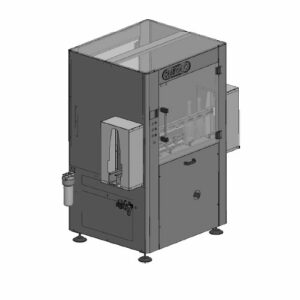

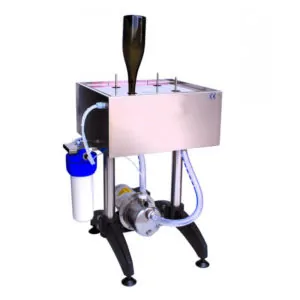

Equipment for rinsing and drying bottles before their filling.

Sale!

not rated

€ 3250 Original price was: € 3250.€ 3125Current price is: € 3125. excluding tax

Add to Cart

BWB-SA1200D : Semiautomatic bottle rinsing machine (up to 1200 bph) with double-phase bottle rinsing