Description

Counter-pressure stainless steel filler for PET bottles (optionally also for NRW type glass bottles – with a special head) . Universal filling system for fast, non-foaming bottling of beer and other carbonated beverages in a protective CO2 atmosphere. Simple connection to any tap stand using a standard 5/8″ thread.

The delivery includes only one head for filling PET bottles. The filling head for glass bottles of the NRW type has to be ordered separately.

Technical specifications:

- Material: stainless steel 1.4301 / AISI 304

- 1x filling head for PET bottles

- Optionally : Filling head for NRW type glass bottles (for a surcharge)

- Connection to the tap stand: thread 5/8″ male / screw length 55mm

- Upper mandrel for hose with an inner diameter of 8mm (CO2 inlet)

- Lower mandrel for a hose with an inner diameter of 8mm (releasing CO2/overflow in case of overfilling of the bottle)

- Side regulation screw for draining air from the bottle and for filling the bottle (flow rate regulation)

- Upper lever with 3 positions: left (filling CO2 bottle), middle (closed) and right (filling bottle with beverage)

Description :

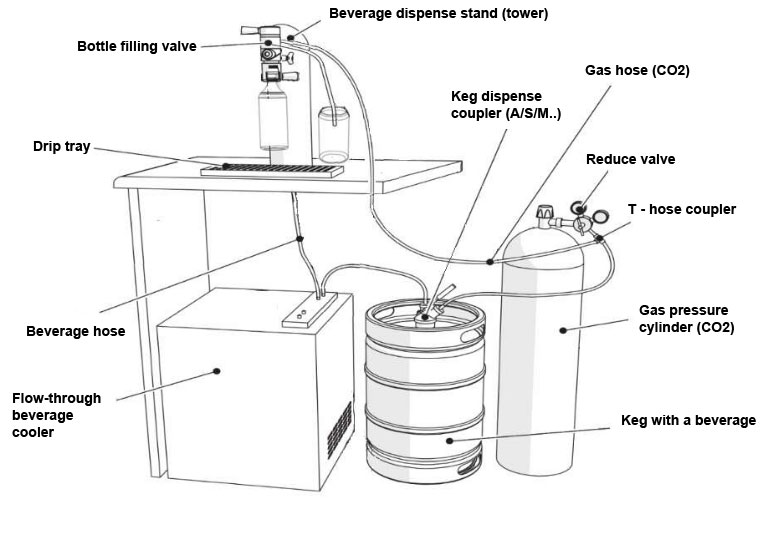

Connection scheme :

Two beverage faucets on the same position :

After removing the plug on the front of the filling valve body, you can mount a second regular beer tap with the 5/8″ screw thread on the filling valve. This way you can use both valves on the same position on your beverage dispense stand and save space.

Cleaning and maintenance

To prevent the filling valve from becoming clogged with dirt, it is necessary to clean and chemically sanitize it regularly. After each use, rinse the filling valve thoroughly with clean water (max. 60°C). Once a week, we recommend chemically cleaning the filling valve with a suitable sanitizing agent with a low concentration of lye (max. concentration 2%, temperature 60°C) and then rinsing it again with water. All seals should be regularly lubricated with food-grade petroleum jelly and replaced with new ones in a timely manner.

Sanitizing plan:

| Cleaning type | Periodicity | Cleaning detergent | Time (minutes) | Temperature (°C) | Source |

| Washing | Daily (after each use) | Hot water | 10 | 60 | Hot water tank |

| Rinsing | Daily (after each use) | Cold water | 15 | 20 | Water supply line |

| Sanitizing | Once a week | Sanitizing alkalic detergent | According to the producer´s recipe (usualy 15 minutes) | 60 | Sanitation keg + pump |

| Washing | After sanitizing | Hot water | 10 | 60 | Hot water tank |

| Rinsing | After sanitizing | Cold water | 15 | 20 | Water supply line |

UF-GPBNWT : Filling head for NRW type glass bottles

UF-GPBAIC : Filling head for glass bottles with the integrated cap

Sanitation keg

KL-MK2BL : Mini-keg 2L (Sanitizing keg) with the BallLock connections | AISI 304

Sanitation pump

MGP-MKII65 : Magnetic pump 230V 65W with a stainless steel head (temperature up to 120°C)

Reviews

There are no reviews yet.