Description

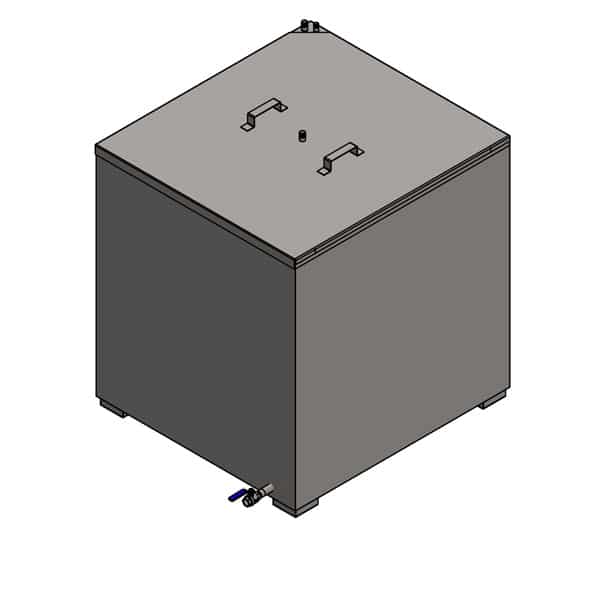

Opened fermentation vat for the primary beer fermentation with capacity 500 liters

Special fermentor for the opened beer fermentation process which is a typical method for production of the traditional Czech lager beer. Nominal capacity 500 liters of wort.

More about : Open beer fermentation process

This vessel is designed only for the primary beer fermentation process. These fermenters are suitable mainly for production of beer types which recipe is based on using of the bottom yeasts.

Description:

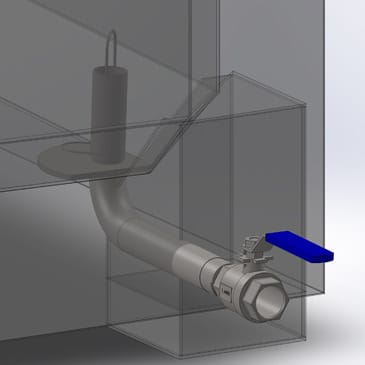

- Supply and discharge flap valve DN 25 / 1.4301

- Duplex jacketing, clearance 12 mm / 1.4301

- Insulation polyurethane, clearance 50 mm

- Insulation covered with metal sheets 1 mm thick, ground surface 1.4301

- Upstream armature DN 25 /1.4301

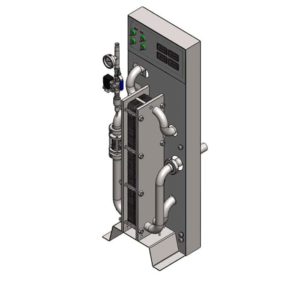

- Electromagnetic valve DN 25 for ice water supply 230V 50 HZ

- NTC probe

- Inlet and outlet pipes provided with food threading DN 25 GG

- Inlet and outlet threaded branches for ice water supply G ¾“

Operating conditions:

- Maximum operating temperature 80°C

- Minimum operating temperature -15°C

- Maximum tank overpressure 0 bar

- Testing tank overpressure 0 bar

- Maximum overpressure of duplex jacketing 0.5 bar

- Testing overpressure of duplex jacketing 0.8 bar

Parameters

- Usable capacity 500 liters

- Overall capacity 580 liters

- Length 1000 mm

- Width 900 mm

- Height 1000 mm

- Weight 232 kg

Warranty:

- Fermentation tank 36 months

- Electromagnetic valve DN 25 24 months

- NTC probe 24 months

- Upstream armature 36 months

Transport

This tank is usually shipped in horizontal position, fixed on special framing.

Ground-plan frame dimensions: 1550*850 mm

Standard included accessories :

- Special sanitable outlet © for releasing of beer and yeast from tank with adjustable yeast level

- Special sanitable inlet © for filling of wort into vat – removable part

Optional accessories :

- Top cover – for keeping of the fermented wort against infection (variant OFV-500C)

- Sanitation system – sprayballs mounted on the cover for easy cleaning and sanitation (variant OFV-500CS)

Why choose the open fermentation method for a beer fermentation process ?

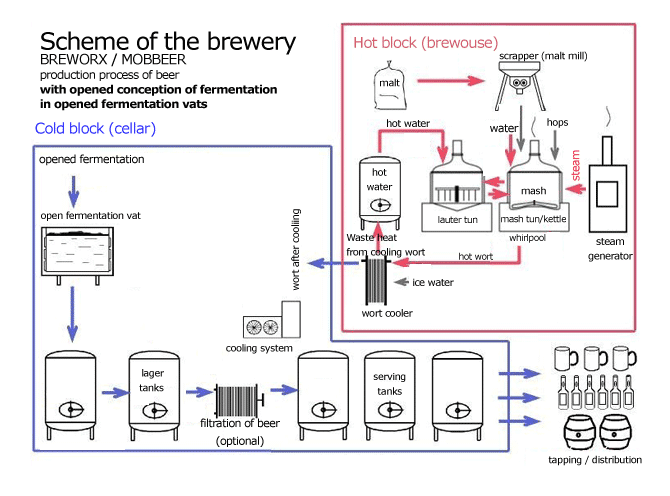

The traditional Czech brewery cellar technology is based on historically proven method of slow fermentation of wort in opened fermentation vats and the maturation of beer in closed lager-tanks at moderate overpressure. In this manner, in Central Europe, beer has been manufactured for at least 150 years.

The traditional Czech brewery cellar technology is based on historically proven method of slow fermentation of wort in opened fermentation vats and the maturation of beer in closed lager-tanks at moderate overpressure. In this manner, in Central Europe, beer has been manufactured for at least 150 years.

Although in the past 50 years, the traditional method of slow fermentation of the beer was usual, in many modern breweries this method was replaced by the more efficient concept of a brewery cellar, which is the production of beer provided in closed cylindrically-conical tanks. But in many small and medium-size breweries lately there is again a shift to a proven classic open fermentation technology.

The concept of a brewery cellar with cylindrical-conical tanks instead of opened fermentation vats has distinct advantages that make this system particularly preferred for large breweries. In contrast the classical concept has several essential characteristics, that make it particularly popular alternative for microbreweries and restaurant breweries. Among the main ones include lower cost, simple operation, and the possibility of convenient collection of so-called “quilt”. It is layer of dead yeasts. Their presence in the beer leaves an unpleasant sour – bitter tinge.

But there is one advantage of the technology of open fermentation for small breweries, which is irrelevant for big breweries. And that is the opportunity to show the beer production in its different phases . Who ever visited a microbrewery as a tourist, in his mind remains the memory of a bathtub full of young beer, which is covered by a layer of foam of interesting structure and colors. Looking at beer at the stage of primary fermentation is simply fascinating, and that is the most important for marketing of the small brewery. The operator of a brewery can boast before the guests with this attraction. The view of the modern brewery that is full of stainless steel closed tanks definitely cannot replace that interesting experience.

We also produce the opened fermentation vats with other than the standard sizes . We can customize all tanks we offer, to your spatial dispositions and needs.

Reviews

There are no reviews yet.