Description

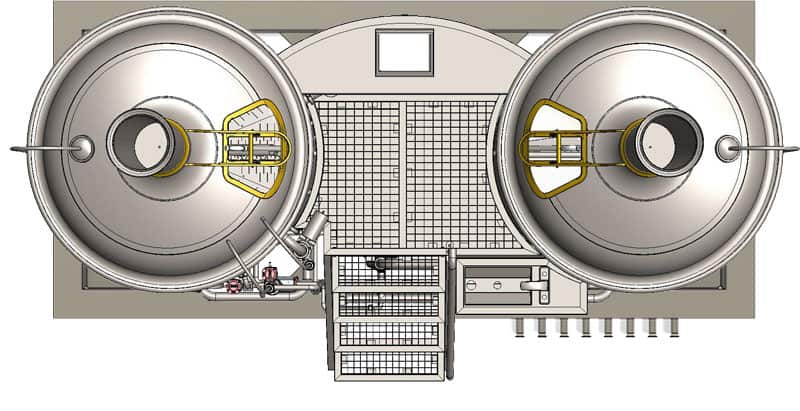

The singleblock brewhouse MODULO LITE-ME 1000 is a compact machine which includes all necessary equipment to produce 1180 liters of beer wort (for production approximately 1000 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The MODULO LITE-ME 1000 brewhouse is simplified machine with similar design like the brewhouse MODULO CLASSIC 1000 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the Modulo Lite-ME 1000 breweries but it can be use with other type breweries too.

Benefits of using brewhouse MODULO Lite-ME

- Easy production of wort without having years of operator´s experience

- Easy to achieve a stable quality of beer without the influence of variable quality of raw materials

- The malt mill is not needed as part of the brewery – safe costs, no problems with storage and preparation of malt grist

- Short learning time for workers in the production process of quality beer

- Possibility of almost complete automation of wort production, which in the production of beer from traditional materials is not economicaly possible

- Significant savings in labor, especially in the automatic version of the brewhouse

- Considerable energy savings up to 50% in the production of wort concentrate

- Reducing the volume of solid waste production by up to 90% – there are no malted grains

- Lower purchase price of microbrewery

- Faster return on investment

The singleblock brewhouse MODULO LITE-ME 1000 is a compact machine which includes all necessary equipment to produce 1180 liters of beer wort from beer concentrates in one batch. It is two-vessels brewhouse. This we have achieved full functionality brewing while we retained the traditional design of the Czech type brewhouse which is ideal for producing of world-famous Czech type beer. However, this brewhouse is fully capable for manufacturing all types of beer, which are offered beer concentrates for.

The brewhouse MODULO LITE-ME 1000 includes in standard :

- mashing tank – kettel for boiling

- whirlpool – for separation of hop dregs from wort

- laboratory sink

- control panel

- platform with steps

- all pipes and wires connections

- all mechanically and automatically controlled valves and armatures

- electric switchboard cabinet

- control panel

- main frame for easy transportation

Options and properties

Two raw materials for production of beer wort :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

Four production capacities of the brewhouse :

- 1180 liters of beer wort per day – one batch within 12 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 2360 liters of beer wort per day – two batches within 24 hours – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 3540 liters of beer wort per day – three batches within 24 hours – source raw materials are malt extract, hops, drinking water and brewer’s yeast

- 4720 liters of beer wort per day – four batches within 24 hours – source raw materials are malt extract, hops, drinking water and brewer’s yeast

Two available heating systems :

- EH : Electrical heating version – The heating of the kettle is performed using an integrated electric heating elements and the heat transfer system using an oil vat that are included in the price of the machine.

- SH : Steam heating version – The heating of the kettle is performed using an external hot steam generator that is not included in the price of the machine.

Special functions :

- CIP function – the special mode ensures cleaning, sanitization and sterilization of the brewhouse, wort pipes and optionally also other devices in the brewery

Technical specification

Wort kettle

- Usable capacity 2 036 l

- Dimensions Ø 1 415 mm, height 1 500 mm

- Heating bottom area 1.13 m2

- Mixing wort using the centrifugal pump

- Lighting 12V 35W

- 2x Sanitary rotating shower DN 20

- Steamer DN 100, 3x spraying device

- Insulation 50 mm plasticized cotton,

- external jacketing copper 1 mm (only for CD – Copper Design version)

- Top cover in copper + steamer imitation DN 200 (only for CD – Copper Design version)

- Measuring rod with ČMI-cz certification/directive 71/316/EEC

- Only the steam heating version includes

- Steam jacketing area 0.56 m2

- Steam valve ASCOjucomatik DN 20

- Steam condensate discharge DN 20

- Only the electric heating version includes

- Set of electric heating elements

Whirlpool tank

- Usable capacity 1 086 l

- Dimensions Ø 1 415 mm, height 800 mm

- Filtration bottom 6 segments with 12% permeability

- Nozzles for rinsing under wire 3 pc

- Lighting 12V 35W

- Mechanical temperature indicator 0-120ºC stainless steel

- 2x Sanitary rotating shower DN 20

- Three-way setting valve with sight glass DN 50

- Tangential nozzle DN 20

- Level indicator DN 20

- Fermenting valve 2x DN 25

- Insulation 40 mm plasticized cotton,

- external jacketing copper 1 mm (only for CD – Copper Design version)

- Top cover in copper + steamer imitation DN 150 (only for CD design version)

Piping, armatures

- Primary line DN 50, 5x flap valve DN 50

- Drain line DN 50, 3x flap valve DN 50

- Sanitary line DN 32, 4x valve DN 32

- Water supply and additional lines DN 32, 5x valve DN 32

- Beer wort filter 2000l/h/DN 80

- Universal centrifugal pump DWO 150 Ebara

- Input power 1.5 W

- H max. 2.2 bar

- pump controlled by frequency converter Fronic 1.5 kW

Electric installation

- Main switch 3x25A with central stop button

- Motor starter 3x 2.5-4A

- 1x Frequency converter Fronic mini 1.5 kW

- 1x Frequency converter Fronic mini 0.75 kW

- Digital temperature regulator of mash kettle Dixel XR20D

- Digital regulator of beer wort output temperature Dixel XR20D

- Circuit breaker 6A 230V

- Circuit breaker 10A 230V

- Circuit breaker 4A 230V

- Plastic DIN switchboard, 36 modules

- Wiring

- 5x 1,5 18 m

- 5x 2.5 10 m

- 3x 1 48 m

Dimensions and weight

- Weight 1 370 kg

- Basic size minimum height 3 000 mm

- Width 4 100 mm

- Depth 2 100 mm

This boiling equipment is mounted in a rigid frame made of 1.4301, 8 pc adjustable supports installed in its bottom part.

Connections:

- Beer wort discharge DN 25

- Cold water supply DN 25

- Hot water supply DN 25

- Drain line DN 50

- Electro 5x 2,5 6000 W

Auxiliaries:

- Wash basin with combined lever taps assembly

- Cooling device for samples

- Flow meter DN 25 of water supply

- Water filter

- Combined water taps assembly with digital indication of temperatures

- Steps to service bridge 750*730*585 mm

Transport

This equipment is usually shipped in assembled state with exception for copper covers, steamer for steam condensation, steps of service bridge and electric switchboard.

Brewery sets equipped with the Modulo Lite-ME 1000 brewhouse :

Breweries MODULO LITE-ME 1001

– Typical kits of modular breweries MODULO with the brewhouse Breworx Lite-ME 1000 and fermenters with volume 1000 liters. Micro Breweries MODULO Lite-ME 1001 are simple brewery sets what customers assembly themself without our technician specialists.

Breweries MODULO LITE-ME 1002

– Typical kits of modular breweries MODULO with the brewhouse Breworx Lite-ME 1000 and fermenters with volume 2000 liters. Micro Breweries MODULO Lite-ME 1002 are simple brewery sets what customers assembly themself without our technician specialists.

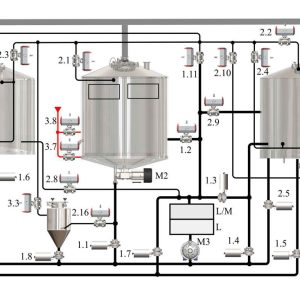

Scheme of the Modulo Lite-ME microbrewery

I. Basic configuration :

II. Expanded configuration :

Optional accessories :

Electric steam-generator ESG-65MWT

The compact and automatic electric hot steam-generator ESG-65MWT with power from 25 kW to 50 kW (from 33 to 65 kg of hot steam per hour), steam pressure from 1 to 6 bar. The Modulo ESG system includes water treatment set, electric switchboard cabinet and all pipe&electric connections. Electric and automatic steam-generator, available power from 25 kW to 50 kW. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 6 bar.

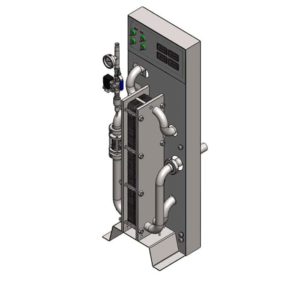

WCASB-1000 – Block wort cooler-aerator 1000 l/h

Two-stage tabular heat exchanger intended for cooling of the wort from 98 ° C to 7 ° C using 15 ° C and 1 ° C water before starting of beer fermentation process. The plate heat exchanger and the aeration candle are attached to a stainless steel panel which is equipped with temperature sensors and digital displays.

WCU-1500 Modulo wort cooling unit 1500 liters

Special module, which integrates the heat exchanger unit for cooling of the wort, stone for aeration of the wort and the storage ice water tank 1500 liters with an independent cooling unit on a shared frame with the wheels and adjustable legs. Ice water for cooling of the wort is preprared in a stainless steel insulated tank and is ready for use.

WCUHWT-1500 Modulo wort cooling & water management unit 2×1500 liters

Special module, which integrates the unit for cooling of the wort consists of heat exchanger, ice water tank 1500 liters and independent water cooler for cooling of the wort , stone for aeration of the wort and the hot water tank 1500 liters on a shared frame with the wheels and adjustable legs. Hot water that we receive from cooling of the wort in the first stage of cooling (in the plate heat exchanger integrated in the brewhouse) is collected in a stainless steel insulated tank and is ready for use. Most often brewers use the hot water for preparing the next batch of brewing, but also when washing and sanitizing other equipment in microbrewery. This recuperation of waste heat from wort cooling contributes to substantial savings in production costs.

FUIC-CHP2C-2x1000CCT Compact fermentation unit 2×1000/1170 liters

The compact unit for the beer fermentation and maturation process with integrated cooling BREWORX MODULO FUIC-CHP1C-2x1000CCT is an independent mobile equipment with two fermenters type of cylindrical-conical tanks 2x 1000 liters (total capacity 2×1170 liters) The FUIC unit includes everything what is necessary to the main fermentation of beer, to the beer maturation under pressure, to an isobaric filling beer into kegs or bottles or to serving beer into drink glasses directly from the fermenters that are included in this unit.

Alternatives :

CFSOT1-10xCCT1000C Complete set for the fermentation of beer with 10x CCT-1000C, on-tank control

Complete set for the fermentation and maturation of beer. This set includes all equipment necessary for professional production of beer using the fermentation and maturation of wort produced before by the brewhouse. This set is also designed for production of cider from fruit or carbonized wine. Assembling of the set is very easy. The installation does not require any professional workers – there is needed only adequate handling equipment for moving and installation of heavy cylindrical-conical fermenters on place after delivering of the set. All wires, temperature measuring and regulation equipment (exclude covered central control cabinet and cooler) operate with safety voltage 24V, therefore they can be installed by customer using the installation manual. Therefore the price of the set does not include the installation work.

Alternatives : CFS – Complete fermentation sets

CFSOT1-10xCCT2000C Complete set for the fermentation of beer with 10x CCT-2000C, on-tank control

Complete set for the fermentation and maturation of beer. This set includes all equipment necessary for professional production of beer using the fermentation and maturation of wort produced before by the brewhouse. This set is also designed for production of cider from fruit or carbonized wine. Assembling of the set is very easy. The installation does not require any professional workers – there is needed only adequate handling equipment for moving and installation of heavy cylindrical-conical fermenters on place after delivering of the set. All wires, temperature measuring and regulation equipment (exclude covered central control cabinet and cooler) operate with safety voltage 24V, therefore they can be installed by customer using the installation manual. Therefore the price of the set does not include the installation work.

Alternatives : CFS – Complete fermentation sets

All set of the brewer´s tools and accessories for small brewery

Sacharimeter brewery + attestation 0 – 6° 1 pc, Sacharimeter brewery + attestation 4°-10° 1 pc, Sacharimeter brewery + attestation 10°– 20° 1 pc, Alcoholometer + attestation(only in ČR) 1 pc, Graduated cylinder 1 pc, Pump for ice water (spare part) 1 pc, Pump for passing beer EBARA CDXM 70/7 1 pc, Beer hose EPDM 4 pcs, Reducion valve CO2 1 pc, Hose and connector CO2 50 m, Hose and connector distribution beer 150 m, Stainless step ladder at CKT/SP 1 pc, Holder of saccharimeter, design oak/stainless 1 pc, Cooling of samples (only with stainless brewhouse) 1 pc, Pump sight glass with detour DN 25 or 32 1 pc, Gauge rod of mash kettle 1 pc, Yeast collector (only with fermentation tank) 1 pc, Beer hose coupling DN 25 or 32 3 pcs, Handling and fixing equipment.

Optional services :

BTS – Brewer´s training services for starting of a new microbrewery and also for already operating microbreweries – all courses are teached by certificated Czech brewer in Czechia or in the country of the customer.

BTS – Brewer´s training services for starting of a new microbrewery and also for already operating microbreweries – all courses are teached by certificated Czech brewer in Czechia or in the country of the customer.

Reviews

There are no reviews yet.