Description

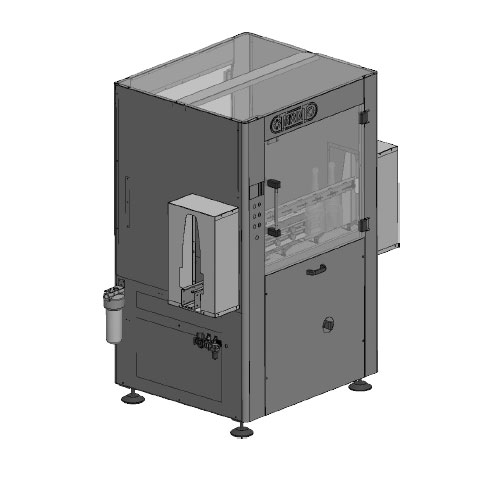

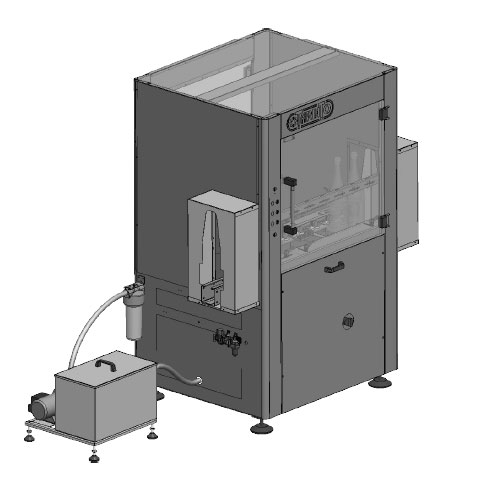

The automatic bottle blowing machine with independent loading and unloading of the bottles, works injection of micro-filtered air.

The machine is designed to quick drying the inside of wet bottles with filtered air, after their rinsing and before filling them with a beverage product.

The air is filtered using a filtering cartridge with nominal filtration rating 0.01μm (filtration efficiency: 99.9%) which is supplied with the machine.

Operation capacity is 1800 bottles per hour.

The machine is mounted on adjustable jointed feet, is manufactured in stainless steel AISI 304 and plastic components in conformity with the international directives.

Machine is designed to be inserted in the line (motor drive and idle wheel not supplied) or it can operate separatelly with manual loading and unloading the bottles.

Main parameters :

- AISI 304 quality stainless steel frame

- Bottle blowing station with 6 positions

- AISI 304 stainless steel water filtering assembly with 0.01 μm cartridge

- Blowing capacity : up to 1800 bottles per hour

- Installed power : 0.75 kW

- Standard voltage : 220V – 1ph – 50/60hz

- Weight : 350 kg

- Maximal bottle diameter : 100 mm

- Minimal bottle diameter : 45 mm

- Maximal bottle height : 380 mm

- Minimal bottle height : 115 mm

Working cycle description :

- Loading the bottles on the enter conveyor (manually or automatically optionally from the incomming conveyor)

- Automatic positioning of the bottles in the machine (6 positions)

- Clamping the bottles through double-acting suction cups

- Turnover of the bottles around the horizontal axis (6 bottles atthe same time)

- Blowing of the internal surface the bottles with filtered air

- Returning the bottles to starting position

- Releasing the bottles on the conveyor belt

- End of the working cycle

- Unloading the bottles from the output conveyor (manually or automatically optionally by the outgoing conveyor)

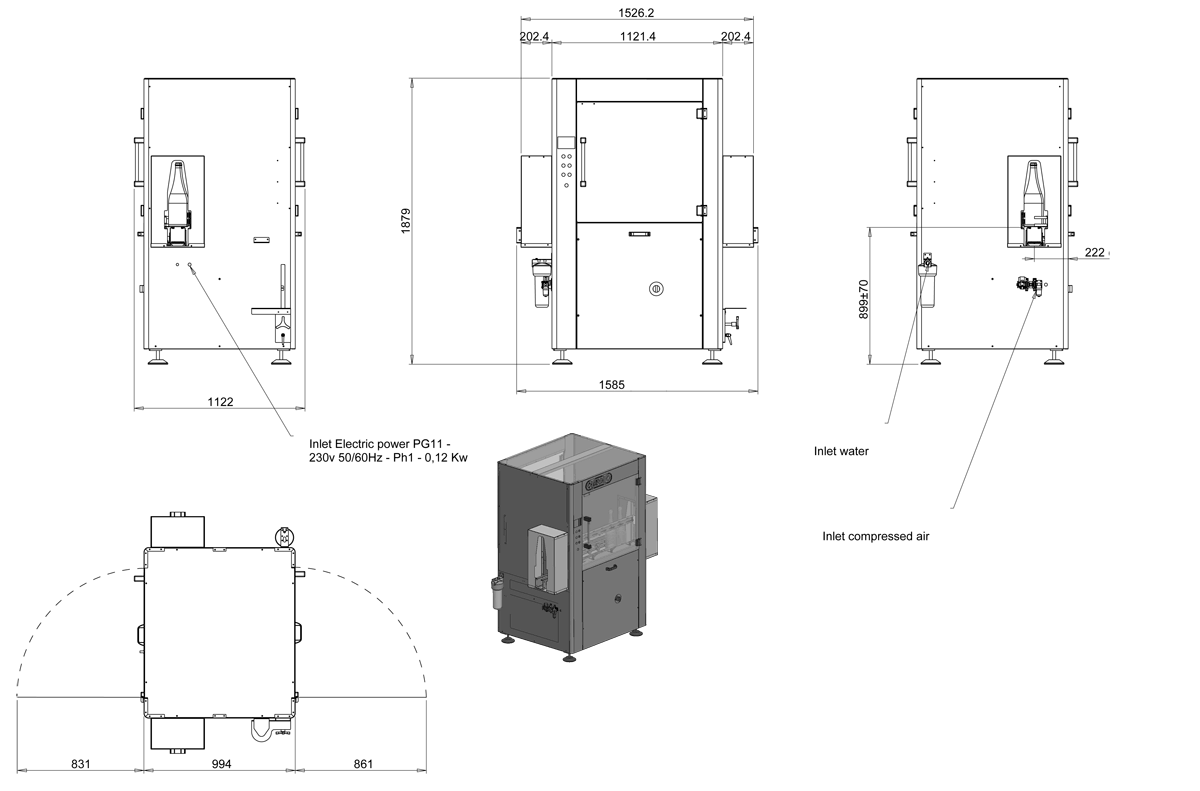

Machine dimensions :

Other optional accessories :

| Description | Price |

| Photocell at the exit | On demand |

| Additional conveyor 100×100 mm | On demand |

| Motor drive and idle wheel | On demand |

Reviews

There are no reviews yet.