Description

Semiautomatic filling machine with a buffer tank and an automatic pump designed to gravity filling non-carbonated beverages with low viscosity into glass (or PET) bottles, Bag-In-Box and Pouch-Up bags.

The machine has a built-in pump, controlled by level switches in the buffer tank. Filling level in the bottles is adjustable, bottle overfill protection. The filler requires minimal maintenance.

The filling machine consists of two units :

GBFU-6 : Semi-automatic gravity bottle filling machine with the buffer tank – up to 600 bottles per hour

Semiautomatic filling machine with a buffer tank and an automatic pump designed to gravity filling non-carbonated beverages with low viscosity into glass or PET bottles.

The machine has a built-in pump, controlled by level switches in the buffer tank. Filling level in the bottles is adjustable, bottle overfill protection. The filler requires minimal maintenance.

BIBFU-180 : Semi-manual gravity filling unit for vacuum bags (Bag-In-Box, Pouch-Up) – up to 1000 L/hr

Semi-manual gravity filling machine for vacuum bags (Bag-In-Box, Pouch-Up bags). Modern BIBFU-180 filling machine is perfect for the small capacity filling of BIB-type vacuum bags from 2 to 20 liters and the Pouch-Up bags from 1.5 to 3 liters. The standard BIBFU-180 machine comes without chassis or pump for filling by gravity. In option, the machine can be equipped with the filling pump to increase the filling rate. Filling capacity from 255 up to 1000 liters per hour (depending on the bag type).

Technical specifications:

Bottle filling unit :

- Filling performance: 600 L/h

- Electric demands: 0.2 kW, 1-phase 230V / 50Hz

- Filling temperature: up to 100°C

- Filling volume in bottles: adjustable height

- Number of filling heads: 6 pcs

- Material: WNr. 1.4301, AISI 304 stainless steel

Filling unit for vacuum bags :

- Beverage flow capacity : 255-1000 liters per hour (depending on the bag type)

- Liquid flow: by gravity

- Compressed air supply (required pressure): from 6 to 6.5 bars

- Air flow consumption : 0.25 m³/h

- Nitrogen supply (required pressure): from 0.5 to 1.0 bars

- Nitrogen consumption : according to the bag type

- Power supply: 230 V 50 Hz.

- Pulse counter : 72 points per liter

- Connection to the source beverage tank: liquid input through the Æ Macon 40 male connector

- Noise level < 80 db

Dimensions:

- Length: 1250 mm

- Width: 1000 mm

- Height: 1650 mm

- Weight: 145 kg

- Connections: DN25 hose connector / BSP 1″ male

- Built-in impeller pump controlled with the level sensors in the buffer tank

- Only for low density materials (fluids, beverages)

- Semi-automatic operating

- Very easy to clean

- Requires minimal maintenance

Optional equipment :

Code |

Description |

Price |

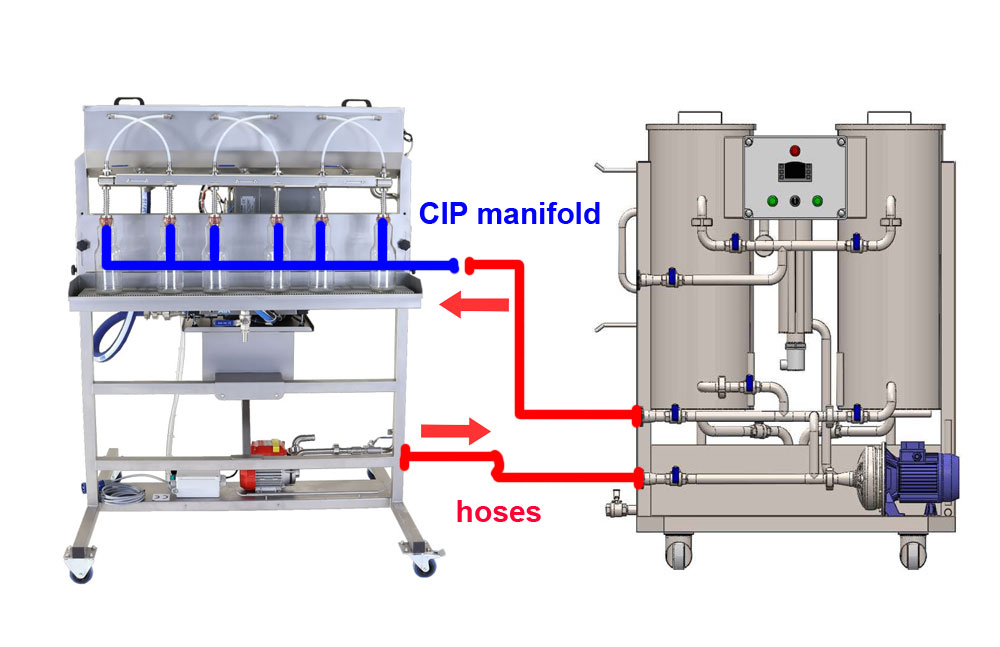

| GBFU-6CIP | CIP manifold – the cleaning adapter for chemical cleaning of the six-head bottle filler (the CIP machine and hoses are not included)

|

€ 295,- |

| GBFU-6TCS | TriClamp hose connector set (5pcs x TriClamp 1.5″ DN25)

|

€ 240,- |

Reviews

There are no reviews yet.