Description

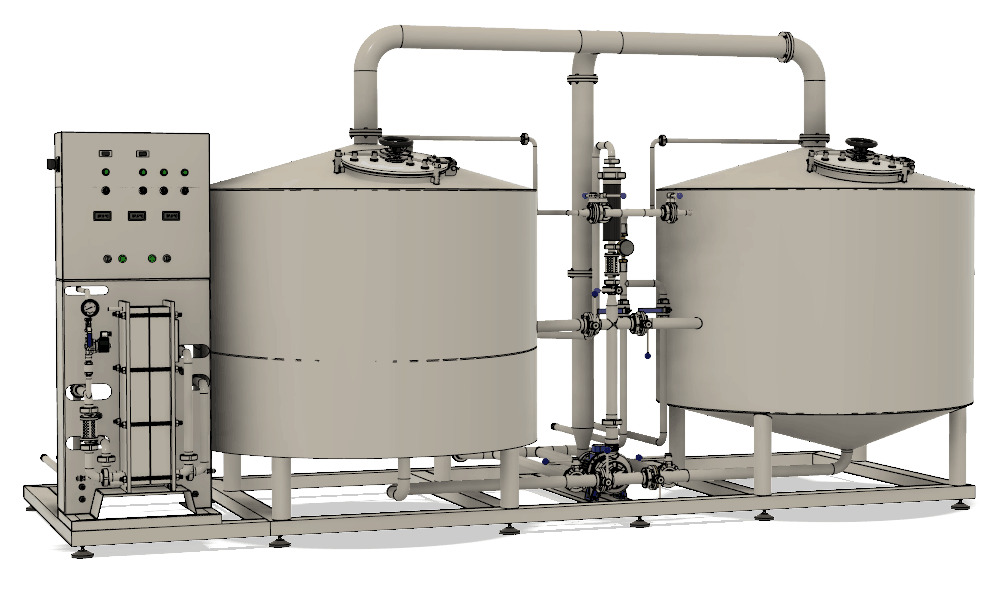

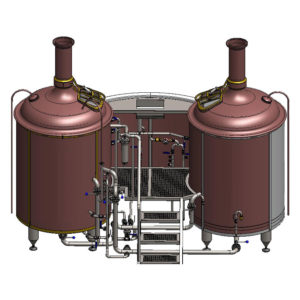

BREWORX LITE-ECO 1000 : Compact simplified brewhouse for big restaurants

The wort brew machine BREWORX LITE-ECO 1000 is a compact food machine which includes all necessary equipment to produce 1100 liters of wort (for production approximately 1000 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). The machine is not equipped with the filtering tank therefore it is not possible to produce wort from malt classic way. A simplified industrial design of the machine allows effective work during entire wort production process using simple step PLC controller for heating of the vessels. Transfer of heat from the electric heating spirals to inner jacket of the vessels ensures oil.

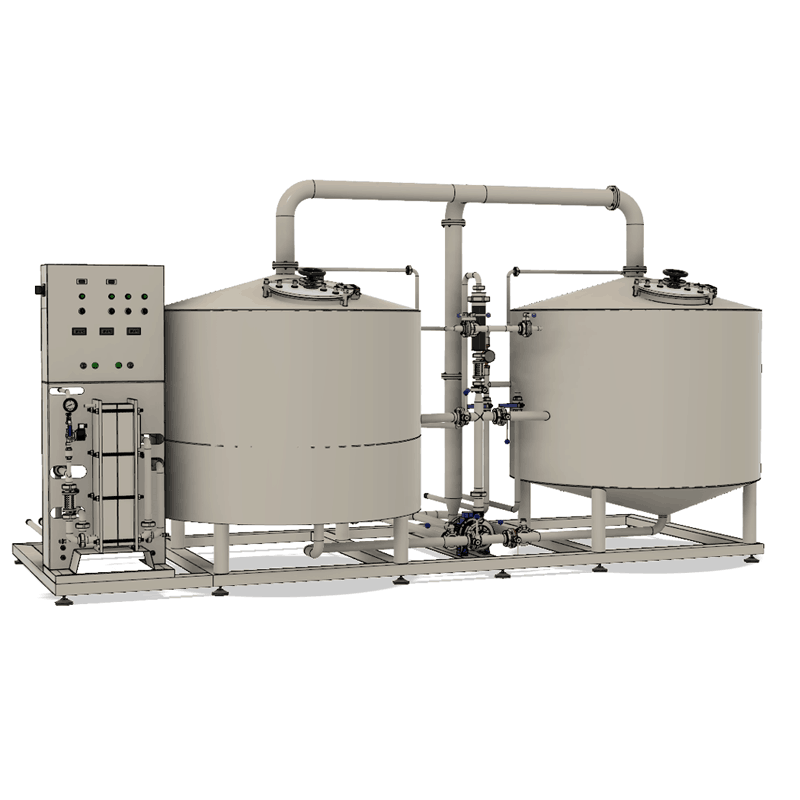

Breweries with the BREWORX Lite-ECO 1000 wort brew machine

This wort brew machine is a main equipment of the BREWORX Lite-ECO 1000 breweries, MODULO Lite-ECO 1000 breweries, but it can be use also with other type breweries too.

- See the recommended basic configurations : BREWORX Lite-ECO 1000 breweries

- See the recommended basic configurations : MODULO Lite-ME 1000 breweries

Benefits of the wort brew machine BREWORX Lite-ECO

- Easy production of wort from concentrates without many years of operator´s experience

- Easy to achieve a stable quality of beer without the influence of unstable quality of raw materials

- Mill of malt grains is not needed – malt is not used – saving costs, no problems with storage and preparation of malt grist

- Short learning time for operators in the production process of quality beer

- Significant savings in labor

- Considerable energy savings up to 50% in the production of wort from the concentrate

- Reducing the volume of solid waste in production by up to 90% – there are no malted grains in the beer production process

- No steam generator is needed

- The wort cooler and the wort aerator may be included in the compact system (optional accessories)

- Compact machine delivered with all components mounted on one steel frame does not require assembly work on the place

- Lower purchase price

- Faster return on investment

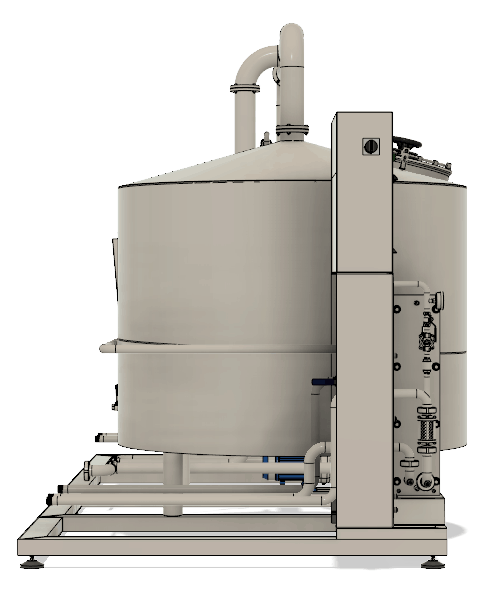

Fully equipped compact wort brew machine BREWORX LITE-ECO 1000 :

(The vapor condenser and the integrated wort cooler/aerator are optional parts that are not included in a basic price … )

The brewhouse wort machine is a food equipment for the production of wort (intermedia product in a beer production). A construction of the brewhouse allows the wort production using only malt concentrates or wort concentrates, hops and water. The production of wort from malt is not possible.

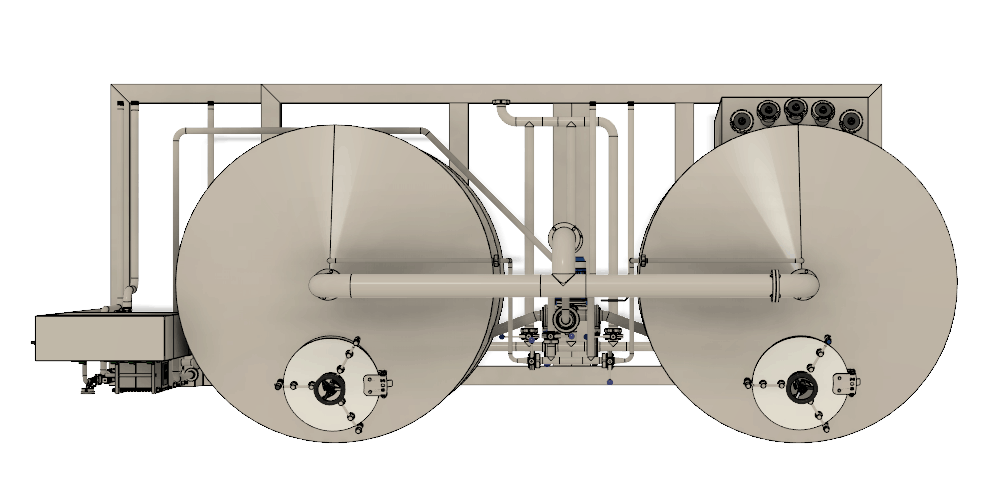

All components are firmly connected to a compact self-supporting frame.

The cooking set is transported in assembled state including all electric wiring and pipelines, valves, sensors and other equipment. Only several parts are dismounted to easy transport and they are simply and quickly assembled by customer on a place using our assembling instructions.

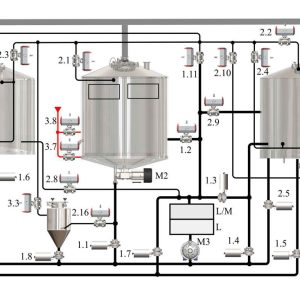

The BREWORX LITE-ECO 600 wort brew machine consists of the following components:

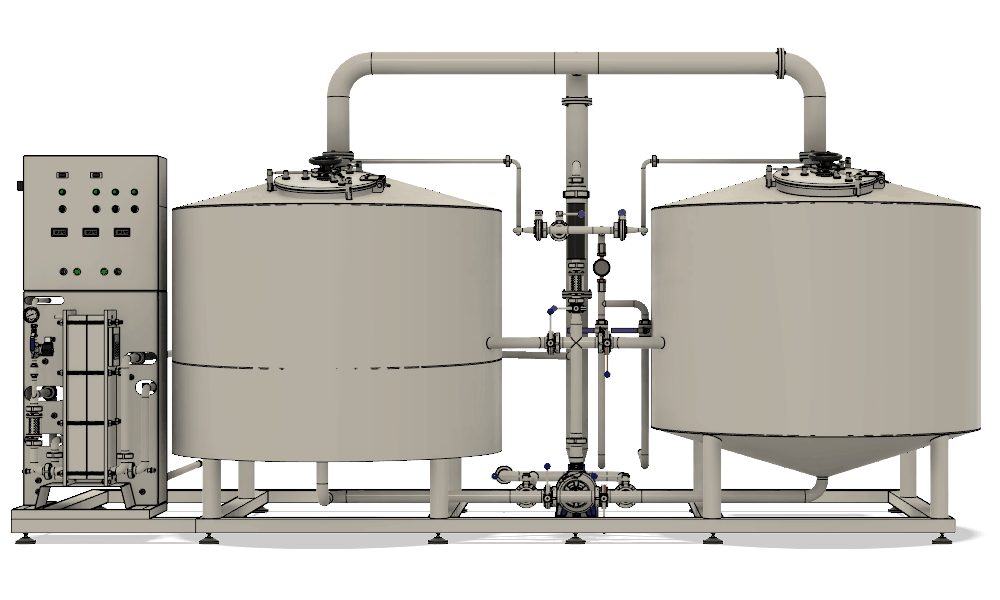

Functional tanks :

- Wort boiling tank – electricaly heated tank for boiling of wort (and mixing water with wort concentrates).

- Whirl tank – this tank is equipped with the tangential inlet for the final centrifugal separation of hop dregs from wort.

Basic equipment :

- Control panel (manual control system – buttons and simple regulators, automatic control system – touch display)

- Oil heating system with electric spiral heaters 5x 6kW

- All pipes and wires connections (cold water input, glycol input, oil filling and draining, wort output, sewage output, electric supply cable with 3-phase connector)

- Centrifugal pump

- All mechanically and automatically controlled valves and armatures

- Electric switchboard cabinet

- Control computer (only version with the automatic control system)

- Main frame for easy transport of pre-assembled machine

Optional equipment (for surcharge) :

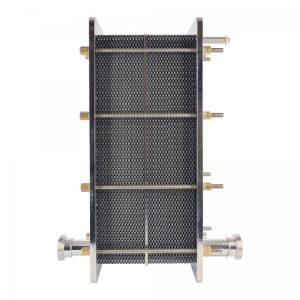

- Compact plate heat exchanger – the set includes both the wort cooler and the integrated wort aerator

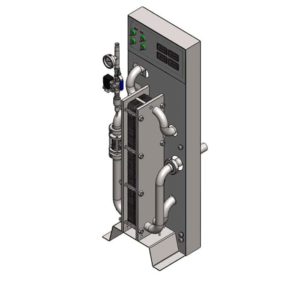

- Condenser of vapors from the wort brewing process with the stainless steel ventilator and regulation system

- Special centrifugal pump EBARA DWO 150 designed for high temperatures up to 115°C with the cooling system of the shaft seal with very long lifetime and liquid anti-leak protection

- Increasing heating power by 6kw – the special heating elments

- Electric switchboard with a case made of stainless steel

- Induction flowmeter (only for the automatic versions)

Progressive wort heating system

Progressive wort heating system

The wort brew machine BREWORX LITE-ECO 1000 is equipped with very effective heating system. This system consists of the electric heating spirals, oil chamber and the pipe turbine without any rotable parts. This progressive heating system ensures very quick transfer oh heat to wort with minimal loses and quick circulation of wort inside the wort boiling tank. This speeds the wort brewing process and ensures production more batches of wort per day. Absention of rotable parts like stirrer minimizes the amount of system failures and increases the reliability of the entire system. This design of the brewhouse increases the efficiency of sanitation of containers and the heating system and reduces the amount of sanitizing solutions and water consumption during the cleaning process.

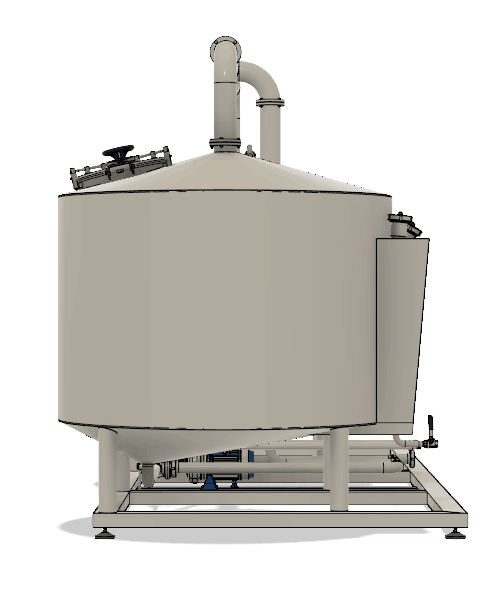

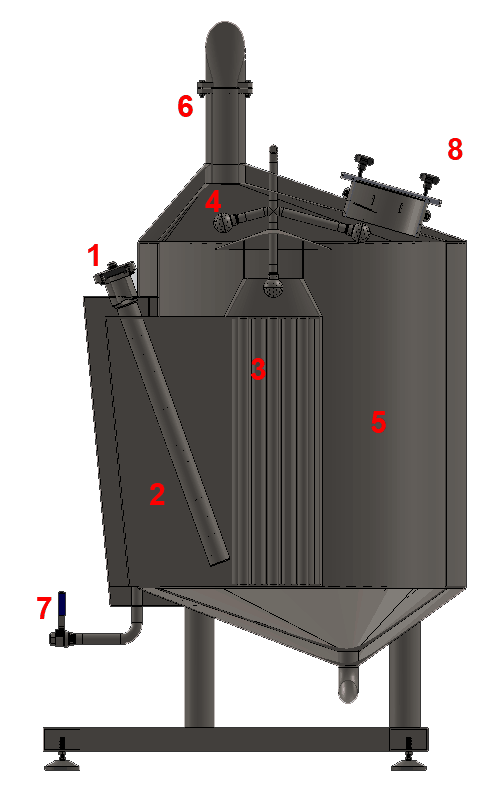

Description of the wort boiling tank :

- Electric spiral heating elements

- Oil chamber – thermotransfer system

- Oil-pipe system of the heating turbine

- Sanitizing shower balls

- Tank to boiling of wort with hops

- Steamer – outlet pipe

- Oil fill and drain pipe

- Inspection manhole with glass door

Easy separation of the hops from malt in the whirl tank

Easy separation of the hops from malt in the whirl tank

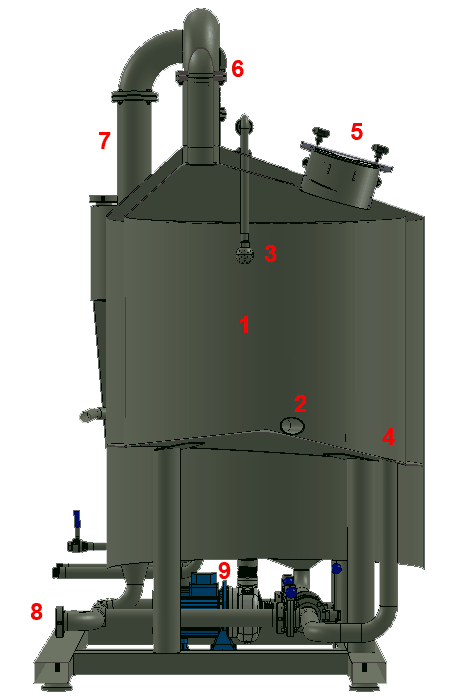

The whirl tank is a second container of the brewhouse. Its purpose is the separation of the hops from malt after the wort boiling process before cooling wort. The separation is ensured by quick rotation of wort inside the tank. Rotation of wort is caused with pumping wort from the wort boiling tank into the whirl tank through a tangentional inlet pipe. Hops cumulates in the axis of the tank and the wort is sucked out by the outlet pipe on the border of the tank directly to the plate heat exchanger where the wort is cooled down using ice water before the fermentation process.

Description of the whirl tank :

- Inner space of the tank

- Tangentional inlet pipe (nozzle)

- Sanitizing shower ball

- Wort outlet pipe

- Inspection manhole with glass door

- Steamer – outlet pipe

- Condenser of waste steam

- Sewage pipe

- Centrifugal pump

Options and properties

Two kinds of raw material for production of wort :

- Wort concentrate : Wort concentrate + drinking water (optionally other ingrediences)

- Malt extract : Malt extract + hops + drinking water (optionally other ingrediences)

Three production capacities of the wort brew machine :

- 1100 liters of beer wort per day – one batch within 12 hours

- 2200 liters of beer wort per day – two batches within 18 hours

- 3300 liters of beer wort per day – three batches within 24 hours

Available control systems :

We offer this wort brew machine equipped with one of these levels of the control system :

MC : manual control system

In the manual version, all fittings are manually operated.

- The temperature steps are controlled by a PID controller which ensures an accurate heating gradient in cooperation with the pump so that the temperature rise gradient does not exceed the allowed limits.

- Each temperature has to be entered manually and it is not possible to program several steps in advance. The pump speed is controlled either manually by a frequency converter or by a PID controller according to the selected process.

- This variant is not equipped with the PLC and touch panel.

- This variant does not have an induction flow meter.

AC : automatic control system

In the fully automatic variant, all steps are controlled by PLC and they can proceed fully automatically. The fully-automatic control system includes these features :

- Filling of tanks with water according to required target volume.

- Wort boiling process – automatization the temperature steps and times within of the whole wort boiling process.

- Pumping of cooled wort – automatic regulation of flow rate according to wort temperature measured on the output of the heat exchanger.

- Start / stop of the vapor condenser. – automatic according to the pressure of the vapors in the tanks.

- This variant is equipped with a PLC and a touch screen, all automatic valves are controlled by a pneumatic elements.

- All valves are fitted with pneumatic actuators.

- Remote control is available via the Android or iOS mobile devices

- Induction flowmeter

- Sensors of empty pipes

Technical specification

Tank for the wort boiling process

- Usable capacity 1350 l

- Dimensions Ø 1503 mm, height 1950 mm

- Heating – thermotransfer area 9.50 m2

- Wort pipe heat exchanger with thermotransfer ensured by oil – heating spiral 5x 6kW / 9.50 m2

- Lighting 12V 35W (optionaly)

- 3x Sanitary shower DN 20

- Water and wort inlet pipe DN 25

- Wort outlet pipe DN 40

- Steam outlet pipe DN 100, 1x spraying device

- Temperature sensor

- Insulation 50 mm plastical mineral cotton

- External jacketing stainless steel 1 mm (optionaly copper 1 mm)

- Measuring rod with ČMI-cz certification/directive 71/316/EEC

Tank for the separation of hops from wort

- Usable capacity 1100 l

- Dimensions Ø 1503 mm, height 1950 mm

- Lighting 12V 35W (optionaly)

- Mechanical temperature indicator 0-120ºC stainless steel

- 1x Sanitary shower DN 20

- Water and wort inlet pipe DN 25

- Wort outlet pipe DN 40

- Steam outlet pipe DN 100, 1x spraying device

- Sigth glass DN 50

- Temperature sensor

- Tangential nozzle DN 25

- Insulation 50 mm plastical mineral cotton,

- External jacketing stainless steel 1 mm (optionaly copper 1 mm)

Cooler and aerator of wort

- Stainless steel plate heat exchanger

- Number of chambers: 20

- Number of chambers in 1st stage of cooling: 10

- Number of chambers in 2nd stage of cooling: 10

- Temperature of wort in inlet of the 1st stage of cooling: 95 ° C

- Temperature of wort in outlet of the 1st stage of cooling: 25 ° C

- Temperature of cold water in inlet: max. 15 ° C (recommended)

- Temperature of warm water in outlet: 65-70 ° C

- Temperature of wort in inlet of the 2nd stage of cooling: 25 ° C

- Temperature of wort in outlet of the 2nd stage of cooling: 7 ° C

- Temperature of ice water in inlet: max. 0-2 ° C (recommended)

- Temperature of ice water in outlet: 3-5 ° C

- Oxygenation of wort – by candle made of sintered stainless steel DN 25, connection required DN10 to hose from an air compressor with carbon bacteriological air filtration

Piping, armatures

- Primary line DN 40

- Drain line DN 50

- Sanitary line DN 25, 3x valve DN 20

- Water supply and additional lines DN 25

- Beer wort filter 1000 L /hr

- Wort centrifugal pump DWO 150 Ebara 750 W

Electric installation

- Stainless steel electric switchbox

- Main switch 3x100A with the central stop button

- Motor starter 3x 2.5A-4A

- Frequency converter FRONIC mini 1.5 kW

- Digital temperature regulator Dixel XR20D

- Wiring

- 5x 1,5 18 m

- 5x 2.5 10 m

- 3x 1 48 m

Dimensions and weight

- Weight 1200 kg

- Basic size minimum height 2 500 mm

- Height 2 350 mm

- Width 4 350 mm

- Depth 1 800 mm

This wort brew system is mounted in a rigid frame made of 1.4301, 8 pc adjustable supports installed in its bottom part.

Connections:

- Wort outlet pipe DN 40

- Pure pressurized air DN 10

- Drinking cold water inlet DN 25 / G 1″

- Cooling cold water inlet DN 25 / G 1″

- Sewage drain pipe DN 50

- Waste steam outlet pipe DN 100 (only if the waste steam condenser is not included)

- Oil filling / discharging pipe G 1″ DN 25

- Electro 3x400V / 50Hz / 63A 33 kW

Transport

This equipment is usually shipped in assembled state.

Optional accessories :

| Recommended options and additional equipment for improvement of the wort brew machine Breworx LITE-ECO 600 | Prices (EUR) |

|---|---|

| WCA : Integrated wort cooler and aerator with flow capacity up to 1000 liters per hour | WCA : Integrated wort cooler and aerator with flow capacity up to 1000 liters per hour

The integration of the compact cooler and aerator to the wort brew machine allows the cooling and aeration of wort without use of external devices. It allows also the measuring and precise regulation of output temperature of wort on the end of the wort production cycle, before start of the beer fermentation, using the automatic control system of the brewhouse. |

7741 |

| BVP : Integrated waste vapor condenser with the stainless steel ventilator and the automatic regulation | BVP : Integrated waste vapor condenser with the stainless steel ventilator and the automatic regulation

This equipment is used for condensation and removal of waste vapors generated in the tanks during the wort brewing process.The vapor condenser allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger may be collected in the hot water tank for later use. |

6221 |

Special centrifugal pump – Special pump designed for high temperatures up to 115°C with the cooling system of the shaft seal with very long lifetime and liquid anti-leak protection (optional accessory) Special centrifugal pump – Special pump designed for high temperatures up to 115°C with the cooling system of the shaft seal with very long lifetime and liquid anti-leak protection (optional accessory) |

3040 |

Increasing of heating power by 6kw – the special heating elments with higher heating power ensure the speeding of the wort brewing process. Very useful if you plan to produce more than only one batch of wort per day. Shorter time of each batch of wort saves your time and work. Increasing of heating power by 6kw – the special heating elments with higher heating power ensure the speeding of the wort brewing process. Very useful if you plan to produce more than only one batch of wort per day. Shorter time of each batch of wort saves your time and work. |

610 |

Reviews

There are no reviews yet.