Description

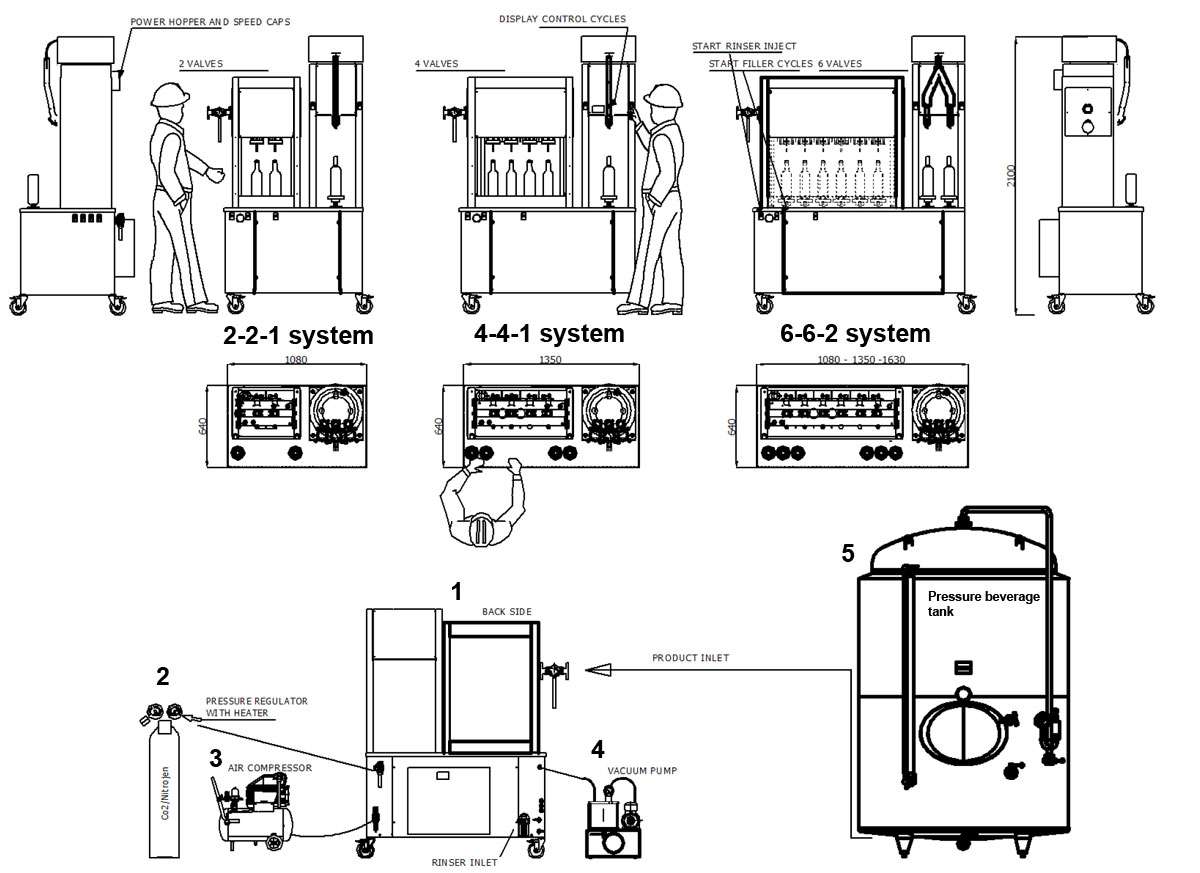

The monoblock 2-2-1 is a compact bottling machine with three integrated units :

- Bottle rinsing unit : semi-automatic rinsing the glass bottles (optionally PET bottles) – 2 electronic valves

- Bottle filling unit : isobaric filling the glass bottles (optionally PET bottles) – 2 electronic valves

- Bottle capping unit : pneumatic capping the bottles with crown caps (optionally screwed caps, ROPP caps) – 1 capping head

with electronic valves, optionally adaptable for aluminium cans, PET bottles, screwed caps, ROPP caps.

Production speed : from 150 up to 200 bottles per hour (depending on the operator, product, temperature, foamicity, pressure)

Technical parameters

| Maximal operation capacity | from 150 up to 200 bottles per hour (depending on the operator, product, temperature, foamicity, pressure) |

| Number of : rinsing valves/filling valves/capping heads | 2/2/1 |

| Height of the worktable | 750 cm |

| Max. bottles size : diameter / height | 120mm / 370mm |

| Max. cans size : diameter / height | 70mm /150mm – only with the upgrade kit for filling cans |

| Power connection | 220-240V / 50 Hz / single phase |

| Electrical consumption | 0.37 kW |

| Max filler tank pressure | 5 bar/72 psi(tested on 9 bar/130 psi ) |

| Compressed air consumption | 180 lt/min (6 bar) |

| Beverage product pipe connection | DIN 32676 TRICLAMP D=51mm (other types on request) |

| Co2/Nitrogen connection | John Guest 8mm or Female G 3/8” gas |

| Compressed air connection | John Guest 8mm or Female G 3/8” gas |

| Beverage temperature | 0-2°C (recommended to avoid foaming) |

| Maximum rinsing temperature | 60°C / 140°F (on request 85°C / 185°F) |

| Filler tank material | AISI 304 (filling valves AISI 316) |

| Beverage products | Beer, sparkling water, wine, soft drinks, non-carbonated beverages |

| Crown caps type | 26 mm or 29 mm |

| Cans type | all types (defined by customer) – only with the upgrade kit for filling cans |

| Dissolved oxygen level | 40-60 PPB (in the bottles after filling and capping) |

Description :

Structure of the machine:

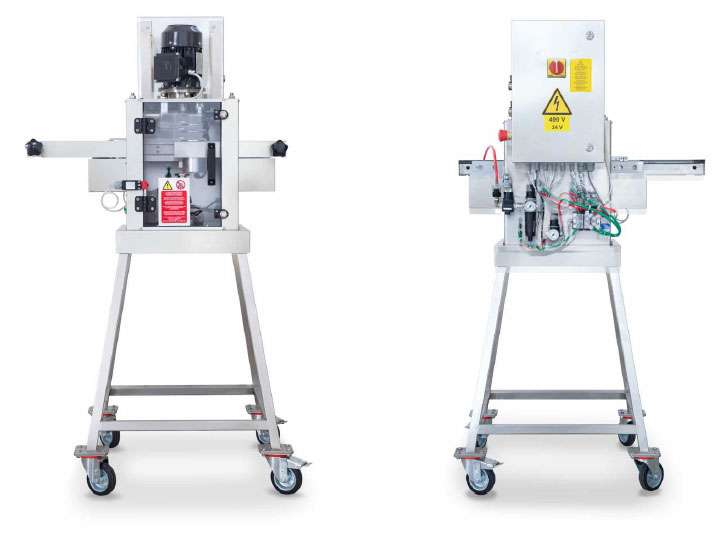

Painted steel frame covered with stainless steel plates.

Machine on 4 lockable wheels for easy moving of the filler-block in client’s factory.

This three-block machine has been designed to assist in filling carbonated or non-carbonated beverages into glass bottles with crown caps. Three phases of bottling process in one compact block with a steel base on wheels. Rinsing + filling + closing with crown caps.

1st section : Bottle rinsing unit – equipment to rinsing the bottles with pure water or with a chemical sterilizing solution

Easy cleanable stainless steel base with recessed working area to prevent product and water spillage. Safe spray activation system – if a bottle is not inserted then the spray nozzle is not active.

- Two rinsing positions

- Rinsing four bottles in the same time (in standard)

- 1st rinsing cycle (in standard) : one-way water

- 2nd rinsing cycle (only with optional equipment) : recirculating solution (for example alkaline sanitizing solution)

- 3nd rinsing cycle (only with optional equipment) : one-way water (for example sterile water)

- 4rd rinsing cycle (only with optional equipment) : recirculating solution (for example sterilizing solution based on alcohol)

- 5th rinsing cycle (only with optinal equipment) : sterile air (drying the bottles)

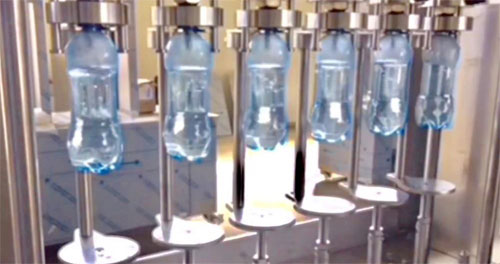

2nd section : Bottle filling unit – equipment to filling beverage into the bottles (counterpressure filler)

- Two filling positions

- Isobaric filling of carbonated beverage into four bottles in the same time (in standard)

- Gravity filling of non-carbonated beverage into four bottles in the same time (in standard)

- Filling beverages into glass bottles (in standard)

- Filling beverages into PET bottles (only with optional equipment)

- Filling beverages into aluminium cans (only with optional equipment)

- The filling process takes place automatically, the operator only has to place all the bottles on the supports and remove them in the end of the process

- Pre-evacuation (only with optional equipment) : First the single or double pre-evacuation of oxygen is carried out inside the empty bottles, by means of an external vacuum pump

- The second pre-evacuation of oxygen is preceded by a CO2 injection, in order to lift the rest of oxygen to the upper part of the bottle.

- This system guarantees an excellent result in terms of dissolved oxygen – less than 28 PPB is reached in beverage in the bottles.

- Injecton of carbon dioxide into neck space of the bottles prior to closing to remove residual oxygen in the bottle head space.

- At the end of the bottle filling process, the pressure compensation occurs between the bottle and the isobaric tank, and the beverage flowes up to the level of the level devices.

- The type of deflector installed determines the correct flow while measures a level through the walls of the bottle.

- The level of product inside the bottles is determined by the interchangeable devices depending on the capacity of the bottle and the level height required.

- In the last phase, the bottles are de-pressurized, controlled by an opening and closing timer in order to gently release the pressure and avoid extremely foaming.

- The controlled creation of a foam avoid entering of the oxygen in the bottles before they are closed.

- By modifying the depressurization times, the operator can set more or less foam.

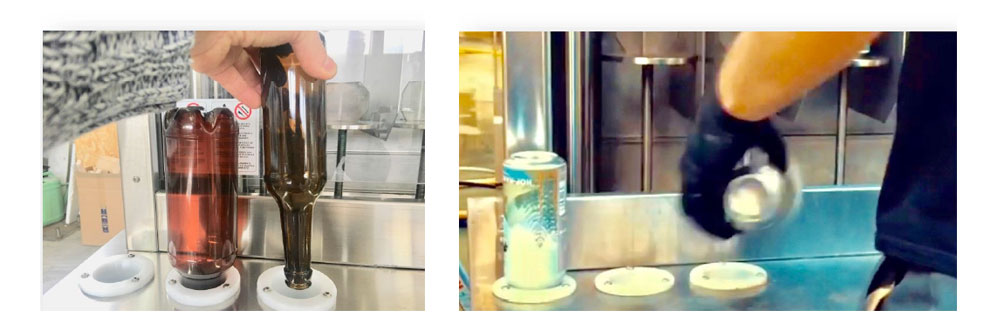

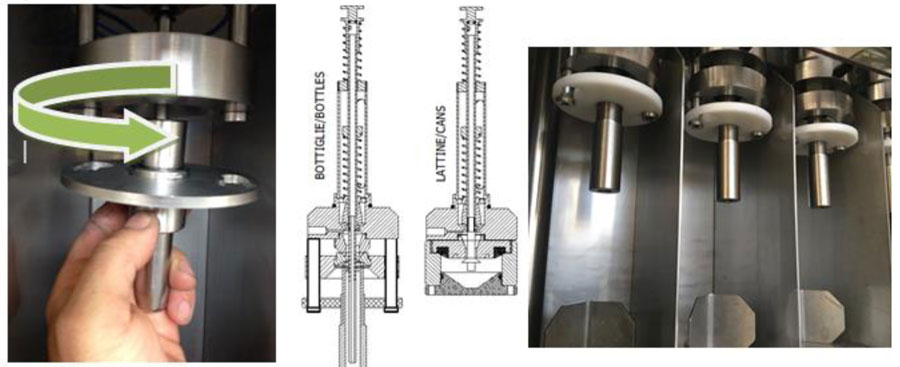

a) Filling the glass bottles

b) Filling the PET bottles (only with optional accessories)

c) Filling the aluminium cans (only with optional accessories)

3rd section : Bottle capping unit – equipment to capping the bottles with crown caps

- Single or double capping head with a crown caps sorter & with automatic feed of crown caps to the capping head

- With the double head capping system you can close two bottles at the same time

- Closing the bottles with steel crown caps (in standard version)

- Designed to closing of all types of the bottles – square, round, special shapes (with optional equipment)

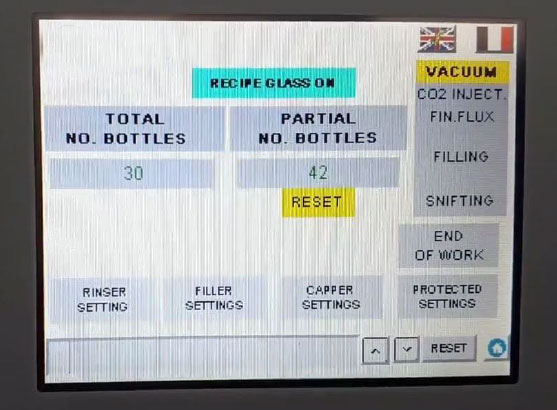

HMI colour control panel for easy management of all controls of the filler block.

Glass vessel on side of the filler serves to prevent flooding of the vacuum pump

Rinser recilcuation 20 liters tank with the pump, filter and paracetic sterile water solution (optionally) :

Upgrade kit for filling cans (optionally) :

- Accessory kit for use the machine to rinsing and filling into aluminium cans – optionally

- External can capping unit (the can seaming machine) – optionally

a) Cannular Pro – a cheap can seaming machine for closing small quantities of cans

b) Canseamizer – a professional can seaming machine for closing big quantities of cans

Stainless steel CIP bottle with a manifold for distribution the sanitizing solution to all valves (optionally) :

Stainless steel pneumatic pump for the CIP system (optionally) :

CIP dummy bottles (optionally) :

This CIP dummy bottles allows high pressure chemical cleaning of the filler on-board tank and filling valves in continuous motion to ensure high quality cleaning and achieve absolutely sterile all parts in contact with a beverage.

Connections :

Operating cycle description :

- Rinse the isobaric tank with ice water to reduce the temperature in the tank and to achieve reduce foaming of beverage.

- Fill the source tank with a beverage intended to be filled into the bottles.

- Remove the air from the tank by carbon dioxide.

- Place the bottles in the rinsing positions.

- Activate the bottle rinsing process by a switch on the PLC control panel.

- Place the bottles on the filling positions

- The machine is then activated by means of pressing two buttons simultaneously

- The safety door comes down automatically (they are pneumatically driven)

- The bottles are lifted automatically under the filling valves

- The vacuum system sucks air out of the bottle

- The machine fills the bottle with fresh carbon dioxide from the CO² pressure bottle (not from the filling tank)

- The vacuum system sucks air out of the bottle

- The machine fills the bottle with carbon dioxide from the header tank

- The machine achieves stability of pressure and starts filling the beverage into the bottle

- The machine snifts the fill level gently (in three micro-impulses) as to prevent foaming

- The bottles lower down from the valve to the rest position

- The safety door opens automatically and the bottles are removed manually and transferred to the capping unit

- Activate the bottle capping process by a switch on the PLC control panel.

- Safety glass door is automatically closed (pneumatically driven).

- The bottles are closed with crown caps automatically using a pneumatically driven capping head.

- Remove the bottles out from the machine.

Main features of the new model :

Hugely improved design with many new and enhanced features including :

- Faster filling cycle

- Higher quality of vacuum for oxygen retention – the highest possible level in the beverage industry

- Oxygen TPO (Total Pickup of Oxygen) values between 40-60 ppb

- User friendly HMI 3 inch touchscreen control panel

- Easy clean stainless-steel base with recessed working area to avoid product spillage

- Total control of fill cycle (pre-evacuation, CO² injection, filling, degassing) through interactive touch screen 3” control panel

- IoT Smart Device: Full internet connection optionally available for remote technical diagnosis and assistance

- Glass vacuum tank to ensure visual monitoring of correct operating statuses

- Easy access from rear via transparent opening doors for easy maintenance of the machine

- Possibility to fill short neck bottles

- Rinser with system : “No bottle – no spraying”

- Flexibility to fill any size glass or PET bottle as well as aluminium cans

- Easy and rapid changeover from glass bottling to aluminium can filling and seaming (optional accessories)

Pricelist of the BFSA-MB221 : Compactblock 2-2-1 (with one capping head)

Standard equipment :

| Code | Description | Price (€ Euro) |

| 893IC | Monoblock Semi-automatic 2-2-1 : rinsing unit (2 positions), filling unit (2 positions), capping unit (1 position) for bottles (crown caps, counter pressure filling) | On demand |

| 0912 | CIP dummy bottles (2 pcs) – special accessory for continuous chemical cleaning all 4 filling valves simultaneously | On demand |

| 864 | Vibrating cap sorter | On demand |

| 865 | Protective door on the bottle capping unit with safety switch | On demand |

| 866 | Automatic cycling for pre-evacuation the bottles, CO² flushing, counterpressure filling and degassing control with the 3 inch touch control panel | On demand |

| HTK | High temperature CIP washing kit | On demand |

| 863 | Pure CO² injection device into the bottles on the filler | On demand |

| Total EXW price | On demand |

Optional equipment :

Items marked ** are highly suggested

| Code | Description | Price (€ Euro) |

| 872 | Upgrade to Compactblock Semi-automatic 2-2-2 : rinsing unit (2 positions), filling unit (2 positions), capping unit (2 positions) | On demand |

| 887 | ** Stainless steel CIP bottle (the product recovery tank) with a manifold for distribution the sanitizing solution to all valves (with all connections) | On demand |

| 973 | ** Pre-evacuation of air from the bottles before filling with an external vacuum tank (highly suggested – to prevent oxygenation and contamination of a beverage ) | On demand |

| 856 | Additional filling tubes for different fill levels of bottled products (2 pcs). Each bottle format requires its own set. | On demand |

| 316LP | All construction parts in contact with the beverage product made of AISI 316 (necessary for cider) | On demand |

| AKPET | Accessory kit for the filling of PET bottles (one format) – Applying of caps is manually. | On demand |

| 974 | ** Pneumatic membrane pump AISI 316 with switch valve TriClamp 1″ and the connection kit to join the filler to pump, all connections to the CIP unit. | On demand |

| 976 | ** System for recirculation of the rinse chemicals in a closed circuit with a pump and filter – to rinse the bottles with peracetic solution | On demand |

| 884 | ** Complete set of replaceable gaskets for all 2 filling valves | On demand |

| 889 | ** Tool for quick change over the valve gaskets | On demand |

| 882 | ** Non-return valve with TriClamp 1 inch connections (suggested) | On demand |

| 962 | Special voltage and frequency (different from EU standard 1x 230V/50Hz) – for example 1x 110V /60Hz without certificate | On demand |

| 962C | Special voltage (different from EU standard 1x 230V/50Hz) – for example 1x 110V /60Hz including the UL conformity electronic parts (needed for American market) | On demand |

| ETRAK | ETH Remote assistance set – Communication set of hardware and software allowing remote assistance, diagnostics and adjusting if a technical problem occurs – via the cable Ethernet connection | On demand |

| WFRAK | ** WIFI Remote assistance set – Communication set of hardware and software allowing remote assistance, diagnostics and adjusting if a technical problem occurs – via the WiFi connection | On demand |

| Total price of recommended optional equipment (marked **) | On demand |

Prices of the minimal and recommended configurations :

| Minimal configuration | On demand |

| Recommended configuration (includes all optional items marked **) | On demand |

Optional services :

| Code | Description | Price (€ Euro) |

| PCKEU | Packing costs EU – wooden crate (normal, transport to EU area – only continental countries) | On demand |

| PCKWD | Packing costs World – wooden crate with chemical protection for transport over sea | On demand |

| PCKSP | Packing costs Special – wooden crate when more devices will be packaged | On demand |

| SHP | Shipping cost | On demand |

| INS | Installation work and other services provided by our specialist on the place (price does not include hotel/dinner/lounch and travel expenses) | On demand |

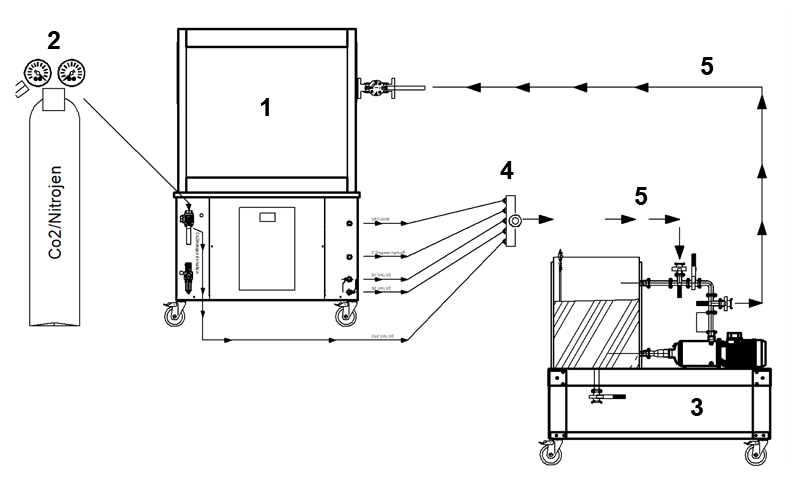

Connections :

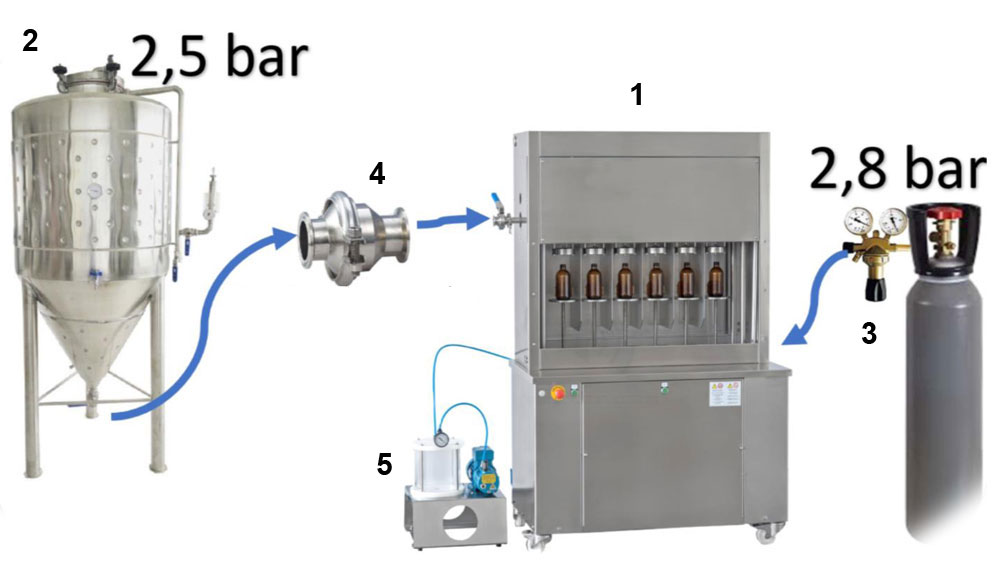

I. Filling carbonated beverages from a pressure tank

Description :

- BFSA-MB bottling machine

- Pressure bottle with carbon dioxide and reduction valve

- Air compressor (needed for powering the pneumatic valves and actuators)

- Vacuum pump (needed for pre-vacuation the bottles)

- Pressure tank with carbonated beverage

Description :

- BFSA-MB bottling machine

- Pressure tank with carbonated beverage

- Pressure bottle with carbon dioxide and reduction valve

- Non-return valve

- Vacuum pump

- Blue lines – pressure hoses

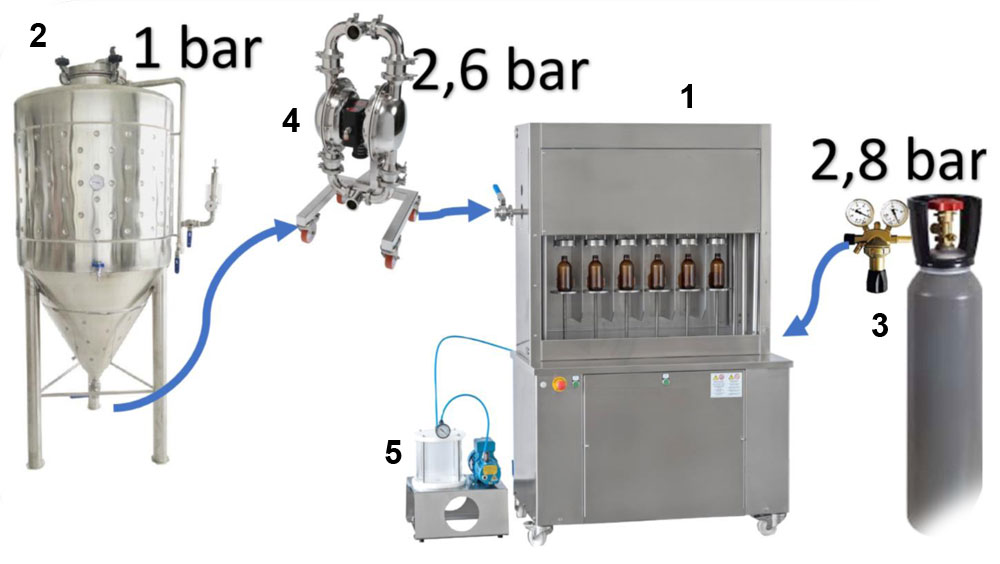

II. Filling non-carbonated beverages from a non-pressure tank

Description :

- BFSA-MB bottling machine

- Pressure tank with non-carbonated beverage

- Pressure bottle with carbon dioxide and reduction valve

- Pneumatic diagphragm pump

- Vacuum pump

- Blue lines – pressure hoses

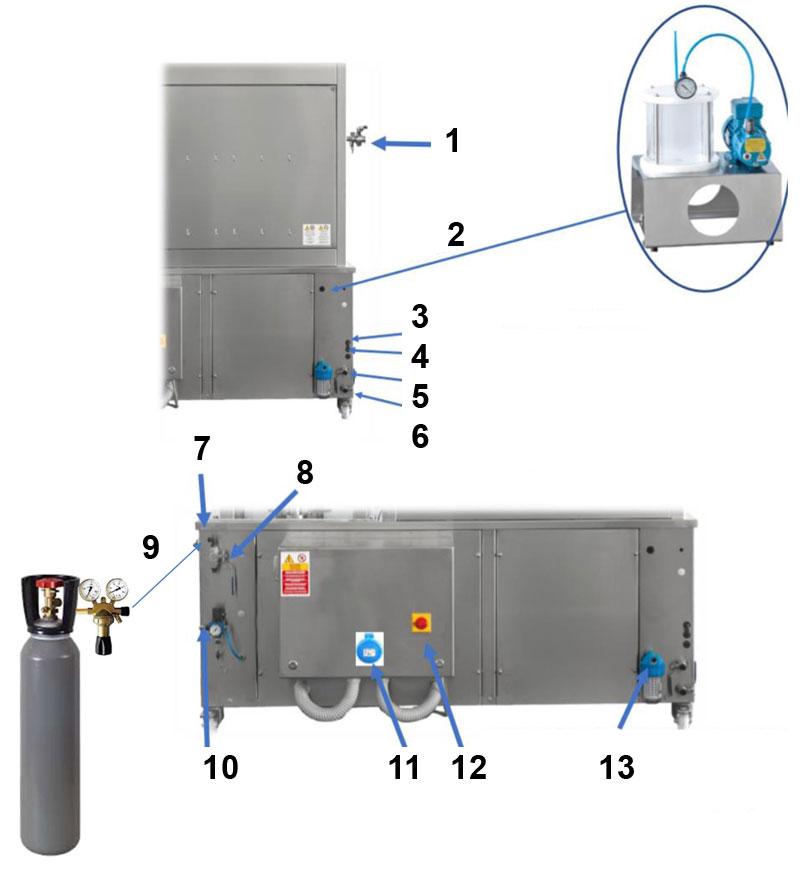

All connections and inputs :

Description :

- Beverage product inlet ( DIN 32676 “TriClamp” Ø 51 mm )

- Vacuum pump connection (beverage hose Ø 8 mm – John Guest couplers)

- CO2 exhaust for the bottle decompression (beverage hose Ø 8 mm – John Guest couplers)

- Water outlet for the rinsing cycle (beverage hose Ø 8 mm – John Guest couplers)

- Outlet CO2 – venting valve of the high level filling (beverage hose Ø 8 mm – John Guest couplers)

- Outlet CO2 – venting valve of the low level filling (beverage hose Ø 8 mm – John Guest couplers)

- Inlet CO2 or N2 from the pressure bottle under maximal pressure 5 bar (beverage hose Ø 8 mm – John Guest couplers)

- Water outlet (beverage hose Ø 8 mm – John Guest couplers)

- CO2 hose between the pressure bottle with the reduction valve and the bottling machine

- Inlet of compressed air min. 5 bar 120 L/min. (pressure hose Ø 10 mm – John Guest couplers)

- Vacuum pump electric socket – for removing oxygen from the bottles

- Power switch for the electric socket

- Water inlet – G 1/2 inch female hose connector (maximal pressure 4 bar)

III. CIP setup – cleaning and sanitizing of the compact bottling machine

Description :

- Compact bottle filling machine

- Bottle with pressure carbon dioxide and reduction valve

- CIP station – we recommend use the machine CIP-52 or CIP-53

- CIP collector for chemical solutions (see optional equipment table)

- Hoses for connection between the CIP station and the compact bottle filling machine

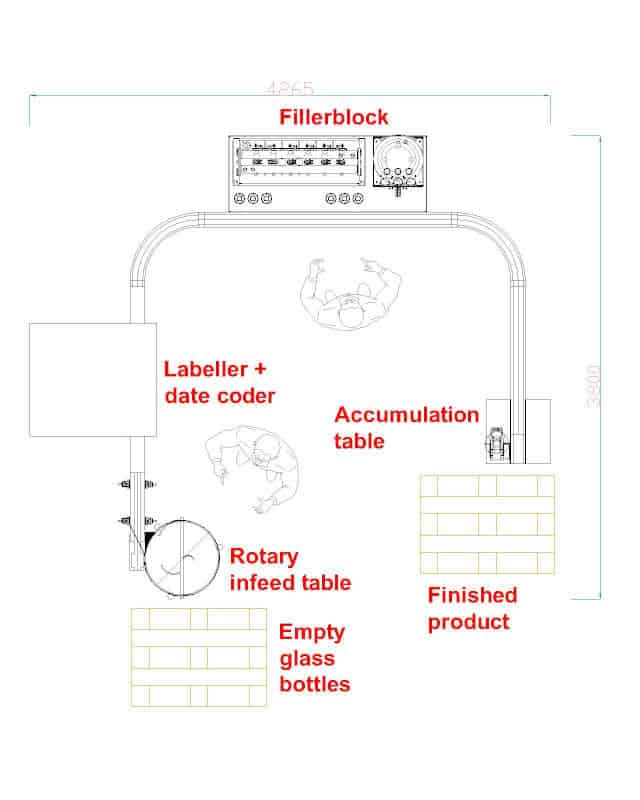

Example of the integration of the compactblock machine to a bottling line

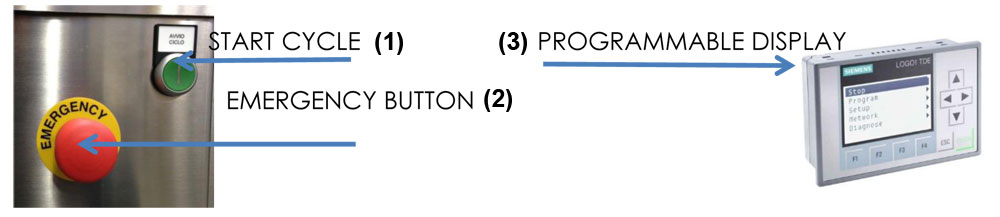

Semi-automatic control system :

Description :

- Start of choosed cycle

- Emergency stop button

- Programmable unit with a display

Automatic cycles (see optional equipment table) facilitates all the operations of the bottle rinsing, filling steps and capping. You can choose different types of the filling process.

Available modes and their settings

I. Bottle rinsing mode :

- Injection timer – editable timing of the automatic valves

II. Bottle filling mode :

- Standard

- Single pre evacuation with CO2 injection timer adjustable

- Double pre evacuation with double CO2 injection timer adjustable

- CO2 purge for remove the oxygen in the bottles before the capping cycle

- You can change the time of the pre-evacuation, time of CO2 injection, time of the degassing

III. Bottle capping mode :

- Time of the bottle capping operation is adjustable

IV. CIP mode :

- Opening all valves for the cleaning and sanitizing the machine using a CIP station

V. Degassing mode :

- Opening and closing the valves when decompressing according on timer setting in two or more steps.

Optional services :

I. Installation work on the place …. € On demand

The price is valid for all countries of the European Union. The price includes five days work (+ two days travelling) of two specialists on the place – assembling and start up of the equipment.

The price does not include : transports costs and accomodation of the workers. Will becalculated individualy.

II. Installation work ensured by customer (with our remote assistance) …. € On demand

Do you want to save your money ? Are you technically skilled and not afraid of challenges? Do your country’s hygienic restrictive regulations not allow a visit of a specialized technician from a foreign country? Don’t be afraid to use the remote assistance service.

How is the installation of the filling line by our customer, using our remote assistance?

1.) The customer positiones all the machines and connects them to power guided by our checklist.

2.) Once photos were sent of the completion of the preliminary phase we proceeds with the start up and commissioning.

3.) First we connects the PLC of the machine via internet to our service console in our factory — this allows our service manager to view and control your PLC on a remote screen, as if he was in front of the machine in person.

4.) We then organise a Microsoft Teams conference call, with one your worker holding the camera, and the others working around the our technician´s instructions.

5.) After only 3-5 days setting up and configuring, first full glass bottles will leave your filling line.

Notice :

Photos and images are indicative only and show the device in the version that was current at the time of acquisition. The actual design of the products may differ slightly from the design shown.