Description

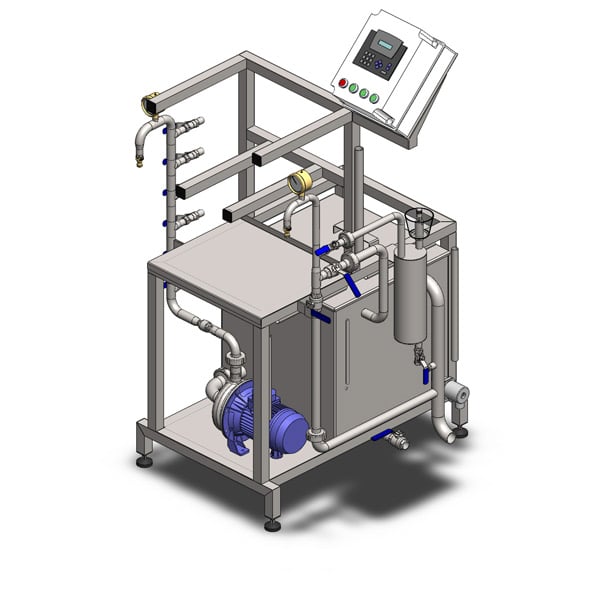

FUIC-SLP1C-2x500CCT

The independent 2×500/625 liters

with two pieces of 500/625 liters Cylindrical-conical tanks (CCT) and one independent compact water/glycol chiller

The fermentation and maturation unit BREWORX MODULO FUIC-SLP1C-2x500CCT is the independent mobile block with two cylindrical-conical tanks 2x 500 liters (total capacity 2×625 liters). This SLP version of FUIC has a simplified construction design without insulation and with the adjustable low-pressure range from 0 to 1.2 bar. The FUIC unit includes everything what is necessary for the main fermentation of beer/cider/wine, maturation of beer/cider/wine, storage and preparation of beer/cider/wine for handy bottling and dispensing process.

The BREWORX MODULO FUIC-SLP1C-2x500CCT consists of these components :

The BREWORX MODULO FUIC-SLP1C-2x500CCT consists of these components :

- 2 pcs of CCT-SLP 500 liters (usable volume) / 625 liters (total volume) – noninsulated cylindrical-conical tanks, the cylindrical part is cooled by water or glycol, pressure 0 – 1.2 bar

- 1 pc of the compact water/glycol chiller 2300 W with four independent temperature regulators and pumps.

- System for measurement and control of temperatures and circulation of coolant

- All pipes and hoses for cooling system – elements for connecting between cooler and tanks

- Supporting frame with adjustable legs or wheels with an aretation

Compact fermentation units BREWORX MODULO are the equipment for fermentation and maturation of beer wort , cider or wine. During the fermentation and maturation of wort made in brewhouse the wort becomes the final drink – beer. Time parameters of the fermentation and maturation process depend on the type of beer, the set pressure in the cylindrical-conical tanks and the requirements of the brewer.

This equipment is also usable to production and tuning samples of new types of beer or wine in little volumes, without blocking main fermenters in the brewery or winery for this reason.

Technical description :

Dimensions, volumes, weight

| Usable volume – both CCTs [liters] | 1000 |

| Total volume – both CCTs [liters] | 1250 |

| Length [mm] | 2750 |

| Width [mm] | 820 |

| Height [mm] | 2380 |

| Weight of empty unit [kg] | 590 |

| Weight of full unit [kg] | 1840 |

Standard properties, design and equipment

Maximum ambient temperature : 35°C

| Maximal allowed overpressure | 1.2 bar |

| PED 2014/68/EU certificate | yes |

| GUM / GOST certificate | not available |

| Inner surface – plates | 2B |

| Inner surface – roughness | Ra<0.8μm |

| Outer surface – plates | 2B |

| Outer surface – welds | natural |

| Cooling channels in the cylindrical parts | 2x G 1″ male |

| Cooling channels in the conical parts | no |

| Insulation of the tanks | surcharge |

| Outer jackets | not available |

| Top manholes | DN400 |

| Clear product drain outlet + ball valve | G 1″ male |

| Complete content drain outlet + ball valve | G 1″ male |

| CO2 input | G ¾ “ female |

| Sampling valves | DN10 |

| Manometers | yes |

| Temperature measuring sensors | DN10 |

| Automatic temperature control system | 2 regulators |

| Independent safety overpressure valves | yes |

| Underpressure – ovepressure valves | 0.1 bar / 1.2 bar |

| Fermentation locks and bungs for fermentation | yes – Piccolino |

| Overpressure setting mechanismes [range] | 0 – 1.2 bar |

| Product level indicators | not available |

| Carbonization stones | not available |

| Height-adjustable legs and feet [pcs] | 4 |

| PUR insulation of CCTs | not available |

| Number of compact water chillers | 1 |

| Digital control regulators PLC for tank cooling [pcs] | 4 |

| Number of independent cooling zones in each CCT | 1 |

| Adjustable temperature range in the CCTs | 1°C – 25°C |

| Maximum ambient temperature – noninsulated CCTs | 25°C |

| Cooling media | water/glycol |

| Cooling power of one chiller [kW] | 2.30 |

| Cooling power total [kW] | 2.30 |

| Electric power consumption of one chiller [kW] | 2.10 |

| Electric power consumption total [kW] | 2.10 |

| Electric connection / protection | 230V/1P/16A |

| Length of the power cord [m] | 3 |

| Usable for the fermentation process | yes |

| Usable for the maturation process | yes |

| Usable for the storage of the finished product | yes |

| Usable for the non-pressure product flotation | yes |

| Usable for the product clearing under pressure | yes |

| Usable for the product filtration under pressure | no |

| Usable for manual filling of the product into kegs | yes |

| Usable for manual filling of the product into bottles | yes |

| Usable for machinery filling of the product into kegs | no |

| Usable for machinery filling of the product into bottles | no |

Optional equipment (for surcharge)

|

|

description |

How to choose the right type of CCT ?

| Type of CCT | CCT-SNP | CCT-SLP | CCT-SHP |

|---|---|---|---|

| Maximal adjustable pressure in the tank | 0.0 bar | 1.2 bar | 2.5 bar |

| Usable for the fermentation process | yes | yes | yes |

| Usable for the maturation process | no | yes | yes |

| Usable for the storage of the finished product | no | yes | yes |

| Usable for the non-pressure product flotation | yes | yes | yes |

| Usable for the product clearing under pressure | no | yes | yes |

| Usable for the product filtration under pressure | no | no | yes |

| Usable for manual filling of the product into kegs | no | yes | yes |

| Usable for manual filling of the product into bottles | no | yes | yes |

| Usable for machinery filling of the product into kegs | no | no | yes |

| Usable for machinery filling of the product into bottles | no | no | yes |

Warning :The water chillers produce heat.

We recommend to place the FUIC unit with uninsulated CC tanks in the ventilated room. In hot summer days the room with uninsulated CCTs has to be cooled by sufficiently powerful air conditioner.

- Maximal different between ambient temperature and required temperature in the uninsulated tanks is 20°C. (It is valid for the FUIC units with standard equipment – noninsulated CCTs)

- Maximal different between ambient temperature and required temperature in the insulated tanks is 35°C. (It is valid for the FUIC units with additional PUR insulation)

Why choose MODULO FUIC/FUEC unit for the fermentation and maturation of beer ?

- Independence of the fermentation unit on the external cooling system – Each fermentation unit has its own independent cooling system

- Easy and quick installation – Customer receives the compact fermentation unit on the pallet, moves it using wheels to the destination, connects the unit to the power and then the equipment can be immediately used to the fermentation of beverages

- Financial savings and quick startup – Customer need not use any specialists – any building reconstruction nor build any new pipe routes for the cooling system are needed.

- Minimizing of operating losses during an equipment failure – In case of a failure of one cooling unit only one tank is temporarily out of operation, not the entire brewery

- Mobility – Change placing of the fermenters in the brewery cellar is very simple and fast because it is easy to move the fermentation unit to another place and the fermenters can start their work immediately again

- Simple connection – The fermentation unit is connectable to the wort brew machine and to other brewery devices using special hoses and fast clamping connectors therefore there is need not to install any welded piping system

- Compatibility – We deliver fermentation blocks with adapters that enable integration of a module into an existing system of any microbrewery – connected via hoses or stainless pipes

Usual values of main parameters during the fermentation and maturation of beer:

Primary fermentation (main beer fermentation)

| Parameters of primary beer fermentation | Beer fermented on tank bottom | Beer fermented on wort surface |

|---|---|---|

| Temperature | From 6°C to 12°C | From 18°C to 24°C |

| Pressure in the tank | From 0.0bar to 0.2bar | From 0.0bar to 0.2bar |

| Time of the beer fermentation | From 6 to 12 days | From 3 to 9 days |

Secondary fermentation (beer maturation, beer carbonization)

| Parameters of secondary beer fermentation | Beer fermented on tank bottom | Beer fermented on wort surface |

|---|---|---|

| Temperature | From 1°C to 2°C | From 1°C to 5°C |

| Pressure in the tank | From 0.8bar to 1.5bar | From 0.8bar to 1.5bar |

| Maturation time for the 10° beer | From 14 to 21 days | From 10 to 14 days |

| Maturation time for the 12° beer | From 30 to 60 days | From 21 to 30 days |

| Maturation time for the 14° beer | From 60 to 120 days | From 60 to 90 days |

| Maturation time for the 16° beer | From 120 to 180 days | From 90 to 120 days |

The tables above show that for the production of beer types which use yeast fermented on bottom (eg. traditional Czech lager beer ), we must consider that the production time of beer is about 50-60% longer than the production time of beer types with the yeast kinds that ferment on the surface of the wort. As well as the period of beer production must be longer if we want to produce stronger beers in the same fermenters because the fermentation and maturation of wort require longer time.

For this reason it is necessary carefully count the number of fermentation and ripening tanks for assess the production capacity of the brewery.

The calculation of the required number fermenters is quite complex and this is always a part of the calculation that we perform for our customer free if we participate in tender for delivery of a brewery. This is a part of our consultation work according we provide on requirements of specific customer.

We recommend use our compact fermentation units in all small-size microbreweries which plan expansion in future without big costs !!

The compact beer fermentation units are basic components of our modular microbreweries Breworx Modulo. Read more : modular microbrewery BREWORX MODULO.

See the video presentation of the FUIC fermentation unit :

General informations about microbreweries MODULO …

Components of the modular microbreweries MODULO – description and prices …

Typical configurations of microbrewery sets MODULO – description and prices …

We recommend to buy also :

1. The CIP cleaning and sanitizing station

The CIP station is very recommended equipment for easy cleaning (by cold and hot water) and sanitizing (by acid and hydroxide) of the tank and all pipes and hoses that are in contact with the product. There is not possible to produce a good beverages without professional care of perfect cleanliness of the production equipment.

2. Draft beer (cider/wine) dispensing equipment

The dispensing of beverages directly in your pub offers the best senses, taste and smell of your production to your customers.

3. Keg rinsing and filling equipment

If you want to offer your product to other pubs then you need our machines for simply rinsing and filling of beverages into kegs.

4. Bottle rinsing, filling, crowning and labelling equipment

If you want to sell your products in retail chains, you can not do it without equipment for filling beverages in bottles.

Our recommendation:

If you are comparing our prices with competitors, please always make sure that any other manufacturer guarantees the same quality as our company offers.

Note: All images of the equipment in this catalog are for illustration only and they do not show exactly the actual design of the device. We always let the customer sign a production drawing before starting production of the ordered equipment. This drawing shows the real actual design and is binding for the final product.