Description

The automatic line for the filling and washing of stainless steel kegs with production capacity from 50 to 68 kegs per hour.

The machines are designed and made with special care paid to hygiene and available in different sizes and models. The entire structure of the machine and the parts that are contact with the liquid are entirely made out of AISI 304 stainless steel.

The filling head was conceived with careful detail to exclude any type of contact with air on the part of the product being worked and to ensure a filling that’s completely sterile.

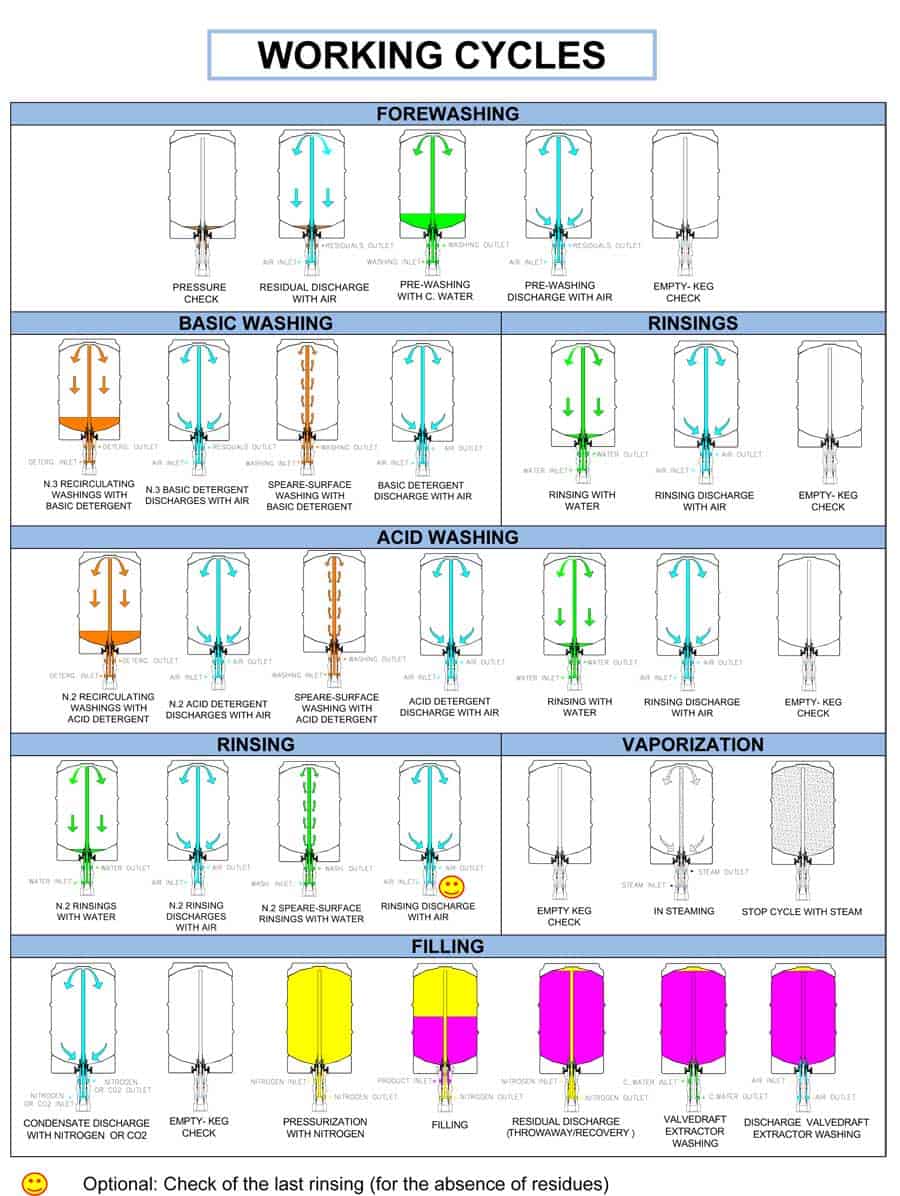

The keg washing systems were conceived to ensure:

a) Perfect cleaning the kegs

b) Checking and monitoring of the rinsing phase

c) At the end of every work phase, the checking for the absence of liquid in the kegs, thus confirming the impossibility of unwanted rackings to then be able to provide the assurance that the discharge phase has occurred.

The systems are fitted for the connection with a steam-generator for hot sterilization of the containers. The command and control parts are positioned in a watertight control board and electronically managed thanks to the use of a PLC.

Our valves for the controlling of the washing and filling cycles are made out of turned-ingot stainless steel and, thanks to their perfect internal finishing, allow for easy washing and sterilization, thereby preventing filth and grime from settling. In addition, the special solid steel

structure guarantees excellent resistance to wear and minimizes the need for ordinary maintenance operations.

The KWFL-MB41A system includes :

- Stainless steel frame

- AISI 304/316 L stainless steel product piping

- AISI 304 L stainless steel control board

- Adjustable supporting feet

- Automatic keg type regulator via pneumatic centering device

- Washing and filling function via PLC

- Transfer of the kegs through a beam detector

- Keg centering device

- Operator interface with touch screen

- Liquid-detection sensor at each rinsing, washing and steaming phase (no condensation)

- Keg-detection sensor (on washing-and-filling head)

- Filling with pressure sensor and maximum liquid-level detection

- Detergent heating via steam pocket or electrical resistance – By choice

- Accident-prevention protection with barriers and door-closure monitoring sensor

- Electrical outlet for connection to the feed pump

- 250 liter CIP (Clean-in-place) tank for basic detergent

- 250 liter CIP (Clean-in-place) tank for acidic detergent

- Pump for the re-circulation of the basic detergent

- Pump for the re-circulation of the acidic detergent

- Kit for the washing and sanitization of the filling heads

- Use and maintenance manual in Italian and English

Technical specifications :

| KWFL-MB21A | KWFL-MB31A | KWFL-MB41A | |

|---|---|---|---|

| CHARACTERISTICS | |||

| Filling capacity range | 10-50 l | 10-50 l | 10-50 l |

| Designed for product | Beer | Beer | Beer |

| Washing heads | 2 | 3 | 4 |

| Filling heads | 1 | 1 | 1 |

| Liter counter - accuracy | ± 0.20% | ± 0.20% | ± 0.20% |

| Average filling accuracy | ± 1.5% | ± 1.5% | ± 1.5% |

| Accident-prevention protection | Barriers with stop blocks | Barriers with stop blocks | Barriers with stop blocks |

| Sanitization – sterilization | Water-chemical-Steam | Water-chemical-Steam | Water-chemical-Steam |

| PRODUCTION | |||

| Maximal capacity - for 20/30L kegs | 40 | 50 | 68 |

| Maximal capacity - for 50L kegs | 30 | 40 | 50 |

| CONSTRUCTION MATERIALS | |||

| Construction material | Aisi 304 L | Aisi 304 L | Aisi 304 L |

| Material in contact with the liquid | Aisi 304/316L | Aisi 304/316L | Aisi 304/316L |

| DIMENSIONS AND WEIGHT | |||

| Height of the work table (mm) | 870 | 870 | 870 |

| Dimensions WxDxH (mm) | 4970x1600x2400 | 4970x1600x2400 | 4970x1600x2400 |

| Weight (Kg) | 1050 | 1230 | 1600 |

| ELECTRICITY | |||

| Filler’s installed power (kW) | 3 | 3 | 3 |

| Power of the heating if is present (kW) | 4.5 | 9 | 9 |

| Electric power supply system | 400V 3/pe 50Hz | 400V 3/pe 50Hz | 400V 3/pe 50Hz |

| CONSUMPTION | |||

| Maximal liquid flow rate (l/h) | 3600 | 3600 | 3600 |

| Product pressure (bar) | 2.5 | 2.5 | 2.5 |

| Air pressure (bar) | 6 | 6 | 6 |

| Air consumption ( l/min) | 1350 | 1350 | 1350 |

| Nitrogen pressure (bar) | 6 | 6 | 6 |

| Nitrogen consumption ( l/min) | 300 | 335 | 365 |

| Water pressure (bar) | 3 | 3 | 3 |

| Water flow rate (liters/hour) | 2300 | 2300 | 2300 |

| Heating steam (kg/h) | 24 | 24 | 24 |

| Sterilization steam (kg/h) | 23 | 25 | 27 |

| CONNECTIONS | |||

| Product | DN 25 F | DN 25 F | DN 25 F |

| Compressed air | ½” F gas | ½” F gas | ½” F gas |

| Nitrogen | ⅜” F gas | ⅜” F gas | ⅜” F gas |

| Detergent-heating steam | ½” F gas | ½” F gas | ½” F gas |

| Sterilization steam | ½” F gas | ½” F gas | ½” F gas |

| Water | ¾” F | ¾” F gas | ¾” F gas |

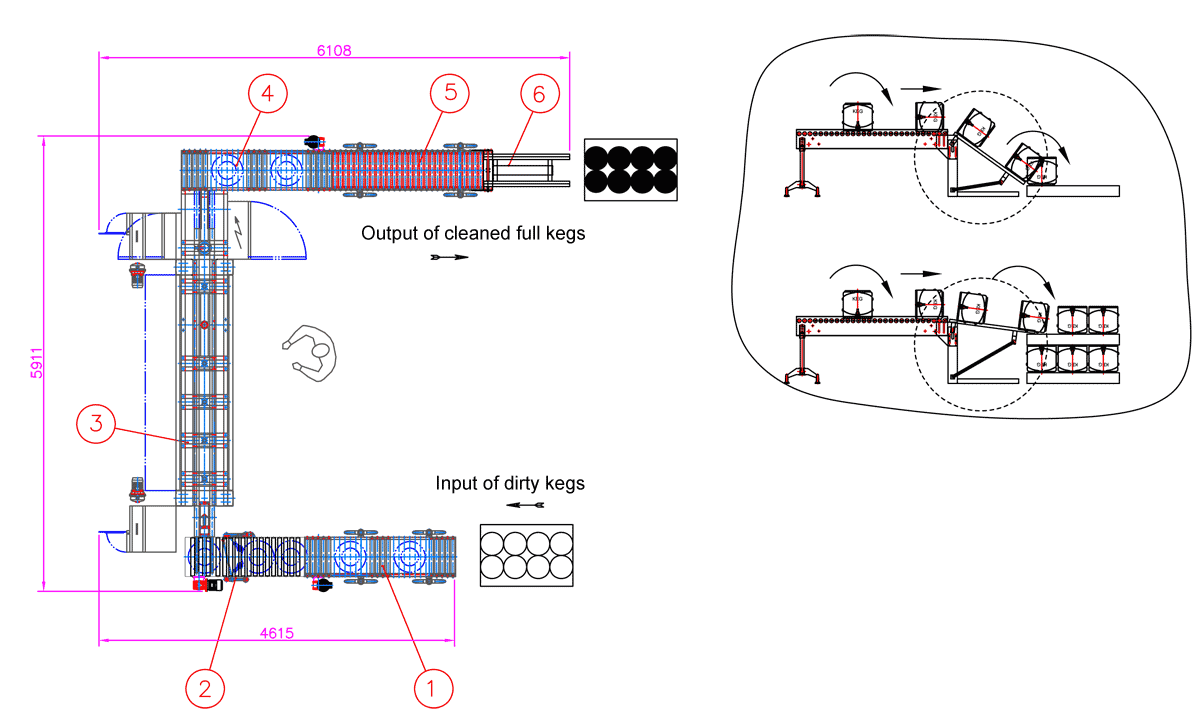

Configuration A : (without the washing the outer surface of kegs, without the ejector of bad kegs) :

This configuration includes :

| Code | Pos. | Description | Q.ty | Total price € |

| 126K045 | 1 | 2m stainless steel iddle roller conveyor (loading the empty dirty kegs) | 1 | On demand |

| 126k137 | 2a | 1.5m stainless steel motorized idle roller conveyor | 1 | On demand |

| 126K030 | 2b | Automatic arms for keg queue stopping and releasing kegs to enter the washing-filling monoblock at prescribed intervals | 2 | On demand |

| 126k004 | / | Keg-probe and filling head rinser | On demand | |

| 126k125 | 3 | KWFL-MB41A : Automatic rinsing-washing-filling monoblock for stainless steel kegs | On demand | |

| 26K067 | 4 | 2m stainless steel motorized roller conveyor | 1 | On demand |

| 126K043 | 5 | Pincer keg dumper | 1 | On demand |

| 126K045 | 6a | 2m stainless steel iddle roller conveyor (loading the empty dirty kegs) | 1 | On demand |

| 6b | Unloading the cleaned full kegs | |||

| 126k135 | / | Perimetrical protections | 24m | On demand |

| 126k130 | / | Perimetrical doors | 4 | On demand |

| Total | On demand | |||

| Related services : | ||||

| Start-up and commissioning of the whole keg washing-filling line by our technician. One week of the specialist´s work. Travelling, board and accomodation is not included in this price. (Indicative price – will be calculated for each individual project). | On demand | |||

| PDI test in our company at the testing time, before loading the equipment. | Included in price |

Configuration B : (with the washing the outer surface of kegs, with the ejector of bad kegs) :

This configuration includes :

| Code | Pos. | Description | Q.ty | Total price € |

| 126K118 | 1 | 1.5m stainless steel idle roller conveyor (loading the empty dirty kegs) | 1 | On demand |

| 126K143 | 2 | 1.5m stainless steel motorized idle roller conveyor | 1 | On demand |

| 126K030 | 3 | Automatic arms for keg queue stopping and releasing kegs to enter the washing-filling monoblock at prescribed intervals | 2 | On demand |

| 12830 | 4 | KEGSJET – Washing tunnel for cleaning the outer surface of kegs | 1 | On demand |

| 26K067 | 5 | 2m stainless steel motorized roller conveyor | 1 | On demand |

| 126k176 | 6 | Roller conveyor on input the kegs into the washing-filling monoblock | 1 | On demand |

| 126k125 | 7 | KWFL-MB41A : Automatic rinsing-washing-filling monoblock for stainless steel kegs | 1 | On demand |

| 126k177 | 8 | Keg output module with ejector of the bad kegs | 1 | On demand |

| 126K045 | 9 | 2m stainless steel iddle roller conveyor (for reject defective kegs) | 1 | On demand |

| 126k055 | / | Additional head for rinsing of keg-extractor connection | 1 | On demand |

| 126K043 | 10 | Pincer keg dumper | 1 | On demand |

| 126K116 | 11 | 3m stainless steel iddle roller conveyor for stocking of full kegs (manual unloading the cleaned full kegs) | 1 | On demand |

| 126k038 | 12 | Semi automatic unloader (stacker) of the full kegs (optionally – see the optional equipment) | – | – |

| 126k135 | / | Perimetrical protections | 24 m | On demand |

| 126k130 | / | Perimetrical doors | 4 | On demand |

| Total | On demand | |||

| Related services : | ||||

| Start-up and commissioning of the whole keg washing-filling line by our technician. One week of the specialist´s work. Travelling, board and accomodation is not included in this price. (Indicative price – will be calculated for each individual project). | On demand | |||

| PDI test in our company at the testing time, before loading the equipment. | Included in price |

Start up

Start up filling kegs system 1 person for 4/6 days (travel, board and lodging) … About 3.000 – 5.000 euro for EU

Optional equipment (on demand) :

| Code | Description | Price € |

| 126k038 | Semi automatic unloader (stacker) of the full kegs (position n.12 in the B – configuration) | On demand |

| 126K037 | Magnetic liter counter (Made by the Endress Hauser) | On demand |

| 126K096 | End-of-the line manual keg unload facilitator | On demand |

| 126K015 | Keg balance with double weighing (net weight) . Netto/brutto scale on the side of the machine. There are 2 scale and the machine weights the kegs before and after the filling. The balance checks the different weiight of the kegs – if the machine founds an defective keg signalizes in alarm . | On demand |

| 126K156 | Mobile alimentary food centrifugal pump 2.5 bar with open impeller – mounted on trolley . | On demand |

| 126K216 | Mobile alimentary food centrifugal pump 2.5 bar with open impeller – mounted on trolley, with the frequency converter (for high performance) | On demand |

| 126K155 | Air filter with stainless housing with the 0.2 µm filtration cartridge. | On demand |

| 126K155 | Gas filter with stainless housing with the 0.2 µm filtration cartridge. | On demand |

| 126K150 | Steam filter with 1×10″ housing with AISI 316 stainless steel cartridge | On demand |

| 126K034 | Water recovery tank 160 lt ( for save about 25% of water) | On demand |

| 126K032 | Checking of the last rinse water – detects if residual of detergent lefts in water | On demand |

| 126K050 | Caustic detergent quality check set: is included the conductivity meter device, the peristaltic pump for take the detergent from tanks, water heater by steam or electric system (by choice) | On demand |

| 126K049 | Acidic detergent quality check set: is included the conductivity meter device, the peristaltic pump for take the detergent from tanks | On demand |

| 126K020 | Modification of the machine to use with special client kegs (2sp.+t°) | On demand |

| 126K020 | Kit of the main recommended spare parts | On demand |

Reviews

There are no reviews yet.