Description

The Chamber Pasteurizer PCH-960C is designed to accommodate food or beverages in their packages one EUR-type pallet (1200 x 800 mm) with maximal height of 1900 mm. Products for pasteurization must be placed in containers on pallets within crates or baskets, ensuring space for air circulation.

High capacity

Filled and closed bottles or cans are placed into the pasteuriser stored in the standard plastic sales crates (bottle carriers) which are in up to 6 layers on standard wooden pallet. This way you can pasteurize up to 960 bottles or cans (12 bottles/cans in each plastic crate, 8 plastic crates in each layer, six layers of crates on a standard pallet 1200 x 800 mm).

Pasteurisation time is normally about 35 minutes after which the pasteurization process shuts down automatically. With capacity of 960 bottles or cans, the PCH-960C range of cabinet pasteurisers are ideally suited for the small to medium size producer requiring an efficient in-bottle pasteurisation method and they don´t want to purchase a big and expensive tunnel pasteurizer.

The following can be pasteurized:

- Liquids in beverage bottles: beer, cider, wine, juice, mead etc.

- Liquids in beverage cans

- Fruits and vegetables in jarred preserves

- Canned goods

- Other beverages or food products

Up to 20 programmable pasteurization procedures …

The pasteurizer is equipped with a programmable control system that allows up to 20 programs to be set. Operators can adjust the pasteurization process parameters, including: Heating temperature, Pasteurization temperature, Number of pasteurization units.

You can really set the pasteurization cycle directly in pasteurization units !! This is really the best fuction of this pasteurizer that make it sufficiently suitable for all food and beverage producers without claim to deep experience in the field of pasteurization.

The pasteurizer can be used universally for various types of products and packaging. For instance, parameters can be adjusted for PET bottles to allow gentler heating, minimizing deformation. Different settings can be used for glass bottles. During one pasteurization cycle, only products with the same type of packaging should be placed in the chamber.

How the pasteurizer works :

-The operator places the food products (packed in their packages like bottles or cans) in the chamber and places a temperature sensor in one package of the goods (or the false bottle).

-The operator starts the process with the START button. Pasteurization takes place automatically according to the set program:

1. Heating phase : The chamber is heated with external steam or an integrated electric steam generator (depending on the optional equipment) to the required temperature and the products are quickly heated.

2. Holding phase : The temperature is maintained at the selected pasteurization temperature until the product has obtained the set number of PU.

3. Cooling phase : The chamber switches from air circulation to active ventilation and begins to cool the products. To speed up cooling, water spraying can be turned on (optional equipment).

4. End phase : After cooling to the required temperature, the machine turns off and calls the operator with an audible signal, or sends an SMS/calls the mobile phone (if equipped with a GSM module).

The operator replaces the food goods in the chamber and the process is repeated.

Main advantages and key features

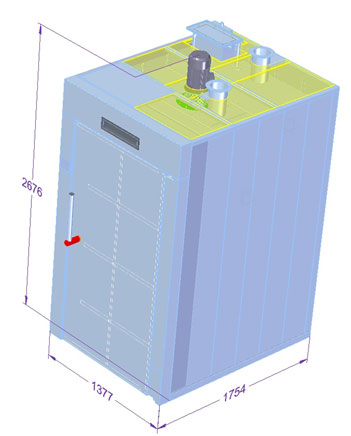

| Compactness | The machine is oriented vertically to take up as little floor space as possible. This makes it different from chamber pasteurizers from other manufacturers, which take up to 2x more floor space with the same capacity. Its compactness stands out especially when compared to huge tunnel pasteurizers. |

| Space saving | The machine can be placed against the wall or in a niche with a minimum width of 1400 mm. Service access is only from the front and top. |

| Capacity | The pasteurizer is capable of holding up to 960 bottles or cans stored in standard plastic crates. When using an external steam generator with a capacity of 120 kW, a capacity of up to 1600 bottles/cans per hour can be achieved. The capacity can be further increased by using lower crates, as long as there is sufficient space between the individual packages for free access of steam. |

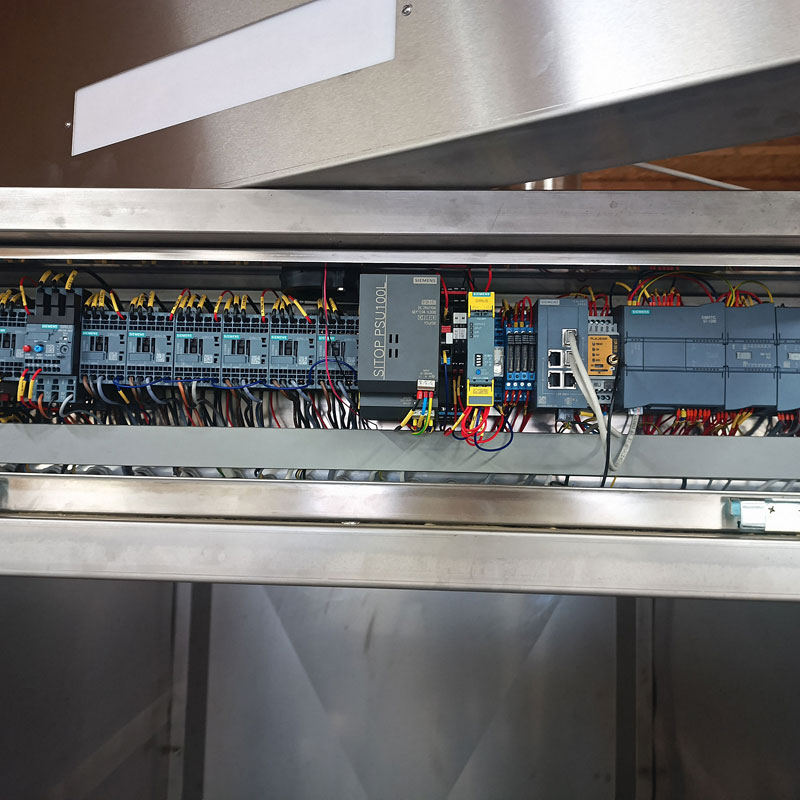

| Intelligent Automatic process controlled by PLC. | Setting of the process directly in number of the pasteurization units (PU). The system counts real number of the PU, automatically calculates the holding time according to the PU requirement, displays and archives the PU in the memory. |

| Setting via touchscreen | |

| Graphical recording of the pasteurization process. | |

| Machine sends an SMS/calls a mobile phone after the process is completed. (if equipped with a GSM module for an additional fee) | |

| Universal | 20 programs can be saved. For example, different pasteurization parameters for beer in a glass, for non-alcoholic beer, for KEG barrels, etc. |

| Collapsible machine | After disassembling the individual parts, it is possible to pass the pasteurizer through a standard door. No need to cut holes in the wall for the installation. |

| Emission-free | It can be operated only on electricity without an external steam source. |

| Easy to install | No specialist of the producer is necessary for the installation. A customer receive the machine with detailed installation instruction manual and it is easy to assembly the machine on the place in one day. Only the electric connection must be ensured by a certified person (electrician). |

| Easy to operate | Only one button for operation. For change of current program an admin access with password is necessary. |

| Reliable | The most of electrical components are Siemens. |

| Easy loading and unloading | The pasteurizer is equipped with flat bottom and optionaly with the integrated folding inclined plate for easy access with a conventional pallet truck. No forklift is required for the loading and unloading the pallets. |

| Active cooling | Acceleration of the process, higher production output, reduced risk of over-pasteurization. |

| Design | The casing is made of stainless steel with brushed surface, the design is washable (water does not leak into the insulation), minimum visible screws. |

| Safety | Complies with current safety standards and the tank according to the “Analysis of occupational safety and potential risks” (can be opened from the inside, spring ventilation, use of the Siemens Sirius safety system, …) According to valid EU standards. Archives process records according to HACCP (obligation according to the Czech National Code) |

| European origin | The machine is fully designed and produced in Czech Republic (the EU country). The most of mechanical parts are produced of stainless steel, the most of electric parts are made in EU. |

Technical specifications

| Pasteurizer type | PCH-960C Compact – 3 versions : PCH-960C-IH (only internal heating) / PCH-960C-EH (only external heating) / PCH-960C-CH (combination of the internal and external heating) |

| The principle of pasteurization | Blowing hot steam into the interior of the pasteurizer, where bottles or cans of beverages are stored on a pallet in plastic or metal transport baskets. The temperature is measured by a thermoprobe, which is placed inside the fake bottle between the other bottles with drinks/food. Steam is generated by an external steam generator (which is not included in price of the pasteurizer) or by the internal steam generator (according to version of the pasteurizer) , inside the pasteurizer the steam circulates using a fan. This achieves almost the same temperature in the entire space of the pasteurizer.

Pasteurization is a thermal process used to destroy microorganisms, thereby extending the shelf life of food products. |

| Capacity | Up to 960 pcs of the 0.50L or 0.33L cans/bottles in one batch (placed in plastic crates in 1-6 layers on a pallet (1200 x 800 mm)

Inner space inside the pasteurizer : approximaly 1300 x 950 x 1990 (L x W x H) Maximally 48 plastic crates 400 x 300 x 300 with bottles or cans on the Eur-pallet. For 0.5L glass bottles in six layers of beer crates, pasteurized to 20 PU (Pasteurization Units) at 62°C under the conditions of steam heating, water cooling, and cooling air temperature of 15°C, the process takes approximately 35 minutes. Approximate output capacity: 1600 bottles/hour. |

| Electrical supply | Version PCH-960C-IH (only internal heating) : 3-phase 400V / Switcheable capacity of 10.3 – 18.6 – 27.0 – 35.2 – 43.6 – 52 kW, depending on the number of active heating elements (max. 6) … An external steam generator is not required. Recommended cable of 5x25A. Recommended main switch and fusing of 125A/B/3.

Version PCH-960C-EH (only external heating) : 3-phase 400V / 2 kW … An external steam generator is required. Recommended cable of 3x16A. Recommended main switch and fusing of 10A/B/3. Version PCH-960C-CH (combination of the internal heating and an external steam generator) : 3-phase 400V / Switcheable capacity of 10.3 – 18.6 – 27.0 – 35.2 – 43.6 – 52 kW, depending on the number of active heating elements (max. 6) … … An external steam generator is recommended. Recommended cable of 5x25A. Recommended main switch and fusing of 125A/B/3. |

| External steam generator | Required : Electric steam generator, Gas steam generator, Diesel steam generator / Capacity of 90-140 kg of steam per hour at 0.5 bar (Only for the PCH-960C-EH/CH versions). Not required for the PCH-960C-IH version. |

| Cold air supply | Minimum pipe diameter Ø 150 mm. It is recommended to install a cold air supply from outdoor space, without the ventilator (the ventilator is included in the pasteurizer). |

| Hot air exhaust | Minimum pipe diameter Ø 150 mm. Pipe for the exhaust of hot air from the pasteurizer when the ventilation with cold air is in process. |

| Condensate discharge | The machine is equipped with a pump for draining condensed and shower water into the sewage system. The drainage is carried out using a hose with an internal diameter of 10 mm. Maximum discharge height is 10 meters. |

| Softened water supply | BSP 1/2″ male threaded pipe. For production steam only treated (softened) water may be used. Use of non-softened water damages heating elements and is a reason for cancel warranty. |

| Cooling water supply | BSP 1/2″ male threaded pipe. Needed only if the water shower is installed. |

| Control system | Automatic control system, based on the PLC Siemens Simatic / HMI Siemens |

| Material | Standard version : Stainless steel AISI 304 / Optionally : AISI 316L (for surcharge 20%) |

| Space required (mm) | Minimal required space : length 1800 x width 1400 x height 2700 mm.

Dimensions for transport on a wooden pallet : length 1800 x width 1400 x height 2800 mm. Dimensions of the pasteurizer : 1754 x 1377 x 2676 mm.

The machine can be disassembled into individual panels that fit through standard doors, eliminating the need for structural alterations during installation. |

| Weight | Netto : 1300 kg / Brutto : 1400 kg |

Price list

Code |

Name |

Description |

Price |

| PCH-960C-IH | Pasteurizer with the integrated heating | Fully equipped cabinet pasteurizer with integrated electric-steam heating 50kW, installation and operating instructions, electrical diagram. | on demand |

| PCH-960C-EH | Pasteurizer with the external heating | Fully equipped cabinet pasteurizer with an external steam heating, installation and operating instructions, electrical diagram. External steam generator 60-120kW is required. | on demand |

| PCH-960C-CH | Pasteurizer with the combinated heating | Fully equipped cabinet pasteurizer with combinated heating. Included : integrated electric-steam heating 50kW. External steam generator 60-120kW is required. Installation and operating instructions, electrical diagram. | on demand |

| PCH-960C-DLS | Door with left-side opening | It is necessary to order this option before the production | in price |

| PCH-960C-SPR | Steam pressure reduce valve | Integrated steam pressure regulation. It is not necessary if the external steam generator includes a reduce valve for setting of steam pressure at 0.5 bar. | on demand |

| PCH-960C-FIR | Folding inclined ramp | Integrated folding inclined plate for easy access by a conventional pallet truck, without the need for a forklift. | on demand |

| PCH-960C-WSH | Water shower | For faster cooling after pasteurization, an additional water shower can be used. | on demand |

| PCH-960C-STG | Steam generator | Only the version of PCH-960C-EH includes an integrated steam generator with switcheable power of 10.3 – 18.6 – 27.0 – 35.2 – 43.6 – 52 kW. An external steam generator is a necessary equipment for versions of PCH-960C-EH, PCH-960C-CH. We offer more types … see recommended types of the steam generators on this page or the catalogue of steam generators | prices |

| PCH-960C-WTS | Water treatment system | Water treatment system – the water softener (necessary equipment for use with the steam generators if water for use with the machine is not absolutelly soft). | on demand |

| PCH-960C-GSM | GSM module | After the pasteurization process is completed, the GSM module calls the human operator by ringing the mobile phone, or in the event of a failure/interruption of the process, it sends an SMS to the selected phone numbers. | on demand |

| PCH-960C-SBT | Special basket or trolley | As a standard, food products (in bottles, cans) are pasteurized on a pallet, stacked in plastic crates. In case of a requirement for pasteurization of beverages or food in pouches or other non-standard packaging, it is possible to order the production of a special stainless steel basket, which will be placed on a wooden pallet. The basket (trolley) can be equipped with wheels. The dimensions and design of the basket will be consulted with the customer. The price will be determined individually according to the production complexity of the special basket or trolley. | on demand |

| PCH-960C-SVF | Special voltage / frequency | Electric system equipment which is designed for power supply system different than 3-phase 400V / 50 Hz (The UL/CSA certificate or other special certificates non-usual in Europe are not available) | on demand |

Recommended external steam generators

An external hot steam generator with minimal capacity 90-140 kg of steam per hour is needed … this equipment is not included in price.

Model |

Picture |

Description |

Electric steam generators – minimum possible capacity :Cheaper machine but the pasteurization cycle will take 2x more time. |

||

MXSG-60 |

|

Electric steam generator GHIDINI MAXI-60 60kW / 90kg/hr | pressure max 4.5 barAutomatic electric hot steam-generator with capacity of 60 kW (90 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

MXSG-60CSF |

|

Electric steam generator GHIDINI MAXI-60 60kW / 90kg/hr | pressure max 4.5 bar | Complete system on the frameAutomatic electric hot steam-generator – the complete system on the frame with capacity of 60 kW (90 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included) The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use. This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

Electric steam generators – recommended capacity :With this machine the pasteurization cycle will be shorter and the pasteurizer output capacity will be 2x higher. |

||

MXSG-120 |

|

Electric steam generator GHIDINI MAXI-120 120kW / 180kg/hr | pressure max 4.5 barAutomatic electric hot steam-generator with capacity of 120 kW (180 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

MXSG-120CSF |

|

Electric steam generator GHIDINI MAXI-120 120kW / 180kg/hr | pressure max 4.5 bar | Complete system on the frameAutomatic electric hot steam-generator – the complete system on the frame with capacity of 120 kW (180 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included) The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use. This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution. Regulation of the working steam pressure is adjustable in range from 1 to 4.5bar |

Gas steam generator – minimum possible capacity :Cheaper machine but the pasteurization cycle will take 2x more time. |

||

GSG-100 |

|

Gas steam-generator 69.7 kW | 100kg/hr | 5 barAutomatic gas steam-generator, available power 67.7 kW – The production capacity from 50 to 100 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar. This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations. + WTS-MX120 : Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) …€ 1190,- |

Gas steam generator – recommended capacity :With this machine the pasteurization cycle will be shorter and the pasteurizer output capacity will be 2x higher. |

||

GSG-150 |

|

Gas steam-generator 112.7 kW | 150kg/hr | 5 barAutomatic gas steam-generator, available power 112.7 kW – The production capacity from 75 to 150 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar. This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations. + WTS-MX180 : Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) …€ 1190,- |

Reviews

There are no reviews yet.