Description

Compact manual semi-automatic counterpressure filler with 8 filling heads and touch display. Designed to isobaric filling carbonated or non-carbonated beverages into glass bottles. Capacity up to 1200 bottles per hour (depends on foamicity of a drink).

Perfect for breweries, carbonated cider makers, lemonade producers etc.

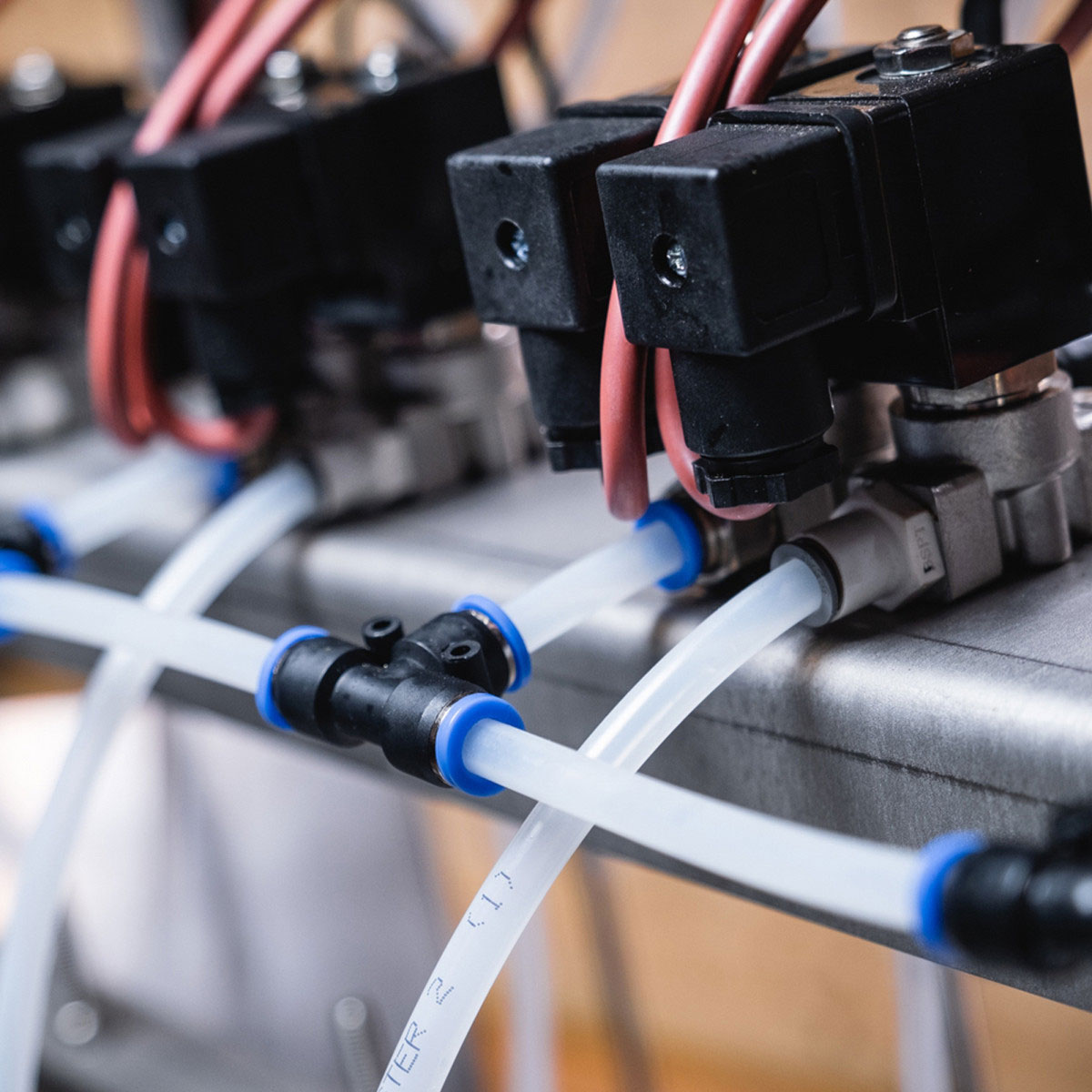

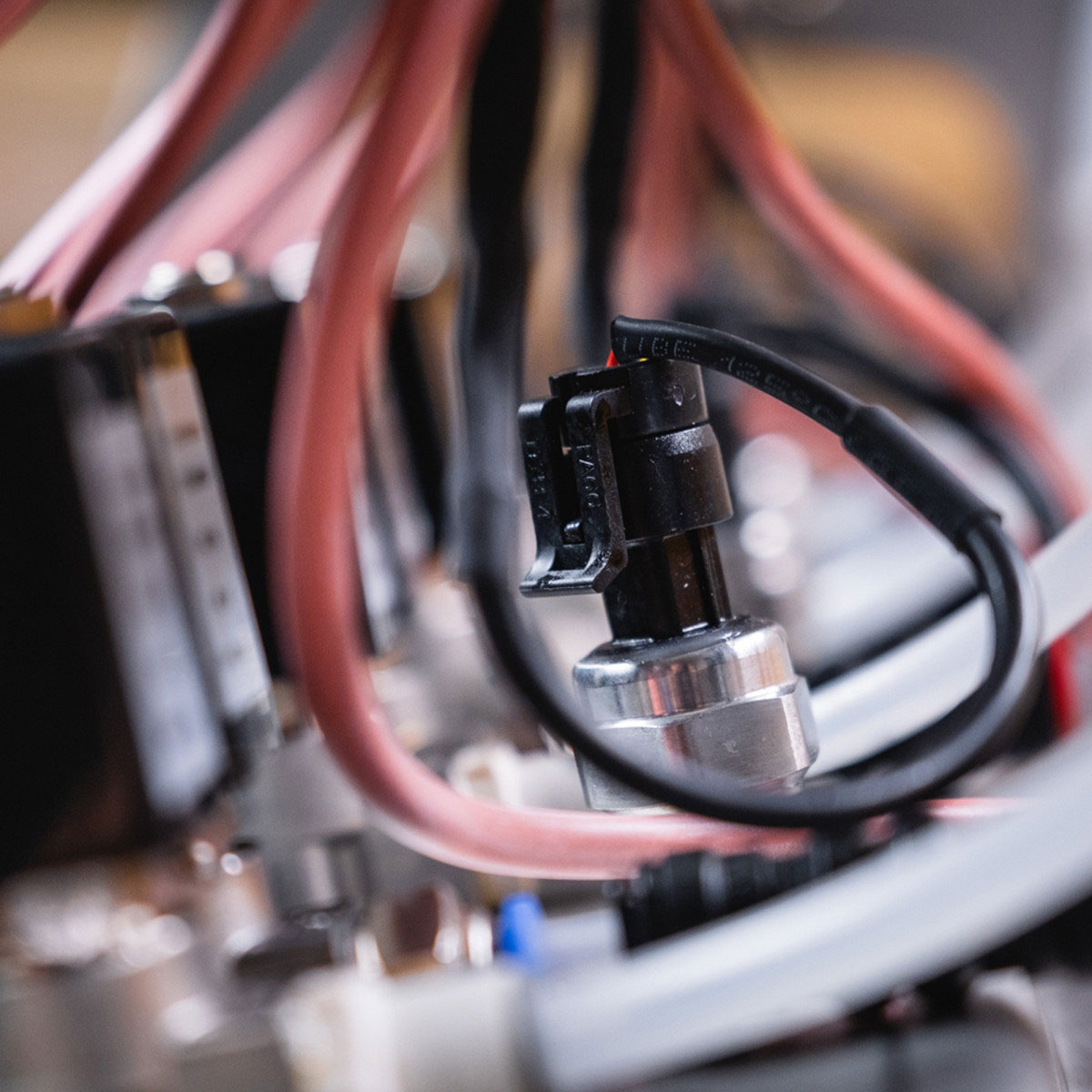

The bottle filling machine is produced in EU from materials friendly with food – stainless steel, polyethylene, silicone.

Chemical cleaning with a CIP station is allowed.

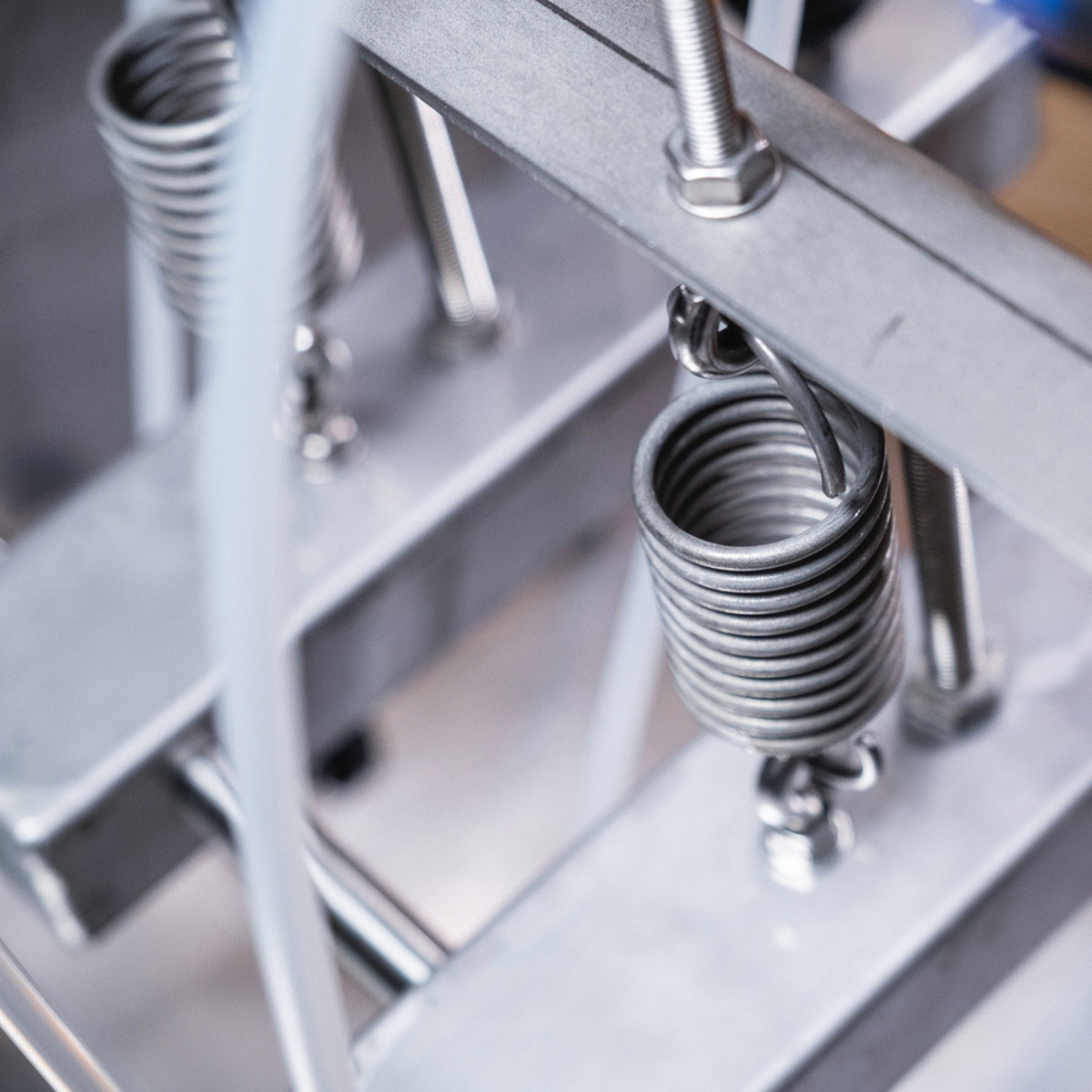

The photos show the bottle filling unit with only 4 filling heads

We are an authorized sales partner of the European producer. Standard delivery time : 2-4 weeks.

Main properties and equipment :

- Stainless steel valves

- 7-inch touchscreen interface – one button operation

- Easy to set-up for multiple bottle sizes

- Filling capacity of up to 1200 bottles per hour when operated by 2-4 people

- Fast Flush system for long shelf life of a beverage in the bottles

- The maximum liquid temperature must be lower than 80°C

- Bottle height and filling height are adjustable

- The machine can fill bottles between 0.2 and 1 litre

- Power supply: 110-320V/50-60Hz 3A max

- Connections :

– CO2 inlet : ¼” female BSP threaded pipe

– Beverage inlet : Triclamp 1.5” (DIN 32676 / DN 40) - Capacity: +/- 150 bottles per hour per filling head when operated by two people (one for filling, one for capping)

- Filling beverages into the bottles with counterpressure (isobaric filling) or without counterpressure is possible (gravity filling)

- Maximal tank/pump pressure : 1.2 bar

- Delivery period : 2-3 weeks

- Warranty : 1 year

- Transport dimensions (without the stand) : wooden pallet 1200x1000x1000(h) / 150KG

Optional equipment :

| Item Code | Description | Price |

| CBF4-1200ST | Stainless steel stand | € 1366,- |

| CBF4-1200KH | Filling heads with heavy springs for filling the 5 litre party kegs (full set = 8 heads) | € 658,- |

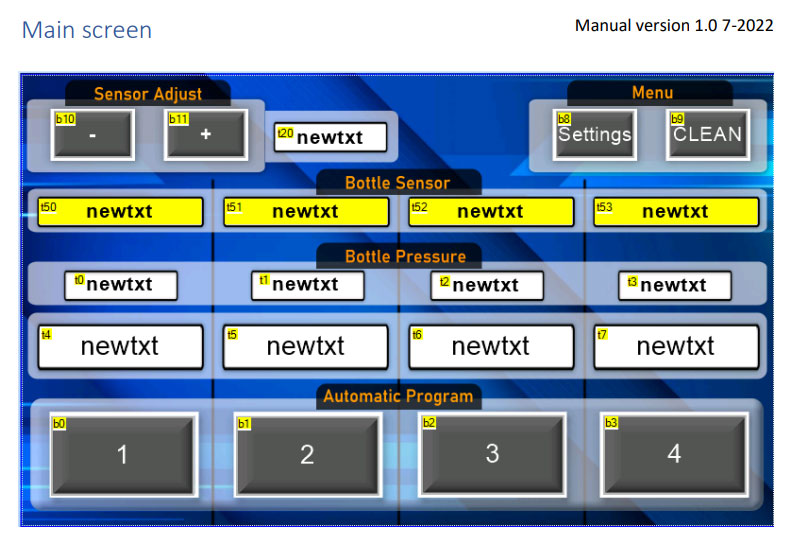

LCD touch display and simple control system

The 7” waterproof touchscreen is used to set all filling parameters:

- CO2 pre-purge time

- Filling time

- Pressure

Filling routine starts automatically by just pressing a single button.

| Item # | Function name: | Description: |

| B10 | Plus | Adjust the sensor value down |

| B11 | Minus | Adjust the sensor value up |

| T20 | Sensor Value | Read the set sensor value |

| B8 | Setting | Go to Settings Menu |

| B9 | Cleaning | Go to the Cleaning Menu |

| T50~T53 | Bottle Sensor Value | Show the current sensor value of bottle 1-4 |

| T0~T3 | Bottle Pressure Value | Show the current pressure value of bottle 1-4 |

| T4~T7 | Bottle Status | Show the current status of bottle 1-4 |

| B0~B3 | Start / Stop | Start automatic filling of bottle 1-4 |

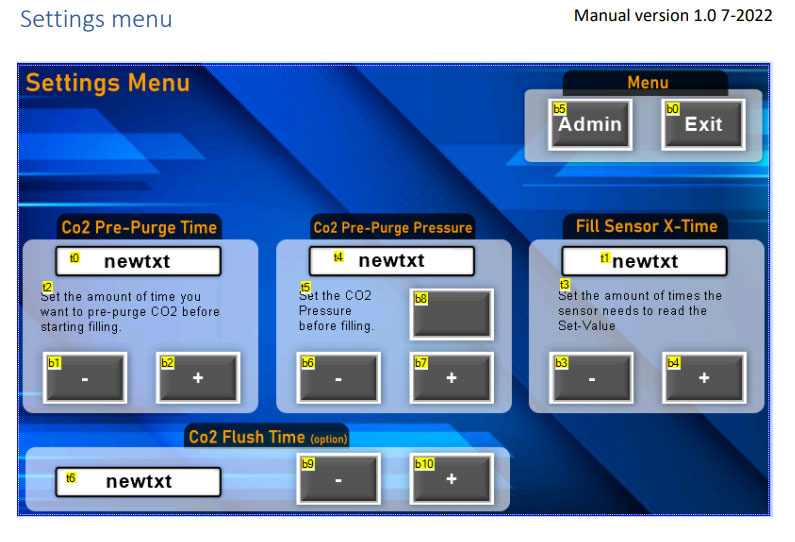

| Item # | Function name: | Description: |

| T0 | CO2 pre-purge time | Show the set CO2 pre-purge time |

| B1 | Minus | Adjust the CO2 time value down |

| B2 | Plus | Adjust the CO2 time value up |

| T4 | CO2 pre-purge pressure | Shows the set CO2 pre-purge pressure. (Never set the value above 1.2 bar) |

| B8 | Pressure / Time | Choose CO2 pre-rinse based on time or pressure |

| B6 | Minus | Adjust the CO2 pressure value down |

| B7 | Plus | Adjust the CO2 pressure value up |

| T1 | Fill sensor quantity X | Show the set sensor number X. (Never put the value lower than 10!) |

| B3 | Minus | Adjust the Sensor X-time value down |

| B4 | Plus | Adjust the Sensor X-time value up |

| T6 | CO2 fast flush time | Shows the set CO2 fast purge time. (Only applicable for machines with “FAST FLUSH”) This value can never be higher than the set time (T0) |

| B9 | Minus | Adjust the fast cleaning value down |

| B10 | Plus | Adjust the fast cleaning value up |

| B5 | Admin menu | Go to the Admin Menu. (Only use this function if the support department allows this) |

| B0 | Back | Go back to the main menu |

New software and hardware

Special features of the 1.2 version (2023)

- Renewed software with the possibility of fine adjustment of each filling head

- USB connector for easy software updates

- PowerCON connector for power supply

The maximum filling capacity depends on several factors such as temperature (up to 4°C, we recommend max. 2°C), pressure in the source tank (max. 1.2 bar) and level of CO2 saturation. Experience shows that 600 bottles can be filled per hour when operated by two people. Two operators are needed for filling more than 300 bottles per hour.

The machine can be completelly cleaned in under 15 minutes with an external CIP equipment or manually.

Easy to operate the bottle filler

How to fill carbonated drink to the glass bottles :

- Lower the lever with one hand and with the other hand slide the bottle under the filling head. By releasing the lever, the bottle will be pressed into place under the filling head.

- Press the start button of the relevant filling head. The filling will now happen automatically.

- First, CO2 will be injected into the bottle so that rest of oxygen is pushed out from the bottle. The time and pressure of the CO2 pre-rinse is fully adjustable.

- After the CO2 flushing, the bottle will be filled until it reaches the sensor value set on the touchscreen.

- You can now remove the bottle and start the process again.

- The filling speed can be regulated so that when you put the last bottle under the head, the first one is ready to be replaced to achieve of maximal possible capacity.

FFS – The Carbon Dioxide Fast Flush System

The bottle filler is equipped with the FFS (The Carbon Dioxide Fast Flush System), this means that it is possible to open an extra valve while PRE-purging of a bottle with carbon dioxid. This way flushing out oxygen from the bottle is faster and you get better shelf life of a drink.

Reviews

There are no reviews yet.