Description

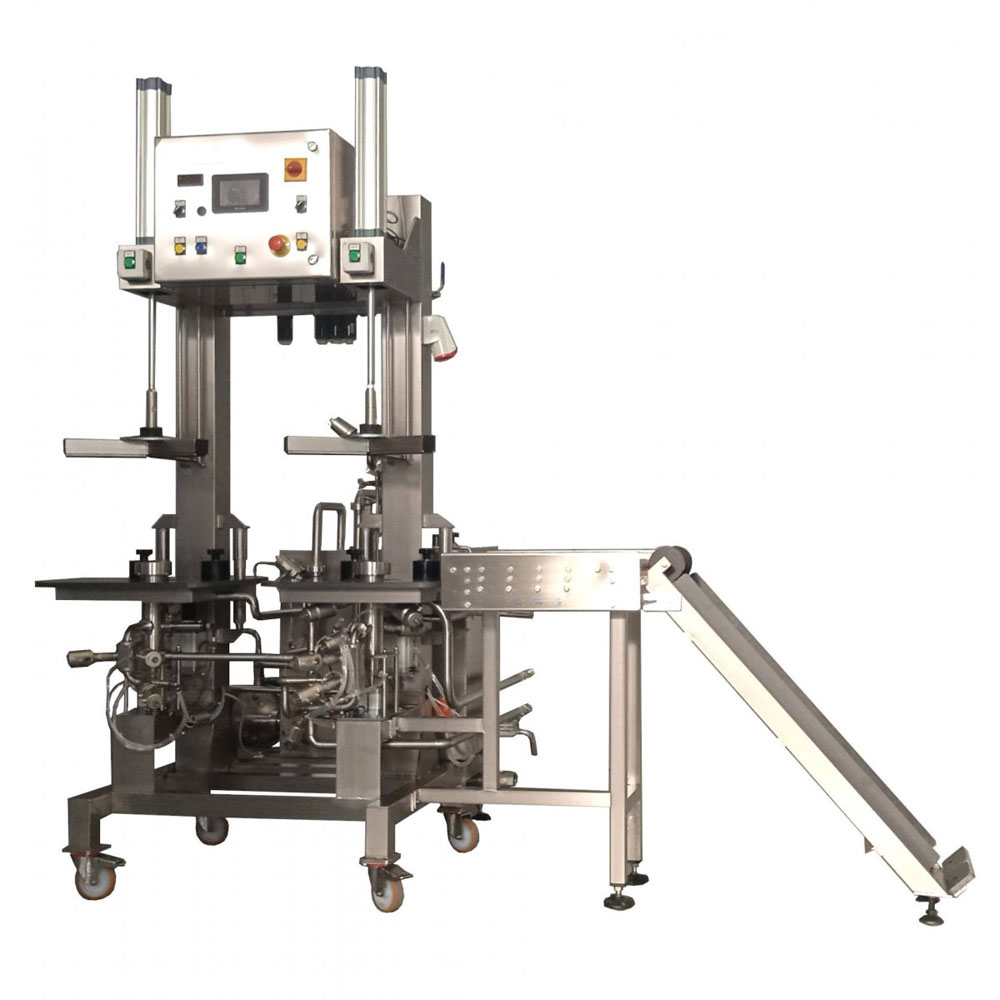

The PKF-GL2T double-head machine is an equipment designed for the automatic filling beer, cider, wine and for other carbonated or non-carbonated beverages into single-use plastic kegs with or without an inner bag. The plastic kegs must be equipped with the standard A, D, G or S filling coupling type.

Operating capacity is 80-100 kegs per hour (valid for the Polykeg, Keykeg, Petainer Hybrid, Dolium, Keg Solution … volume of 10-30 liters).

By using the same machine, you can use the simple keyboard on the control panel to fill different types of plastic kegs.

The set consists of a centering devices (ferrules) and a head that adjusts to the type of keg system.The entire structure of the machine and the parts that are in contact with the filling liquid are made of AISI 304 and 316 stainless steel. The work steps are managed automatically. The only step that needs to be done manually: to put and remove the plastic keg at/from the machine.

Main properties and advantages :

- Semi-Automatic Double-Head Filling machine designed one or more types of PET kegs (Petainers), with or without inner bags.

- The end customer will decide which and how many types of kegs he intends to work with.

- On request, the machine can also be prepared for filling empty sanitized stainless steel kegs (without the keg washing cycle)

- Compatible kegs: Polykeg, Petainer, Dolium, Keykeg + on request, stainless-steel kegs (filling only)

- Quick and easy keg format change thanks to the indications and buttons on the PLC.

- Electro-welded A304 stainless steel frame. All components which come in contact with the product compliant with food processing use.

- Isobaric filling by steam sanitizable electromagnetic flowmeter

- Keg valve sterilization / drying before filling and at the end of the cycle

- Pressure test inside the keg before the filling cycle.

- Bagless keg flushing to eliminate oxygen inside, replacing it with inert gas.

- C.I.P. cycle supplied as standard for washing / drying the filling head

- Human Machine Interface (HMI) via touch panel: It is possible to save, edit and recall working recipes where is possible to store all parameters values

- Interconnection to factory IT systems that makes our machines compliant with “Industry 4.0” standard.

- It is possible to install a modem for remote assistance on the machine if the buyer is at a great distance. This allows our technicians to provide remote support (at a distance) with direct interaction, sending commands and analyzing the relative responses from the software and hardware of the machine.

- The work cycles are completely automatic excluding the loading, unloading and handling of the kegs, usually by a human operator. It can be facilitated by integrating the line with roller conveyors and / or slide.

- Voltage and frequency adaptable to the electrical standards in use in the final destination country.

Technical parameters :

| Characteristics : | Description : |

| Processable kegs | Petainer® “Hybrid” 20-30l; Polykeg® 12-30l (with or without bag); Keykeg® 10-30l;Unikeg® 10-30l; Dolium®20-30l; Keg Solution® 20-30l. |

| Keg Fitting | A / D / G / S |

| Products handled | Beer, Wine, Cider, all water based products |

| Filling heads | 2 |

| Flow meter accuracy | ±0.02% |

| Filling accuracy | ±0.01l |

| Residual Oxygen | <20ppb |

| Cleaning/Sterilization | Hot Water 80°C , Steam 110°C / 0.5 bar |

| Productivity : | Description : |

| Maximal hourly production | 80-100 kegs/h (Actual output capacity very depends on the working cycle parameters set by the operator) |

| Materials : | Description : |

| Conduits and components in contact with liquids | Stainless steel AISI 304/316L, Gaskets EPDM, PTFE |

| Other construction parts | Stainless steel AISI 304 |

| Electronic equipment : | Description : |

| PLC, HMI | 7″ Touch Colour LCD display |

| Flow Meters | ENDRESS+HAUSER Dosimag series |

| Transducers | ENDRESS+HAUSER 4-20mA |

| Consumption : | Description : |

| Max flow rate (product) | 5000 L/h |

| Product pressure / Temperature (product) | 2÷3 bar / Max 3°C |

| Air pressure | Supply 8÷10bar, use 6bar |

| Air consumption | 2720 N l/min |

| Inert gas pressure | 6 bar |

| Inert gas consumption | 700 N l/min |

| Water pressure | 1 bar |

| Electrical power installed | <1kW 240V-50/60Hz(single-phase) |

| Connections : | Description : |

| Product inlet | Tri Clamp 1 ½” / DIN 32676 DN 25 (Disc D=50.5 mm) |

| Compressed air inlet | BSP 1/2″ female / gas-type |

| Inert gas inlet | BSP 1/2″ female / gas-type |

| Steam inlet | BSP 1/2″ female / gas-type |

| Water inlet | BSP 3/4″ female / gas-type |

| CIP return pipe line | Tri Clamp 1 ½” / DIN 32676 DN 25 (Disc D=50.5 mm) |

Filling cycle steps :

| Step number : | Description : |

| 0 | Manual putting the keg on the right position on the machine |

| 1 | Keg clamping (keg lifting toward the filling head) |

| 2 | Keg valve cleaning (with mains water or recommendly with hot water from an external hot water tank) |

| 3 | Keg valve drying with inert gas (CO2 or N2) |

| 4 | Keg valve opening (with control of the correct opening) |

| 5 | Keg pressure test (if activated, the keg is rejected if it’s pressure is lower than limit) |

| 6 | Keg purge with inert gas (duration of purge adjustable) |

| 7 | Bag purge with vacuum and inert gas (duration of purge adjustable) for kegs with bag |

| 8 | Keg pressurization with inert gas (necessary for the counter pressure filling) |

| 9 | Isobaric filling using the Endress+Hauser magnetic flow meter and pressure control. The product flow is controlled by counter pressure and Plc controlled vent valve resulting in 3 filling speeds. Operator can set proper filling pressure threshold) |

| 10 | Inert gas injection at the filling end (selectable) |

| 11 | Keg valve closing |

| 12 | Keg valve cleaning (with mains water) |

| 13 | Keg valve drying with inert gas (CO2 or N2) |

| 14 | Keg release from the filling head |

| 15 | Manual unloading the keg from the machine |