Description

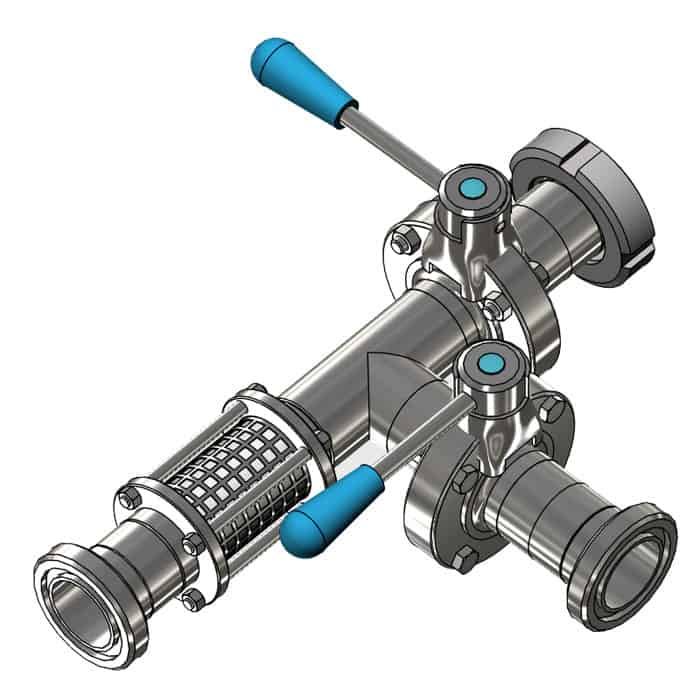

The product filling hub is a special tool to easy filling of product (like beer wort , cider must) to the fermetntation tank. It is pipe hub with, one product input, two product outputs a sight glass and two butterfly valves. This equipment is designed for brewer ´s work during filling wort into fermenters after finishing of the brewing process and precisious separation of dirty wort or water from the clear wort during pumping wort from whirlpool tank. Connections 1x DIN 11851 female DN 40, 2x DIN 11851 male DN 40.

Beverage hose splitter DIN11851 DN40

Technical parameters :

- product input …. DIN 11851 male DN 40

- output of the clear product … DIN 11851 female DN 40

- output of the dirty product (water/sludges) … DIN 11851 male DN 40

- Material … AISI 304

Connection :

The beverage hose splitter has to by connected to outside coupler of the RO1 bottom filling armature of the modular CCTM tank. It can be connected also to any other type of the beverage production tank. Input pipe has to be connected to hose with the beverage product incomming.

How to use the beverage hose splitter :

- The hose end (leading from the source device – wort brew machine, fruit press …) is mounted on the product input throat of the beverage hose splitter (branch with a glass sight glass).

- The second end of the beverage hose splitter ( output of clear product) will be connected to the RO1 botttom filling armature of the CCT M-tank.

- On the dirty product output branch you will connect a hose to the drain canal.

- The valve on input to the tank will be opened , other valves stay closed.

- Start a pump on source of the product (for example the wort pump on a wort brew machine or mash pump under a fruit press) where is connected the hose.

- At the beginning the beverage product contains sludges and water which go out to the canal through the dirty product output of the beverage hose splitter.

- When the product is already enough clear, the dirty product output valve will be closed and the clear product output valve will be opened. Then the pure beverage product flows into the tank.

- The beverage hose splitter has to be cleaned and sanitized after each use.

Material : AISI 304

Reviews

There are no reviews yet.