Description

The semi-automatic bottle washing machine for 15pcs of new or used glass bottles. Working capacity from 400 up to 500 bottles per hour.

The bottle washing unit has a compact design, very low consumption and it is practically “maintenance free” as it has almost no mechanical parts. It all combines the features of a traditional bottle washer in a single machine: bottle washing, label removal and final bottle rinsing.

All this while safeguarding the environment and reducing production costs, allowing you to easily recycle and reuse previously “disposable” bottles.

Also, the modular structure of the machine allows to progressively increase its functions and level of automatization as well as the level of sophistication, by inserting optional special washing and / or sanitizing sections.

The “Czech Brewery System” reserves the right to re-confirm this offer upon receipt and evaluation of samples the bottles delivered before production. The machine is designed for use with common bottles, labels and glues used with the bottles, for washing the bottles dirted with common beverages. A producer does not keep guarancee that the machine is able to work with all types of bottles, kind of dirts in the bottles, all kinds of glues on the bottles.

Main technical parameters :

| Operation capacity with new bottles without glued labels | 450-500 bottles per hour |

| Operation capacity with used bottles without glued labels | 400-450 bottles per hour |

| Operation capacity with used bottles with glued labels | 100-200 bottles per hour |

| Bottle format | Glass, universal (0.1 – 2.0 liters) |

| Number of bottles in one cycle | 15 pcs |

| Recommended detergent | (NaOH 1~3% – 70°C) |

| Electric supply | 3-phase 220-400 Volt – 50 Hz (or other on demand) |

The actual working capacity of the machine may differ from the capacity stated by the manufacturer. It depends on kind and old of dirt in the bottles, type and volume of the bottles, on the chemical composition, concentration, temperature and contamination of the cleaning chemical solution.

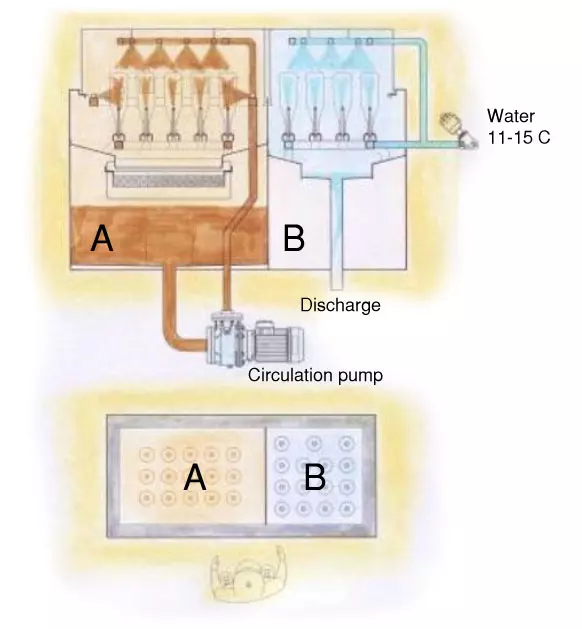

Bottle washing cycle description :

A – Manual loading of the dirty bottles: open the cover and position manually the bottles in the special washing positions in the A-section. The machine is predisposed for 15 dirty bottles.

B – Once the cover is closed, the bottles are rinsed over (internally and externally) with a big flow of warm water with the chemical solution (NaOH 1~3% – 70°C) for effective washing and label removal.

C – Finishing the washing, the operator manually moves the washed bottles from the washing station (A-section) to the rinsing station (B-section), freeing the place for other dirty bottles.

Then places other dirty bottles in the special washing positions (A-section) and, once the cover is closed, it restarts the machine.

D – Finishing the new washing/rinsing cycle, the operator removes rinsed bottles out of the machine, manually moves the washed bottles from the washing station (A-section) to the rinsing station (B-section) and loading the new dirty bottles in the washing positions.

The machine is equipped with:

1 – The machine is in compliance with Machine Directive 2006/42/CE dated May 17 2006.

2 – Frame of the washer is made from steel plates and outlined in stainless steel type Aisi 304. Outside finishing with external micro glass balls.The internal tanks are with inclined bottom for facilitating cleaning, and suitably profiled to equip the structure with greater rigidity and resistance. Ample doors in stainless steel are provided for cleaning the tanks and principal cover in steel glazed stainless steel, hinging at the structure with opening system “easy-open”.

3 – Safety protection (with safety limit switch) positioned on the opening cover. When the operator opens the cover the machine instantly jams the washing operation.

4 – Inside washing system is made with special penetrating nozzles at high pressure. External washing and labels removal made with special nozzles with high flow rate and low head. The water currents are carried through a filter (made of stainless steel) for filtering the detergent solution and for separated the labels.

5 – The pumps are of the monoblock centrifugal type with pump body and impeller in stainless steel type AISI 316. The external showers are of “easy maintenance” because are extremely easy to get off and to clean.Rinsing stations are made with special penetrating nozzles and the external rinsing made through nozzles fed by the net water. On the rinsing alimentation (mains water supply) there is installed an economy valve that interrupts water flow to the machine when it is stopped.

6 – The detergent solution heating block can be furnished, without price variation with :

– heating exchanger (always made in stainless steel ready for steam alimentation, automatically control by an electro-pneumatic valve with respective condensation vents;

– incorporated combustion room (included burner);

– electric heating.

The bottle washing temperature is easily adjustable through a thermostat.

7 – A ball valve for the detergent tank emptying.

8 – Utility connections at a single point.

9 – Electrical circuit (in IP55) with power switchbox in stainless steel installed on the machine. The 24V control panel made of stainless steel is equipped with LED indicators and control switchers for visual monitoring and control of all operations.

10 – Chimney for the vapors spillage from the machine, predisposed for a possible steam extractor application.

11 – Adjustable feet positioned along the sides of the machine.

12 – The User’s/ Maintenance manual in English language version.

Technical features, parameters and requirements :

| 1 | Number of places in the washing section (A-section) | 15 |

| 2 | Number of places in the rinsing section (B-section) | 15 |

| 3 | Bottles total number in the machine | 30 |

| 4 | Bottles that can be washed/rinsed: diameter max./min. – height max./min. (subject to our approval for special shapes). |

Diameter : 125 – 45 mm Height : 400 – 150 mm |

| 5 | Water consumption (the filling tank in the A-section) | ~ 225 liters |

| 6 | Average fresh water consumption at 1,5 bar (rinsing the bottles in the B-section) | ~ 100 liters per hour |

| 7 | Water hardness [F°] | min.7 – max.15 |

| 8 | Water pressure [bar] | min.1 – max.2 |

| 9 | Water discharge PH | ~ 9 |

| 10 | Water discharge temperature | ~ 35°C |

| 11 | Water consumption per bottle | ~ 0,2/0,7 ml/bottle |

| 12 | Steam pressure [bar] (to communicate in phase of order will be required the exact pressure of the steam inlet at the bottle washer) | min.1 – max.6 |

| 13 | Consumption in calories: during machine heating [kcal/h] / at slow running [kcal/h] |

12.500 85 x bottles per hour |

| 14 | Direct heating by burner (gas-oil): during machine heating [lt/h] / at slow running [lt/h] |

1,75 1,25 |

| 15 | Electrical heating – installed heating | 16 kW |

| 16 | Electric power : installed / absorbed | 2 kW / 1,75 kW |

| 17 | Electric alimentation | 3PH+NT 380-420V / 50 Hz |

| 18 | Chemical detergent consumption (NaOH 1~3% – 70°C) | ~ 0,1/0,3 g/bottle |

| 19 | Machine dimensions: length x width (max. encumbrance) x height | 2050 x 1250 x 1300 mm |

| 20 | Empty / Full weight | 525 / 765 kg |

| 21 | Number of adjustable feet | 4 pcs |

| 22 | Average load per each foot | ~ 200 kg |

Machine working time calculated at 200 bottles per hour :

| 1 | Detergent washing of the bottles (NaOH ~1,5-2,0% – 70°C) | 2 min + 37 sec |

| 2 | Rinsing of the bottles with pure water | 2 min + 37 sec |

| 3 | Exchange of the bottles (manually) | 2 min + 00 sec |

Price list :

| Description | Price : |

| BWRB-SA15 : The bottle washing machine with a set of parts for one bottle format | € 31.900,- |

| MXSG-18CSF : Recommended external steam generator (in the standard version an external steam generator is needed but not included) | MXSG-18CSF : GHIDINI MAXI-24 18kW / 7 bar |

| Options : | |

| BWRB-SA15-ONVF : Non-standard voltage and frequency (EU standard is : 3-phase 400V / 50 Hz) | € 980,- |

| BWRB-SA15-OTAR : Timer for the automatic regulation of the bottle washing and the bottle rinsing time, easily adjustable by the operator | € 1650,- |

| BWRB-SA15-OPOF : Parts for handling each additional bottle format | € 565,- |

| BWRB-SA15-ODGB : Extra price for direct gas-oil burner (an external steam generator is not needed) | € 3490,- |

| BWRB-SA15-OEHS : Extra price for electric heating 15 kW (an external steam generator is not needed) | € 3950,- |

| BWRB-SA15-OSSP : Recommended set of spare parts | € 1250,- |

| BWRB-SA15-PKEU : Packing for on-truck transport to EU countries (wooden pallet / shrink film) | € 250,- |

| BWRB-SA15-TREU : On truck transport to EU countries (without over-sea shipping) | € 950,- |

General sales conditions :

This document is subject to final confirmation after receipt of samples of the bottles, labels, caps, capsules and information on all raw materials to be processed. Following conditions are applicable unless otherwise stated in the above document.

1. General Principles

These terms and conditions of sale shall be applied unless otherwise specified in an agreement written by the seller and the customer (herein referred as the “Buyer”). When a Buyer sends an order, it implies full acceptance of these Conditions of Sale and supersedes any previous offers, correspondence and quotations between the Parties.

2. Sales Contract

The Seller shall be bound to abide solely by the terms specifically set forth in the present document. The Parties are bound to respect the terms of the Conditions of Sale only after the Seller has accepted the Buyer’s order in writing, in the form of a confirmation of receipt of the order.

3. Prices

Prices are “EX-WORKS”, VAT is not included. The quoted prices do not include shipping, insurance or packing. These items will be calculated separately.

Prices are established on the basis of economic and financial conditions as of the date of the quotation.

Prices are quoted for Products only and do not include technical data, or patent or proprietary rights.

4. Delivery

4.1. Delivery terms shall be calculated as of the date of the confirmation of the receipt of the order.

Delivery time is subject to receipt of the payment to deposit account, samples necessary for the construction of the equipment and technical details. In any event, if the order is suspended, after that date, for any of the following reasons such as non-payment of invoices, lack of approval of drawings, non receipt of samples or prototypes, transfer of export or import licenses, credit facilities, etc., the delivery date shall be considered as of the date said conditions are fulfilled.

4.2. The delivery date indicated by the Seller shall be considered an estimate. Unless specifically agreed otherwise by the Seller and Buyer, missing the delivery date shall not be cause for cancellation of the order or entitle the Buyer to any indemnification.

5. Force Majeure

Any conditions of force Majeure shall be cause for the Seller to suspend its commitments until said conditions shall cease to exist. The following conditions shall be considered force Majeure to the terms and conditions of sale: any unforeseeable circumstance the effects of which could not be reasonably prevented by the Seller and which are of such nature as to prevent the Seller from fulfilling its obligations.

The following conditions constitute force Majeure : fire, flood, interruption or delay in transportation, shortcomings on the part of a supplier or subcontractor, strikes of any kind, machine breakdowns, epidemy, goverment restrictions etc.

6. Insurance and Transportation

The goods shall be shipped at the buyer’s risk. The buyer shall be responsible for inspecting the goods upon arrival and, if necessary, advise the shipper of any damages. Upon receipt of specific instructions from the Buyer, shipments may be insured by the Seller who will then bill the buyer for the insurance costs.

7. Installation & Setting up

In case that assembly and start-up operations are requested, the Seller will guarantee the execution of the plant assembling and start-up in the lowest possible time, at prices indicated in the standard tariff unless otherwise specified in the present document. Seller´s technicians will start assembling work after a communication with the Buyer who confirms that the machines arrived on site in good condition, that the eventual preparing operations have been carried out and that all rooms and relative utilities in place have been finished in accordation with the Seller´s requirements (building works, piping and electric nets). It is understood that at technician/s arrival the necessary manual labour, all lifting and movement means will be at disposal as well as the necessary work-shop equipment and needed tools.

The Buyer will prepare and ensure :

• the area provided for the installation and the appropriate access routes free from stored materials or equipment;

• the necessary mains supply requirements such as water, steam, inert gas, product, electrical connections, compressed air, etc. available at the specified predetermined user points.

• the necessary handling equipment (forklifts, cranes, etc.) to discharge, to allow site positioning and handling of equipment and materials on site and the necessary personnel dedicated to such tasks.

• placing the products and all required raw materials on site in sufficient quantity for conducting the necessary equipment tests.

If the installation is not carried out or will be prolonged, due to delays whether attributable to the Buyer, then the Seller will charge the Buyer the costs related to technicians’ time at an hourly rate prescribed in our intervention tariff, and also the cost of expenses incurred for travel, food and lodging.

Furthermore, the Buyer’s staff, appointed to control and maintain the equipment, must co-operate with the Seller’s technicians for the assembling operations and to receive training.

Installation, start up and commissioning of the equipment are at the expense of the Buyer who will be charged the cost of technical assistance provided at our standard rates and terms and conditions (details provided on request and may vary depending on the country of destination).

During the commissioning of the system, the technical personnel of the Seller will carry out various routine tests on the equipment which may cause a certain amount of product loss. The Seller will not be held responsible for such losses and will not be liable for any claim of compensation.

8. Conditions for Acceptance on the part of the Buyer

8.1. Product features shall be those published in the most recent edition of the manufacturer’s specifications, unless other features are specifically agreed upon between the Seller and the Buyer.

8.2. The output capacity of the Products described in the present document result from an average calculation carried out with similar product characteristics or as a result of a theoretical calculation, unless otherwise specified. The Seller will advise the Buyer about the real effective capacity after having trialled the Product with the sample Products supplied by the Buyer. In the case that product samples are not supplied by the Buyer, the Seller shall not be responsible for properties different from the values stated in the offer.

8.3. The Seller’s goods are subject to tests and inspections in the factory where they are manufactured. The Buyer is entitled to request that the goods be inspected in his presence. If the Buyer cannot attend said inspections after having been given the agreed, advance notice of the date by the Seller, the Seller may send the

Buyer the inspection report that the Buyer will accept without discussion.

8.4. In order to be accepted to the provisions of this paragraph, all claims regarding the goods supplies shall be prepared according to the instructions provided by the Seller and contained in the documents sent with the goods.

8.5. No goods may be returned without prior authorisation from the Seller.

8.6. When a return of goods is accepted by the Seller, the Seller shall have the option to repair or replace the item(s) or to issue a credit note for the items acknowledged to be defective. In any event, the Buyer shall not be authorised to consider the return of goods, to suspend any payments due to the Seller, nor to cancel all or any part of any still pending order.

9. Payment Terms

Payments to the Seller covering price of the goods and related services supplied shall be effected according to the conditions set forth on the present quotation or order confirmation and the invoice. In the event the purchaser does not pay an invoice or part of it, the Seller shall be entitled, without prejudice to its other rights, to suspend all deliveries, irrespectively of the terms of the order(s) until full payment is received.

10. Title

Notwithstanding the effected delivery to the purchaser, the goods shall remain the property of the Seller until full payment is received. In the event that the purchaser does not effect payment by the established date, the Seller may repossess back already the delivered goods. In any event, as specifically stipulated, the purchaser shall be responsible for all damages and losses that may occur after delivery.

11. Warranty

The Seller engages to try solving all eventual defects coming from designing, production and assembling defects, guaranteeing the regular running of the supplied equipment for a period of 12 months from the date of shipment, if not agreed different time.

The warranty does not include normal wear and tear , and break downs due to an incorrect or improper use, to lack of diligent maintenance and to the non observance of technical descriptions as well as instructions indicated on the hand books which will be supplied to the Buyer. Warranty is limited to mechanical parts which are not subject to wear and does not include electric and electronic components, as per international guarantee regulations. Defective parts under guarantee must be returned to the Seller for examination and assessment of the defect, for the Buyer´s costs.

Replacement of damaged parts will occur after the manufacturer’s examination and confirmation of the damage of the returned defective component.

Replacing the components with non original parts by the Buyer or his customer shall invalidate the warranty unless such replacement has been specifically permitted by the Seller in writing. Spare parts supplied under guarantee are delivered free of charge EX-WORKS. All expenses for shipment of such parts from EX-WORKS to destination, including our technician’s travel, food and lodge are at customer charge. The Seller’s own technician labour for installation of spare parts under guarantee is free of charge. Any intervention carried out on the Seller’s equipment by the Buyer or by third party technical personnel are only for customer’s charge and responsibility. Modifications or interventions on the equipment may invalidate the guarantee terms unless explicitly authorised by the Seller.

12. Transfers

By virtue of this document, any transfer by the purchaser of any contract without prior makes agreement from the Seller shall render the contract null and void and shall relieve the Seller of any future obligations.

13. Court of Jurisdiction and Applicable Laws

In the event of judicial proceedings, the rights, obligations and claims of both parties will be decided by a court in a European country and city chosen by the Seller, irrespectively of the agreed upon terms of sale and payment, as well as warranty problems or in the event of multiple defendants.

The agreement and any difference or dispute arising out of it or related to it shall be governed, construed and interpreted in accordance with the Laws of Czech Republic. If any dispute, difference in opinions or question shall arise between the Parties under or in connection with the Contract, including any dispute on the validity of the Contract, such dispute, difference or question shall be finally settled by arbitration under the Rules of Arbitration of the Ministry of commerce of Czech Republic as in force and effect at the date hereof by one or more arbitrators appointed in accordance with the said Rules. The language to be used in the arbitrate proceedings shall be English. The seat of arbitration shall be Opava, Czech Republic. The decision of the arbitrators shall be final and conclusive and shall be binding on the Parties.

14. Compliance with Safety Regulations

The Equipment is built according to the European CE regulations. It is the duty of the Purchaser to inspect all Products and to provide proper safety devices to safeguard the operators from harm and to ensure compliance with all Safety Regulations. By accepting the “Order Confirmation”, the Purchaser acknowledges and agrees that the goods may not include or require the necessary safety equipment to permit safe operation or comply with Local, State, Federal, Industry and/or other applicable Safety Standards or requirements which may be different from the CE regulations. Before placing the equipment in operation the Buyer agrees to utilise such safety equipment and will give operators such instructions and/or warnings as necessary to permit safe operation and to comply with Local, State, Federal, Industry and/or other applicable Safety Standards or requirements. Purchaser further agrees to indemnify and hold Seller and their officers, employees harmless from any and all liability which may be imposed upon Seller and any and all costs, including attorney fees, incurred as a result of any claim made against Seller for injury arised out with the Products, that was caused or contributed to by purchaser’s or user’s failure to provide safety equipment and/or instructions and/or warnings necessary to operate this Products safely.

15. Instruction manuals:

The instruction manuals, assembly manuals, operation manusls, maintenance manuals are supplied exclusively in English language.

Reference standards :

The planning/manufacturing of the machine is carried out in compliance with the following rules:

- Planning and manufacturing of the machine:

Machine Directive 2006/42/CE of European Parlament and Council dated 17 May 2006;

- Electric installation:

– Low-tension Directive 2006/95/CEE;

– Electromagnetic compatibility Directive 2004/108/CEE;

- The electric installation of our supply complies with the following regulations:

– European regulations: EN 60204-1;

– International regulations: IEC 204-1

- Steam heating system:

Directive 97/23/CE PED

- Piping thermal insulation:

EN 563;

- Operator safety guards:

Machine Directive 2006/42/CE of European Parlament and Council dated 17 May 2006;

- Machine not suitable to be installed in premises with explosion risk:

Directive 99/92/CE Atex

General technical features of the supplier :

| (1) | Machine efficiency as DIN 8782 | 95% |

| (2) | Grid voltage | 230 Volt Volt ±4% |

| (3) | Grid frequency | 50 Hertz ±0,5% |

| (4) | Distribution | 3F + N + T |

| (5) | Distribution system | T – N separate |

| (6) | Auxiliary circuits voltage | 24 Volt DC |

| (7) | Instrumentation voltage | 24 Volt DC – 240 Volt AC |

| (8) | Plant IP degree | IP 54 |

| (9) | Motors IP degree | IP 55 |

| (10) | Noisiness | < 85 dB(A) |

| (11) | Humidity | min. 20% – max. 80% |

| (12) | Temperature | min. 5°C – max. 40°C |

| (13) | Maximal altitude | 750 metri m asl |

| (14) | Harmful gases presence | NO |

| (15) | Ambient light level | min. 100 Lux. |

| (16) | Water hardness | min.7 – max.15 F° |

| (17) | Water pressure | min.1 – max.2 bar. |

| (18) | Air pressure | 6 bar. |

| (19) | Steam pressure [bar] (to communicate in phase of order the exact pressure of the steam at the bottle washer) | min.1 – max.6 |

Reviews

There are no reviews yet.