Description

CIP-1004SQ : Cleaning-In-Place – / The static CIP machine for the cleaning and sanitizing of vessels and piping routes in breweries and other food production plants with four tanks 1000 liters

version of the standard quality

The CIP-1004SQ (version of the standard quality) is used for sanitation and sterilization of vessels and piping routes. This is a fully equipped system for breweries and other food production plants : Cleaning-In-Place. The CIP equipment provides heating and circulation of water, alkaline and acid solutions through sanitary shower that sprays sanitary chemical solutions on the wall of a vessel. The device consists of four separate containers with nominal volume of 1000 liters and one neutralization vessel (300 l), one or two centrifugal pumps, manual and automatic valves and all installation pipes as well. The steam version of the CIP station includes also a pipe heat exchanger (the heating by hot steam using an external hot steam generator) with a digital temperature control in range of 0-80 °C. This type of the CIP station is recommended for cleaning and sanitation of tanks with a volume more than 12000 liters.

Main benefit of the four-vessel CIP system is two separated tanks for alkaline solution – first tank to alkaline cleaning-sanitation of the brewhouse, second tank to alkaline cleaning-sanitation of other brewery equipment (tanks, filter, pipes …).

The equipment CIP-1004SQ is installed in a rigid frame provided by lockable wheels. Used material is stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316) according of selected variant. Containers (vessels) are not insulated.

Two variants of the CIP unit :

- SH : CIP unit without the steam generator – The heating has to be ensured using an external hot steam generator that is not included in the price.

- EH : CIP unit with the steam generator – The heating is ensured using an external hot steam generator that is included in the price.

Functions of the tanks (5):

- First alkaline vessel: alkaline cleaning-sanitation of the brewhouse

- Second alkaline vessel: alkaline cleaning-sanitation of other brewery equipment (tanks, filter, pipes …)

- Acid vessel: acid cleaning and sanitation of all brewery equipment

- Water tank: collecting and heating of water

- Neutralizing vessel: neutralization of acid and alkaline solutions before they pour into the drain

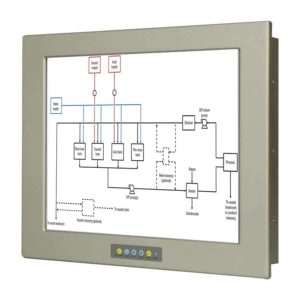

Technological scheme of the CIP station connected with an external tank to be cleaned and sanitized

Automatic version :

Technical parameters :

- The equipment CIP-1004SQ is installed in a rigid frame provided by stable legs.

- Used material is stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316) according of selected variant. Containers (vessels) are not insulated.

- containers (vessels) are not equipped with insulation.

- Surface of the tanks is matt.

- Manual control system.

- Pump SXH for high-temperature

- Basic filter

- Basic frame with steps

- Pipe system

- Steam-ready heating system – a hot steam generator is not included

Description of the cleaning-sanitizing cycle

The cleaning-sanitizing cycle usually consists of these steps :

- Pre-rinsing – rinsing of the production equipment using cold or hot water.

- Cleaning – cleaning of the production equipment using circulated hot water.

- Rinsing – thorough rinsing of the production equipment using cold or hot water.

- Chemical disinfection (sanitation) – washing of technology using alkaline and then acid sanitizing solution at the desired concentration.

- Rinsing – thorough rinsing of the production equipment using cold or hot water.

- Neutralization – is performed after the finish of several cleaning and sanitizing cycles – mixing alkaline and then acidic sanitizing solution to achieve neutral pH of the solution and their discharge to the channel.

More informations : All about the process Cleaning-In-Place

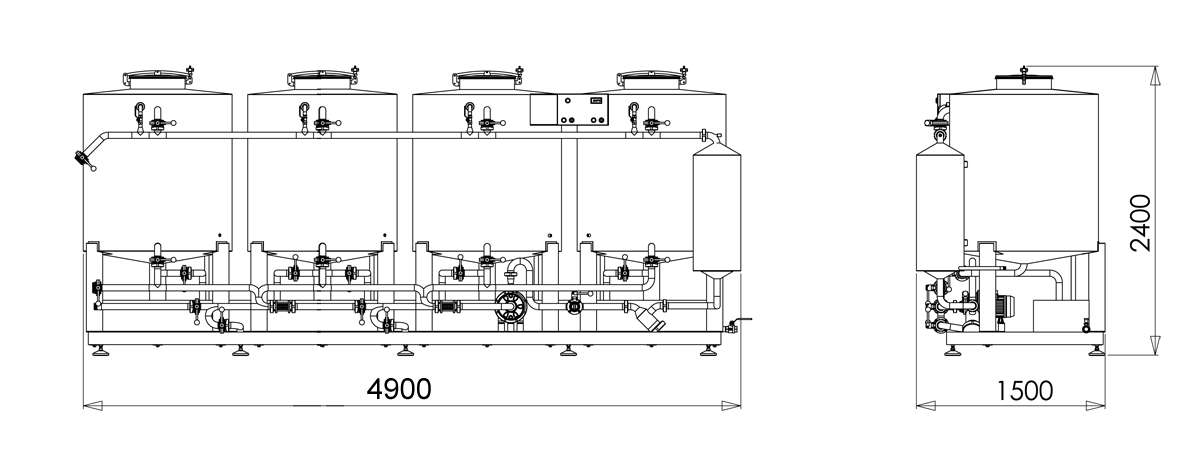

Dimensions :

Parameters

Parameters

- Width … 4 900 mm

- Height … 2 400 mm

- Depth … 1 500 mm

- Weight netto … 950 kg

- 1st container with NaOH … 1200 lt (only for cleaning of the brewhouse)

- 2nd container with NaOH … 1200 lt (for cleaning of all other brewery equipment)

- Container with H2SO4 … 1200 lt (for cleaning of all brewery equipment)

- Container with water … 1200 lt

- Neutralization vessel … 300 lt

- Pipe heat exchanger … 1.8 m3

- Distribution piping … DN 40

- Water armatures (outputs / inputs) DN 40 … 1.4301

- Steam armatures (steam input / condensate output) DN 15/ DN20 … 1.4301 (only steam version)

- Pump, type Ebara CDX 200/25 1.8 kW, 3ph 400V/50Hz

- Electric switchboard

- Main electrical connection 3*400V/50Hz 32A

- Circuit breaker 230V 32A

- Digital regulator Dixel XR 20 D

- Contactor of heating 400V 32A

- Motor starter 400V

- Probe NTC 6 mm

- Cable 5x 2.5 6m

- Inlet (suction part) G DN 32

- Outlet (delivery part) G DN 25

- Steam-ready heating system – a hot steam generator is not included

Warranty

- Equipment CIP 504 36 months

- Electric installation 24 months

- Pump 24 months

Material

- Version CIP-1004SQ-304 : Pump inner parts and heating chambers are made from stainless steel AISI 316. Pipes, fittings, frame and tanks are made from stainless steel AISI 304.

- Version CIP-1004SQ-316 : All parts are made from stainless steel AISI 316.

- Steam-ready heating system – a hot steam generator is not included

Warranty

- Equipment CIP 504 36 months

- Electric installation 24 months

- Pump 24 months

Material

- Version CIP-1004-304 : Pump inner parts and heating chambers are made from stainless steel AISI 316. Pipes, fittings, frame and tanks are made from stainless steel AISI 304.

- Version CIP-1004-316 : All parts are made from stainless steel AISI 316.

Optional equipment :

I. Basic frame – delivery of a fully assembled CIP station mounted on the frame

-

Material AISI 304 … € 4724,-

-

Material AISI 316 … € 6220,-

A delivery of the fully assembled CIP station which is mounted on the stainless steel frame is a good solution for remote customers who are able to transport the assembled CIP from a truck to a final place using their own lift and transport machines. Main benefit is a very quick start up of the CIP station without any assembly work and costs for our assembly specialists. We recommend to our customer make sure in time that the machine is to be transportable to its place – before the order.

II. Secondary pump 900W with the speed control (pump No. 2) … € 2769,-

The secondary pump is necessary in the systems with big tanks and long pipes to be sanitized with the CIP station. Contact us for decision if the secondary pump is needed for your system. The function of the secondary pump is the suction of used solutions back from the sanitized system into the CIP station for next use.

III. PHCS-1000 : Pipe-Hose cleaning set

Special enhanced equipment for the cleaning and sanitizing the pipes and hoses.

-

PHCS-1000-304 Material AISI 304 … € 1597,-

-

PHCS-1000-316 Material AISI 316 … € 2076,-

IV. Flow speed regulation :

- Frequency controller for the pump speed regulation (without measure of the flow speed) … 788 Eur

- Frequency controller for the pump speed regulation with measure of the flow speed – setting of desired stabil flow speed is possible … 2100 Eur

V. Measurement of quality the chemical solutions

- Conductivity meter : Mettler Toledo EasySense77 conductivity sensor (0.2 – 400mS/cm) with the Transmitter M200 numeric display unit … 3938 Eur

VI. The automatic control system for CIP-1004

CIP-A1004 is an automatic control system for the Cleaning In Place system CIP-1004. The automatization includes all functions necessary to perfect cleaning and sanitation of all containers and optionally also pipes and hoses in a brewery using a special program, sensors, pneumatic valves and industrial computer with the touch display. This control system is compatible with the CIP-1004 machine.

CIP-1004SA with the automatic control system and the steam heating system – visualization :

VII. The hot steam generator (only for the steam version of the CIP)

If no other steam generator is available in the brewery then we recomment these models of the hot steam generators to use with the CIP station :

VII. a) ESG-45 Electric automatic hot steam-generator … only the generator without accessories

Electric and automatic steam-generator, available power from 15 kW to 30 kW (from 17 to 45 kg of hot steam per hour). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 6 bar. This steam-generator is equipped with two independent sets of stainless steel heaters 2×15 kW. The steam-generator shell is manufactured in accordance to the current PED regulations.

VII. b) ESG-45MWT Electric automatic hot steam-generator compact … the generator with all accessories

The compact and automatic electric hot steam-generator ESG-45MWT with power from 15 kW to 30 kW (from 17 to 45 kg of hot steam per hour), steam pressure from 1 to 6 bar. The Modulo ESG system includes water treatment set, electric switchboard cabinet and all pipe&electric connections

This steam-generator is equipped with two independent sets of stainless steel heaters 2×15 kW. The steam-generator shell is manufactured in accordance to the current PED regulations.

The water treatment system (for automatic water softening) and electric switchboard cabinet is included in this set. All system is mounted on the stainless steam frame. Easy installation – without electrician works – it is needed only to plug on the electric power socket on the wall.

Why to use the CIP for cleaning and sanitation of the brewery equipment ?

Advantages of our CIP stations compared to the simple cleaning and sanitatizing technology with a pump:

- Less preparatory work: Sanitizing solutions are always prepared in the CIP containers and they are available in the desired dilution for several cleaning and sanitizing cycles. Their preparation before each cleaning and sanitizing cycle is not needed.

- Increasing work safety: Limiting the frequency of manipulation with sanitizing solutions reduces the likelihood of burns the operator when handling concentrated acids and alkalis.

- Saving of time and energy: Continuous heating of cleaning and sanitizing solution during the cleaning and sanitizing cycles and keeping them at a prescribed temperature increase considerably the efficiency of cleaning and sanitation, resulting in time saving operation of the equipment and saving of electricity consumption. All cleaning process, pump operations, heating of sanitizing solutions and water, they all take significantly less time, require less human work and electric energy.

- High efficiency of cleaning and sanitation: Compared with the cleaning and sanitizing of the food processing equipment by simple circulation pump there is still the same temperature of the sanitizing solutions during all time of the CIP cycle, if our CIP unit is used for this operation. Cleaning and sanitation with hot water and disinfectant solutions is definitely more effective than the same procedure with cold solutions, and therefore containers and equipment are perfectly clean after disinfection and washing cycles and are also free of organic and other impurities, which is desirable not only in the brewing industry but also in any other beverage or food production process. This is a prerequisite for compliance with legal hygiene requirements.

- Simple and efficient neutralization of acid and alkaline solutions after use: Neutralizing vessel (part of the CIP station) allows easy, safely and completely neutralize the used acid and alkaline sanitizing solution before pouring into the channel. It fully meets the requirements of laws to protect the environment and prevents damage to sewerage systems and other building components. Furthermore, this increases the safety when handling used washing and sanitization solution.

VIII. Installation work on the place

-

– manual version …….. € 5500,-

-

– automatic version …. € 6600,-

The price is valid for all countries of the European Union. The price includes two day work of two our specialists in the place – assembling and commissioning of the CIP machine including tests with water.

All connections between the CIP station, the steam generator, the secondary pump and the devices to be cleaned will be realized with hoses. If the customer requires connections made of stainless steel pipes then price of the installation work and material will be calculated individually. Price of installation work will be at least two times higher because preparation the stainless steel pipes and welding work takes much time in comparation with the hose connections.

A customer must prepare the unloading the CIP station from a truck, transport of the CIP machine, the secondary pump and the steam generator (if is ordered) to its final place. A customer prepares the installation place and all connection points maximally 2 meters from the CIP machine, the secondary pump and the steam generator. A customer ensures all electric connections of the CIP station, the secondary pump and the steam generator in accordance with local standards and send scans of electric revision documents made by a certified person for the electric installations and revisions, before arriving of our technicians.

If a gas steam generator is included in the order the customer ensures its complete installation in accordance with local standards by a certified company and all necessary revision documents made by certified company before arriving of our technicians.

The price does not include : travelling, accomodation of the workers. These items will be calculated individualy.

The installation works are not necessary if the CIP station will be mounted and transported fully assembled on the basic steel frame.

This offer includes :

- CIP station CIP-1004 …. all hardware

- Electric steam generator ESG-45MWT with power from 15 kW to 30 kW (from 17 to 45 kg of hot steam per hour), steam pressure from 1 to 6 bar (only EH version)

- Water treatment system – softening of the water for use with the steam generator (only EH version)

- Assembling the CIP in the production factory in Czech Republic

- Assembly instruction manual in Czech, English or Russian version and photos

- Operation manual in Czech, English or Russian version

- Basic function tests of the CIP station in the production factory

- Instructing of the customer to use and control the station. This work is included only if the customer is present in the production factory prior to expedition the device.

- Disassembling the CIP station and packing before the expedition

This offer does not include :

- Optional equipment …. Secondary pump, Automatic control system, Other non-standard equipment for customer´s requirements

- Palletes and other packing material

- Transport costs of the equipment

- Installation work on the place

- Instructing of the customer to use and control the station on the installtion place.