Description

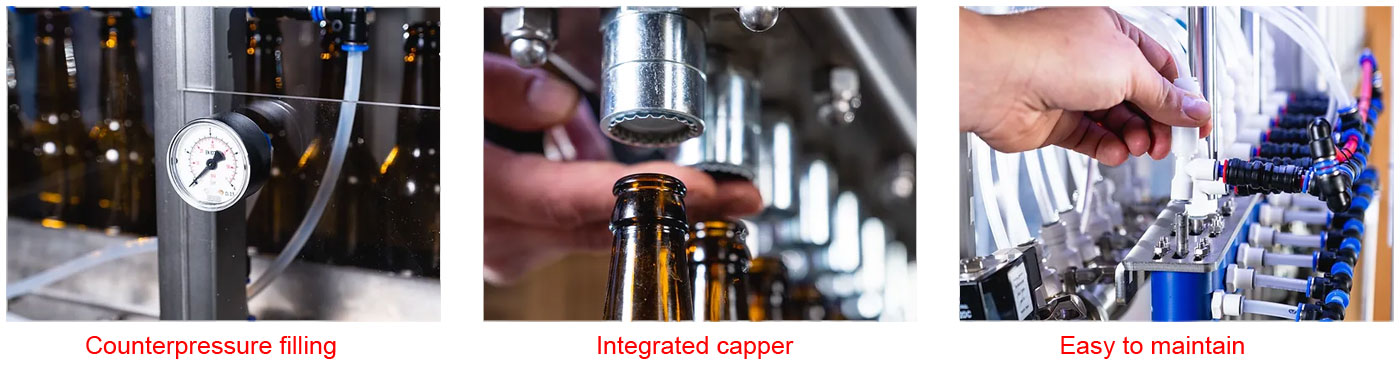

Universal semi-automatic four-head filling machine for glass bottles and cans with the filling capacity up to 800 containers per hour. The universal counter-pressure filling machine is ideally suited for beverage producers who do not want to be tied to one type of bottle or can. The configuration of the isobarical filling machine can be changed between different bottle sizes in 5 minutes and can be converted from filling the bottles to cans in 20 min.

We are an authorized sales partner of the European producer.

Technical specifications :

- Dimensions: 2150 x 800 x 2300mm (W x D x H)

- Weight: 210 KG

- Stainless steel frame

- Stainless valves with EPDM seal

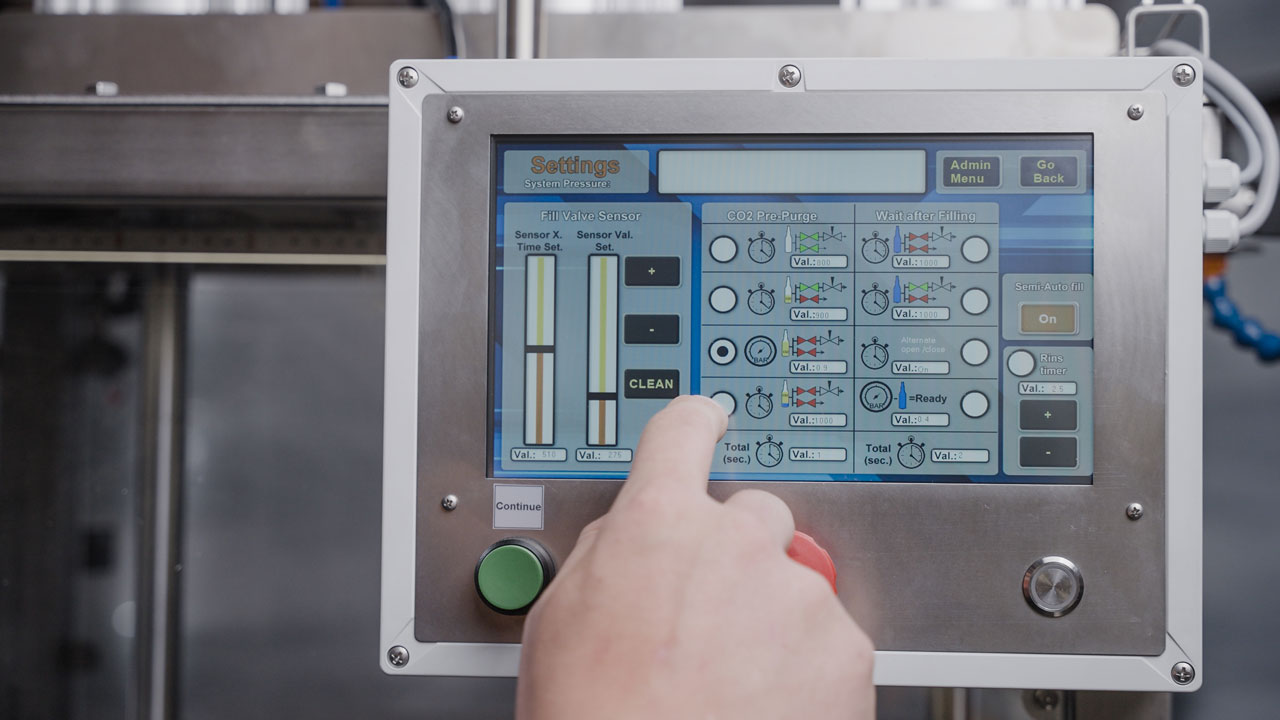

- 10” waterproof touchscreen

- The Arduino PRO PLC controller with lifetime updates.

- Power supply : 110 ~ 230V / 50-60Hz @ 6A maximal input power

- Beverage input : DIN 32676 (TriClamp) 1,5” / DN40

- Compressed air input : 8mm hose (John Guest quick coupler) @ pressure 8 bar max

- C02 input: 8mm hose (John Guest quick coupler)

- Number of the bottle/can rinsing positions : 12

- Number of the bottle/can filling heads : 4

- Number of the bottle/can capping heads : 4

- Output capacity with one operator : 250-500 bottles/cans per hour (depends on foamicity of a beverage)

- Output capacity with two operators : 400-800 bottles/cans per hour (depends on foamicity of a beverage)

How the machine works :

The universal filler comes standardly with a manual rinser for 12 bottles/cans. Filling starts with this rinser. A user places manually bottles/cans in the rack and presses the start button. Water or chemical sanitizer sprays into the bottles/cans for the set time. The pump for the water or chemical sanitizer is not included in the machine.

The bottles/cans are manually then placed in special trays which correspond in size to the diameter of the bottle / can. The trays bring the bottles and cans under the filling heads and then under the capping heads.

At the end the bottles/cans are slid towards the user after which the bottles and cans can be manually removed from the trays.

Delivery time : 3-4 months after the order.