Description

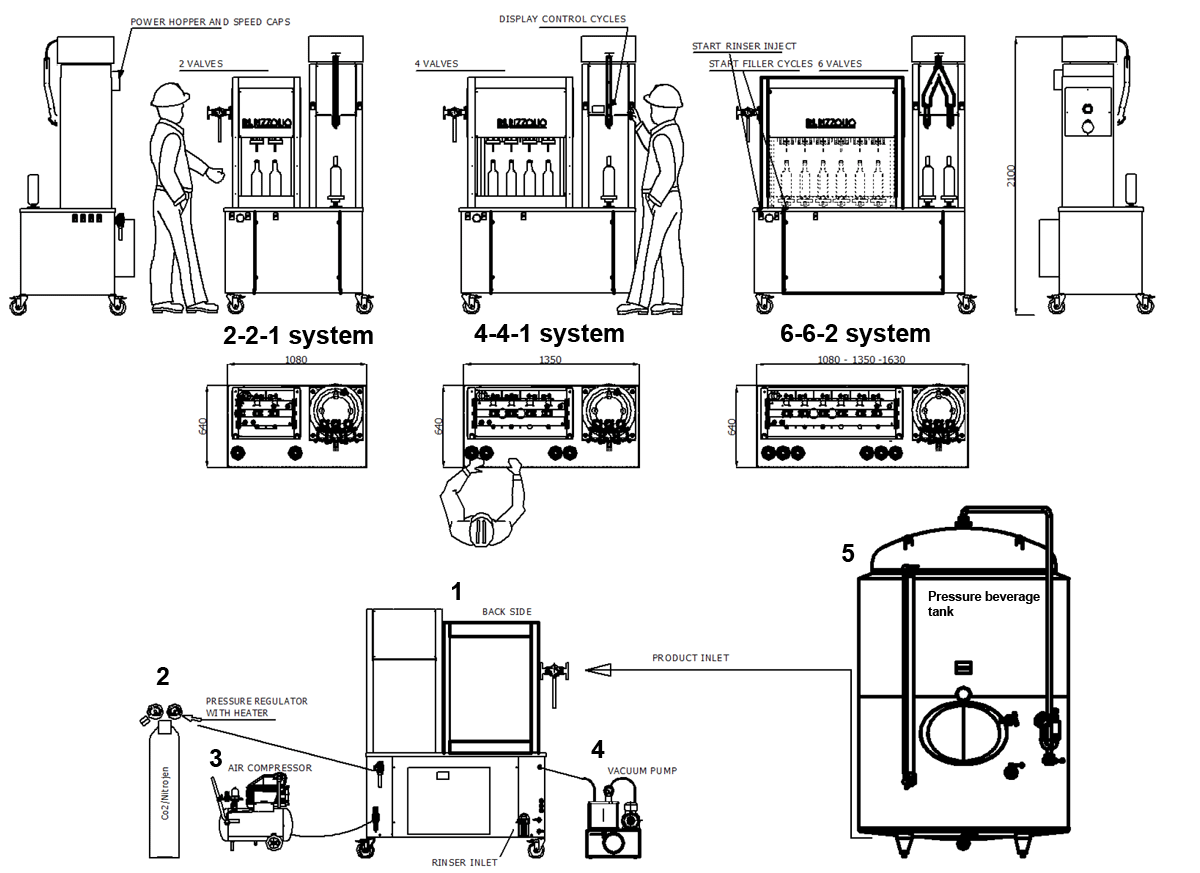

Compact semi-automatic machine to filling bottles with carbonated beverages

includes four integrated machines :

-

rinsing of bottles … six bottle positions

-

isobaric filling beverage into bottles … six bottle positions

-

pneumatic closure of bottles with champagne natural cork or straight natural cork … one bottle position

-

wire cork closure … one bottle position

The semiautomatic machine includes in a single compact machine the functions of bottle rinsing, bottle filling, closing bottles by natural cork stopper and fixing of cork on the bottle by steel wires. It is suitable for the filling beverages into glass bottles with a diameter ranging from 55 mm to 115 mm and a height from 190 mm up to 375 mm.The isobaric filling machine is suitable for the bottling every kinds of effervescent beverages and carbonated non-alcoholic beverages (only with an optional equipment on demand)

Production speed : 280-400 bph (depending on operator’s ability, bottle size & filling temperature)

Product : carbonated beverages (sparkling wine, cider, beer …)

Bottles : glass bottles (from 190 to 375 mm height / from 55 to 115 mm diameter )

How the machine works

This machine is suitable to filling of carbonized alcoholic beverages into bottles. It is suitable for beverages obtained according to the Charmat method (fermentation of the wine in tanks), mainly products such as alcoholic cider, beer etc.

According to the product to be bottled, the machine can be equipped with the pre-evacuation equipment (to create of the vacuum in the bottle before the filling) … see Options.

After adding fittings and electro-valves to every single valve, the pre-evacuation is obtained the same pressure inside the bottle like in the filling valve, after that a vacuum pump sucks the air contained in the bottle.

Then, using the valve opening throttle, the CO2 is injected into the bottle so that both pressures go in compensation. Then the filling of the product starts.

Option recommended for beer, cider and for all products with the same requirements.

The isobaric filling process works fully automatically so the operator needs to perform only the loading and unloading of the bottles on / from the holding cups.

The filling valve is designed to avoid the foaming of the product, it guarantees the maximum fluidity during the entire fillinf process using a completely automatic leveling system.

The machine is equipped with four filling valves that enable filling of two bottles at a time. So, while the machine performs the filling of two bottles on one side, on the other side other two bottles can be unloaded and loaded by human operator.

The filler is equipped with no-return valve G 1” made of AISI 316 stainless steel (it prevents the return of the beverage into the tank and its consequent foaming).

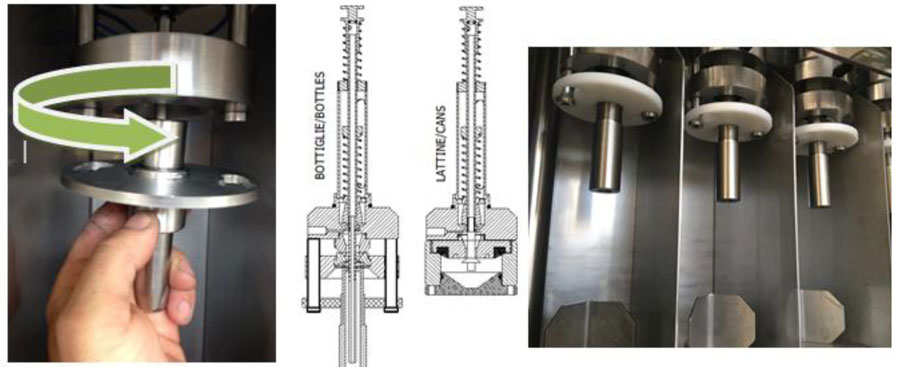

Pneumatic cap head for the cork stoppers is made of stainless steel and equipped with a safety device. It is designed to closing bottles by natural champagne corks and is suitable for small or medium volumes of production. By request and with the suitable adaptation kit (see Options) it is possible to apply natural wine corks with the same head.

The closing system of the corking unit consists of four hardened steel jaws ground. The jaws can be easily demounted for cleaning and sterilization. It can work with corks with maximal diameter 30mm and maximal height 52 mm. After the bottle is put on the holding cup, the machine is operated through safety two-hand control and stops at the end of every cycle. The distribution of the corks into the closing head is automatic. The corks are firstly loaded manually into a steel tube that serve like stocker.

The machine to fixing corks by wire is suitable for the application of the wire-hoods and their closure. It is possible to apply the following types of wire-hoods : four-leg wire-hood with cap and four-leg wire-hood without cap. Its operation system is mechanical and pneumatic; the wire-hoods are first manually loaded on the steel stick which is then taken out (capacity of the stick is 20 wire-hoods).

The wire-hoods are distributed in automatic. The bottle is positioned on a suitable support and the cycle is started through a two-hand control.

When the cycle is completed the machine stops and no part remains in movement.

The hour production capacities of the various units are different.

The filling part can reach a production capacity of 280/400 bottles per hour (with optimal conditions of the product which is under constant pressure and is pushed into the filling tank from the beverage tank under pressure or through a membrane pump connected to the electrovalves of the machine).

The cork applicator and wire applicator can reach a production capacity up to 800 bottles per hour.

Both data depend on the ability of the operator.

The front safety panel prevents any accident due to breakages.

By request the machine can be supplied in version with wheels.

By request the machine is available also in the version consisting of filling part and cap applicator for crown corks (for effervescent and still drinks to be packaged with crown caps).

First section : rinse of bottles (six positions)

Second section : six filling valves (diameter: 15mm)

Third section : one head to closing the bottle neck by a cork stopper – the cork applicator

Fourth section: one head for fixation of the cork stopper on the bottle using a metallic wire – the wire lock applicator

Constructive characteristics

- The machine is completely manufactured of stainless steel, a material with high compatibility with food products and easy to be cleaned.

- Some parts are made of plastic material or rubber. Also these materials are certified for food contact. The plastic cover panels at the entrance to the working zone are of shock-resistant or high-resistance transparent material, which allows the operator monitoring of the working process.

- All components of the machine can be easily inspected to facilitate the cleaning and maintenance operations so guaranteeing a long life.

The delivery of the machine includes :

- 1 set of sizing parts for one format of glass bottles (Additional formats will be calculated separately – see Options)

- 1 operation and maintenance manual. We will supply the standard documentation in Italian, English, French, or Spanish. Other translations and/or customizations are not included in the price and will be offered separately.

- Safety guards in compliance to the EC regulations

- Set of first intervention wrenches

- Certification of conformity is compliant to the EC regulations

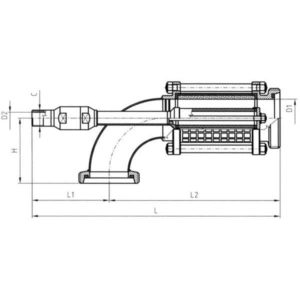

Technical data

- Capacity : Rinsing / filling : 280/400 bottles/hr

- Capacity : Corker / wire hooding : 800 bottles/hr

- Type of bottle: glass

- H from 190 to 375 mm. +/- 5

- D from 55 to 115 mm. +/- 2

- Main electric supply: 380V 50Hz (modifications by request)

- Auxiliary felectric supply: 24V 50Hz (modifications by request)

- Total power installed: 1.75 Kw

- Weight: 550 Kg.

Filling machine

- Type of product: effervescent/still drinks

- Air feed pressure : 6bar

- Air consumption at 6bars : 0.30 L/sec.

- Isobaric filling valves: 4pcs

Cork applicator

- Type of cork

- (natural champagne/natural straight cork):

- maximal height 52 mm

- maximal diameter 31 mm

- Cork feed tube, capacity 10/15 pcs of standard natural corks

- Manual revolver (for unidirectional and bidirectional corks), capacity 160pcs: option

- Mechanical hopper (for bidirectional corks), capacity 1000 pcs: option

Wire lock applicator

- Type of wire locks:

- 4-legs wire lock with cap

- 4-legs wire lock without cap

- Air feed pressure : 6bar

- Air consumption at 6bars : 0.15 L/sec

- Wire lock rod, capacity 250 pcs of standard wire locks

- Manual revolver – capacity 900/1200 pcs: option

CBFSA-MB6611 consists of :

| DESCRIPTION | Quantity | EURO |

|---|---|---|

| CBFSA-MB6611 Compact semi-automatic machine : bottles rinser, filling, corking and wire-hooding | 1pc | Price on demand |

| OPTIONS | ||

| FOR RINSER (rinsing of bottles) | ||

| Beverage recycling kit including 5-liters stainless steel tank | 1set | Price on demand |

| FOR FILLER (isobaric filling beverage into bottles) | ||

| Pre evacuation of oxygen from the bottles with external tank | 1pc | Price on demand |

| Special dummy bottles with continuous flow CIP system for high level cleaning process and product return exhaust to your CIP unit | 1set | Price on demand |

| Additional tubes, for different levels of bottled beverages | 1set | Price on demand |

| Non return valve TRICLAMP 1″ | 1set | Price on demand |

| FOR CORKER (pneumatic closure of bottles with natural cork) | ||

| Manual cork loader, revolver-type, consisting of 20 tubes as cork stocks (capacity 160 pcs of corks), for unidirectional and bidirectional corks | 1set | Price on demand |

| Mechanical cork hopper (capacity 1000 pcs), exclusively for bidirectional corks | 1set | Price on demand |

| Kit for treatment of corks (for both natural corks – champagne and cylindrical corks) | 1set | Price on demand |

| FOR WIRE-HOODER (wire cork closure) | ||

| Manual wire loader, revolver-type, consisting of 9 sticks (capacity 900/1200 pcs of sticks), for wire-hoods | 1set | Price on demand |

| Additional capping head with rapid connection (with head connection device + 2 heads for wire-hood holding ) | 1set | Price on demand |

| Additional holding head for wire-hoods, unit price for each | 2pcs | Price on demand |

| TOTAL – (for EUROPE) | Price on demand | |

| OTHER RECOMMENDED ACCESSORIES AND SERVICES |

||

| PNEUMATIC PUMP INOX 304 with switch valve TRICLAMP 1 inch | 1set | Price on demand |

| PNEUMATIC PUMP INOX 316 with switch valve TRICLAMP 1 inch | 1set | Price on demand |

| Pipe connnections for the pump | 1set | Price on demand |

| Construction parts in contact with the product – Filler AISI 316 | 1set | Price on demand |

| SPECIAL VOLTAGE Including UL conformity electronic parts | 1set | Price on demand |

| Protective door with automatic operation cycle to closure | 1set | Price on demand |

| CO² injection into the bottle: before closing of the bottles | 1set | Price on demand |

| PACKING COST WOODEN CRATE SEA PROTECTION | 1set | Price on demand |

| PACKING COST WOODEN CRATE | 1set | Price on demand |

| Bottles centering Slim or Standard | 4pcs | Price on demand |

| Manifold for CIP filling system | 1pc | Price on demand |

| Installation days except Hotel/dinner/lounch and travel expenses | Price on demand | |

| ROM Software recovery | Price on demand | |

| Complete set of replaceable seals for all 4 filling valves | Price on demand | |

| Shipping cost including packing | Price on demand | |

| Memory card backup for PLC programme | Price on demand | |

| Wooden crate packaging | Price on demand | |

| Delivery & insurance (only Europe) | Price on demand |

I. CIP setup – cleaning and sanitizing of the compact bottling machine

Description :

- Compact bottle filling machine

- Bottle with pressure carbon dioxide and reduction valve

- CIP station – we recommend use the machine CIP-52 or CIP-53

- CIP collector for chemical solutions (see optional equipment table)

- Hoses for connection between the CIP station and the compact bottle filling machine

II. Dummy bottles setup for CIP (in motion)

III. Dummy bottles – set for high pressure CIP operation (in motion)

Connections :

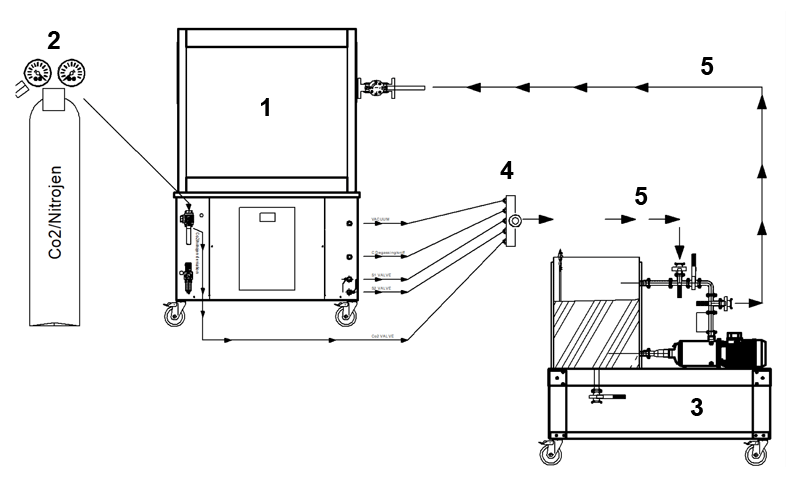

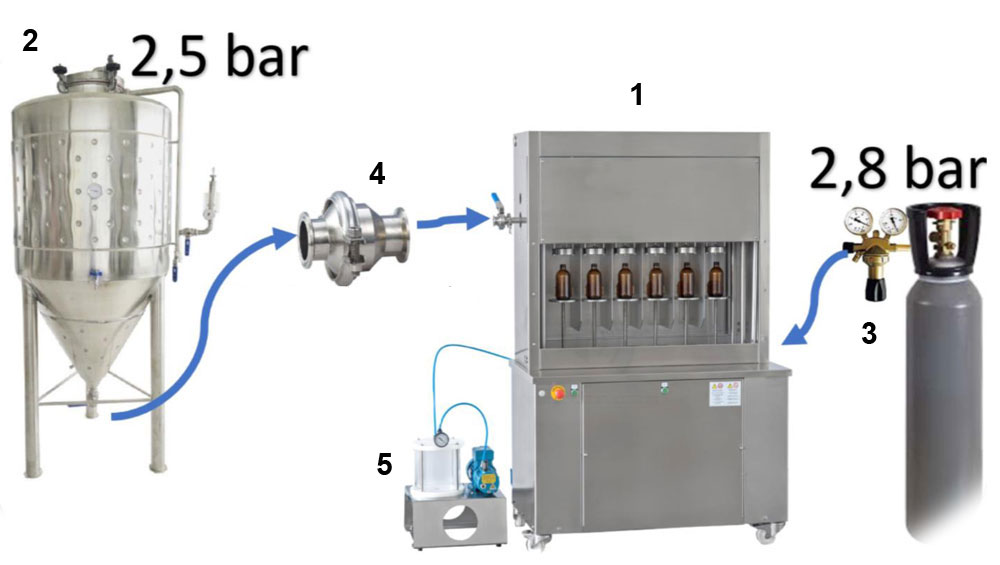

I. Filling carbonated beverages from a pressure tank

Description :

- BFSA-MB bottling machine

- Pressure bottle with carbon dioxide and reduction valve

- Air compressor (needed for powering the pneumatic valves and actuators)

- Vacuum pump (needed for pre-vacuation the bottles)

- Pressure tank with carbonated beverage

Description :

- BFSA-MB bottling machine

- Pressure tank with carbonated beverage

- Pressure bottle with carbon dioxide and reduction valve

- Non-return valve

- Vacuum pump

- Blue lines – pressure hoses

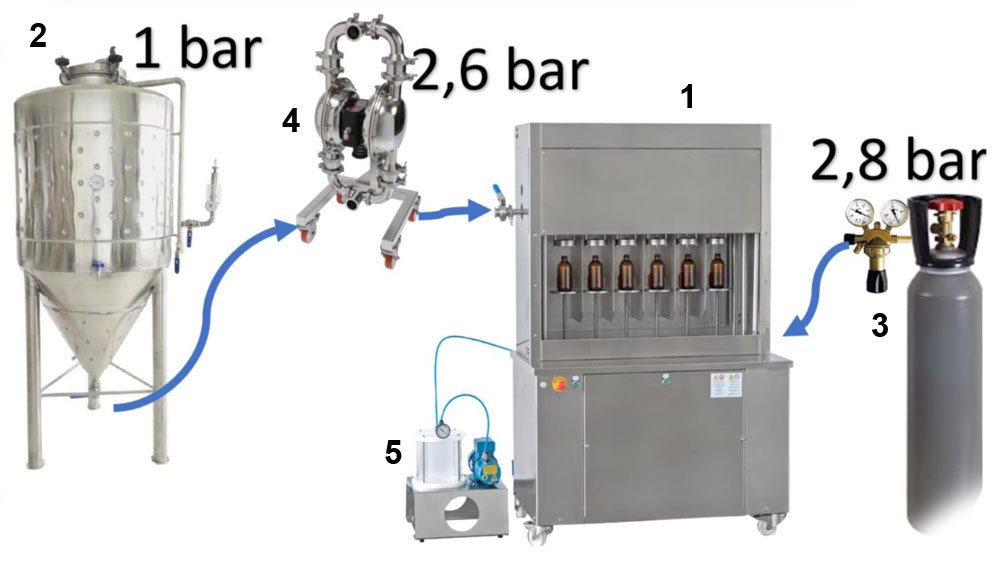

II. Filling non-carbonated beverages from a non-pressure tank

Description :

- BFSA-MB bottling machine

- Pressure tank with non-carbonated beverage

- Pressure bottle with carbon dioxide and reduction valve

- Pneumatic diagphragm pump

- Vacuum pump

- Blue lines – pressure hoses

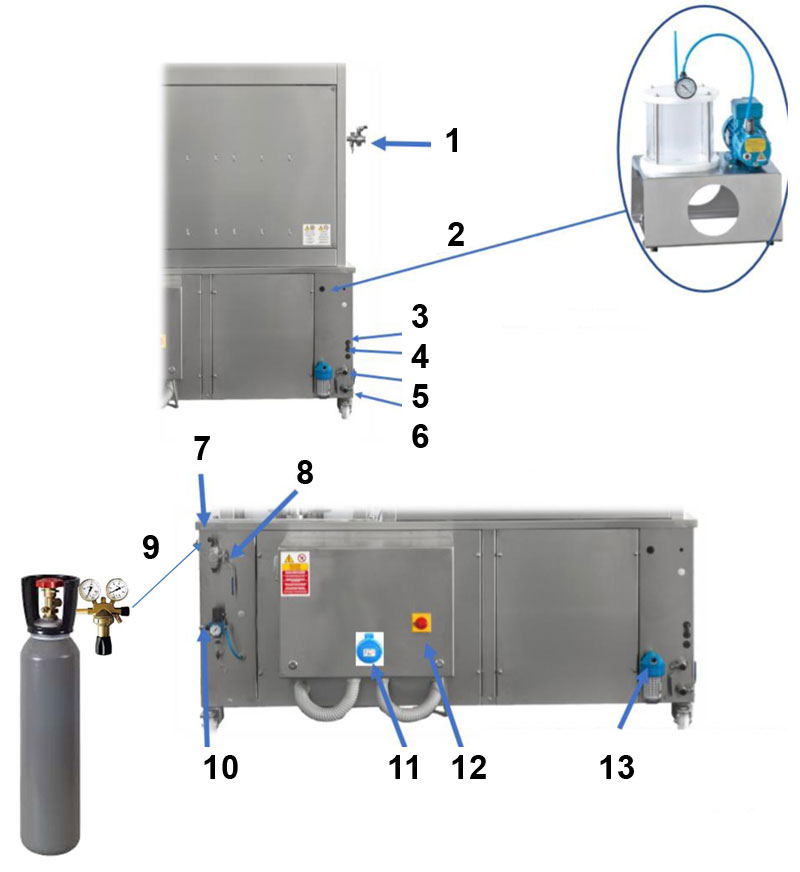

All connections and inputs :

Description :

- Beverage product inlet ( DIN 32676 “TriClamp” Ø 51 mm )

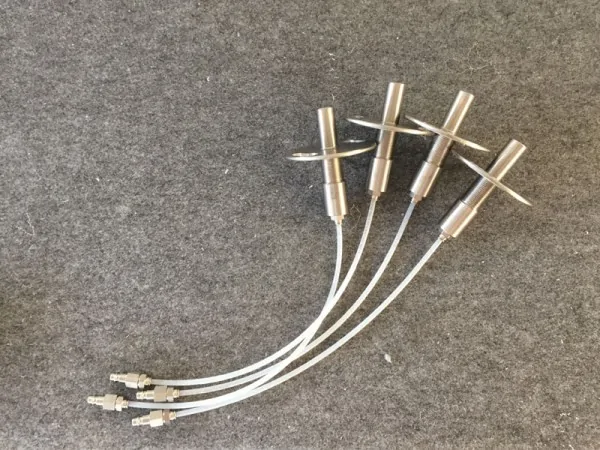

- Vacuum pump connection (beverage hose Ø 8 mm – John Guest couplers)

- CO2 exhaust for the bottle decompression (beverage hose Ø 8 mm – John Guest couplers)

- Water outlet for the rinsing cycle (beverage hose Ø 8 mm – John Guest couplers)

- Outlet CO2 – venting valve of the high level filling (beverage hose Ø 8 mm – John Guest couplers)

- Outlet CO2 – venting valve of the low level filling (beverage hose Ø 8 mm – John Guest couplers)

- Inlet CO2 or N2 from the pressure bottle under maximal pressure 5 bar (beverage hose Ø 8 mm – John Guest couplers)

- Water outlet (beverage hose Ø 8 mm – John Guest couplers)

- CO2 hose between the pressure bottle with the reduction valve and the bottling machine

- Inlet of compressed air min. 5 bar 120 L/min. (pressure hose Ø 10 mm – John Guest couplers)

- Vacuum pump electric socket – for removing oxygen from the bottles

- Power switch for the electric socket

- Water inlet – G 1/2 inch female hose connector (maximal pressure 4 bar)

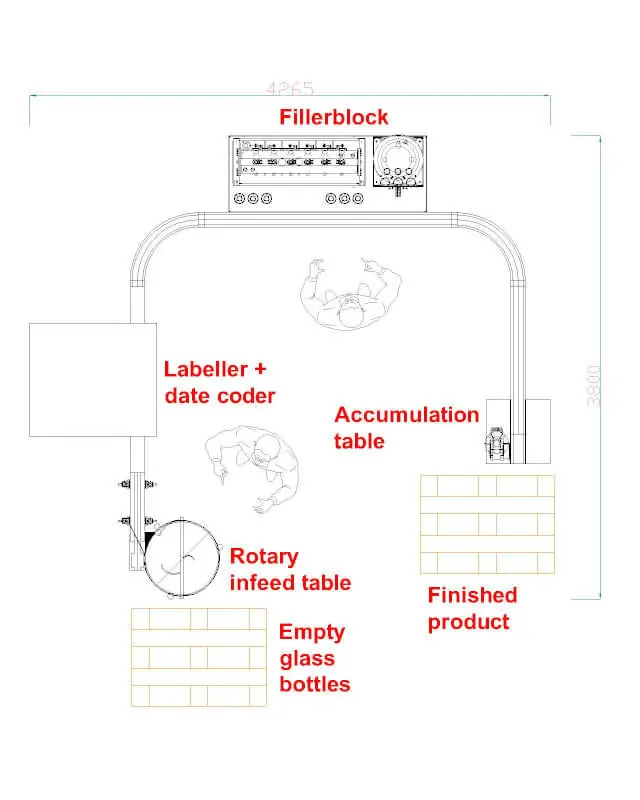

Example of the integration of the machine to exist bottling line

Semi-automatic control system :

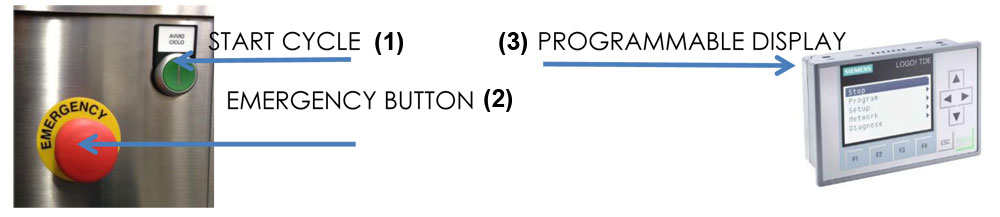

Description :

- Start of choosed cycle

- Emergency stop button

- Programmable unit with a display

Automatic cycles (see optional equipment table) facilitates all the operations of the bottle rinsing, filling steps and capping. You can choose different types of the filling process.

Available modes and their settings

I. Bottle rinsing mode :

- Injection timer – editable timing of the automatic valves

II. Bottle filling mode :

- Standard

- Single pre evacuation with CO2 injection timer adjustable

- Double pre evacuation with double CO2 injection timer adjustable

- CO2 purge for remove the oxygen in the PET bottles and cans before the capping cycle

- You can change the time of the pre-evacuation, time of CO2 injection, time of the degassing

III. Bottle capping mode :

- Time of the bottle capping operation is adjustable

IV. CIP mode :

- Opening all valves for the cleaning and sanitizing the machine using a CIP station

V. Degassing mode :

- Opening and closing the valves when decompressing according on timer setting in two or more steps.