Description

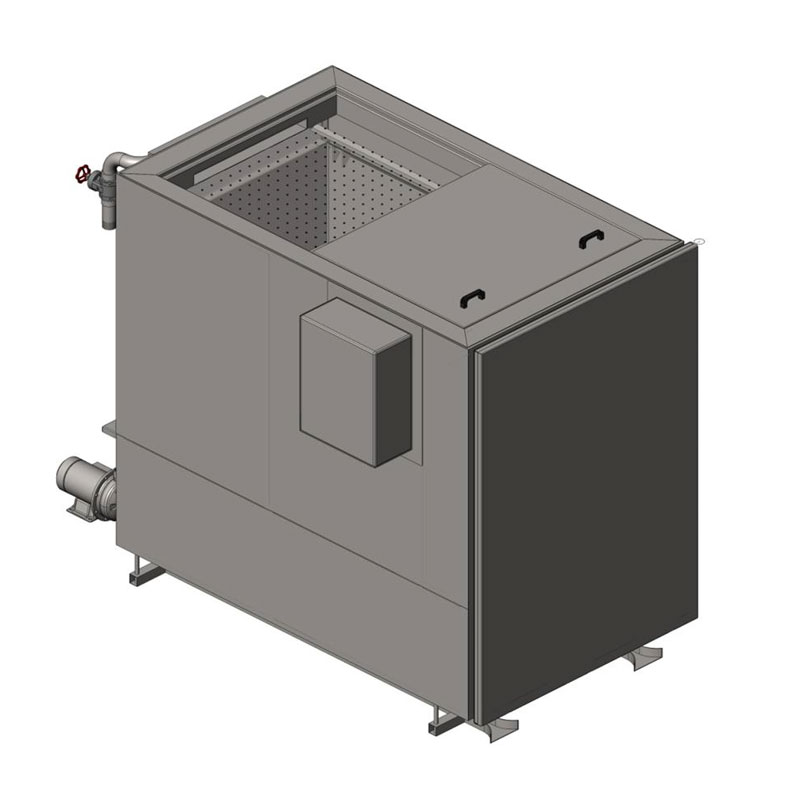

The chamber water-shower pasteuriser is an ideal equipment for pasteurising of filled and closed bottles or cans, whether they contain fruit juice, vinegar, cider, conserves and even canned fruit or vegetables. Pasteurization capacity of the PCH-360WS pasteurizer : up to 360 pcs of the 1L, 506 pcs of the 0.50L standard cans, up to 668 pcs of the 0.33L pcs of the SLEEK cans, up to 786 pcs of the 0.20L SLIM cans (or bottles) in one batch.

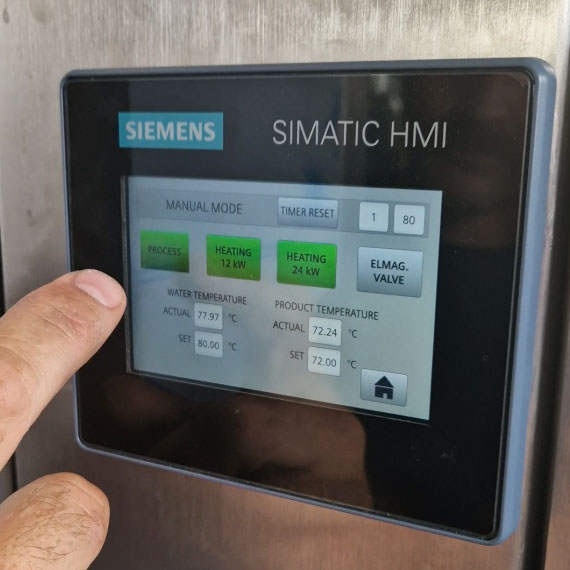

The cabinet-pasteurisers for beverages offer safe and easy use, they are controlled via a digital panel for an adjusting of heating temperature and the cooling time. Filled and closed bottles or cans are placed into the pasteuriser, beverage does not flow through the pasteurizer parts, therefore the need for cleaning of the equipment is drastically reduced.

Filled and closed bottles or cans are placed into the cabinet, the temperature level and duration can be programmed via a digital control pannel and heating time and cooling time can both be adjusted. Pasteurisation time is normally one hour after which the process shuts down automatically. The PCH-360 cabinet pasteurizer is ideally suited for the small to medium producers requiring an efficient in-bottle pasteurisation method.

Equipment for easy pasteurisation of beverages. Very simple pasteurizer designed as a stainless steel cabinet. This pasteurizer has advantage that also bottles or cans are well cleaned from outside during the pasteurizing process. The pasteuriser is an integral part of the beer or other beverage production process. Keeping the right method of pasteurisation is incredibly important for managing of beverage product quality and achieving low production costs.

Note :

If this water-shower pasteurizer is used to pasteurize beverages that have defined a specific number of pasteurization units (e.g. beer), we recommend using only one layer (grid) with bottles/cans in the cart. When using both layers (on both grids), it cannot be guaranteed that the beverages on both layers will be exposed to the same number of pasteurization units.

Key features:

- Large capacity – up to 360 pcs of the 1L, 506 pcs of the 0.50L standard cans, up to 668 pcs of the 0.33L pcs of the SLEEK cans, up to 786 pcs of the 0.20L SLIM cans (or bottles) in one batch

- Stainless steel construction with an insulated stainless steel cabinet

- Electronic temperature and time control

- Capable of pasteurising a wide range of products

- Automatic temperature control with individual sensors for water and product temperature

- Suitable for use with a wide range of product types and packaging sizes

- External heating – an external steam generator with capacity of at least 36 kW is required (it is not included in price)

- Main advantage – you can use your current steam generator if you have it already

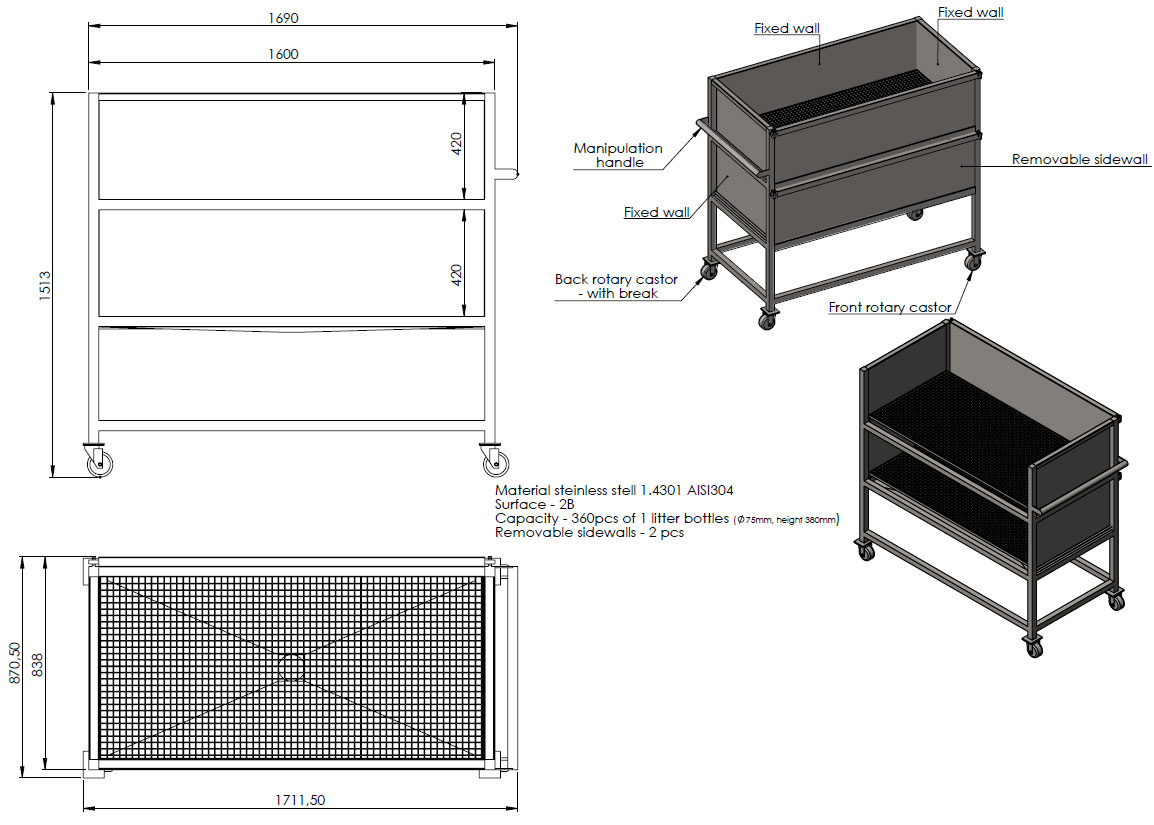

- One bottle trolley with capacity approximally 500 pcs of 0.33L bottles or cans is included.

- It is possible to order a secondary bottle trolley for higher production capacity.

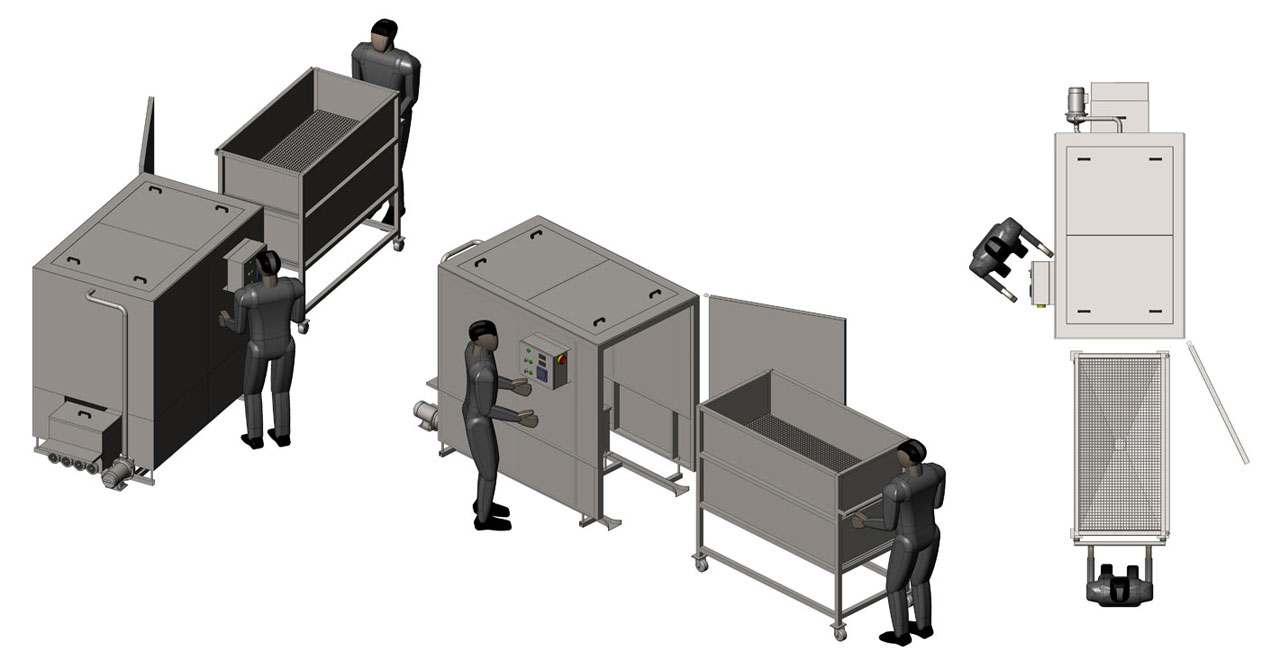

The trolley loaded with cans to pasteurization :

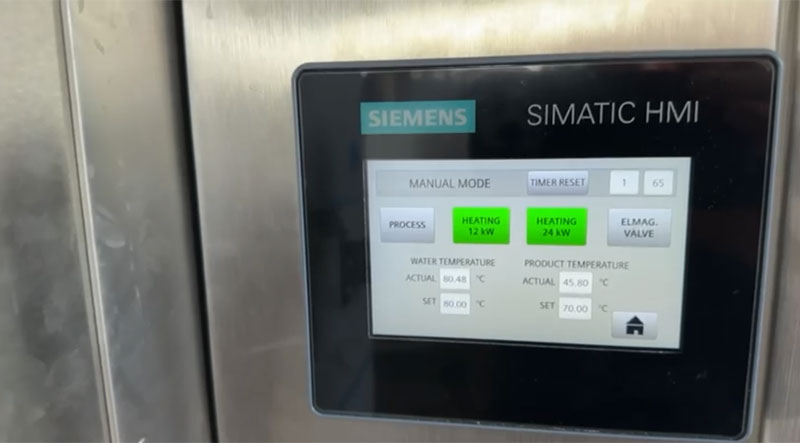

Accurate measuring of temperature directly in a can/bottle.:

Automatic control system based on the PLC Siemens S7-1500 / HMI Siemens

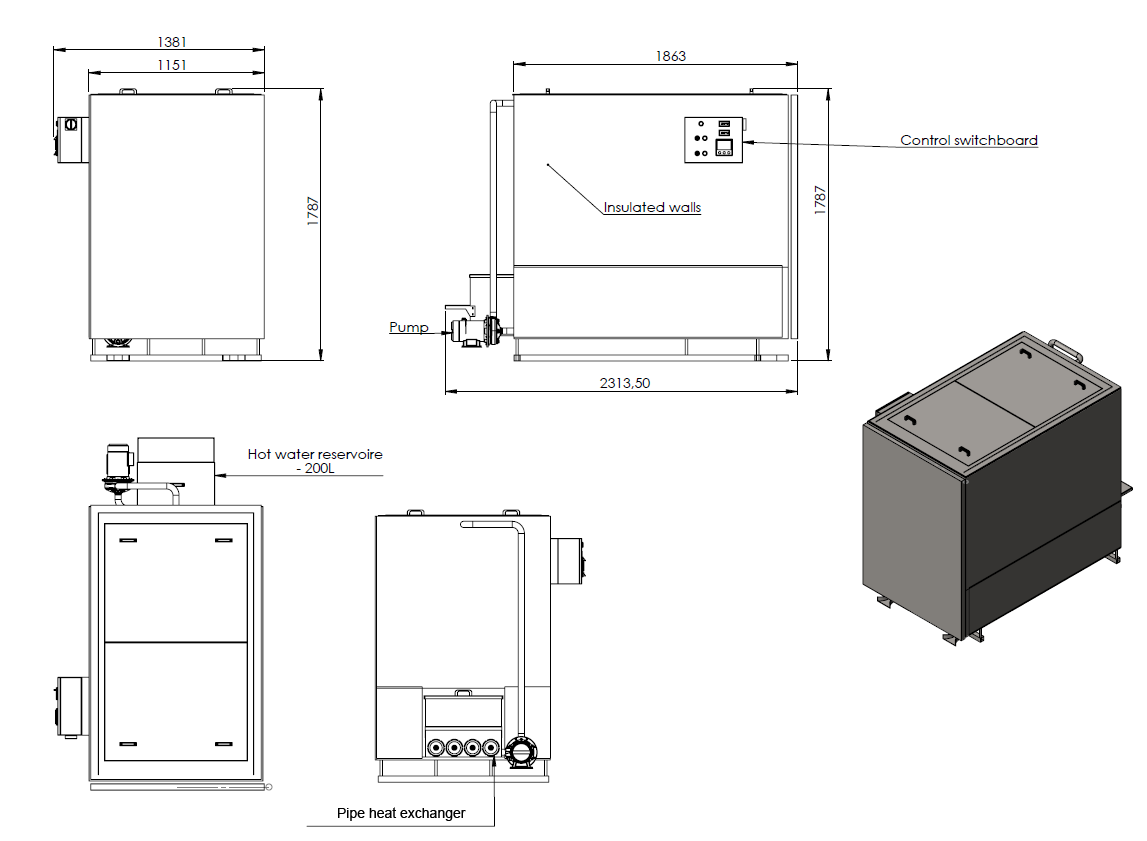

Technical Specification

| Model | PCH-360WS |

| The principle of pasteurization | Showering beverage containers with hot water at a set temperature for a set time – temperatures and times can be programmed in a few steps. The water is heated by integrated pipe heat exchanger placed inside the pasteurizer. The heat exchanger must be powered with hot steam from en external steam generator (which is not included in price of the pasteurizer) |

| Capacity | up to 360 pcs of the 1L, 506 pcs of the 0.50L standard cans, up to 668 pcs of the 0.33L pcs of the SLEEK cans, up to 786 pcs of the 0.20L SLIM cans (or bottles) in one batch |

| Heating power | Minimal power capacity of the external steam generator is of 36kW. Recommended capacity of 45-60 kW. |

| Electrical supply | 400V / 63A / 1.5 kW (without an external steam generator) |

| External heater | Electric steam generator, Gas steam generator, Diesel steam generator |

| Control system | Automatic control system, based on the PLC Siemens S7-1500 / HMI Siemens |

| Material | Standard version : Stainless steel AISI 304 / Optionally : AISI 316L (for surcharge 20%) |

| Space required (mm) | length 2500 width 1400 height 1800 |

| Weight | 700 kg |

Dimensions :

Recommended optional equipment :

| Code | Description | Price |

| PCH-360BT | Additional bottle trolley for the PCH-360 chamber pasteurizer | € 7170,- |

| PCH-360DR | Drying of the bottles with the air after the pasteurization | € 3350,- |

| PCH-360DV | Electric system equipment different than 3-phase 380-420V 50 Hz (EU standard) | On demand |

Additional bottle trolley for the PCH-360 chamber pasteurizer………….. for next 360 – 786 bottles or cans

Recommended steam generators :

… necessary accessory for an external heating

Model |

Picture |

Description |

Electric steam generators : |

||

MXSG-40 |

|

Electric steam generator GHIDINI MAXI-60 40kW / 60kg/hr | pressure max 4.5 barAutomatic electric hot steam-generator with capacity of 40 kW (60 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5 bar |

MXSG-60 |

|

Electric steam generator GHIDINI MAXI-60 60kW / 90kg/hr | pressure max 4.5 barAutomatic electric hot steam-generator with capacity of 60 kW (90 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included). Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 4.5 bar |

MXSG-40CSF |

|

Electric steam generator GHIDINI MAXI-60 40kW / 60kg/hr | pressure max 4.5 bar | Complete system on the frameAutomatic electric hot steam-generator – the complete system on the frame with capacity of 40 kW (60 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included) The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use. This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution. Regulation of the working steam pressure is adjustable in range from 1 to 4.5 bar |

MXSG-60CSF |

|

Electric steam generator GHIDINI MAXI-60 60kW / 60kW / 90kg/hr | pressure max 4.5 bar | Complete system on the frameAutomatic electric hot steam-generator – the complete system on the frame with capacity of 60 kW (90 kg of hot steam per hour) – if returned condensate is reused (the condesate recovery set is included) The compact build pre-assembled and tested steam generator with all recommended accessories. All is delivered on the stainless steel frame, with all internal connections, ready-to-use. This type of execution makes it possible to minimize both dimensions and on-site installation costs and start-up activities. Once it is set in its installation point, the whole equipment only needs to be connected to the essential utilities, such as electric power supply, steam output pipes and water distribution. Regulation of the working steam pressure is adjustable in range from 1 to 4.5 bar |

Gas steam generators : |

||

GSG-50 |

|

Gas steam-generator 34.7 kW | 50kg/hr | 5 barAutomatic gas steam-generator, available power 34.7 kW – The production capacity from 25 to 50 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar. This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations. + WTS-MX60 : Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) …€ 990,- |

GSG-100 |

|

Gas steam-generator 69.7 kW | 100kg/hr | 5 barAutomatic gas steam-generator, available power 69.7 kW – The production capacity from 50 to 100 kg of hot steam per hour. Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5 bar. This steam-generator is equipped with gas burner RIELLO RS 4DF MBZRDLE 412g – gas inlet pressure 2-36 kPa. The steam-generator shell is manufactured in accordance to the current PED regulations. + WTS-MX60 : Water treatment simple system (necessary equipment if water for use with the machine is not absolutelly soft) …€ 990,- |

Reviews

There are no reviews yet.