Description

PolyKeg Pro – polyethylene barrels with volume 30 liters to storage, distribution and dispensing beverages

with standard couplers of A-type, without the inner bag

What is PolyKeg and why use it ?

PolyKeg is a fully-recyclable, sustainable “one-use” keg, made mostly from Polyethylene terephthalate (PET).

PolyKeg specialise in the production of large one-use PET kegs, for different applications in the draft beverage sector. PolyKeg’s experience and constant research make this type of kegs ultra-innovative, extremely safe and of high quality for use with non-carbonated and carbonated beverages.

The PolyKeg kegs are suitable for a wide range of carbonated and non-carbonated products, such as beer, wine, soft-drinks, cider, etc. They preserve the aroma and taste of the product, thanks to their high oxide barrier and efficient protection against sunlight . UV light and visible blue light won’t penetrate your drinks.

Innovative, lightweight and immediatelly ready-to-use polyethylene keg with capacity of 20 liters for safely storing and transporting drinks. Easy to disassemble and to recycle.

Main features :

- Single use beverage keg made of polyethylene terephthalate

- Wide application possibilities: beer, wine, cider, soft drinks, cocktails, juices, coffee

- Fully compatible with common beverage dispense systems

- Easy to disassemble after use

- To be used with inert gases for push the beverages – carbondioxide, nitrogen, biogon

- High-efficient CO2 barrier

- O2-free (*)

- Wide application possibilities for beverages : beer, cider, wine…

- Stackable

- High pressure resistance

- Strong impact resistance; the keg remains intact after a fall from a height of 2 metres

- Full traceability

(*) The keg is pre-flushed and pressurised with nitrogen, leaving only 400 ppb of oxygen in the keg.

Specifications:

- Type: PRO PolyKeg

- Nominal working pressure: max. 3.5 bar

- Burst pressure: 8 bar

- Colour: silver

- Volume capacity :30 liters

- Filling/dispensing coupler : A-type

- No plastic bag is in the keg

- For beverages containing up to 20% alcohol

Item codes according to quantity of the PolyKegs in one order :

| Item code | Packing | Layers | Quantity | Description | Discount |

| PKP30LSA-11 | 1 wooden pallet 120 x 80 cm | 1 | 11 pcs | PolyKeg Pro 30L, silver colour, without inner bag, A-coupler | 0.0 % |

| PKP30LSA-22 | 1 wooden pallet 120 x 80 cm | 2 | 22 pcs | PolyKeg Pro 30L, silver colour, without inner bag, A-coupler | 1.5 % |

| PKP30LSA-33 | 1 wooden pallet 120 x 80 cm | 3 | 33 pcs | PolyKeg Pro 30L, silver colour, without inner bag, A-coupler | 3.0 % |

| PKP3LSA-44 | 1 wooden pallet 120 x 80 cm | 4 | 44 pcs | PolyKeg Pro 30L, silver colour, without inner bag, A-coupler | 4.0 % |

| PKP30LSA-1056 | 1 full 40-feet container (24 pallets) | 24 x 4 | 1056 pcs | PolyKeg Pro 30L, silver colour, without inner bag, A-coupler | 10 % |

1 pallet is the minimum orderable quantity of this product.

Price does not include the wooden palletes and transport costs (will be calculated additionally)

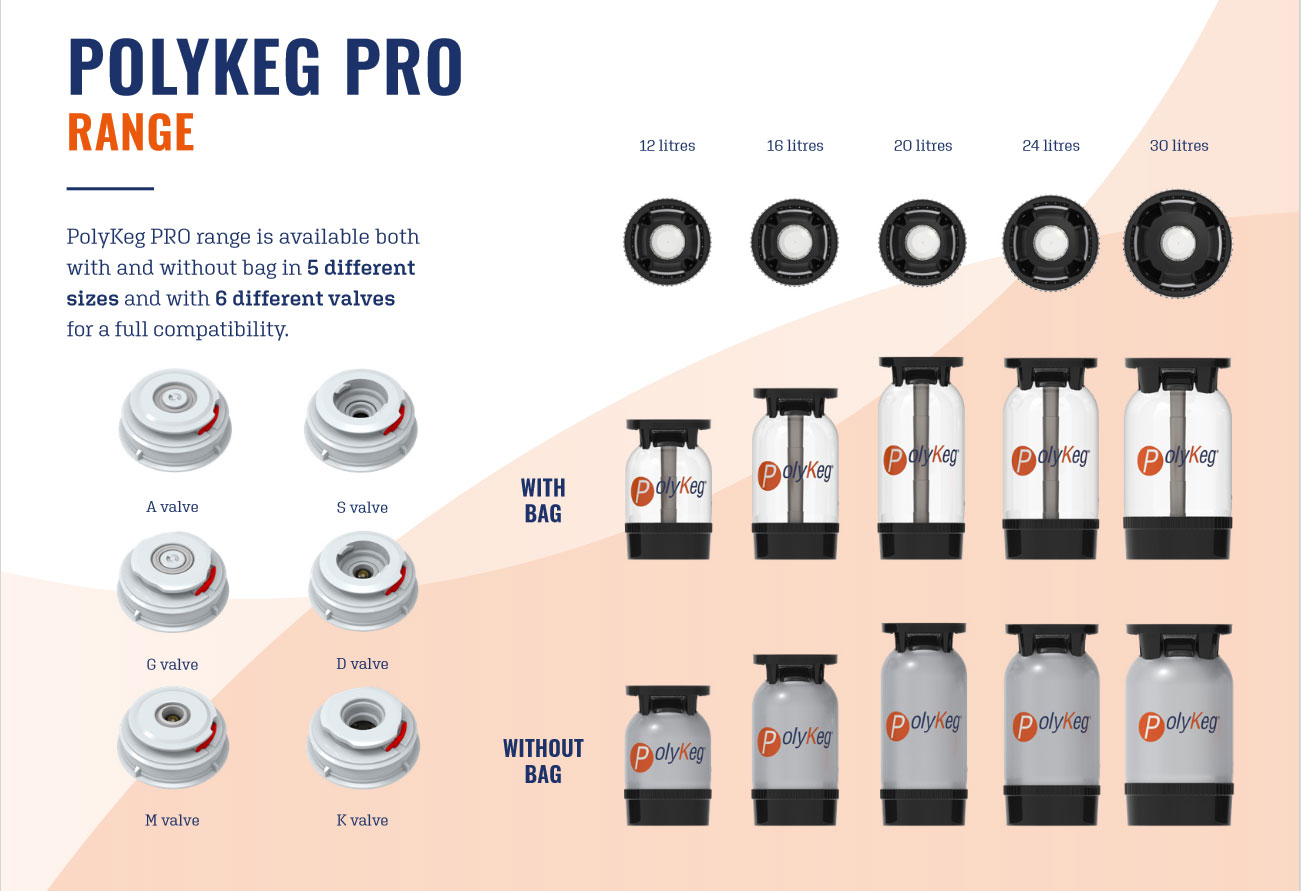

The new PolyKeg PRO offers different advantages to beverage manufacturers, distributors and final users:

Pressure-relief valve (PRV)

Each PolyKeg PRO is equipped with a pressure relief valve (PRV):

- Automatic release of overpressure when it exceeds the set value, during the entire keg life cycle. The PRV closes automatically once the internal pressure drops below the set value.

- Complete and quick depressurization of the keg after use, with easy removal of the PRV lever.

Anti-rotation system

PolyKeg PRO’s anti-rotation system stops the keg from slipping and rotating on the pallet, ensuring the stability of the goods both in the warehouse as well as during shipment. It’s simple, fast and safe since the keg does not need to be oriented during the palletisation process.

Light and strong

The innovative design and materials used to make PolyKeg PRO lightweight, yet strong and safe, ensure high resistance to internal pressure and handling during transport and storage.

Security seal (not included with the keg, see accessories)

The tamper evident seal, exclusive of PolyKeg®:

- Guarantees the integrity of the keg, showing possible manipulation by third parties.

- Protects the valve from external agents and against shocks during the handling.

Ready for use

PolyKeg PRO is ready for filling without any additional steps and extra costs on the customer’s side. It is supplied flushed and without residual oxygen. This ensure excellent sanitary conditions inside the keg.

Screw neck

The neck closure has a unique design to ensure automatic pressure relief in case of tampering, and a higher resistance in the unlikely case of valve detachment from the keg.

Barrier

Thanks to the special materials, PolyKeg PRO guarantees a high barrier to O2, CO2, and light keeping the product qualities unchanged over time.

Filling

PolyKeg PRO can be filled either upside down or upside up, manually or with automatic filling machines.

PolyKeg aim high on sustainability

With the aim of achieving higher plastic recycling rates and more sustainable consumption and production models, the complete keg is in plastic. The keg can be dismantled completely, so all the different plastics can subsequently be recycled separately.

The light weight of one-way kegs optimises the logistic process, reduces the number of transports, avoids the return of empty kegs and the subsequent washing steps, resulting in a significant reduction in environmental pollution.

Easy to disassemble

Thanks to the innovative eco-design, PolyKeg PRO can be easily disassembled into various components and materials, everywhere and without using any power.

Logistics

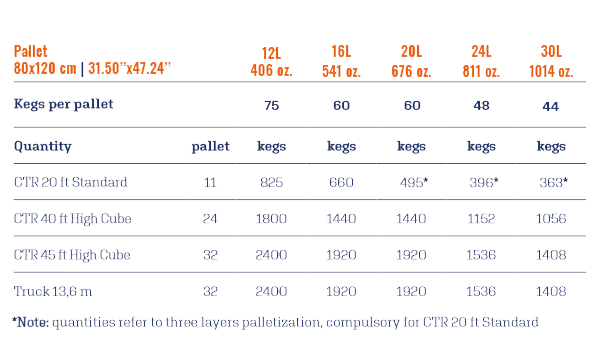

The PolyKeg PRO range has been designed to maximise the quantity of kegs per pallet, truck or container, resulting in reduced storage space and costs, handling and transport.

Raw material optimisation

PolyKeg PRO kegs have been designed to optimise the quantity and type of materials used, avoiding metal components. This is the best solution to optimise the recycling process and the reuse of materials.

Decentralisation

PolyKeg® developed a modular and compact production process that allows to decentralise the production of their kegs as close as possible to the target market, and in some cases directly in-house. This innovative solution makes possible to cut down secondary packaging and improve handling and logistics.

Weight and dimensions, logistic parameters:

| 12 l | 16 l | 20 l | 24 l | 30 l | ||

| Max. diameter | 246 mm | 247 mm | 247 mm | 273 mm | 308 mm | |

| Max. height | 404 mm | 494 mm | 569 mm | 566 mm | 566 mm | |

| Empty weight for standard keg | 0.99 kg | 1.05 kg | 1.17 kg | 1.35 kg | 1.57 kg | |

| Wooden Pallet 120 x 80 cm | # Kegs / pallet | 75 | 60 | 60 | 48 | 44 |

| # Layers / pallet | 5 | 4 | 4 | 4 | 4 | |

| Transport Container 40-feet (High Cube) | # Kegs / container | 1800 | 1440 | 1440 | 1152 | 1056 |

| # Pallets / container | 24 | 24 | 24 | 24 | 24 | |

Important documents

PolyKeg innovative PET kegs allow you to deliver beer, wine and cider anywhere in the world at a fraction of the previous cost.

Below are documents which must be downloaded and understood before use:

| User manual | download pdf |

| Product specifications | download pdf |

Video about the PolyKeg plastic barrels :

We recommend to order also :

KFM-01 : PolyKeg filling coupler for manual filling

KFM-01 : PolyKeg filling coupler for manual filling

The filling head has valves adapted to the slow filling of PET kegs like the PolyKeg barrels under back pressure. The head also allows filling of PET kegs before filling with inert gas. Please specify properly a type of the filling head in your order : K-coupler is designed for this type of the PET kegs.