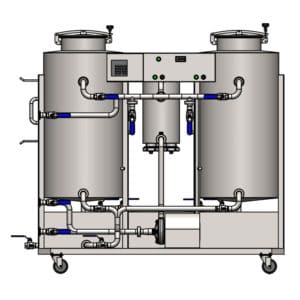

Description

The non-pressure closed cylindrical fermentation tank (CFT) with usable volume 8000 liters for the main fermentation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304).

Typical equipment of CFT 8000

- Cooling channels – duplicators for circulating of coolant

- PUR insulation – thickness corresponding to the size of the tank and the environment

- Stainless steel jacket – with the customer selected surface finishing

- Guaranteed inner surface roughness of Ra = 0.8 or less (except in very small tanks and terminate-welds on medium-size tanks)

- Manhole on the top bottom

- Multifunction outlet / inlet for beer, wine or cider, and for discharge of yeast

- Sanitation shower – sprayball (static or rotary) – one or more pcs

- Double-acting air vent valve

- Thermometer pocket

- Removable yeast separator

Optional equipment of CFT 8000

- Adjustable pure product drain valve with a sight glass (adjusting high of the suction inlet according to level of yeast)

- Scale for the beverage level indicator

- Thermometer or thermo-sensor

- Automatic valves for regulation the coolant flow in the cooling channels

- Local thermostat unit (control valves duplicators, depending on the temperature)

- Control system for manual or automatic control of fermentation process

- Cleanable and sanitizable glass level indicator

- Cleanable and sanitizable sampling cock

Technical parameters of the CFT 8000 liters

These are the usual standard parameters – the manufacturer reserves the right to change these parameters.

Each customer always approves with the actual parameters of the tank – it is specified in the contract document and construction drawings.

Description:

This cylindrical tank is installed on three adjustable feet, with efficient capacity of 8000 l. The vessel is designed for separated main fermentation.

Accessories:

Round manhole 510 mm

Sanitary shower RTS 25 1.4301- AISI304

Level indicator DN 20 1.4301- AISI304

Supply and discharge flap valve DN 25 1.4301- AISI304

Duplex jacketing, clearance 12 mm 1.4301- AISI304

Insulation polyurethane, clearance 50 mm

Insulation covered with metal sheets 1 mm thick, ground surface 1.4301- AISI304

Upstream armature DN 25 1.4301- AISI304

Electromagnetic valve DN 15 for ice water supply 230V 50 HZ

NTC probe

Inlet and outlet pipes provided with food threading DN 40 GG

Sanitary piping provided with food threading DN 40 GG

Inlet and outlet threaded branches for ice water supply ½“

Operating conditions:

Maximum operating temperature 80°C

Minimum operating temperature -15°C

Maximum tank overpressure 0 bar

Testing tank overpressure 0 bar

Maximum overpressure of duplex jacketing 0,5 bar

Testing overpressure of duplex jacketing 0,8 bar

Parameters :

Overall height 5180 mm

Diameter 1800 mm

Overall capacity 8882 l

– Cylindrical part 8256 l

– Ached bottom 626 l

Empty weight 1890 kg

Warranty:

Fermentation tank 36 months

Electromagnetic valve DN 15 24 months

NTC probe 24 months

Upstream armature 36 months

Transport

This tank is usually shipped in horizontal position, fixed on special framing.

Ground-plan frame dimensions: 5300*2000 mm