Description

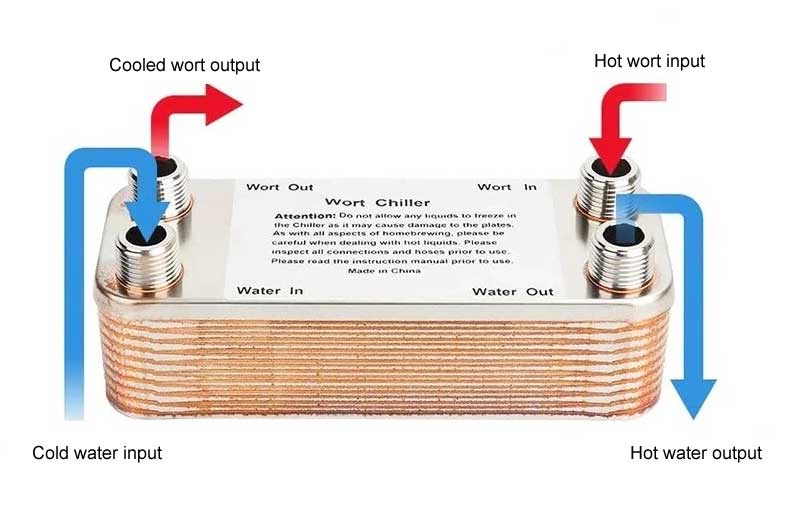

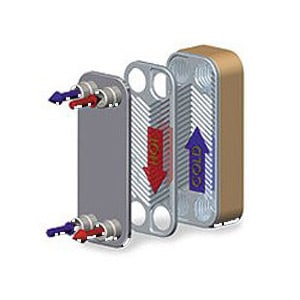

Stainless non-dismantling plate wort cooler MINI with 50 plates made of stainless steel (AISI 304). The cooling plates are soldered with pure copper. The cooling rate of the wort depends on the temperature of the water entering the heat exchanger and the flow rate of both the water and the wort.

Description of the wort cooling process :

This is a necessary equipment for preparation of wort produced by each brewhouse. The single-stage plate heat exchanger is intended for cooling of the wort from 90 ° C to 25°C (a fermenting temperature for production of “ale” beer type) using the cooling medium with temperature from 12°C to 15°C (cold water).

If you use a double system (two pieces of this plate heat exchanger) then the second PHE system is intended for cooling of the wort from 25°C to 6°C (a fermenting temperature for production of “lager” beer type) using the cooling medium with temperature from -4°C (glycol).

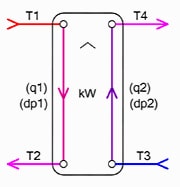

The heat exchanger is not equipped with temperature and flow sensors and control elements.

Technical specifications :

- Size: 190x75x130 mm (without connecting fittings)

- Number of cooling plates: 50

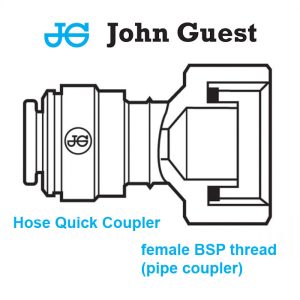

- Cooling medium connection: inlet/outlet BSP 3/4″ external thread

- Connection of cooled medium (beer wort): inlet/outlet BSP 1/2″ external thread

- Material: made of stainless steel (AISI 304) and brazed with pure copper

- Use: we recommend mounting in a vertical position.

Applications

Cooling or heating of beer wort up to 50 lt/hour from 90°C to 25°C (single PHE system) or from 90°C to 6°C (double PHE system).

Chemical cleaning :

Connect the plate cooler in countercurrent when is chemically cleaned otherwise you will not achieve the required efficiency.

We recommend a vertical installation to minimize sediment build-up and make the plate heat exchanger easier to clean. Plate coolers cannot be cleaned mechanically, as they are not disassembled. They need to be chemically cleaned regularly to prevent clogging. The plate cooler is flushed in the opposite direction to normal operating fluid flow. Depending on the type of pollution, use chemicals for cleaning:

Limescale:

- Nitric acid 4% at max. 60°C

- Citric acid 4% at max. 60°C

Organic deposits:

- 2% sodium hydroxide solution at max. 40°C

Mud, metal oxides:

- Nitric acid 8% at max. 60°C

- Citric acid 4% at max. 60°C

The following substances are prohibited for cleaning and use in the heat exchanger:

- hydrochloric acid – solutions containing HCl

- free chlorine in a concentration higher than 0.5 ppm; (Cl2 < 0.5 ppm)

- chlorides for heating water above 100°C (Cl- = 0 ppm)

- any substance from which alkaline residues or phosphorus would be deposited

Reviews

There are no reviews yet.