Description

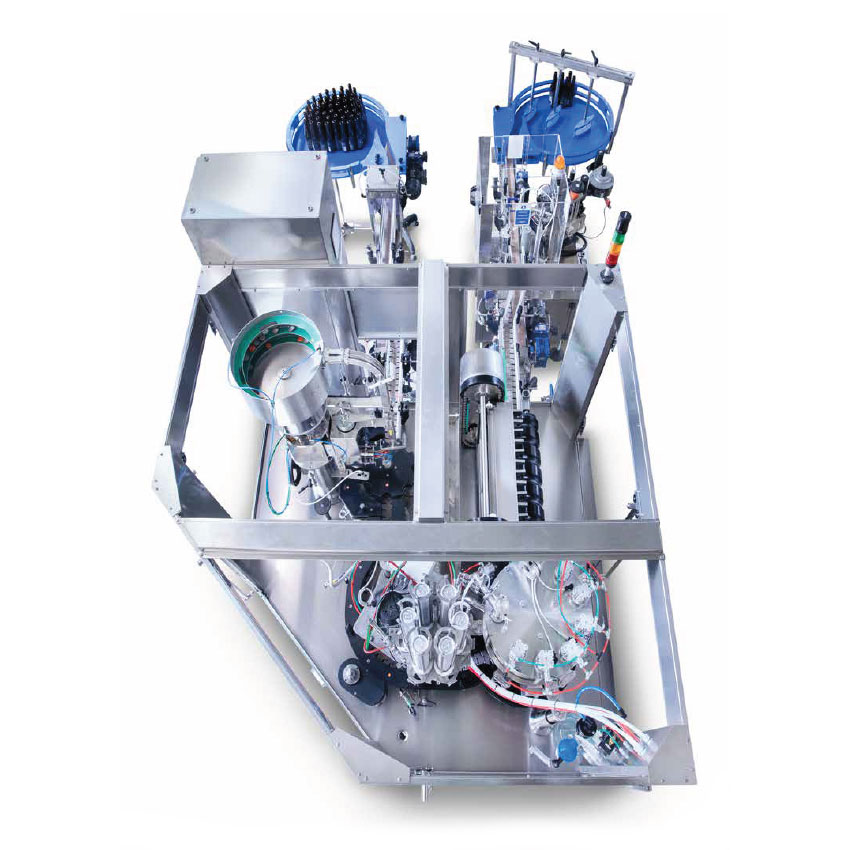

The automatic bottle filling line BFL-MB1200 is fully equipped filling technology with the production capacity up to 1200 bottles (0,33L) per hour. It consists of these components and blocks :

- Automatic monoblock machine for rinsing, filling and closing the glass bottles.

- Special CIP bottle for full cleaning and sanitizing the machine in closed circuit.

- High temperature washing kit for the hot internal cleaning of the machine at 85 ⁰C using a caustic solution.

- Linear labelling unit for application of paper labels on the bottles.

- Photocell to avoid bottle jam out in the labelling unit.

- Coder integrated into the labelling unit to printing the filling day date.

- Rotary table to inserting the bottles.

- Rotary table to full bottles accumulation before unloading (Ø800mm).

- Conveyor system to connection of all units each other.

The bottle filling line is designed to be operated only with one worker.

Main benefits of this bottle filling line

…. in comparation with similar machines of other producers

This automatic line with the rinsing/filling/capping units will make filled up to 1,200 pcs of 330ml bottles per hour. You can see the machine in operation on a video on this site bellow.

This automatic line with the rinsing/filling/capping units will make filled up to 1,200 pcs of 330ml bottles per hour. You can see the machine in operation on a video on this site bellow.

This whole bottling line in a “U-shape” conveyor system can be run with just one operator.

Unlike some other filling systems available on the market, you can easy fill different size bottles with this line. It is an extremely flexible & versatile machine.

It is simple solution when you purchase additional bottle handling parts for different bottle diameters.

Changeover time is only 10/15 minutes from one bottle format to another.

This system is also fully automatic and does not have the “manual” rinsing operation like some systems on the market do so it is a lot less labour intensive and therefore extremelly efficient.

Our fillerblocks, thanks to the electro-pneumatic control of the filling valves, offer high-speed precision filling and, in the case of beer and cider filling, minimal DO pickup levels.

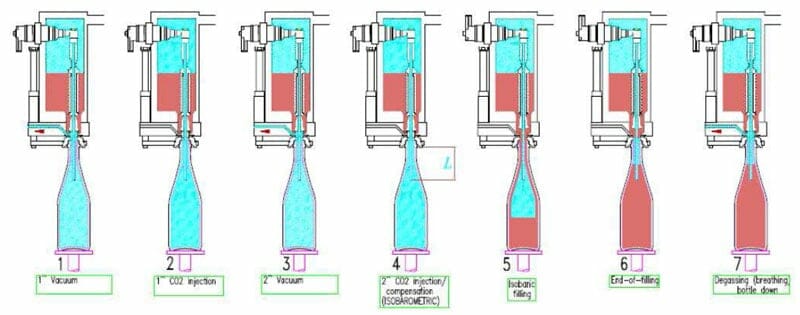

Method of operation:

The glass bottle is firstly pressed on and then undergoes double pre-evacuation.

Once the pressure is the same in the filling tank and in the bottle, the filling process commences.

Once the liquid level reaches the end of the vent tube, no more gas can escape from the bottle – and the filling valve is closed.

After a settling phase, the snifting valve lowers the pressure in the bottle’s head space and the filled bottle leaves the machine.

Characteristics:

■ Reliable calculation of the fill level using the length of the vent tube

■ Low-oxygen filling process thanks to double pre-evacuation with intermediate CO² flushing

■ Closed CIP circuit

■ Hygienic design

■ Electro-pneumatically controlled filling valve functions for maximum flexibility, which is managed by the operator on the main control panel.

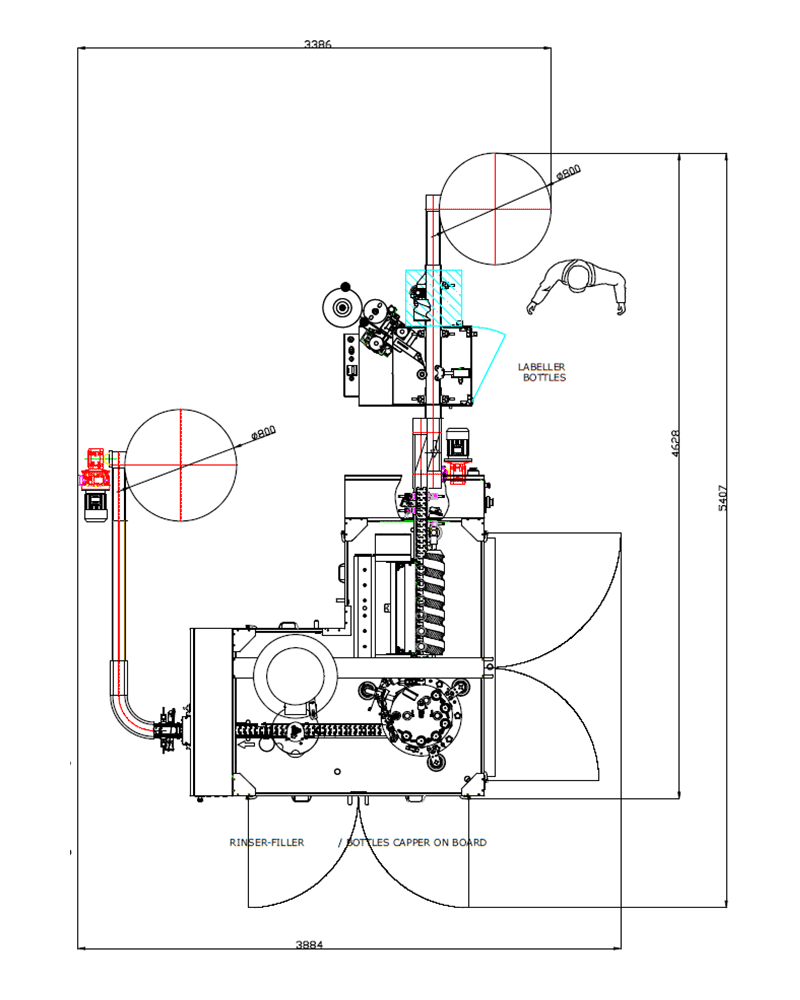

Scheme and dimensions of the fully equipped system for the bottle rinsing, filling, capping and labelling:

Technical parameters

| Product to be filled | Carbonated beverages like beer, cider, sparkling wine etc. |

| Type of containers | Glass bottles |

| Type of closure | Crown caps Ø 26 mm |

| Number of bottle rinsing positions | 6 |

| Number of bottle filling valves | 6 |

| Number of bottle capping heads | 1 |

| Rinsing system | with water |

| Filling system | electro pneumatic isobaric filling valves |

| Filling temperature | 0-2°C |

| Machine rotation | Clockwise, with outlet at 90° to the right |

| Pressure | Max: 2.0bar – 2.5bar |

| Bottle standard dimensions | Diameter min. 50mm/max. 100mm, height min. 180mm/max. 340mm |

| Speed adjustment | electronic, by frequency inverter |

| Recommended minimal floor space | L x W : 6000mm x 4000mm |

| Output capacity | 1,200bph on 330ml glass bottles |

The bottle/can filling line consists of these main units :

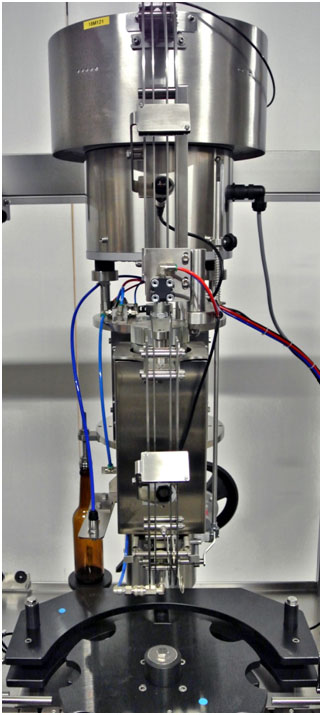

I. Automatic monoblock for the rinsing and filling the bottles

A high quality monoblock machine designed to rinsing and isobaric filling the glass bottles. Long lifespan thanks to our special double degassing of oxygen, with six electropneumatic filling valves for the rinsing and filling processes.

Operation capacity:

– Up to 960 pcs of the 0.5 lt bottles per hour

– Up to 1200 pcs of the 0.3 lt bottles per hour

The machine includes :

- 6-valves rinsing unit for the bottles

- 6-valves filling unit for the bottles

- Crown caps applicator

Rinsing unit :

Rinsing unit :

- Rinsing unit, supplied with six grippers with standard fixed nozzles.

- The bottle gripper pads can be easy extra-rapid assembles and disassembled.

- The bottle rinser modul is supplied with a single stage rinsing water treatment

- Electro-valve to automatic control the rinsing fluid. The valve stops the reatment fluid flow every time the machine stops and starts it at the machine re-starting.

- Manual turret height adjustment

Filling unit :

- Counter-pressure filling unit, supplied with six electropneumatic valves suitable for filling beer into glass bottles

- Manual filling turret height adjustment for use the turning turret with different bottles

- The filling turret has a tank with a mirror polished internal surface and a level control probe

- Filling level accuracy +/- 2mm

Capping unit :

The one-head automatic capping unit with maximal throughput 2.700 bottles per hour, is suitable for the application of aluminium caps on cylindrical glass bottles with diameter between 30 mm and 115mm and height from 160 to 355mm.

The one-head automatic capping unit with maximal throughput 2.700 bottles per hour, is suitable for the application of aluminium caps on cylindrical glass bottles with diameter between 30 mm and 115mm and height from 160 to 355mm.

The crown caps (or optionally other types of the caps) are dosed through automatic vibration feeder directly on the bottles.

The capping head is operated by an electrical motor mounted on a slider with expansion pulley allowing increase or reduce the rotation speed of the threading head sinking on the caps to be closed through a special plastic cam working at the centre. Therefore distributing the loads is in a balanced way and guaranteeing a long life.

The change of the parts and the height adjustment are rapid and simple, the head lifting is mechanical and happens manually through a hand-wheel operating on the endless screw reducer; special safety devices stop immediately the machine in case of problems to avoid breakages the bottles and any other anomalies.

- Capping the bottles with crown corks on the pneumatic capping turret equipped with the large capacity crown caps feeder

- Automatic vibrating sorter, made of AISI 304 stainless steel; equipped with device for monitoring caps level in the stack

- Chute equipped with cap presence monitoring device, made of AISI 304 stainless steel

- Capping head with pressure-closing cone for permanent crown cap deformation.

- Device to removing beer foam before capping – it removes oxygen from the bottle neck.

Optional equipment (prices on request) :

- Revolving unit with two types of heads mounted on the same turret.

- Special heads for : screw corks, mushroom corks, wine corks, plastic caps.

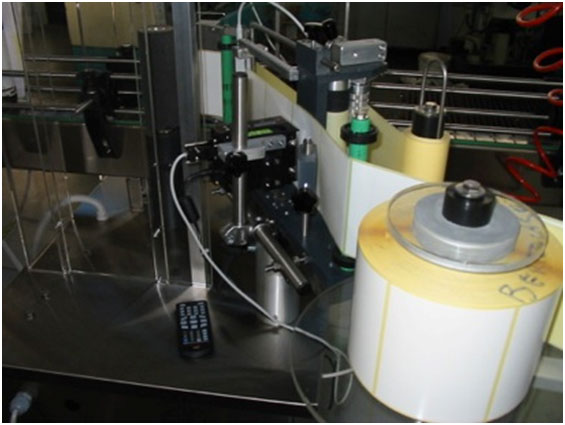

II. Automatic machine for the labelling the bottles

Automatic bottle labelling unit for applying self-sdhesive labels. Automatic linear labelling machine equipped to apply one self adhesive label on glass bottles. For bottles with maximal diameter 300mm.

Capacity up to 1500 bottles per hour.

- Label minimum length: 10 mm

- Label maximum length: 130 mm

- Label minimum height: 10 mm

- Label maximum height: 80/120/160/240 mm

- Container minimum diameter: 40 mm

- Container maximum diameter: 130 mm

- Container minimum height: 150 mm

- Container maximum height: 370 mm

Base Frame and General Structure

- The support frame is made of welded steel profiles and is equipped with height adjustable feet.

- The top surface is a carbon steel plate, covered with AISI 304 stainless steel metal sheet.

- Inspection is possible through side doors and frame side skirting clad with AISI 304 stainless steel plate.

- Standard machine colour: RAL 7038.

- Machine prearranged to install a second labelling station in the future.

Self-adhesive labelling station

Machine equipped with one self-adhesive labelling station installed on vertical slides easy adjustable composed of:

- Stepping motor

- Drive and control microprocessor pre-disposed to operate the printing unit (optional)

- Dragging rubber roll with contrast roll mounted on springs

- Labelling tongue for labels of 80/120/160/240 mm height

- Supporting reel plate Ø 320mm equipped with unwinding shaft

- Motorized labeller paper re winder

- Bottles detection photocell

- Label detection photocell

- Drive buttons included in the group

- Box containing drive and electrical parts in stainless steel, with open able access panel complete of lock general switch

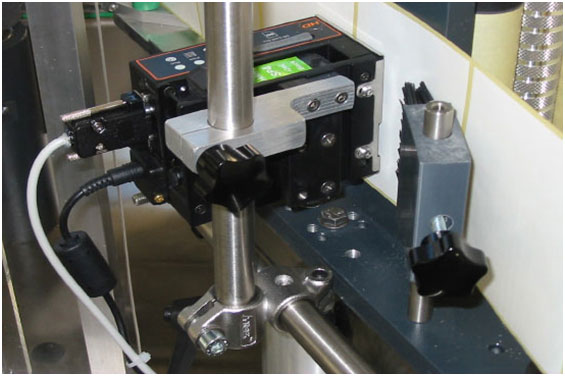

- Manual adjustable stainless-steel support system, complete of digital indicator for an easy adjustment

- Maintenance and lubrication easy and short time requiring due to the high quality of components and materials used

- The machine has been designed to have maximum accessibility for cleaning and debris removal purposes

Safety guards

- Safety guards are present along the whole base frame perimeter.

- Guards are made in AISI 304 stainless steel with transparent material windows. Openable doors are fitted with interlock type micro-switches.

- Main gear box is of crown-screw worm type and oil bath lubricated.

- Feed screw transmission systems are complete with safety electro-mechanical clutch devices to stop the machine in case of bottle jamming.

Wiping system

- Labels wiping by sponge rollers.

Machine control system

- Pneumatic plant is complete with pressure regulation unit, air filter and air lubricator.

- Main electrical panel, waterproof type, is integrated in the machine structure.

- All machine controls and status/signal lights are centralized on a single operator panel, complete with removable push-button station (emergency stop + pulse motion buttons).

- Machine infeed automatic closure in case of bottles build-back at discharge side.

- All electric and pneumatic power and control circuits are built in accordance with the latest applicable international standards.

Anticorrosion treatment

- Use of materials not subject to corrosion as stainless steel, not-ferrous alloys and plastic materials.

- Carbon steel parts undergo an anticorrosion treatment by multicoating epoxy painting.

DATE CODER

- Display : 2,8″ full color LCD

- Plug´n Play design : Hewlett Packard TIJ 2.5 printing technology

- Printable images : Alphanumeric , logo, date/time, expiry date

- Printable lines : 1,2,3,4 lines. Total line heigh is limited to 12.7 mm

- Conveyor speed : 76 meters per minute

IV. Rotary tables for the manual loading and unloading the bottles

V. Conveyors for transporting the bottles between all units

- The complete conveyors set made in AISI 304 stainless steel, with wear-proof plastic rollers and sliding profiles.

- Table top type conveyor belt, AISI 304 stainless steel (or Delrin) made.

- Bottles are guided by stainless steel plus plastic contact profiles side guard-rails, adjustable in width.

- Infeed device to space out the bottles by pneumatic lever.

- Infeed device to center the bottles before every operations with micrometric adjustment in width by hand wheel.

- Device to stabilize the bottles during the labelling and wiping with micrometric adjustment in height by hand wheel with synchronized speed to the one of the conveyors.

- The infeed gate lock device can be manually or automatically operated.

1st operation : Loading the bottles on the infeed rotary table (may be replaced with a infeed conveyor)

The bottles are manually loaded on the rotary input table, then they are automatically transported with a conveyor to the main monoblock to be ready for the rinsing, filling and capping .

The input rotary table may be optionally replaced with a conveyor that transportes the bottles from other machine.

- Infeed rotary table for manual loading the bottles – diameter 800 mm

2nd operation : Labelling the bottles

The bottles are transported with the conveyor to the labelling unit to applying self-sdhesive labels.

3rd operation : Rinsing the bottles on the rinsing turret equipped with six grippers

The bottles are spaced by an infeed snail to allow the rinser’s pincers to pick them up.

Once the bottles are in the correct position , they are picked up by the pincers and upturned to the rear section of the rinser, where they are rinsed with the water jets.

The drain water is collected via a collector under the jets, and the then may be drained away or recycled, filtered and re-used as required (optional kit extra is needed).

After the rinse cycle is completed the bottles are re-positioned onto the conveyor belt and the infeed snail moves them over towards the filling unit.

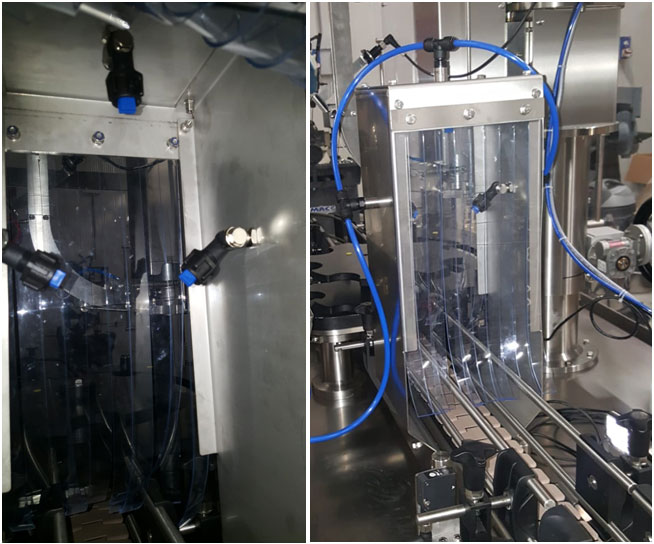

4th operation : Filling the bottles on the filling unit equipped with electropneumatic counterpressure valves

The filling unit is suitable for counter pressure filling the bottles with carbonated beverages, with CO² flushing, with a counterpressure up to 3 bars.

The feeding mechanism works in a linear step -by-step mode and moves six bottlesone after the other inside the filling unit to be positioned one bottle to each filling valve.

When all six bottles have reached their correct filling position, the pneumatic cylinders under each valve lift the bottles and put them in direct contact with the filling valves, sealing the neck.

Phases of the bottle filling process

| 1st phase | First pre-vacuumation | After the lifting of the bottle, the vacuum pump starts - exhausting air from bottle |

| 2nd phase | First CO2 injection | The vacuuming pipe is closed and the injection of CO2 starts - filling bottle with CO2 |

| 3rd phase | Second pre-vacuumation | The valve for the CO2 closes and the vacuuming pump starts - exhausting CO2 from bottle |

| 4th phase | Second CO2 injection | The vacuum pipe stays open for a very short time while the CO2 is opening and then it is closed |

| 5th phase | Filling the beverage | When the pressure inside the bottle is the same as the pressure in the upper filling tank the filling valves is open and the filling process of the bottle starts |

| 6th phase | End of filling | When the filling of the bottle is finished, after a short pause, the snift is open for degassing of the bottle |

| 7th phase | Degassing | The electro mechanical valve opens and degasses the bottle |

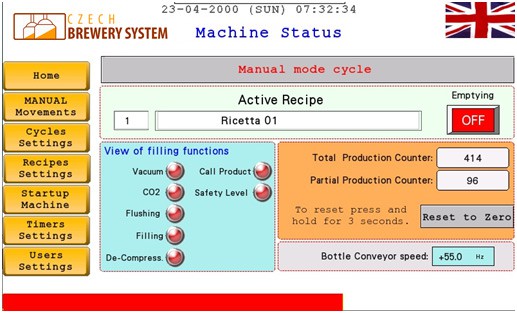

All of the above mention cycles are adjustable and recordable in the PLC so that they can be verified and used in future.

5th operation : Capping the bottles

- Capping the bottles with crown corks on the pneumatic capping turret equipped with the large capacity crown caps feeder

In the upper part of the lid distributor there is a revolving turret with 6 lid feeding cylinders. The cylinders can be removed and refilled as the lids are used up. The cylinders are filled up off-line ready to be installed rapidly at intervals. Each cylinder can hold up to 300 lids each, offering approximately one hour of total autonomy of production with all 6 full cylinders.

Extra kits of stainless steel cylinders are available as optional equipment to reduce stoppage time between refills.

6th operation : Washing the full bottles

The full bottles are washed to remove residual foam from the outside of the bottles.

7th operation : Unloading the full bottles from the outfeed rotary table (may be replaced with an outfeed conveyor)

The bottles are manually unloaded from the rotary output table.

The output rotary table may be optionally replaced with a conveyor that transportes the full bottles to an other machine.

Control panel (touch display) :

Remote assistance via internet service

Interactive HMI interface on OMRON PLC for onsite production progress monitoring, production management & control and remote assistance.

The system allows our technician to be directly in contact with our customers in case of problems.

The bi-directional communication between the machine and remote system permit to see in real time if the operator is working in the correct way on the touch screen, and can be used to control the machine from our side for real time intervention (if necessary, for customer´s demand).

Price list :

BASIC CONFIGURATION

|

|

| DESCRIPTION |

PRICE IN EURO |

| Automatic monoblock with the bottle rinsing unit, bottle filling unit, bottle closing unit + parts for one format bottle and crown caps Ø26mm | On demand |

| Bottle capping unit now included in the monoblock with parts for one bottle format and Ø26mm crown cap | On demand |

| Dummy bottles/cups for the CIP process – for cleaning the bottle filling valves | On demand |

| High temperature washing kit at 85 ⁰C – for CIP hot caustic solution for the internal cleaning | On demand |

| Injection of CO² into the neck of the bottle before the capping with a crown | On demand |

| Spraying device after the bottle capping operation to wash exterior surface of the bottles free of excess foam | On demand |

| Parts in contact with the product in stainless steel AISI 316 (needed for handling with cider) | On demand |

| Linear self-adhesive labelling unit for wraparound labels application onto bottles | On demand |

| End of reel label – alarm | On demand |

| Bottle jam light signal – cooperation with the alarm | On demand |

| Inkjet date coder integrated into labelling unit | On demand |

| TOTAL PRICE |

On demand |

| OPTIONS FOR THE MAIN MONOBLOCK (RINSING UNIT, FILLING UNIT, CAPPING UNIT) | |

| DESCRIPTION | PRICE IN EURO |

| ROPP capping unit – one format 28×15 ROPP (instead the crown capping unit) | On demand |

| Pneumatic stainless steel diaphragm pump with the input pipe connections | On demand |

| Non-return valve for a beverage inlet line | On demand |

| Spare seals for the six filling valves | On demand |

| Modem with the Ethernet connection for remote software assistance | On demand |

| Set of parts to handle with additional bottle format (different diameter) | On demand |

| Six additional filling level pipes – required for each additional bottles filling level | On demand |

| Closed circuit rinsing with buffer tank, filtration system & product relaunch pump (for rinsing with peracetic acid) | On demand |

| Conveyor system to connect labeler & Microblock together with rotary bottle infeed table & rotary unloading bottle accumulation table Ø800mm (to allow by single man operation) | On demand |

| OPTIONS FOR THE BOTTLE CAPPING UNIT | |

| DESCRIPTION | PRICE IN EURO |

| Parts to handle with additional format diameter bottles | On demand |

| Caps level monitoring device in the caps feeding bowl | On demand |

| Device to detect the presence of the cap on the bottle at the exit of the machine | On demand |

| Injection of CO² into the neck of the bottle before the capping with a crown | On demand |

Optional services :

I. Installation work on the place …. call for price

The price is valid for all countries of the European Union. The price includes five days work (+ two days travelling) of two specialists on the place – assembling and start up of the equipment.

The price does not include : transports costs and accomodation of the workers. Will becalculated individualy.

II. Installation work ensured by customer (with our remote assistance) …. call for price

Do you want to save your money ? Are you technically skilled and not afraid of challenges? Do your country’s hygienic restrictive regulations not allow a visit of a specialized technician from a foreign country? Don’t be afraid to use the remote assistance service.

How is the installation of the filling line by our customer, using our remote assistance?

1.) The customer positiones all the machines and connects them to power guided by our checklist.

2.) Once photos were sent of the completion of the preliminary phase we proceeds with the start up and commissioning.

3.) First we connects the PLC of the machine via internet to our service console in our factory — this allows our service manager to view and control your PLC on a remote screen, as if he was in front of the machine in person.

4.) We then organise a Microsoft Teams conference call, with one your worker holding the camera, and the others working around the our technician´s instructions.

5.) After only 3-5 days setting up and configuring, first full glass bottles will leave your filling line.

Video :

Reviews

There are no reviews yet.