Description

The independent compact unit for the beer fermentation and maturation process with integrated cooling : FUIC 2×2000 liters

with two 2000 lt / 2300 lt Cylindrical-conical tanks (CCT) with classic design, insulated, double-jacket, cooled by water/glycol, adjustable pressure from 0bar to 3bar

The compact unit for the beer fermentation and maturation process with integrated cooling BREWORX MODULO FUIC-CHP4C-2x2000CCT is an independent mobile equipment with two cylindrical-conical tanks 2x 2000 liters. (total capacity 2×2300 liters). The FUIC unit includes everything what is necessary to the main fermentation of beer, to the beer maturation under pressure, to an isobaric filling beer into kegs or bottles or to serving beer into drink glasses directly from the fermenters that are included in this unit. The FUIC unit may be used also for the fermentation of other alcoholic beverages like sparkling wine, cider etc.

This type of the FUIC unit consists of these components :

- 2 pcs of CCT 2000 liters (usable volume) / 2300 liters (total volume) – Cylindroconical fermenters made of stainless steel that are insulated by PUR foam, cooled by water or glycol that circulated in cooling channels of double-jacket

- 4 pcs of the liquid cooling unit with integrated condenser

- Elements for measurement and control of temperature and circulation of coolant

- Piping for cooling liquid – elements for connecting between coolers and tanks

- Supporting frame with adjustable legs or wheels with an aretation

Compact fermentation units BREWORX MODULO – This is a very universal compact equipment for fermentation and maturation of wort. During the fermentation and maturation of wort made in brewhouse the wort becomes the final drink – beer. Time parameters of the fermentation and maturation process depend on the type of beer, the set pressure in the cylindrical-conical tanks and the requirements of the brewer.

This equipment is also usable to production and tuning samples of new types of beer or wine in little volumes, without blocking main fermenters in the brewery or winery for this reason.

See the video presentation of the FUIC fermentation unit :

Technical description :

| Parameters | FUIC-CNP4C-2x2000CCT – 0.5 bar | FUIC-CHP4C-2x2000CCT – with PED certficate |

| Usable volume [liters] | 2x 2000 | 2x 2000 |

| Adjustable overpressure | from 0 to 0.5 bar | from 0 to 3.0 bar |

| Fermentation of wort | suitable | suitable |

| Maturation of wort | unsuitable | suitable |

| Serving of beer from the tanks | unsuitable | suitable |

| Manual filling beer into kegs | unsuitable | suitable |

| Machine filling of beer into kegs | unsuitable | suitable |

| Filtration of beer | unsuitable | suitable |

| Cooling power [kW] | 4x 0.65 kW | 4x 0.65 kW |

| Cooling capacity [22°C > 7°C] | 4x 300 lt / hour | 4x 300 lt / hour |

| Cooling control system | PLC | PLC |

| Refrigerant | water | glycol |

| Adjustable temperature range in CCT | 1°C – 25°C | 1°C – 25°C |

| Power input | 4.2 kW | 4.2 kW |

| Electrical connection | 400V/3P/32A | 400V/3P/32A |

| Maximal temperature in the room | 35°C | 35°C |

| Length [mm] | 3850 | 3850 |

| Width [mm] | 1400 | 1400 |

| Height [mm] | 3780 | 3780 |

| Weight netto [ kg ] | 1892 | 1892 |

| Weight brutto [ kg ] | 6572 | 6572 |

| Mobility | wheels | wheels |

| Stability | adjustable legs | adjustable legs |

| Material | AISI 304 | AISI 304 |

| Warranty | 24 months | 24 months |

Notice :

All dimensions and weights are approximate – they are calculated according to the materials that were available at the time of market introduction. The manufacturer reserves the right to change dimensions and weights if they are not available the same materials and subcomponents upon production of a particular product, or if the customer has individual requirements. The customer receives a drawing of the product from the manufacturer. All important dimensions of the actual product will be shown in this drawing. The customer always confirms dimensions of the product before its production.

quipment of the Cylindrical-conical tank Classic 2000/2300 liters

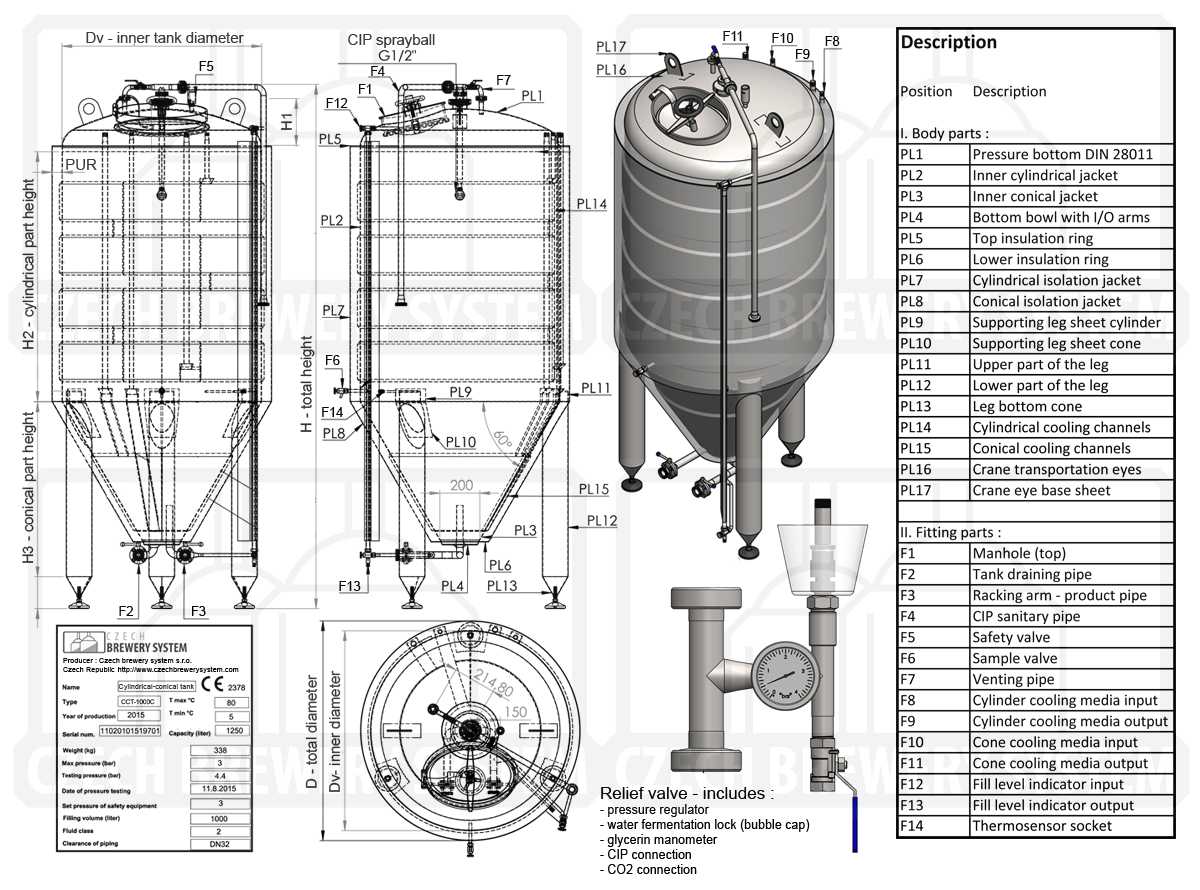

Assembly drawing of the cylindroconical tank CCT-2000C (model 2015 / SQ / standard dimensions) :

Cylindroconical tank CCT-2000C |

Standard qualitywithout PED |

Standard qualityPED certificate |

High qualitywithout PED |

High qualityPED certificate |

Parameters (standard dimensions) |

SQ no-PED |

SQ PED |

HQ no-PED |

HQ PED |

| Vu Usable volume [liters] | 2000 | 2000 | 2000 | 2000 |

| Vt Total volume [liters] | 2300 | 2300 | 2300 | 2300 |

| V1 Upper arched bottom – volume [liters] | 188 | 188 | 188 | 188 |

| V2 Cylindrical part – volume [liters] | 1740 | 1740 | 1740 | 1740 |

| V3 Conical part – volume [liters] | 372 | 372 | 372 | 372 |

| D Total tank diameter [mm] | 1300 | 1300 | 1300 | 1300 |

| Dv Inner tank diameter [mm] | 1200 | 1200 | 1200 | 1200 |

| H Total height [mm] | 3262 | 3262 | 3262 | 3262 |

| H1 Upper arched bottom – height [mm] | 244 | 244 | 244 | 244 |

| H2 Cylindrical part – height [mm] | 1539 | 1539 | 1539 | 1539 |

| H3 Conical part – height [mm] | 1039 | 1039 | 1039 | 1039 |

| Mn Weight netto [kg] | 496 | 496 | 496 | 496 |

| Mb Weight brutto [kg] | 2796 | 2796 | 2796 | 2796 |

Equipment standard |

SQ no-PED |

SQ PED |

HQ no-PED |

HQ PED |

| Pressure range (allowed by PED) | 0.0 – 0.5 bar | 0.0 – 3.0 bar | 0.0 – 0.5 bar | 0.0 – 3.0 bar |

| Real pressure range (tested by producer) | 0.0 – 4.4 bar | 0.0 – 4.4 bar | 0.0 – 4.4 bar | 0.0 – 4.4 bar |

| PED 2014/68/EU certificate | no | yes | no | yes |

| Material (Origin in Europe) | AISI 304 | AISI 304 | AISI 304 | AISI 304 |

| Inner surface – upper bottom + cylinder | 2B / Ra<0.8 grinded | 2B / Ra<0.8 grinded | 2C / Ra<0.5 polished | 2C / Ra<0.5 polished |

| Inner surface – conical part | 2C / Ra<0.5 polished | 2C / Ra<0.5 polished | 2C / Ra<0.5 polished | 2C / Ra<0.5 polished |

| Outer surface | 2B grinded | 2B grinded | 2B grinded | 2B grinded |

| External sheets – joints | riveted / welded | riveted / welded | all welded | all welded |

| Peak angle of the cone | 60° | 60° | 60° | 60° |

| PUR insulation | 50 mm | 50 mm | 50 mm | 50 mm |

| CT / CJ1 Cooling duplicator cylinder – in/out welded with G-thread | 1 zone > 60% surface IN-OUT G1/2″-G3/4″ | 1 zone > 60% surface IN-OUT G1/2″-G3/4″ | 1 zone > 60% surface IN-OUT G1/2″-G3/4″ | 1 zone > 60% surface IN-OUT G1/2″-G3/4″ |

| CT / CJ1 Cooling duplicator cone – in/out welded with G-thread | 1 zone > 50% surface IN-OUT G1/2″-G3/4″ | 1 zone > 50% surface IN-OUT G1/2″-G3/4″ | 1 zone > 50% surface IN-OUT G1/2″-G3/4″ | 1 zone > 50% surface IN-OUT G1/2″-G3/4″ |

| Transport hinges | 2pcs | 2pcs | 2pcs | 2pcs |

| Upper service door (manhole) | 420x340mm open inside | PED 420x340mm open inside | 420x340mm open outside | PED 420x340mm open outside |

| Side service door (manhole) | optional 440x310mm | optional 440x310mm | optional 440x310mm | optional 440x310mm |

| Ovepressure/vacuum safety valve | Max 0.5 / 0.2 bar | Max 3.2 / 0.2 bar | Max 0.5 / 0.2 bar | Max 3.2 / 0.2 bar |

| Pure-beverage output armature | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Bottom filling/emptying armature | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Sample valve | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit |

| CIP and manometer connection fittings | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC |

| Venting valve | yes | yes | yes | yes |

| Sanitizing ball-shower | static | static | rotational | rotational |

| Fermentation pressure adjusting valve, sanitizable | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Manometer with glycerine | yes | yes | yes | yes |

| Filling level indicator fixed | yes | yes | optional | optional |

| Filling level indicator removable | optional | optional | yes | yes |

| Thermosensor socket | 2 pcs DN9 | 2 pcs DN9 | 2 pcs DN9 | 2 pcs DN9 |

| Ladder eyes | 2ks | 2ks | 2ks | 2ks |

| Rubber adjustable feet | 3 pcs | 3 pcs | 3 pcs | 3 pcs |

| Type label – tank parameters PED | yes | yes | yes | yes |

| Minimum operating temperature | -15 °C | -15 °C | -15 °C | -15 °C |

| Maximum operating temperature | +80 °C | +80 °C | +80 °C | +80 °C |

| Guaranteed number of pressure cycles (for max. pressure) | 500 | 500 | 500 | 500 |

| Standard warranty | 2 years | 2 years | 3 years | 3 years |

Equipment optional – surcharges |

SQ no-PED |

SQ PED |

HQ no-PED |

HQ PED |

| Side service door (manhole) | € 192 | € 192 | € 192 | € 192 |

| Upper service door (manhole) | € 192 | € 192 | included | included |

| Upper service door with a sight window | € 462 | € 462 | € 462 | € 462 |

| Upper service door fully-glass | € 692 | € 692 | € 692 | € 692 |

| Ladder | € 302 | € 302 | € 302 | € 302 |

| Side universal armature for hopgun, carbonization, filtration, flotation | € 38 | € 38 | € 38 | € 38 |

| Upper special armature-set for a dry hopping | € 192 | € 192 | € 192 | € 192 |

| Carbonization stone | € 423 | € 423 | € 423 | € 423 |

| Sanitizing ball-shower – rotational | € 56 | € 56 | yes | yes |

| Adjustable pure-beverage output armature with the sight glass | € 385 | € 385 | € 385 | € 385 |

| Scale on the pressure adjusting valve | € 115 | € 115 | € 115 | € 115 |

| Scale for Filling level indicator mm | € 192 | € 192 | € 192 | € 192 |

| Temperature measuring and control system | see a pricelist | see a pricelist | see a pricelist | see a pricelist |

| Foam compensator for Sample valve | € 103 | € 103 | € 103 | € 103 |

| Non-standard dimensions of the tank by customer | 10% and more | 10% and more | 10% and more | 10% and more |

| Non-standard equipment of no-PED tank | € 173 | € 173 | € 173 | € 173 |

| Non-standard equipment of PED tank | € 1 040 | € 1 040 | € 1 040 | € 1 040 |

Legend :

N/A = Not available

DC = Dairy Coupling DIN 11851, TC = TriClamp DIN 32676 (type of the coupling depends on requirement of a customer)

PED = Certification for pressure vessels required in all EU countries – the EU Directive PED 2014/68/EU Pressure Equipment

The manufacturer reserves the right to change the parameters according to the current availability of materials and fittings. A customer will always receive our production drawing for approval before manufacturing the ordered tank.

Standard equipment – description

- Adjustable pressure valve – Overpressure setting mechanism with a glycerine manometer (standard range from 0 bar up to 3 bar ) – it allows all fuctions : fermentation + maturation + bottling

- Cooling channels – duplicators for circulating of coolant in the cooling jacket (one, two or more according type of the tank)

- PUR insulation – polyurethane insulation with thickness according to the size of the tank and the target environment (standard = 50mm )

- Outer jacket of the tank of stainless steel – Kind of the surface finishing (standard = grinded) choosed by customer.

- Guaranteed inner surface roughness : Ra < 0.8 μm or less (grinded surfaces) / Ra < 0.5 μm or less (polished surfaces)

- Service door (manhole) on the top cone or on cylinder part, according to customer requirements (SQ = open inside / HQ = open outside)

- Pure-beverage output armature with a butterfly valve for pure beverage (beer, wine, cider) output – the racking arm (optionally with variable height of a suction)

- Bottom filling/emptying armature – The inlet / outlet pipe with a butterfly valve for filling tank, discharging of yeast and draining of full content of the tank

- Sanitizing ball-shower – CIP sanitizing ball-shower (SQ = statical / HQ = rotational) – one or more pcs

- Sanitation pipe – A multifunction pipe with a ball valve for connection of a shower head to the cleaning-sanitizing CIP station , the adjustable pressure valve with manometer, CO2 inlet

- Sample valve – cleanable and sanitizable sampling cock for collection product samples

- Safety valve – Double-acting overpressure valve (standard = 3.2 bar) and underpressure protection valve (0.2 bar) safety valve – it is included only in the pressure version of the tank

- Venting valve – Dedicated venting valve for safety draining of the tank and for accurate measuring of current pressure in the tank using manometer (it ensures properly function of the manometer when the shower ball shower is blocked with a foam)

- Thermometer socket – welded socket for inserting of thermosensor or thermometer (one or more according type of the tank)

- Manometer – It is included in the set of the adjustable pressure valve. Made of stainless steel, with glycerine inside.

- Filling level indicator – Sanitizable glass or plastic pipe for visualisation height level of the beverage product in the tank (SQ = fixed / HQ = removable)

- Transport hinges – steel welded hinges for safety transport of the tank with crane or forklift

- Adjustable feet – 3 or Four legs with rubber feet for accurate horizontal adjusting of the tank on an uneven floor

- Type label – the steel label with all parameters that are required from European Union for pressure vessels

- PED 2014/68/EU – certificate – the European certificate for the overpressure vessel + document for archiving history of the pressure vessel

Optional equipment – description

- Variable outlet-pipe for pure beverage (adjustable racking arm) – instead the fix clear product pipe – a rotatable pipe with a butterfly valve and sight glass to accurate adjusting high of the suction inlet according to current level of yeast in the tank

- Special doors – manholes – secondary site manhole, manhole with sightglass, manhole with glass door

- Special cleaning-sanitizing ball-showers – rotational, pulse or other special cleaning equipment for extreme effective cleaning of the tank

- Side or upper universal armature – Universal multi-use armature for connection of the flotation equipment, carbonization stone or the hop extractor for dry hopping.

- Scale for the filling level indicator – a liter scale on a cover of the filling level indicator for visualization of the current product volume in the tank

- Scale for the adjustable pressure valve – a bar scale on a adjustable pressure valve screw for indication of just required pressure in the tank (a manometer shows the current pressure)

- Temperature measurement and regulation components – we deliver several types of thermosensors, thermometers and also fully equipped temperature control systems for our tanks

- Thermometer, thermocouples, thermoregulators – more types for installation directly on the tank or on a wall

- Automatic thermo regulation valves for regulation the coolant flow in the cooling channels

- On-tanks termo-controllers – measurement and regulation of temperature on dedicated temperature controller placed directly on each tank

- On-the-wall control box – measurement and regulation of temperature in more tanks from one control box

- Automatic tank temperature measurement and control system – for an automatic control of full fermentation and maturation processes

- Carbonization stone – the special porous stone for carbonization of beverages from CO2 bottles

- Ladder – for easy operating with manholes and other upper accessories of tanks

- Tank product filling hub – a special tool to easy filling of product (like beer wort , cider must) to the fermentation tank

- Stirring equipment – to stirring contents of the tank, It is mounted on the side of the tank shell

- Other customizations of the tank – according on customer´s requirements – non-standard dimensions, special armatures, special surface and design of the tank etc.

Why choose MODULO FUIC/FUEC unit for the fermentation and maturation of beer ?

- Independence of the fermentation unit on the external cooling system – Each fermentation unit has its own independent cooling system

- Easy and quick installation – Customer receives the compact fermentation unit on the pallet, moves it using wheels to the destination, connects the unit to the power and then the equipment can be immediately used to the fermentation of beverages

- Financial savings and quick startup – Customer need not use any specialists – any building reconstruction nor build any new pipe routes for the cooling system are needed.

- Minimizing of operating losses during an equipment failure – In case of a failure of one cooling unit only one tank is temporarily out of operation, not the entire brewery

- Mobility – Change placing of the fermenters in the brewery cellar is very simple and fast because it is easy to move the fermentation unit to another place and the fermenters can start their work immediately again

- Simple connection – The fermentation unit is connectable to the wort brew machine and to other brewery devices using special hoses and fast clamping connectors therefore there is need not to install any welded piping system

- Compatibility – We deliver fermentation blocks with adapters that enable integration of a module into an existing system of any microbrewery – connected via hoses or stainless pipes

Usual values of main parameters during the fermentation and maturation of beer:

Primary fermentation (main beer fermentation)

| Parameters of primary beer fermentation | Beer fermented on tank bottom | Beer fermented on wort surface |

|---|---|---|

| Temperature | From 6°C to 12°C | From 18°C to 24°C |

| Pressure in the tank | From 0.0bar to 0.2bar | From 0.0bar to 0.2bar |

| Time of the beer fermentation | From 6 to 12 days | From 3 to 9 days |

Secondary fermentation (beer maturation, beer carbonization)

| Parameters of secondary beer fermentation | Beer fermented on tank bottom | Beer fermented on wort surface |

|---|---|---|

| Temperature | From 1°C to 2°C | From 1°C to 5°C |

| Pressure in the tank | From 0.8bar to 1.5bar | From 0.8bar to 1.5bar |

| Maturation time for the 10° beer | From 14 to 21 days | From 10 to 14 days |

| Maturation time for the 12° beer | From 30 to 60 days | From 21 to 30 days |

| Maturation time for the 14° beer | From 60 to 120 days | From 60 to 90 days |

| Maturation time for the 16° beer | From 120 to 180 days | From 90 to 120 days |

The tables above show that for the production of beer types which use yeast fermented on bottom (eg. traditional Czech lager beer ), we must consider that the production time of beer is about 50-60% longer than the production time of beer types with the yeast kinds that ferment on the surface of the wort. As well as the period of beer production must be longer if we want to produce stronger beers in the same fermenters because the fermentation and maturation of wort require longer time.

For this reason it is necessary carefully count the number of fermentation and ripening tanks for assess the production capacity of the brewery.

The calculation of the required number fermenters is quite complex and this is always a part of the calculation that we perform for our customer free if we participate in tender for delivery of a brewery. This is a part of our consultation work according we provide on requirements of specific customer.

We recommend use our compact fermentation units in all small-size microbreweries which plan expansion in future without big costs !!

The compact beer fermentation units are basic components of our modular microbreweries Breworx Modulo. Read more : modular microbrewery BREWORX MODULO.

Variations of the CCT 2000 according to the overpressure limit :

In addition, the customer can choose between the pressure and non-pressure vessels. According to the maximum allowable overpressure in the vessel we produce CCT fermentation tanks in two designs:

- Non-pressure fermentation tank CCT-2000 – The maximum available overpressure is 0.5 bar – it is designed as 3.0 bar tank, tested for pressure up to 4.0 bar, but it is not declared as pressure tank according to EU Directive PED . Suitable for non-pressure fermentation of beer or cider, or also as pressure vessel in some countries out of European Union.

- Over-pressure fermentation tank CCT-2000 – The maximum available overpressure is 3.0 bar (optionally, according to specific customer requirements up to 5.0 bar), includes the certificate for pressure vessels according to EU Directive PED. The vessel can be used not only for the fermentation and maturation of beer, but also as pressure tank for isobarical filling of beverage into kegs or bottles, for filtration and isobaric serving of beer or cider into glasses.

Variations of the CCT 2000 according to their quality and equipment :

According to quality requirements and financial possibilities of customers we recognize the fermentation tanks with four classes of quality and equipment:

- TQ- TOP Quality – The highest quality we offer. The inner surface has a guaranteed roughness Ra<0.5 μm – glossy design. The outer surface is fully polished-unified. All functional armatures and fittings that have an impact on the reliability and safety of the products are made in Europe or in the USA. The best separation of the used yeast from the beer or cider, especially at single-phase fermentation of beer or cider when the both fermentation and maturation process are provided in the same tank. Luxury equipment of the tanks. The main advantage is very luxury design of the tank.Three years warranty for stainless steel main parts and also for the fittings. Price will be calculated individually for each tank.

- HQ – High quality – High quality workmanship of all parts, welded joints and surfaces. The inner surface has a guaranteed roughness Ra<0.5 μm – glossy design. The outer surface is grinded-unified. All functional armatures and fittings that have an impact on the reliability and safety of the products are made in Europe or in the USA. A perfect separation of the used yeast from the beer or cider, especially at single-phase fermentation of beer or cider when the both fermentation and maturation process are provided in the same tank. Luxury equipment of the tanks. The main advantages are the savings of sanitizing solutions, water and energy, minimized losses of beverages, shorter work time, reduction of production costs. Three years warranty for stainless steel main parts and also for the fittings. The quality class for the most demanding customers.

- SQ – Standard quality – Standard quality workmanship of all parts, welded joints and surfaces. All functional armatures and fittings that have an impact on the reliability and safety of the products are purchased from approved suppliers from Europe or USA. Inspection of all critical welds and joints. The inner surface has a guaranteed roughness Ra<0.8 μm – grinded design, inner surface of the cone part is polished with guaranteed roughness Ra<0.5 μm . Usual equipment af the vessels, usual set of fittings. Tanks in this quality class comply with all European regulations for pressure vessels and food processing plants. Two years warranty for stainless steel main parts, two year for the fittings. It is the most often ordered quality variation of tanks for our customers.

- LQ – Lower quality – Lower quality workmanship of all parts, welded joints and surfaces. The most of functional armatures and fittings are purchased from approved suppliers from Asia. The inner and outer surface are not unified. Not guaranteed surface roughness on the inside of the containers. One year warranty for stainless steel main parts, one year for the fittings. This solution is interesting only for starting small breweries because it saves an investition costs. Unfortunatelly, this brings higher beverage production costs. Longer period of sanitation, greater consumption of the sanitizing solution, energy, labor and hot water. High losses of produced beverages. We don´t offer this quality class for our products, because the equipment with the LQ quality class does not comply with the European regulations for pressure vessels and food processing plants. It is the quality of tanks of very cheap world producers of the tanks.

Applicability of fermentation units according to brew machine type and required number of wort batches in a brewing day

Applicability of fermentation units for different production operations

General informations about microbreweries MODULO …

Components of the modular microbreweries MODULO – description and prices …

Typical configurations of microbrewery sets MODULO – description and prices …

Catalogue of the modular microbreweries MODULO – to download & print …