Description

CCT-6000C Cylindrical-conical tank Classic 6000/7135 L (insulated, cooled with liquid)

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 6000 liters and total volume 7135 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European Standards EN 13445 and PED 2014/68/EU (Pressure Equipment Directive).

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 6000 liters and total volume 7135 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European Standards EN 13445 and PED 2014/68/EU (Pressure Equipment Directive).

The PED certificate (and all documents related with the pressure equipment in accordance with PED 2014/68/EU standard) is not included in price of the tank and for use the tank in European countries it is necessary to add the item “PED 2014/68/EU certificate” . All parts are made in European Union.

Equipment of the Cylindrical-conical tank Classic 6000/7135 liters

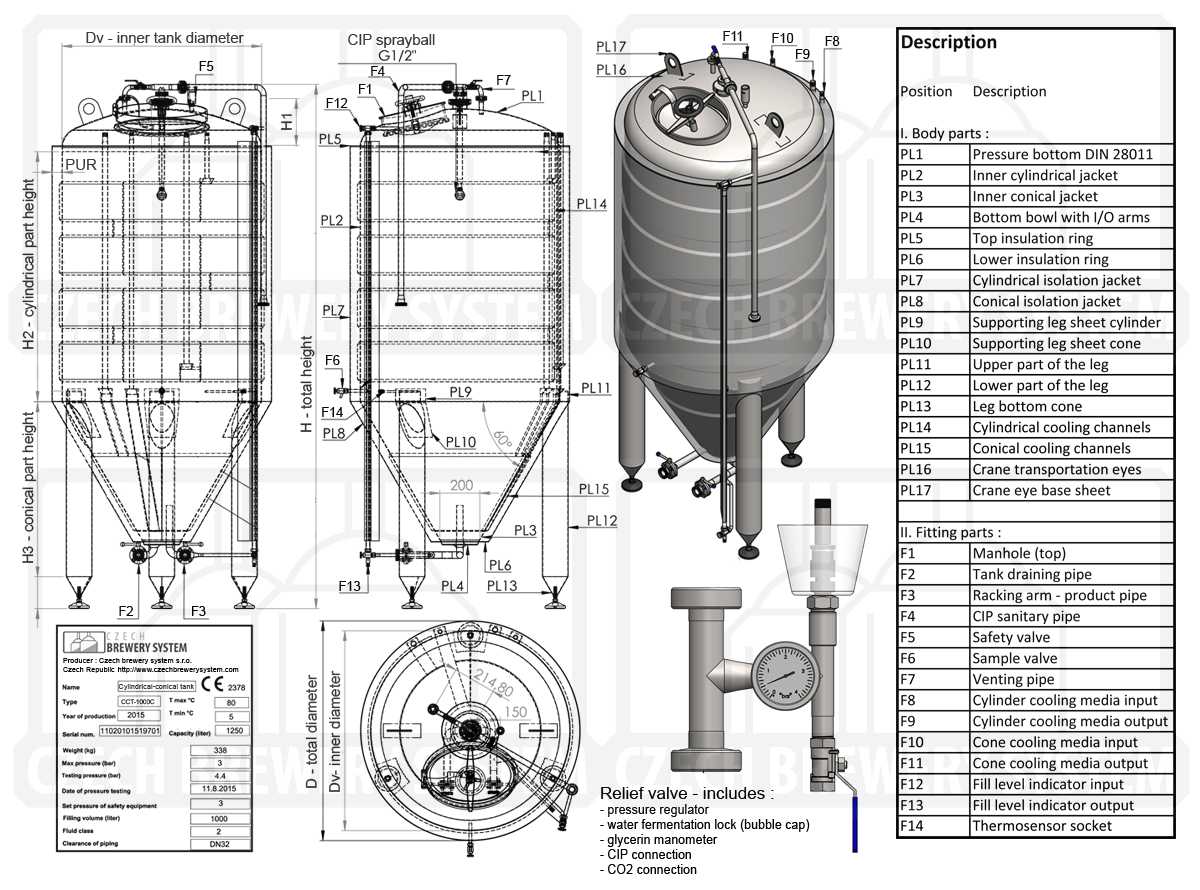

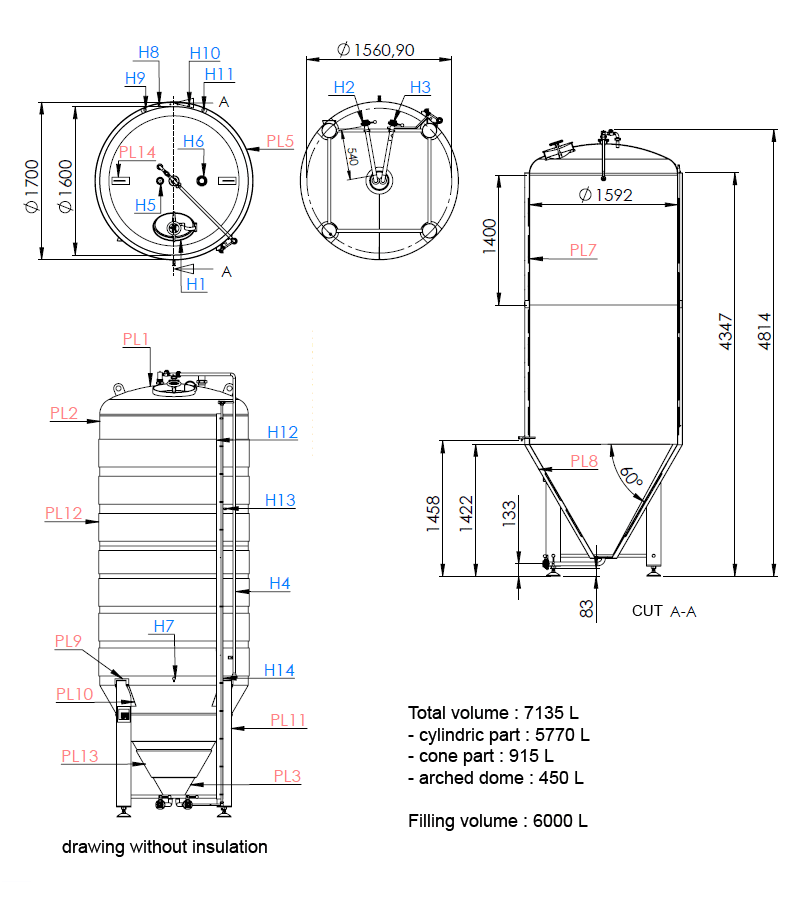

Assembly drawing of the cylindroconical tank CCT-6000C (model 2015 / SQ / standard dimensions) :

CCT-6000C : Technical parameters

Technical parameters of the CCT-6000C : The universal cone fermenter, the cylindrically-conical pressure tank for both fermentation and maturation of beer or cider, usable volume 6000 liters, with PUR insulation, cooled by water/glycol.Cylindrically-conical tank CCT-6000C / classic fermentor | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

|---|---|---|---|---|---|---|

Parameters (standard dimensions) | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

| Vu Usable volume [liters] | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Vt Total volume [liters] | 7135 | 7135 | 7135 | 7135 | 7135 | 7135 |

| V1 Upper arched bottom - volume [liters] | 450 | 450 | 450 | 450 | 450 | 450 |

| V2 Cylindrical part - volume [liters] | 5770 | 5770 | 5770 | 5770 | 5770 | 5770 |

| V3 Conical part - volume [liters] | 915 | 915 | 915 | 915 | 915 | 915 |

| D Total tank diameter [mm] | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

| Dv Inner tank diameter [mm] | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 |

| H Total height [mm] | 4814 | 4818 | 4814 | 4814 | 4814 | 4814 |

| H1 Upper arched bottom - height [mm] | 322 | 322 | 322 | 322 | 322 | 322 |

| H2 Cylindrical part - height [mm] | 2900 | 2900 | 2900 | 2900 | 2900 | 2900 |

| H3 Conical part - height [mm] | 1386 | 1386 | 1386 | 1386 | 1386 | 1386 |

| Mn Weight netto [kg] | 1200 | 1200 | 1200 | 1320 | 1320 | 1320 |

| Mb Weight brutto [kg] | 6200 | 6200 | 6200 | 6320 | 6320 | 6320 |

Equipment standard | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

| Pressure range (allowed by PED) | 0.0 - 0.5 bar | 0.0 - 1.5 bar | 0.0 - 3.0 bar | 0.0 - 0.5 bar | 0.0 - 1.5 bar | 0.0 - 3.0 bar |

| Testing pressure range (in production) | 0.0 - 0.7 bar | 0.0 - 2.1 bar | 0.0 - 4.2 bar | 0.0 - 0.7 bar | 0.0 - 2.1 bar | 0.0 - 4.2 bar |

| PED 2014/68/EU certificate | no | yes | yes | no | yes | yes |

| Material | AISI 304 | AISI 304 | AISI 304 | AISI 304 | AISI 304 | AISI 304 |

| Inner surface - cylindric part | 2B / Ra≤0.8µm grinded | 2B / Ra≤0.8µm grinded | 2B / Ra≤0.8µm grinded | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished |

| Inner surface - conical part | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished | 2C / Ra≤0.5µm polished |

| Outer surface | 2B grinded | 2B grinded | 2B grinded | 2B grinded | 2B grinded | 2B grinded |

| External sheets - joints | riveted / welded | riveted / welded | riveted / welded | all welded | all welded | all welded |

| Peak angle of the cone | 60° | 60° | 60° | 60° | 60° | 60° |

| PUR insulation | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| CT / CJ1 Cooling jacket on the cylinder : input/output G-thread | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" | 1 zone > 60% surface IN-OUT G1/2″-G3/4" |

| CT / CJ1 Cooling jacket on the cone : input/output G-thread | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" | 1 zone > 50% surface IN-OUT G1/2″-G3/4" |

| Transport hinges | N/A | N/A | N/A | N/A | N/A | N/A |

| Manhole with door / at the top | 420x340mm / opening inward | PED 420x340mm / opening inward | PED 420x340mm / opening inward | 412x315mm / opening outward | PED 412x315mm / opening outward | PED 412x315mm / opening outward |

| Manhole with door / at the side | optional / 440x310mm / opening inward | optional / PED 440x310mm / opening inward | optional / PED 440x310mm / opening inward | optional / 440x310mm / opening inward | optional / PED 440x310mm / opening inward | optional / PED 440x310mm / opening inward |

| Ovepressure/vacuum safety valve | Max 0.5 / 0.2 bar | Max 3.2 / 0.2 bar | Max 3.2 / 0.2 bar | Max 0.5 / 0.2 bar | Max 3.2 / 0.2 bar | Max 3.2 / 0.2 bar |

| Pure-beverage output armature | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC |

| Tank filling/emptying armature | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC | DN40 DC/TC |

| Sampling valve | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit | DN10 sanit |

| CIP and manometer connection fittings | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC | DN25DC/TC |

| Venting valve | yes | yes | yes | yes | yes | yes |

| Sanitizing ball-shower | static | static | static | rotational | rotational | rotational |

| Fermentation apparatus with the pressure adjusting valve and air lock, sanitizable | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC | DN32 DC/TC |

| Manometer with glycerine | yes | yes | yes | yes | yes | yes |

| Filling level indicator | yes | yes | yes | yes | yes | yes |

| Thermosensor socket | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 | 1 pc DN9 |

| Ladder hinges | 2 pcs | 2 pcs | 2 pcs | 2 pcs | 2 pcs | 2 pcs |

| Adjustable feet with rubber | 4 pcs | 4 pcs | 4 pcs | 4 pcs | 4 pcs | 4 pcs |

| Type label with the tank parameters | yes | yes | yes | yes | yes | yes |

| Minimum operating temperature | -15 °C | -15 °C | -15 °C | -15 °C | -15 °C | -15 °C |

| Maximum operating temperature | +80 °C | +80 °C | +80 °C | +80 °C | +80 °C | +80 °C |

| Guaranteed number of pressure cycles (for max. pressure) | 500 | 500 | 500 | 500 | 500 | 500 |

| Standard warranty | 2 years | 2 years | 2 years | 3 years | 3 years | 3 years |

Equipment optional - surcharges | SQ / 0.5 bar | SQ / 1.5 bar | SQ / 3.0 bar | HQ / 0.5 bar | HQ / 1.5 bar | HQ / 3.0 bar |

| Manhole with door / at the top / opening inwards | in price | in price | in price | € 569 | € 569 | € 569 |

| Manhole with door / at the top / opening outwards | € 623 | € 623 | € 623 | in price | in price | in price |

| Manhole with door / at the top / with the sight glass / opening outwards | € 1326 | € 1326 | € 1326 | € 1326 | € 1326 | € 1326 |

| Manhole with door / at the side / opening inwards | in price | in price | in price | in price | in price | in price |

| Side universal connector for hops extractor, usable also for the carbonization, filtration, flotation etc. | € 124 | € 124 | € 124 | € 124 | € 124 | € 124 |

| Upper special armature for the hops extractor, | € 247 | € 247 | € 247 | € 247 | € 247 | € 247 |

| Carbonization stone | € 462 | € 462 | € 462 | € 462 | € 462 | € 462 |

| Sanitizing ball-shower - rotational | € 119 | € 119 | € 119 | in price | in price | in price |

| Adjustable pure-beverage output armature without the sight glass | N/A | N/A | N/A | N/A | N/A | N/A |

| Sight glass on the adjustable pure-beverage output armature | N/A | N/A | N/A | N/A | N/A | N/A |

| Scale on the pressure adjusting valve (bar) | € 49 | € 49 | € 49 | € 49 | € 49 | € 49 |

| Scale on the fill level indicator (mm) | € 247 | € 247 | € 247 | € 247 | € 247 | € 247 |

| Temperature measuring and control system | see a pricelist | see a pricelist | see a pricelist | see a pricelist | see a pricelist | see a pricelist |

| Foam compensator for the sampling valve | € 110 | € 110 | € 110 | € 110 | € 110 | € 110 |

| Ladder | € 413 | € 413 | € 413 | € 413 | € 413 | € 413 |

| Stirrer + electric equipment (maximal density 1200kg/m3) | € 8964 | € 8964 | € 8964 | € 8964 | € 8964 | € 8964 |

| Speed regulation for the stirrer (frequency converter) | € 996 | € 996 | € 996 | € 996 | € 996 | € 996 |

| Stirrer shaft seal 3bar | € 807 | € 807 | € 807 | € 807 | ||

| Non-standard dimensions of the tank | 10% and more | 10% and more | 10% and more | 10% and more | 10% and more | 10% and more |

| Customized equipment of no-PED tank (work on drawings) | € 237 | € 237 | € 237 | € 237 | € 237 | € 237 |

| Customized equipment of PED tank (work on drawings) | € 237 | € 237 | € 237 | € 237 | € 237 | € 237 |

| Transport pallet (Europe) | € 68 | € 68 | € 68 | € 68 | € 68 | € 68 |

| Transport pallet (Over sea) | € 268 | € 268 | € 268 | € 268 | € 268 | € 268 |

Legend :

N/A = Not available

DC = Dairy Coupling DIN 11851, TC = TriClamp DIN 32676 (type of the coupling depends on requirement of a customer)

PED = Certification for pressure vessels required in all EU countries – the EU Directive PED 2014/68/EU Pressure Equipment

The manufacturer reserves the right to change the parameters according to the current availability of materials and fittings. A customer will always receive our production drawing for approval before manufacturing the ordered tank.

Standard equipment – description

- Adjustable pressure valve for controlled fermentation – Overpressure setting mechanism with a glycerine manometer (standard range of adjustable pressure inside the tank : from 0 bar up to 3 bar ) – it allows two processes in the same tank : primary fermentation + secondary fermentation (maturation)

- Cooling channels – duplicators for circulating of coolant in the cooling jacket (one, two or more according type of the tank)

- PUR insulation – polyurethane insulation with thickness according to the size of the tank and the target environment (standard = 50mm )

- Outer jacket of the tank of stainless steel – Kind of the surface finishing (standard = grinded) choosed by customer.

- Guaranteed inner surface roughness : Ra < 0.8 μm or less (grinded surfaces) / Ra < 0.5 μm or less (polished surfaces)

- Service door (manhole) on the top cone or on cylinder part, according to customer requirements (SQ = open inside / HQ = open outside)

- Pure-beverage output armature with a butterfly valve for pure beverage (beer, wine, cider) output – the racking arm (optionally with variable height of a suction)

- Bottom filling/emptying armature – The inlet / outlet pipe with a butterfly valve for filling tank, discharging of yeast and draining of full content of the tank

- Sanitizing ball-shower – CIP sanitizing ball-shower (SQ = statical / HQ = rotational) – one or more pcs

- Sanitation pipe – – A multifunction pipe with a ball valve for connection of a shower head to the cleaning-sanitizing CIP station , the adjustable pressure valve with manometer, CO2 inlet

- Sample valve – cleanable and sanitizable sampling cock for collection product samples

- Safety valve – double-acting overpressure (standard = 3.2 bar) and vaccum protection (0.2 bar) safety valve – only pressure version of the tank

- Venting valve – Dedicated venting valve for safety draining of the tank and for accurate measuring of current pressure in the tank using manometer (it ensures properly function of the manometer when the shower ball shower is blocked with a foam)

- Thermometer socket – welded socket for inserting of thermosensor or thermometer (one or more according type of the tank)

- Manometer – It is included in the set of the adjustable pressure valve. Made of stainless steel, with glycerine inside.

- Filling level indicator – Sanitizable glass or plastic pipe for visualisation height level of the beverage product in the tank (SQ = fixed / HQ = removable)

- Transport hinges – steel welded hinges for safety transport of the tank with crane or forklift

- Adjustable feet – 3 or Four legs with rubber feet for accurate horizontal adjusting of the tank on an uneven floor

- Type label – the steel label with all parameters that are required from European Union for pressure vessels

- PED 2014/68/EU – certificate – the European certificate for the overpressure vessel + document for archiving history of the pressure vessel