A3-configuration of the CCT-M modular cylindrically-conical fermentation tanks

Modular cylindrically-conical fermentation tanks CCT-M are very versatile products from our production portfolio that enable freely assemble the beer production tank to a configuration that is momentally required by user with respect to the intended use. A current configuration of the tank can be changed at any time to any other configuration according to required purpose using optional accessories and their many combinations.

More about the CCT-M modular fermentation system :

- CCT-M modular cylindrical-conical tank system

- All available configurations of the CCT-M modular fermentors

- Basic tanks for the CCT-M modular fermentation system

- Optional accessories and equipment for the CCT-M tanks

About the A3 configuration

The A3 configuration is a simplified assembly of the CCT-M tank (without a filling level indicator), that allows a controlled fermentation of all alcoholic beverages like beer, carbonated cider, wine, sparkling wine, kombucha etc.

If the tank is equipped with a safety valve 0.5bar (non-pressure vessels that do not require a certification by the European Directive PED 2014/68/EU), then the tank is suitable for the production of non-carbonized beverages (wines, ciders, soft drinks) but also for the primary fermentation process of beer, cider or sparkling wines.

If the tank is equipped with a safety valve 3.0bar and certified according to PED 2014/68/EU, it can be used for both primary fermentation and maturing process of all carbonizated beverages. The configuration 3.0bar is suitable for controlled fermentation and maturation (under pressure) of all kinds of beer, cider and carbonized wines.

Equipment of the tank in the A3 configuration allows you to set the required pressure in the tank and also monitoring of the actual pressure on the manometer. The fermentation process is indicated by bubbling CO2 gas through a fermentation lock with water. Everything you need is included in the adjustable pressure valve (optional part). For the production of non-fermented beverages the adjustable pressure valve is not necessary accessory (it may be excluded from the configuration).

The tank is also equipped with a fixed or rotating spray ball with a pipe connection for easy automatic washing and sanitizing tank using the CIP station (optional equipment).

The sampling valve (optional part) allows collection of product samples to their analysis. The fermentor can be equipped with the carbonization candle with a porous stone (optional part) to additional carbonation of beverages before the final bottling process, using the multiport MT-DN40. The same multiport may be used also for the hops extraction into cold beer whenever some special types beer like IPA are produced in the fermentation tank. The port is also available for connection of the flotation machine (optional equipment) that is needed during the juice or cider production.

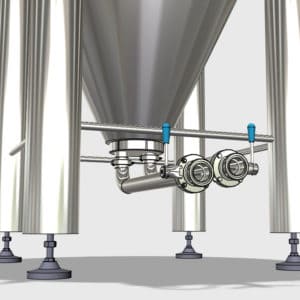

The only difference in comparison with the configuration A1 is : The tank in the A3 configuration includes the removable input/output pipe for a pure product RO1 with the valve and the removable draining pipe DO1 with the valve for easy access to the tank with hoses to filling and draining. The valves are placed on the end of the pipes. Both of these pipes should be dismounted and cleaned before each use of the tank.

A placing of the input/output product valve and the tank draining valve on the end of the long pipes is the usual location of the valves on the tanks of most manufacturers.This configuration is suitable for all customers who prefer comfortable handling when connecting and disconnecting the hoses.