of temperatures in fermentation and maturation process

- Automatic system for control of media

Control panel :

How looks the automatic control panel ? This is a main menu. Choose one from several beer types or other functions, fill stackes by all required raw materials, then click and let the computer to brew your beer :

Special functions :

- CIP function – the special mode ensures cleaning, sanitization and sterilization of the brewhouse, wort pipes and optionally also other devices in the brewery

Technical specification and functions

The control unit is developed on PC platform with an operating system and control programme.

In the price of the automatization of the boiling equipment is contained a complete assembly of hardware included the pneumatic actuators and the installation elements of the boiling equipment. The automatization also contains the operation system including the licence and software for an automatic production of wort using this machine.

The software enables to change the recipes for brewing more different kinds of beer directly via the control panel or by installation via USB port. Software and boiling equipment are both designed to brew all of the world known beers in decoction way or in infusion way as well. Also at decoction way, it is possible to brew on one or two mashing cycles.

Process sequences as times, speed of pumps, timing of all phases, temperature measuring and control etc.

Individual volumes of water refilling or the overflow volumes, temperatures and flow rate of each media can operator set himself after entering the user password on the third level.

Automatic control of the wort production machine with controlling the most of steps and operations by computer – according to a specified program from a central control panel ( touch screen ) . An human operator selects a recipe and starts a program that controls all production processes. The operator checks the progress of all procedures and performs laboratory tests , solves non-standard conditions and ensure the preparation of raw materials for the wort production process .

Manual operations before start of brewing :

- Preparation of malt using a mill machine (milled malt grist)

- Mixing of malt – sprinkling malt grist into warm water (mashing proces)

Automatical operations :

- Heating of tanks and timing (precise temperature gradients and time control all phases according to selected recipe)

- Decoction or infusion brew process including control of all pumps

- Filtering of wort (Lautering wort process)

- Boiling of wort with hops + dosing of hops (automatic adding of hops into wort during boiling)

- Whirpooling (separation of wort from hops using a centrifugal rotation)

- Cooling of young beer and saturation of wort with air

- Throwing out of rests malt from the filtration tank

- Sanitisation of all pipes (CIP process)

The control programme operates in Czech, Russian and English language. We can customize the program also for other languages.

Hardware and software description

Automatized beer brewing process is custom-built to exactly match the requirements of a particular type of boiling equipment and also the user´s requirements.

Automatic includes the following items:

1st Hardware

1st Hardware

-

- Pneumatic valves and flaps including the actuators

- Flowmeter with digital output

- PLC control systém

- Touch panel for operator control

- instalation and connection of the automation components.

2nd Software

- Original operation system

- Support for setting custom lengths and work sequences

- Preprogrammed recipies for several beer types

10° light beer (Czech light lager beer)

11° dark beer (Czech black lager beer)

12° light beer (Traditional Czech lager type Pilsen)

13° weissenbeer (Beer made of wheat malt)

14° special beer (Stronger lager beer)

Hardware description :

Automatic control system

– 1pc PLC Tecomat Foxtrot CP 10006 13x AI/DI, 10x RO, 2x AO, 2x SSR, SD/MMC slot, Ethernet, WebServer

– 1pc IB 1301 12x DI 24V DC (4 x DI High Speed)

– 5pc IR 1401 12x DO 24V DC (transistor outputs 0,5A)

Display and communication system of automatization

Display and communication system of automatization

– 3 pc display operation panels Weintek CMT-IV5

- screen resolution 1024×768

- screen diagonal 9,7“ capacit TFT

- brightness 350 cd/m²

- 500:1 contratst ration

- support for multi-touch

- 1 Ghz RISC Cortex A9 processor

- 512 MB Flash, 1GB RAM

- Ethernet communication port

- 24 VDC power supply

- Degree of protection IP65

- external dimensions 257,2×199,7×32,7mm (LxWxH)

- weight 760g

- working temperature 0 ~ +50°C

– 1 pc vizualization server Weintek SMT – SVR

1 pc vizualization server Weintek SMT – SVR

- ARTEX A8 RISC processor

- 256 MB flash memory, 256 MB RAM

- inputs/outputs – USB2.0- Serial port- SD card- Ethernet

- 24 VDC power supply

- Degree of protection IP65

- External dimensions 130x115x24mm (LxWxH)

- Weight 180g

- Working temperatre -20 ~ +55°C

Pneumatic valves

– screw-thread size

- G 1/2“ (DN15)

- G3/4“ (DN20)

- G 1 1/4“ (DN32)

–  PTFE seal

PTFE seal

– working temperature -30 ~ +180°C

– min. and max. pressure 0 ~ 16 bar

– min. and max. working pressure 6 ~ 8 bar

– weight and dimensions are variable depending the type of the valve/flap

– material – body – stainless steel no. 1.4408

– pneumatic actuator – aluminum body

– 14 pcs of pneumatic valves

Pneumatic flaps

– screw-thread size 2“ – brightness flaps DN50

– sealing VMQ – Silicon

– max. working temperature 100°C

– steam sanitation max. temperature 130°C

– working pressure max. 10 bar

– valve and actuator are made of stainless steel 1.4301

– 24 pcs of pneumatic flaps

Electromagnetic valves

Water

Water

– screw-thread size – G 1/2“ (DN15)

– G 3/4“ (DN20)

– max. pressure 16 bar

– ambient temperature -20 ~ +65°C

– temperature of medium -20 ~ +120

– material: stainless steel AISI304

Steam

– screw-thread size G 1/2“ (DN15)

– max. pressure 25 bar

– ambient temperature -20 ~ +65°C

– temperature of medium +5 ~ +185°C

– material: stainless steel AISI304

In Oppidum brewhouses are 16 pcs of water and steam electro-magnetic valves

Electrical installation is carried out according to standard ČSN EN 60204-1, the degree of protection IP 65

Software and description of available program modes

Available operations

– The PLC programe is devided into processes

– The measuring processes are: – temperature measurement – impuls counting of data from the flowmeters ( induction , impulse)

– Another process is responsible on the basis of data received from the operator panel to run different processes according to the selected recipe

– Infusion

– Method of one boiling cycle of malt mash per batch

– Method of two boiling cycles of malt mash per batch

– Other possible processes and brewing methods

– Back-flush of pipes,, pumps and tanks

– Sanitation of all important parts of the machine

Access modes

– For vizualization is used the operator panel with touch panel

– User is able to work in four available modes with different access rights.

User mode

– Allowed only monitor the progress of the brewing process

Extend user mode

– User mode + the possibility of switching valves, motors, pumps and pausing the automatic process

Admin mode

– Extending user rights + the possibility of starting the automatic brewing and changing the procedures parametres

Programming mode

– Full setting of all programm parameters and constants

Manual control mode

– The operator panel is used for remote control of valves, dampers, mixers and pumps

Automatic control mode

– Possibility of setting up the parametres of individuals recipes and starting the automatic process

– Operator panel displays the name of the beer, the type of cooking, monitoring of the actual step either with countdown timer, or with deduction liters or with reached temperature

– On the panel the current statuses of all important elements in each step are visualized – valves, motors, pumps, sensors

– Process is possible to suspend or interrupt everytime by human operator

Extending of possibilities

– Customization of all hardware and software equipment according to individual costumer requests and the available technology

Optional accessories and upgrades

| Recommended options and additional equipment for improvement of the wort brew machine Breworx Oppidum 3000 | Prices (EUR) |

|---|---|

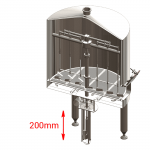

| ELS : Electric lift of the knife-stirrer in the filtering tank (lifting up to 200mm) | ELS : Electric lift of the knife-stirrer in the filtering tank (lifting up to 200mm)

This customization of the wort brew machine allows you very variable setting position of the knife-stirrer inside the filtering tank. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. The lifting of the knife-stirrer ensures you to speed up the process of souring wort. This is important to avoid excessive oxidation of the wort during the filtering process. |

11688 |

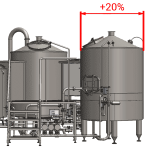

| EFT : Enlarged filtering tanks to production of stronger beer types with EPM (plato) higher than 15° | EFT : Enlarged filtering tanks to production of stronger beer types with EPM (plato) higher than 15°

The special customization – the filtration tank with diameter by 20% larger than standard version of the (wort filtration tank). This customization of the wort brew machine allows production of beer types with EPM (Plato) from 12 to 17 (Our brew machines with the standard filtering tank are optimalized for production beer types with EPM (Plato) from 10 to 15). According to customer´s requirements we can produce the wort brew machines with more larger diameters as well (the price will be calculated individually). |

5313 |

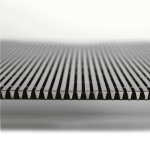

| WSF : Wire sieve to acceleration process filtering of wort | WSF : Wire sieve to acceleration process filtering of wort

Special wire sieve to filtering wort during the wort brew process has by 30% bigger filtering area in comparation with the classic filtering sieves where the holes are cut using a profiled knife. The main benefit is faster filtering of wort through the malt sediment layer. This is useful during filtration of wort through the malt grain sediment when some stronger beer types are produced. It is important to avoid excessive oxidation of the wort during the filtering process. |

2508 |

| Fully-welded outer stainless steel jacket without rivets and with glossy outer surface | 25000 |

| PID control of the hot steam heating of the kettle + three-phase steam heating (for accelerating of the wort brew cycle) | 3770 |

- Automatic control system for media and fermentation & maturation process – this system allows you the automatic monitoring and controlling the most important parts of beer fermentation and maturation process (from 1 to 30 tanks max) and operations with all media in the brewery.

- STG – Steam generator – necessary only for version with the steam heating system

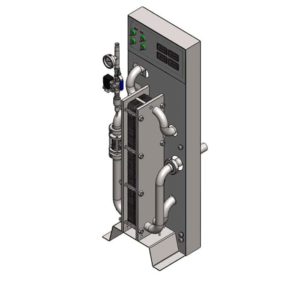

- WCS – Wort cooling system – equipment for controlled hot wort cooling to the fermentation temperature (7°C or 25°C depending on the type of beer)

- MMG – Mill of malt grains – equipment for grinding of malt – necessary only for production of wort from malt (not necessary for production of wort from malt extract)

- LEA – Laboratory equipment and accessories – saccharimeters, alcoholmeters, graduated cylinder, wooden rod for manual level measurement

- HWT – Heat water tank – An insulated stainless steel tank with electrical and steam hesters for heating water and storage of heated water which is heated during the wort cooling process. This hot water is needed for some operations in the brewery like production of wort, cleaning of brewing tanks and fermentation tanks etc..

- ITWT – Tank for cold treated water – Insulated stainless steel tank for cooling, storaging and pumping of ice water which is necessary in wort cooling process. This treated drinking ice water is heated in wort cooling process and becomes then hot water storaged in HWT. If is not available drinking water with requested chemical composition, it is needed to use some equipment for water treatment – WTS. Available for breweries with one-level wort cooling system – we recomment it for brewhouses with production capacity above 1000 liters of wort per one brew, instead ICWT tank.

- ICWT – Tank for cooling ice water – insulated vessel for cooling, storaging and pumping of ice water which is necessary in cooling of wort, and for cooling all beer production tanks and fermenters. This treated drinking water works as a cooling media during the cooling process of wort and then is comming back to the storage tank where is cooled down again to next use. Available for breweries with two-level wort cooling system – we recommend it for breweries with production capacity maximally 1000 liters of wort per one brew instead the ITWT tank.

- WTS – Water treatment systems – an equipment for treating of cold water, if water does not suit requested chemical composition for production of choosed type of beer. It is always needed a chemical analysis for assessment of suitable water chemical composition before delivery of a brewery..

Optional services

BTS – Brewer´s teaching services – We recommend use this service before start operation of any new brewery equipped with an original Czech brewing technology. All courses are teached by certified Czech specialist for production of beer. The course takes place in Czechia or in the country of the customer, according to customer´s requirement.

Reviews

There are no reviews yet.