Description

Complete set for the fermentation and maturation of beer. This set includes all equipment necessary for professional production of beer using the fermentation and maturation of wort produced before by the brewhouse. This set is also designed for production of cider from fruit or carbonized wine.

Assembling of the set is very easy. The installation does not require any professional workers – there is needed only adequate handling equipment for moving and installation of heavy containers (cylindrical-conical fermenters) on place after delivering of the set. All wires, temperature measuring and regulation equipment (exclude covered central control cabinet and cooler) operate with safety voltage 24V, therefore they can be installed by customer using the installation manual. Therefore the price of the set does not include the installation work.

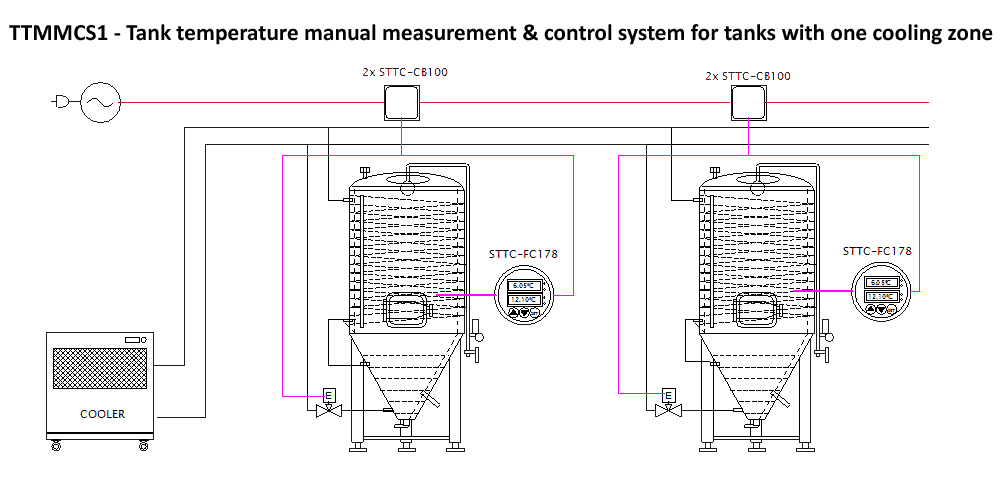

Scheme of the tank temperature cooling and control system with simplified fermenters :

The set consists of the equipment described bellow:

1. Beer fermentation-maturation tanks

6 pcs of the Cylindrical-conical tank Classic CCT-2000/2340 L (insulated 2-jacket)

The cylindrically-conical fermentation tank (CCT, CCF, cylindrically-conical fermenter) with the usable tank volume 2000 liters and total volume 2340 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. PED certificate (optional also GUM, GOST).

2. Glycol cooler

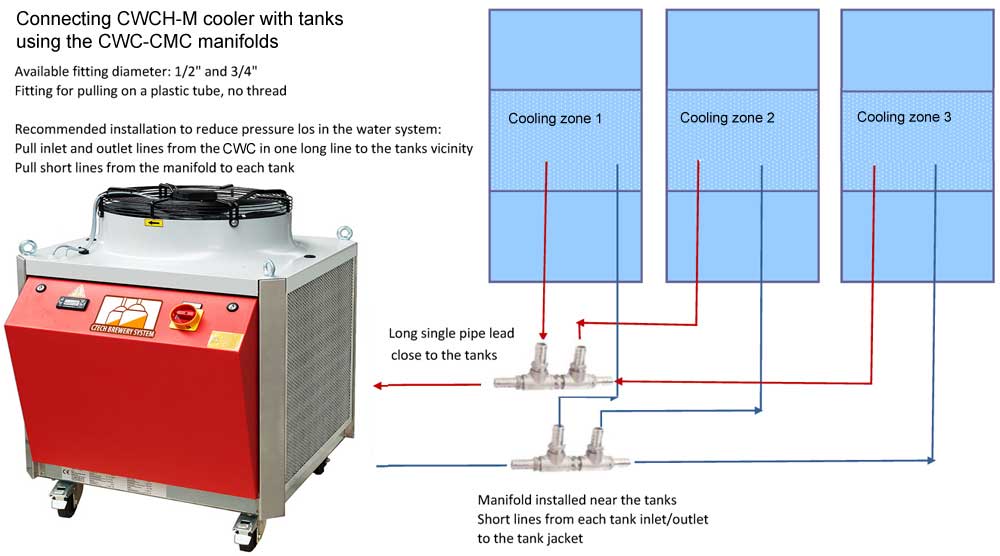

CWCH-M90 Compact water chiller-heater 10.7 kW

The CWCH-M90 is the compact water or glycol cooler with integrated condenser. This cooling unit is designed to cool, with the accumulation of ice or water heating. It can be used for cooling (or heating) of beer, cider, freeze-drying wines or heating mash. Cooling power is 10700 W (14.35 HP). This cooling-heating unit is designed for indoor or covered outdoor use. The main advantages are very easy instalation without team of cooling specialists. It is produced with 3-phase or 1-phase electrical standard (EU/USA). Suitable for cooling tanks with volume up to 20,000lt each – output / input cooling media fittings 2x 3/4” AG (male) . Designed in Germany.

3. Temperature control system

TTMMCS1-6AS Local tank temperature manual measuring & control system for 6 pcs of single cooling zone fermenters

The control system allows the manual monitoring and controlling of temperatures in tanks. This is necessary function for controlled beer fermentation and maturation process and operations with media. This M&R system for temperature control is fully designed in Europe.

The tank temperature manual measurement and control system is designed as the simple assembly kit.

The control system set is designed for the measuring and control of temperatures in 6 pcs of fermenters with one cooling zones on each tank.

4. The installation set – connecting material

Complete connecting material that is necessary for easy installation of the CFS set by customer.

Reviews

There are no reviews yet.