Description

The CCT-64N is an universal stainless steel cylindrically-conical fermenter with total capacity of 64 liters (1/2 BBL). Recommended filling capacity is maximally 62 liters. 100% Tri Clamp connections DIN32676, the neoprene cooling jacket for temperature control and the controlled fermenting (up to 50% more cooling surface area), and the ability to carbonate in one vessel make this tank a perfect fermenter at any Micro Brewery looking to brew little beer batches.

The tank is completely designed in USA, produced in China, with all certificates needed for European customers.

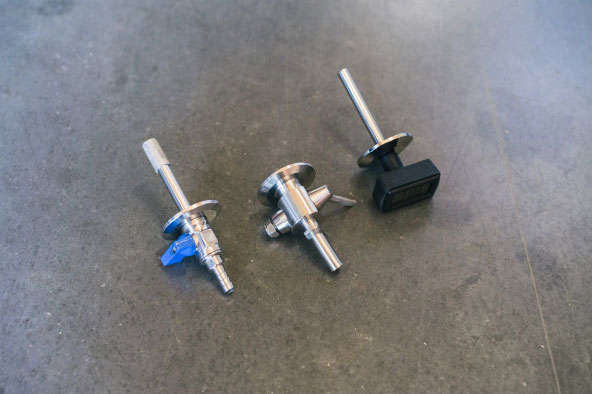

This offer and price includes the tank which is equipped with the most common equipment (see the picture bellow).

This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories”

Main features:

- Combi 3” TriClamp port (DIN32676 DN80) with three functions : dry hop adding, CIP inlet and the pressure relief valve port

- Carbonation stone with 3/8” ball valve

- Professonal sanitary pressure gauge and sampling valve

- Simple neoprene insulation jacket (removable with a zip)

- Adjustable feet with stainless steel lower part

Complete technical description :

The Nano line of the cylindroconical tanks designed to bridge the gap between home and professional brewing.

Dimensions :

| Usable volume [liters] | 60 |

| Total volume [liters] | 64 |

| Total height [mm] (from feet to pressure gauge) | 1210 |

| Total diameter [mm] | 550 |

| Weight of empty tank [kg] | 37 |

| Weight of full tank [kg] | 101 |

Standard properties, design and equipment

| Maximal recommended operating pressure | 1.0 bar / 15 psi |

| Maximal safety pressure (limited with the ovepressure safety valve) | 2.0 bar / 30 psi |

| PED 2014/68/EU certificate | yes |

| Fully welded flanges | TC = TriClamp DIN32676 |

| Safety overpressure valve | yes / 2 bar / 30 psi |

| Combi port with three functions : dry hop adding, CIP inlet and the pressure relief valve port | 3” TC / DN80 |

| Cup with the pressure relief valve | 0 – 2 bar / 0 – 30 psi |

| Carbonation stone with 3/8” ball valve | 1.5” TC DN40 |

| Dump valve | 1.5” TC DN40 |

| Pure product valve | 1.5” TC DN40 |

| Blow-off pipe with welded blow-off arm mount (for connection of the spunding adjustable pressure relief valve) | 1.5” TC DN40 |

| ½” ball valve for blow-off pipe | 1.5” TC DN40 |

| Sanitary pressure gauge | 1.5” TC DN40 |

| Sanitary sampling valve | 1.5” TC DN40 |

| Thermowell with the LCD thermometer and the digital temperature regulator | 1.5” TC DN40 |

| Double jacket with the cooling channels | yes |

| Simple neoprene insulation jacket (removable with a zip) | yes |

| Stainless steel lower shelf | yes |

| Adjustable feet | yes |

| Material | AISI 304 |

Recommended use

| Usable for the fermentation process | yes |

| Usable for the maturation process | yes |

| Usable for the storage of the finished product | yes |

| Usable for the non-pressure product flotation | yes |

| Usable for the product clearing under pressure | yes |

| Usable for the product filtration under pressure | no |

| Usable for manual filling of the product into kegs | yes |

| Usable for manual filling of the product into bottles | yes |

| Usable for machinery filling of the product into kegs | no |

| Usable for machinery filling of the product into bottles | no |

Optional accessories (for surcharge)

|

|

description |

|

|

description |

|

|

description |

|

|

description |

|

description |

|

description |

|

description |

|

description |

Micro sight glass TC 1.5″Simple pipe sight glass to multi use in your brewery to see how looks and flows beverage you just transport in the pipes or hoses. |

description |

|

|

description |

|

|

description |

|

description |

|

|

description |

|

description |

|

description |

|

description |

|

description |

|

description |

|

|

description |

|

|

description |

|

description |

How to choose the right type of CCT ?

| Type of CCT | CCT-SNP | CCT-SLP | CCT-SHP |

|---|---|---|---|

| Maximal adjustable pressure in the tank | 0.0 bar | 1.2 bar | 2.5 bar |

| Usable for the fermentation process | yes | yes | yes |

| Usable for the maturation process | no | yes | yes |

| Usable for the storage of the finished product | no | yes | yes |

| Usable for the non-pressure product flotation | yes | yes | yes |

| Usable for the product clearing under pressure | no | yes | yes |

| Usable for the product filtration under pressure | no | no | yes |

| Usable for manual filling of the product into kegs | no | yes | yes |

| Usable for manual filling of the product into bottles | no | yes | yes |

| Usable for machinery filling of the product into kegs | no | no | yes |

| Usable for machinery filling of the product into bottles | no | no | yes |

Our recommendation:

If you are comparing our prices with competitors, please always make sure that any other manufacturer guarantees the same quality as our company offers.

Wort oxygenation set TC 1.5″

Wort oxygenation set TC 1.5″ The HOP BONG CARBO flow saturator 2 µm

The HOP BONG CARBO flow saturator 2 µm Sample valve for small fermentors | TriClamp 1.5″ 50.5mm

Sample valve for small fermentors | TriClamp 1.5″ 50.5mm Anti foam sampling spiral – the foam remover

Anti foam sampling spiral – the foam remover

Short extension pipe TC 1.5″

Short extension pipe TC 1.5″

Pipe Reducer TC 1.5″ to BSP 1/2″F

Pipe Reducer TC 1.5″ to BSP 1/2″F Pipe Reducer TC 1.5″ to BSP 1/2″M

Pipe Reducer TC 1.5″ to BSP 1/2″M Thermowell 300 mm

Thermowell 300 mm Compact liquid cooler 500W for 1-2 tanks

Compact liquid cooler 500W for 1-2 tanks Compact liquid cooler 500W for 1-4 tanks

Compact liquid cooler 500W for 1-4 tanks

Cleaning and sanitizing station 2x30L

Cleaning and sanitizing station 2x30L