Description

CCT-4000C Cylindrical-conical tank Classic 4000/4386 L (insulated, cooled with liquid)

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 4000 liters and total volume 4386 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European Standards EN 13445 and PED 2014/68/EU (Pressure Equipment Directive).

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 4000 liters and total volume 4386 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European Standards EN 13445 and PED 2014/68/EU (Pressure Equipment Directive).

The PED certificate (and all documents related with the pressure equipment in accordance with PED 2014/68/EU standard) is not included in price of the tank and for use the tank in European countries it is necessary to add the item “PED 2014/68/EU certificate” . All parts are made in European Union.

Equipment of the Cylindrical-conical tank Classic 4000/4386 liters

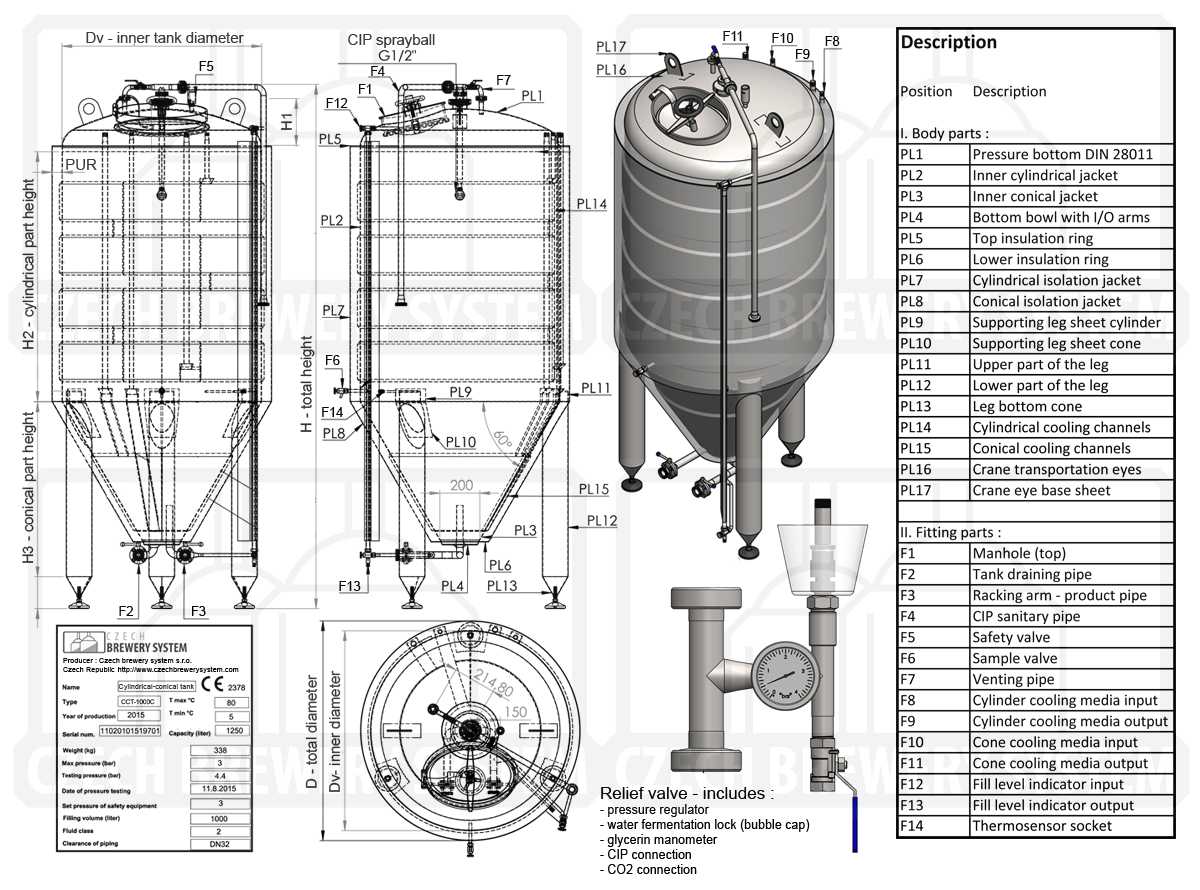

Assembly drawing of the cylindroconical tank CCT-4000C (model 2015 / SQ / standard dimensions) :

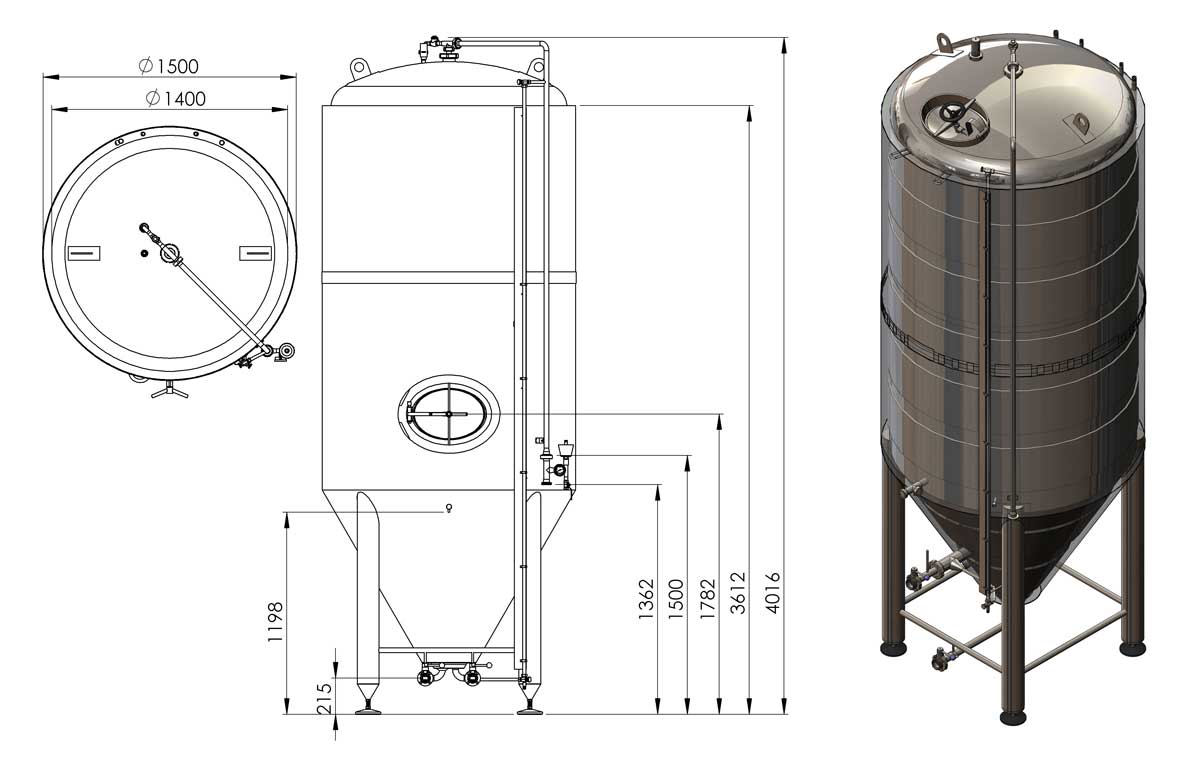

CCT-4000C : Technical parameters

Technical parameters of the CCT-4000C : The universal cone fermenter, the cylindrically-conical pressure tank for both fermentation and maturation of beer or cider, usable volume 4000 liters, with PUR insulation, cooled by water/glycol.Cylindrically-conical tank CCT-4000C / classic fermentor | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

|---|---|---|---|---|---|---|

Parameters (standard dimensions) | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

| Vu Usable volume [liters] | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 |

| Vt Total volume [liters] | 4386 | 4386 | 4386 | 4386 | 4386 | 4386 |

| V1 Upper arched bottom - volume [liters] | 301 | 301 | 301 | 301 | 301 | 301 |

| V2 Cylindrical part - volume [liters] | 3463 | 3463 | 3463 | 3463 | 3463 | 3463 |

| V3 Conical part - volume [liters] | 622 | 622 | 622 | 622 | 622 | 622 |

| D Total tank diameter [mm] | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Dv Inner tank diameter [mm] | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 |

| H Total height [mm] | 4016 | 4016 | 4016 | 4016 | 4016 | 4016 |

| H1 Upper arched bottom - height [mm] | 334 | 334 | 334 | 334 | 334 | 334 |

| H2 Cylindrical part - height [mm] | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 |

| H3 Conical part - height [mm] | 1212 | 1212 | 1212 | 1212 | 1212 | 1212 |

| Mn Weight netto [kg] | 910 | 910 | 910 | 1092 | 1092 | 1092 |

| Mb Weight brutto [kg] | 4900 | 4900 | 4900 | 5080 | 5080 | 5080 |

Equipment standard | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

| Pressure range (allowed by PED) | 0.0 - 0.5 bar | 0.0 - 1.5 bar | 0.0 - 3.0 bar | 0.0 - 0.5 bar | 0.0 - 1.5 bar | 0.0 - 3.0 bar |

| Testing pressure range (in production) | 0.0 - 0.7 bar | 0.0 - 2.1 bar | 0.0 - 4.2 bar | 0.0 - 0.7 bar | 0.0 - 2.1 bar | 0.0 - 4.2 bar |

| PED 2014/68/EU certificate | no | yes | yes | no | yes | yes |

| Material | AISI 304 | AISI 304 | AISI 304 | AISI 304 | AISI 304 | AISI 304 |

| Inner surface - cylindric part | 2B / Ra≤0.8µm grinded | 2B / Ra≤0.8µm grinded | 2B / Ra≤0.8µm grinded | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished |

| Inner surface - conical part | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished |

| Outer surface | 2B grinded | 2B grinded | 2B grinded | 2B grinded | 2B grinded | 2B grinded |

| External sheets - joints | riveted / welded | riveted / welded | riveted / welded | all welded | all welded | all welded |

| Peak angle of the cone | 60° | 60° | 60° | 60° | 60° | 60° |

| PUR insulation | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| CT / CJ1 Cooling jacket on the cylinder : input/output G-thread | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" |

| CT / CJ1 Cooling jacket on the cone : input/output G-thread | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" |

| Transport hinges | N/A | N/A | N/A | N/A | N/A | N/A |

| Manhole with door / at the top | 420x340mm / opening inward | PED 420x340mm / opening inward | PED 420x340mm / opening inward | 412x315mm / opening outward | PED 412x315mm / opening outward | PED 412x315mm / opening outward |

| Manhole with door / at the side | optional / 440x310mm / opening inward | optional / PED 440x310mm / opening inward | optional / PED 440x310mm / opening inward | optional / 440x310mm / opening inward | optional / PED 440x310mm / opening inward | optional / PED 440x310mm / opening inward |

| Ovepressure/vacuum safety valve | Max 0.5 / 0.2 bar | Max 3.2 / 0.2 bar | Max 3.2 / 0.2 bar | Max 0.5 / 0.2 bar | Max 3.2 / 0.2 bar | Max 3.2 / 0.2 bar |

| Pure-beverage output armature | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Tank filling/emptying armature | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Sampling valve | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit |

| CIP and manometer connection fittings | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC |

| Venting valve | yes | yes | yes | yes | yes | yes |

| Sanitizing ball-shower | static | static | static | rotational | rotational | rotational |

| Fermentation apparatus with the pressure adjusting valve and air lock, sanitizable | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Manometer with glycerine | yes | yes | yes | yes | yes | yes |

| Filling level indicator | yes | yes | yes | yes | yes | yes |

| Thermosensor socket | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 |

| Ladder hinges | 2 pcs | 2 pcs | 2 pcs | 2 pcs | 2 pcs | 2 pcs |

| Adjustable feet with rubber | 4 pcs | 4 pcs | 4 pcs | 4 pcs | 4 pcs | 4 pcs |

| Type label with the tank parameters | yes | yes | yes | yes | yes | yes |

| Minimum operating temperature | -15 °C | -15 °C | -15 °C | -15 °C | -15 °C | -15 °C |

| Maximum operating temperature | +80 °C | +80 °C | +80 °C | +80 °C | +80 °C | +80 °C |

| Guaranteed number of pressure cycles (for max. pressure) | 500 | 500 | 500 | 500 | 500 | 500 |

| Standard warranty | 2 years | 2 years | 2 years | 3 years | 3 years | 3 years |

Equipment optional - surcharges | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

| Manhole with door / at the top / opening inwards | in price | in price | in price | € 569 | € 569 | € 569 |

| Manhole with door / at the top / opening outwards | € 623 | € 623 | € 623 | in price | in price | in price |

| Manhole with door / at the top / with the sight glass / opening outwards | € 1326 | € 1326 | € 1326 | € 1326 | € 1326 | € 1326 |

| Manhole with door / at the side / opening inwards | € 569 | € 569 | € 569 | € 569 | € 569 | € 569 |

| Side universal connector for hops extractor, usable also for the carbonization, filtration, flotation etc. | € 124 | € 124 | € 124 | € 124 | € 124 | € 124 |

| Upper special armature for the hops extractor, | € 247 | € 247 | € 247 | € 247 | € 247 | € 247 |

| Carbonization stone | € 462 | € 462 | € 462 | € 462 | € 462 | € 462 |

| Sanitizing ball-shower - rotational | € 119 | € 119 | € 119 | in price | in price | in price |

| Adjustable pure-beverage output armature without the sight glass | N/A | N/A | N/A | N/A | N/A | N/A |

| Sight glass on the adjustable pure-beverage output armature | N/A | N/A | N/A | N/A | N/A | N/A |

| Scale on the pressure adjusting valve (bar) | € 49 | € 49 | € 49 | € 49 | € 49 | € 49 |

| Scale on the fill level indicator (mm) | € 247 | € 247 | € 247 | € 247 | € 247 | € 247 |

| Temperature measuring and control system | see a pricelist | see a pricelist | see a pricelist | see a pricelist | see a pricelist | see a pricelist |

| Foam compensator for the sampling valve | € 110 | € 110 | € 110 | € 110 | € 110 | € 110 |

| Ladder | € 600 | € 600 | € 600 | € 600 | € 600 | € 600 |

| Stirrer + electric equipment (maximal density 1200kg/m3) | € 8585 | € 8585 | € 8585 | € 8585 | € 8585 | € 8585 |

| Speed regulation for the stirrer (frequency converter) | € 901 | € 901 | € 901 | € 901 | € 901 | € 901 |

| Stirrer shaft seal 3bar | € 773 | € 773 | € 773 | € 773 | ||

| Non-standard dimensions of the tank | 10% and more | 10% and more | 10% and more | 10% and more | 10% and more | 10% and more |

| Customized equipment of no-PED tank (work on drawings) | € 237 | € 237 | € 237 | € 237 | € 237 | € 237 |

| Customized equipment of PED tank (work on drawings) | € 237 | € 237 | € 237 | € 237 | € 237 | € 237 |

| Transport pallet (Europe) | € 57 | € 57 | € 57 | € 57 | € 57 | € 57 |

| Transport pallet (Over sea) | € 257 | € 257 | € 257 | € 257 | € 257 | € 257 |

Legend :

N/A = Not available

DC = Dairy Coupling DIN 11851, TC = TriClamp DIN 32676 (type of the coupling depends on requirement of a customer)

PED = Certification for pressure vessels required in all EU countries – the EU Directive PED 2014/68/EU Pressure Equipment

The manufacturer reserves the right to change the parameters according to the current availability of materials and fittings. A customer will always receive our production drawing for approval before manufacturing the ordered tank.

Standard equipment – description

- Adjustable pressure valve for controlled fermentation – Overpressure setting mechanism with a glycerine manometer (standard range of adjustable pressure inside the tank : from 0 bar up to 3 bar ) – it allows two processes in the same tank : primary fermentation + secondary fermentation (maturation)

- Cooling channels – duplicators for circulating of coolant in the cooling jacket (one, two or more according type of the tank)

- PUR insulation – polyurethane insulation with thickness according to the size of the tank and the target environment (standard = 50mm )

- Outer jacket of the tank of stainless steel – Kind of the surface finishing (standard = grinded) choosed by customer.

- Guaranteed inner surface roughness : Ra < 0.8 μm or less (grinded surfaces) / Ra < 0.5 μm or less (polished surfaces)

- Service door (manhole) on the top cone or on cylinder part, according to customer requirements (SQ = open inside / HQ = open outside)

- Pure-beverage output armature with a butterfly valve for pure beverage (beer, wine, cider) output – the racking arm (optionally with variable height of a suction)

- Bottom filling/emptying armature – The inlet / outlet pipe with a butterfly valve for filling tank, discharging of yeast and draining of full content of the tank

- Sanitizing ball-shower – CIP sanitizing ball-shower (SQ = statical / HQ = rotational) – one or more pcs

- Sanitation pipe – – A multifunction pipe with a ball valve for connection of a shower head to the cleaning-sanitizing CIP station , the adjustable pressure valve with manometer, CO2 inlet

- Sample valve – cleanable and sanitizable sampling cock for collection product samples

- Safety valve – double-acting overpressure (standard = 3.2 bar) and vaccum protection (0.2 bar) safety valve – only pressure version of the tank

- Venting valve – Dedicated venting valve for safety draining of the tank and for accurate measuring of current pressure in the tank using manometer (it ensures properly function of the manometer when the shower ball shower is blocked with a foam)

- Thermometer socket – welded socket for inserting of thermosensor or thermometer (one or more according type of the tank)

- Manometer – It is included in the set of the adjustable pressure valve. Made of stainless steel, with glycerine inside.

- Filling level indicator – Sanitizable glass or plastic pipe for visualisation height level of the beverage product in the tank (SQ = fixed / HQ = removable)

- Transport hinges – steel welded hinges for safety transport of the tank with crane or forklift

- Adjustable feet – 3 or Four legs with rubber feet for accurate horizontal adjusting of the tank on an uneven floor

- Type label – the steel label with all parameters that are required from European Union for pressure vessels

- PED 2014/68/EU – certificate – the European certificate for the overpressure vessel + document for archiving history of the pressure vessel

Optional equipment – description

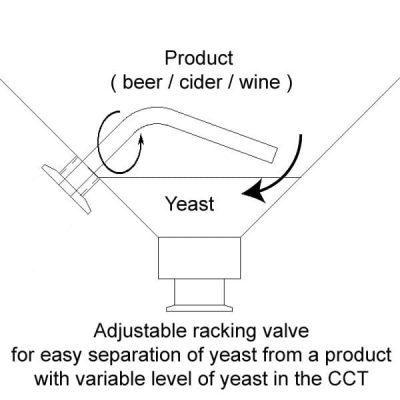

- Variable outlet-pipe for pure beverage (adjustable racking arm) – instead the fix clear product pipe – a rotatable pipe with a butterfly valve and sight glass to accurate adjusting high of the suction inlet according to current level of yeast in the tank

- Special doors – manholes – secondary site manhole, manhole with sightglass, manhole with glass door

- Special cleaning-sanitizing ball-showers – rotational, pulse or other special cleaning equipment for extreme effective cleaning of the tank

- Side or upper universal armature – Universal multi-use armature for connection of the flotation equipment, carbonization stone or the hop extractor for dry hopping.

- Scale for the filling level indicator – a liter scale on a cover of the filling level indicator for visualization of the current product volume in the tank

- Scale for the adjustable pressure valve – a bar scale on a adjustable pressure valve screw for indication of just required pressure in the tank (a manometer shows the current pressure)

- Temperature measurement and regulation components – we deliver several types of thermosensors, thermometers and also fully equipped temperature control systems for our tanks

- Thermometer, thermocouples, thermoregulators – more types for installation directly on the tank or on a wall

- Automatic thermo regulation valves for regulation the coolant flow in the cooling channels

- On-tanks termo-controllers – measurement and regulation of temperature on dedicated temperature controller placed directly on each tank

- On-the-wall control box – measurement and regulation of temperature in more tanks from one control box

- Automatic tank temperature measurement and control system – for an automatic control of full fermentation and maturation processes

- Carbonization stone – the special porous stone for carbonization of beverages from CO2 bottles

- Ladder – for easy operating with manholes and other upper accessories of tanks

- Tank product filling hub – a special tool to easy filling of product (like beer wort , cider must) to the fermentation tank

- Stirring equipment – to stirring contents of the tank, It is mounted on the side of the tank shell

- Other customizations of the tank – according on customer´s requirements – non-standard dimensions, special armatures, special surface and design of the tank etc.

Customizations

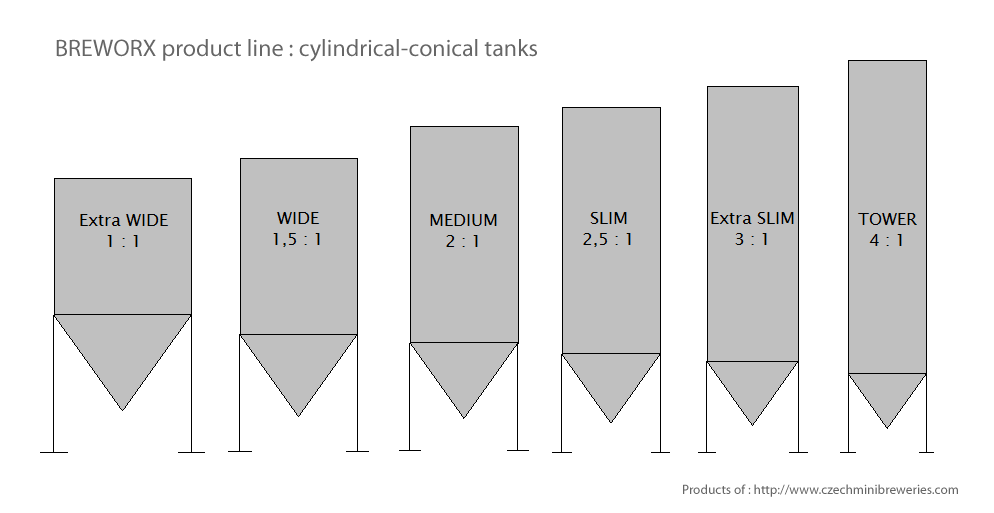

I. Dimensional variability of the CCT 4000 liters :

We can produce CCT fermentation tanks with volume 4000 liters in six dimensional variations, according to a ratio between the height and diameter of the tank. It is advantage for customers, because the customization of tank dimensions is often necessary due limited space dispositions od the building.

In this eshop we descript only the most offered standard size variation of the CCT 4000 liters . If you want another variation, send us your request and we will send you an individual quote for the tank.

Variations of the CCT 4000 according to the overpressure limit :

In addition, the customer can choose between the pressure and non-pressure vessels. According to the maximum allowable overpressure in the vessel we produce CCT fermentation tanks in two designs:

- Non-pressure fermentation tank CCT-4000 – The maximum available overpressure is 0.5 bar – it is designed as 3.0 bar tank, tested for pressure up to 4.0 bar, but it is not declared as pressure tank according to EU Directive PED . Suitable for non-pressure fermentation of beer or cider, or also as pressure vessel in some countries out of European Union.

- Over-pressure fermentation tank CCT-4000 – The maximum available overpressure is 3.0 bar (optionally, according to specific customer requirements up to 5.0 bar), includes the certificate for pressure vessels according to EU Directive PED. The vessel can be used not only for the fermentation and maturation of beer, but also as pressure tank for isobarical filling of beverage into kegs or bottles, for filtration and isobaric serving of beer or cider into glasses.

Variations of the CCT 4000 according to their quality and equipment :

According to quality requirements and financial possibilities of customers we recognize the fermentation tanks with four classes of quality and equipment:

- TQ- TOP Quality – The highest quality we offer. The inner surface has a guaranteed roughness Ra<0.5 μm – glossy design. The outer surface is fully polished-unified. All functional armatures and fittings that have an impact on the reliability and safety of the products are made in Europe or in the USA. The best separation of the used yeast from the beer or cider, especially at single-phase fermentation of beer or cider when the both fermentation and maturation process are provided in the same tank. Luxury equipment of the tanks. The main advantage is very luxury design of the tank.Three years warranty for stainless steel main parts and also for the fittings. Price will be calculated individually for each tank.

- HQ – HIGH Quality – High quality workmanship of all parts, welded joints and surfaces. The inner surface has a guaranteed roughness Ra<0.5 μm – glossy design. The outer surface is grinded-unified. All functional armatures and fittings that have an impact on the reliability and safety of the products are made in Europe or in the USA. A perfect separation of the used yeast from the beer or cider, especially at single-phase fermentation of beer or cider when the both fermentation and maturation process are provided in the same tank. Luxury equipment of the tanks. The main advantages are the savings of sanitizing solutions, water and energy, minimized losses of beverages, shorter work time, reduction of production costs. Three years warranty for stainless steel main parts and also for the fittings. The quality class for the most demanding customers.

- SQ – STANDARD Quality – Standard quality workmanship of all parts, welded joints and surfaces. All functional armatures and fittings that have an impact on the reliability and safety of the products are purchased from approved suppliers from Europe or USA. Inspection of all critical welds and joints. The inner surface has a guaranteed roughness Ra<0.8 μm – grinded design, inner surface of the cone part is polished with guaranteed roughness Ra<0.5 μm . Usual equipment af the vessels, usual set of fittings. Tanks in this quality class comply with all European regulations for pressure vessels and food processing plants. Two years warranty for stainless steel main parts, two year for the fittings. It is the most often ordered quality variation of tanks for our customers.

- LQ – LOWER Quality – Lower quality workmanship of all parts, welded joints and surfaces. The most of functional armatures and fittings are usually purchased from suppliers from Asia. The inner and outer surface are not unified. Not guaranteed quality and homogenity of surface on the inside of the containers. One year warranty for stainless steel main parts, one year for the fittings. This solution is interesting only for start-up small breweries because it saves an investition costs. Unfortunatelly, this brings much higher beverage production costs. Longer period of sanitation, great consumption of the sanitizing solution, energy, labor and of water. High losses of produced beverages. We don´t offer this quality class for our products, because the equipment with the LQ quality class does not comply with the European regulations for pressure vessels and food processing plants. It is the quality of tanks of many very cheap world producers of the tanks, mainly made of Asia.

Our tip : Adjustable pure product drain valve for CCT – the special equipment for preventing loss of the product

We recommend to use our new adjustable pure product drain valve system for easy separation of yeast from the product (beer, cider, wine …) without loss of product residues. This system allows the precise height setting of the outlet pipe suction hole just above the actual level of yeast in the tank.

We recommend to use our new adjustable pure product drain valve system for easy separation of yeast from the product (beer, cider, wine …) without loss of product residues. This system allows the precise height setting of the outlet pipe suction hole just above the actual level of yeast in the tank.

No more product loss – no unusable residues in the tanks.

>> More about the adjustable pure product drain valve for CCT

Our quality declaration: Why to buy the cylindrical-conical tank 4000 liters just from us?

We design, manufacture, weld, mount and test of all vessels (excluding non-pressure vessels) in accordance with the strict European standards and guidelines for pressure vessels (EU Directive PED 2014/68/EU Pressure Equipment). I.e :

- Each pressure vessel contains an independent overpressure/vacuum safety valve (prevents against a very dangerous overpressurization and vaccum collapse of the vessel )

- Each pressure vessel is designed by certified designer who is qualified for the designing and calculation of pressure vessels.

- Production documentation for each pressure vessel containing a static strength calculation, the exact description of a right manufacturing process, including the required types of welds, thickness of material, critical points solutions.

- All the manufactured pressure vessels are subjected to rigorous testing of tightness and porosity of welds, using a special liquid that detects even the slightest unwanted leaks, pores or micro-cracks = The Penetration Test

- Pressure vessels are tested at overpressure which is at least 1 bar higher than the overpressure, for which containers are certified.

- The Protocol on the tightness and pressure tests and the EU declaration of conformity are issued to all pressure vessels. We also attach the Document of pressure tank history., at the request of the customer.

- Manufacturing processes, design drawings, manufacturing, tightness and pressure tests are supervised by an inspector of TÜV or another authorized and certified company, supplying quality control and verification compliance with European standards.

- Each pressure vessel contains an indelible label with the obligatory name of the manufacturer, the ultimate pressure or other data that uniquely identifies the concrete pressure vessel in accordance with EU PED 2014/68/EU

- Optionally we can produce the pressure equipment according to the conditions and standards of GOST-R or GUM certification rules. In this case, we charge an extra surcharge for the special certification :

- PED certification (European Union)… is included in the price

- GUM certification (Poland)… surcharge 10% – We ensure all necessary technical equipment of the tank (GUM compliant), a customer pays and handles the certification process for the tank on site.

- GOST-R certification (Russia)… surcharge 10%

- We produce food containers fundamentally from food-friendly stainless steel that fully comply with the Regulation of the European Parliament and Council Regulation EC no. 1935/2004. These materials do not release their constituents to food in quantities which could endanger human health or bring about an unacceptable changes in the composition of food or a deterioration in their organoleptic and sensory characteristics in contact with food under normal or foreseeable conditions. We do not use cheap stainless steel with lower quality, which will soon lose their corrosion resistance and inactivity to food, especially after repeated contact with aggresive solutions during the cleaning and sanitizing process.

- We are looking into suppliers of construction and installation materials and components from which we produce equipment for food production and handling. We do not buy any material from importers who are unable to prove its European origins and characteristics.

- All the tanks, which we design for fermentation, maturation and storage of beverages, have optimized dimensions for the fermentation processes, maturation process, carbonation, carried out in accordance with technological standards for beverages production. We do not set the dimensions of the containers by an unqualified estimate .

- All tanks that are made in HQ quality class, are produced with the guaranteed inner surface roughness of Ra < 0.5 microns, containers that are made in SQ quality class, are produced with the guaranteed inner surface roughness of Ra < 0.8 microns (except in very small tanks and terminate-welds on medium-size tanks), which is the European standard prescribed roughness of the inner surfaces of the tanks that come into contact with food and sanitation alkalic and acid solutions. Guaranteed roughness of the inner surface of the vessel is extremely important to ensure thorough cleaning and sanitation tanks. This is an essential prerequisite for achieving purity and sterility of food production equipment. We guarantee this limited roughness for 100% of the interior surface also for the tanks. We repeatedly do measurements of all internal surfaces of tanks with the special roughness-meter TR-130 during all their manufacturing process. We polish the inner surface of the tank until the desired roughness is reached.

- Each container is designed and manufactured in such a way as to ensure easy cleaning and sanitizing of all surfaces that come into contact with food. Therefore, the vessels are equipped with at least one sanitation shower, removable and sanitizable fill level-indicators and sampling cocks. We do not use any cheap armatures, for which the manufacturer has failed to sanitary design and cleanability.

- Tanks in HQ quality class have an united outer surface. All joints of the outer sheets (thickness at least 2 mm) are either welded or completely sealed. This is important to prevent ingress of moisture into the double casing, moistening the insulating material and the loss of insulating ability. This ensures a consistent quality and insulating capacity of the tanks. For containers in SQ quality, the external sheets are usually riveted and they have a thickness of at least 1 mm.

- We isolate all the pressure vessels by quality PUR foam. The insulating polyuretan foam is professionally applied to the insulating space of the tanks so as to avoid formation of thermal bridges, unisolated empty space or deformation of tanks. We do not use cheap little functional replacements for the isolation of the tanks such as insulating wool, polystyrene beads, inexpertly applied foam.

- Diameters of nozzles, valves and piping are sized correctly according to the volume and vessel function – we do not mount underpowered functional elements on the tanks.

- The warranty for the tanks produced in HQ is 36 months, warranty for the tanks produced in SQ is 24 months. The warranty on tanks in LQ quality is 12 months. The practical life of the tanks is usually several decades, while elements with lower lifetime (valves, seals, etc.) can usually to be easily replaced with a new standardized elements of the same or another manufacturer.

Our recommendation:

If you are comparing our prices with competitors, please always make sure that any other manufacturer guarantees the same quality as our company offers.

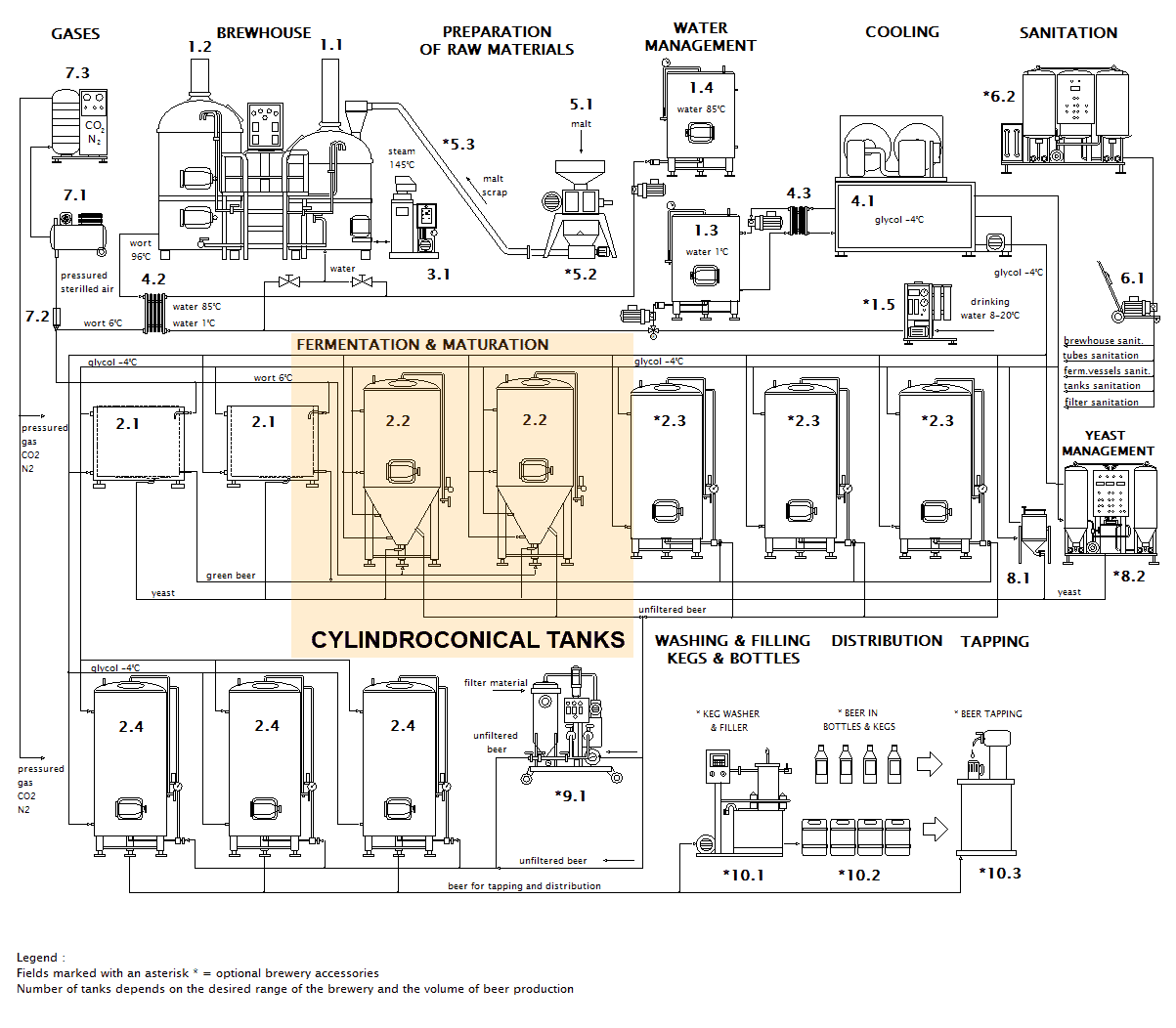

How does a pressure cylindroconical tank work?

Cylindrical-conical tanks, Cylindroconical tanks, Cylindrical fermentation tanks, Cylindrical fermentors – these are the most common names, including the same class of special pressure vessels with conical (funnel) bottom, designed for the single brewing of beer, the main fermentation of beer and maturation (lying, lagering) beer. The beer wort (intermediate beer product) from the brewhouse is pumped into the cylindroconical tank immediately after the hot brewing process. There, in the cylindrical conical tank, the main fermentation takes place under mild overpressure or without overpressure. Then the sedimentary yeast is separated from the tank and brewer sets required pressure in the tank using the adjustable pressure valve, and beer passes into the lagering phase when the beer in the tank maturates at elevated overpressure and at low temperature. Both stages of the fermentation process usually take place in the same tank, or the beer is transferred to another purified cylindrical conical tank after the main fermentation.

See more about the pressure cylindrical-conical tanks …