Description

The KRF-31 is a multifunction machine that includes a device for rinsing of stainless steel kegs with- one position for a keg. The equipment is designed for the rinsing of kegs for beer, cider, wine and for other beverages, using semi-automatically operated valves and a pump.

Operating capacity : from twelve up to twenty kegs per hour (rinsing and sanitizing).

Basic features:

- The machine is made of stainless steel 1.4301 / AISI 304

- The electric switchbox is made of lacquered steel sheet, optionally stainless steel (for surcharge)

- Operation place for KEGs is made of polyethylene, plate thickness 20 mm

- Connections of the KEGs with machine are made with the food hoses and the connection fittings

- Pneumatically operated stainless steel piston valves with PTFE seals

- Isolated 80 liter detergent tank with electric heating spiral and level sensor

- Electric, steam or combined heating of the detergent – caustic or alcalic solution

- Adjustable stainless steel feet for machine balance

- Control via buttons, adjustment via color touch screen

- Sensors to check the correct function of the machine

- Components from world leading manufacturers (Siemens, Endress + Hauser, Sensit, etc.)

Features :

- The machine is designed to the intensive rinsing inside of the KEG barrels

- Performance from 12 up to 20 KEGs per hour *)

- For all types of coupler fittings (A, D, G, M, S, U, Flat, Corb, Combi, etc.)

- For all KEG sizes (volumes from 15 to 50 liters)

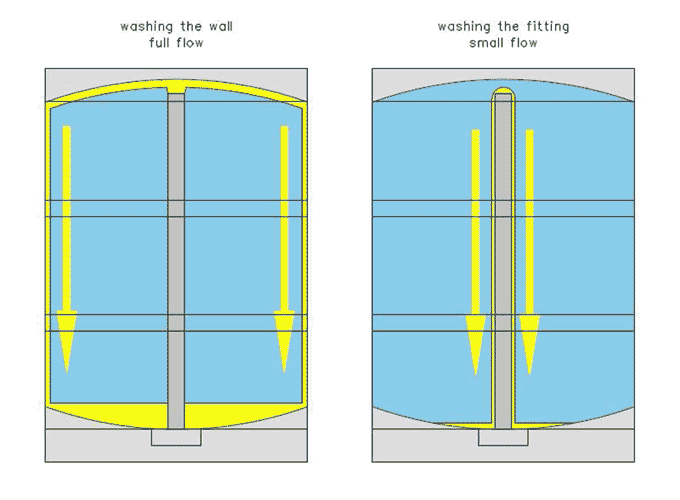

- Alternate rinsing of walls and coupler fittings of KEGs

- Automatic checking the correct function of the machine

- Detergent quality monitoring (based on the number of rinsed KEGs)

- Built-in 80L tank for one chemical deterent

- Two washing programs, the intensity of rinsing or filling can be adjusted

- Washing statistics

*) The performance of the machine depends on the actual settings of the the keg washing process

Technical parameters :

- Power supply – 400 VAC

- Power consumption – 9 kW, of which 8 kW electric heating

- Volume of the built-in detergent tank : 80 liters

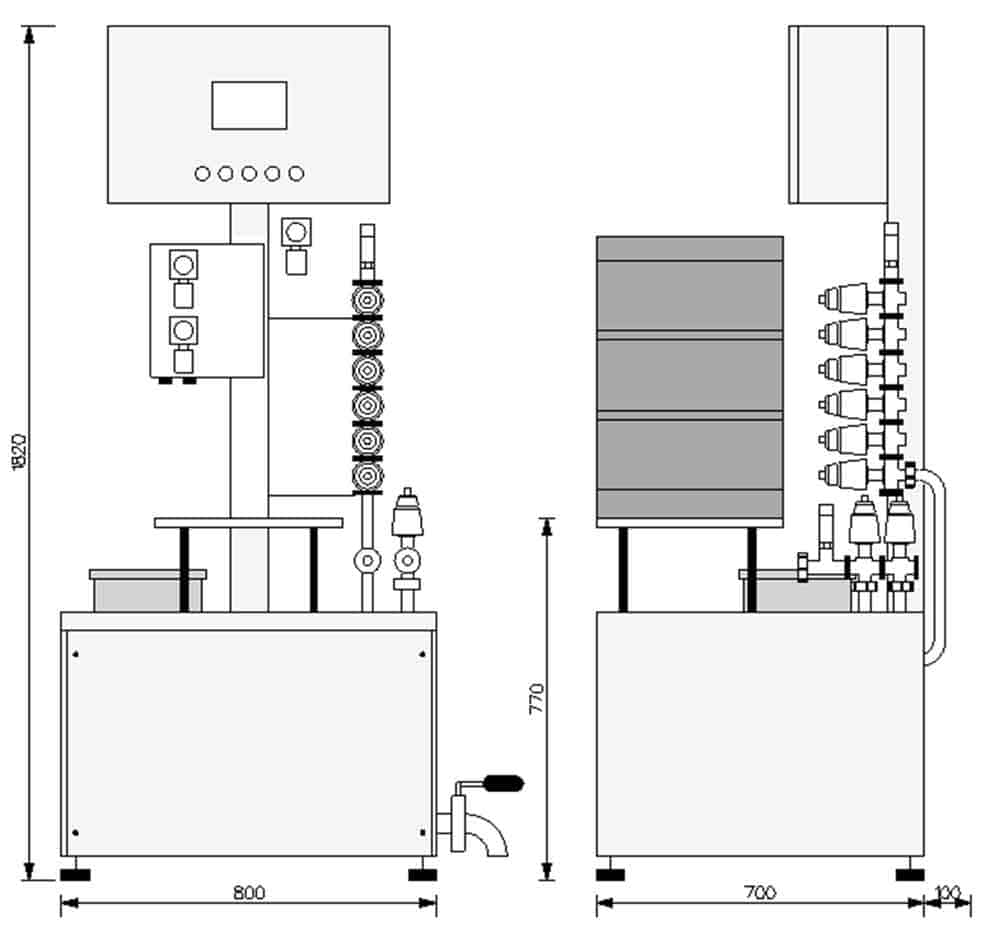

- Dimensions – w x h x d – 900 x 1850 x 800 mm

- Weight – 165 kg

How the machine works :

Rinsing-sanitizing program :

Rinsing-sanitizing program :

- Check the correct KEGs connection

- Draining of rests from KEGs

- Rinsing of the walls and fittings with cold water

- Blowing out the cold water residue with sterile air

- Rinsing of the walls and fitting with hot detergent

- Blowing out of the cleaning solution from KEGs with sterile air

- Rinsing of the walls and coupler fittings with hot water

- Blowing out of rinse water with sterile air

- Blowing of the KEG with sterile steam

- Pressurizing of the KEGs with sterile steam

- Sterilization inside space of the KEG

- Blowing out steam residues with CO₂ / N₂

- Pressurization KEG with CO2 / N2

- Sound signal “End of rinsing”

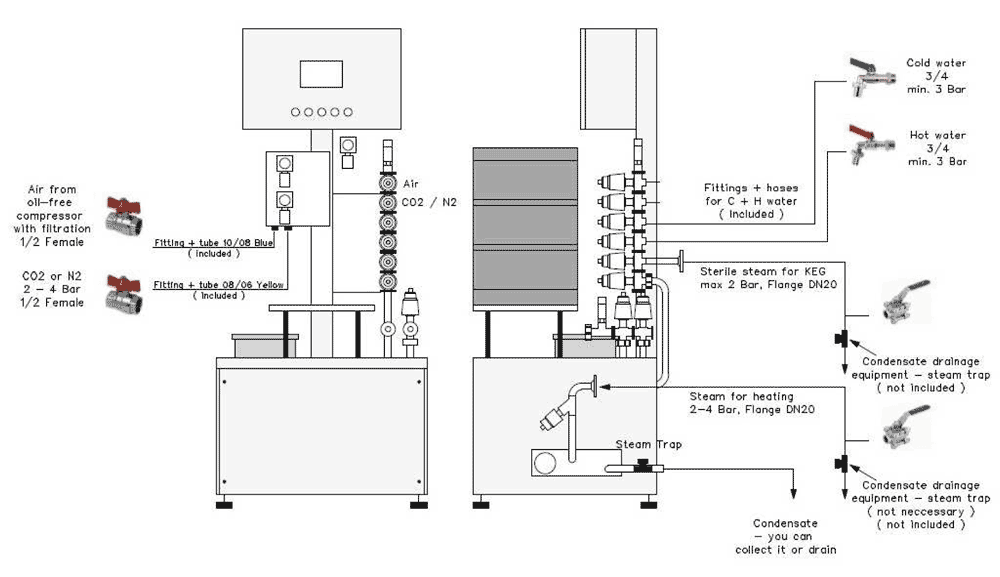

Required connections and media consumption guidelines :

| Media | Connection | Pressure | Consumption |

|---|---|---|---|

| Sterile air | ½ female | min. 5 Bar | 0.3 m³ / KEG |

| CO₂ / N₂ | ½ female | min. 1.5Bar | 0.2 m³ / KEG |

| Cold water | ¾ female | min. 3 Bar | 5 L / KEG (17 L / KEG **) |

| Hot water | ¾ female | min. 3 Bar | 12 L / KEG |

| Cold water | ¾ female | min. 3 Bar | 5 L / KEG (17 L / KEG **) |

| Steam for KEG | flange DN20 | approx. 2 Bar | 0.4 kg / KEG |

| Steam for heating | flange DN20 | approx. 2 Bar | 0.5 kg / KEG |

| Electricity | 400VAC / 32A TN-S fork, rated power – 9 kW | ||

| Connection of electrical earthing | min. 4 mm² | ||

| Chemically resistant waste gully | min. DN50 | ||

**) If hot water is not installed

Dimensional drawing :

Subject to technical modifications without prior notice.

Options and prices :

| Code | Equipment | Description | Price | Surcharge |

|---|---|---|---|---|

| KRF-31 | Keg rinsing machine (basic) | One keg position

Air input CO2 / N2 input Cold water input Detergent tank with the electric heater 8 kW |

12990,- Eur | |

| KRF-31-SKS | Sterilization the kegs with hot steam | Hot steam valve – input

The hot steam generator is not included |

198,- Eur | |

| KRF-31-SKW | Rinsing the kegs with hot water | Hot water valve – input

Hot water tank is not included Heating of water is not included |

386,- Eur | |

| KRF-31-CHW | Combi heating the hot water (electric + steam) | Combinated heating of detergent with electric spiral and hot steam

The hot steam generator is not included |

584,- Eur |