Description

The CWCH-Q2262 is the compact water or glycol cooler with integrated accessories like the heat exchanger, pump and water tank. This cooling unit is designed for cooling or heating external media, with the accumulation of ice (or hot) water or glycol. It can be used for cooling (or heating) of beer, cider, freeze-drying wines or heating mash. Cooling power is 226 kW. The units are designated to be placed outdoor, at environment temperatures from -10°C to +45°C.. The main advantages are very easy instalation without team of cooling specialists. It is produced with 3-phase (EU/USA). Designed in Germany.

About QUANTOR : Compact water chillers / heat pumps

QUANTOR are air-cooled cooling-units, which was developed specifically for the beverages industry. QUANTOR water cooler is a solution which is ideal for manufacturers of wine, beer, cider and other drinks who need ensure the cooling, heating, controlling the temperature of the cooling media during the beverage manufacture process. The QUANTOR units are compact long-life cooling devices characterized by their modularity, in offering many configurable features to the user’s choice.

The units are designated to be placed outdoor for operation between environment temperatures from -10°C to +42°C. The rated cold-water temperature is between -10°C and +18°C, (warm water up to +55°C). The cooling units are available in capacities from around 60 to 1000 kW.

The QUANTOR units cover the complete bandwidth of process steps and utility possibilities in Beer-Brewing, generally drinks industry and winemaking: Cold maceration, cold-settling, fermentation control, wine-stabilization, wort cooling to stop the enzymes activity, cooling for beer storage and beer maturation process, fast cooling of mixed-drinks and syrupes in heat exchangers.

(Minimal possible temperature is up to -10°C). The reversible-heating units can warm-up wine before bottling. Secondary possible function of these cooling units is temperating of room or buildings in winter using integrated fans and used air.

Characteristics

- Cooling water temperature : From -10° to +18°C

- Heating water temperature : From +25° to +50°C

- Ambient temperature : From -10°C to +42°C

Applications

- Cooling or heating of beer, must or wine

- Cooling of wort

- Cold maceration and tartaric stabilisation of wines

- Heating of stabilized wine or cold storage of wine before bottling

- Biological reduction of acids

- Wine stabilization

- Regulation of fermentation temperature

- Cool storage of wine until bottling

- Air cooling of the cellar in combination with additional equipment (thermo-ventilators and accessories)

Standard features

- Stable construction from galvanised sheet metal with premium polyester powder-coating with anti vibration mounts

- Hermetic Scroll compressors of the latest models

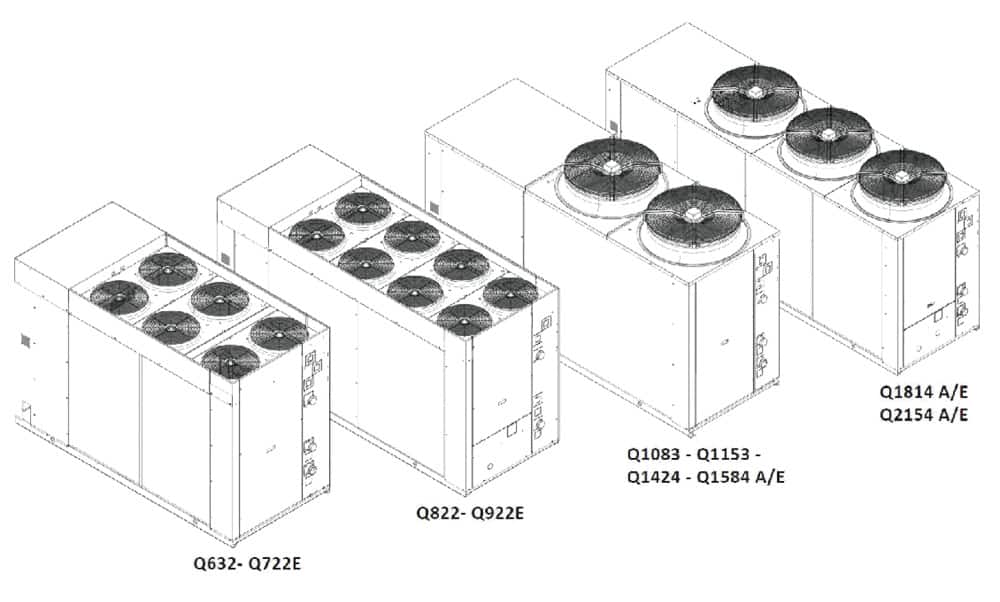

- Increased operation safety – units with double cooling circuits (Q632 – Q2154). Larger models have more cooling circuits.

- Gradual activation of the compressors allows higher efficiency by partial-load operation, and significantly positive values of the European seasonal energy efficiency ratio EER

- Latest generation micro-processor control with supervision above all the relevant parameters

- Compressor encapsulated in noise-reduction box

- Stainless steel evaporator with itegratedfrost – protection heating element

- High efficiency (EER till 4,15 and COP till 3,38) and low power consumption

- Low noise level

- Environmentally friendly refrigerant R 410 A

- In the model sizes Q632 to Q922 the fan-motors are equipped with frequency-converter in standard

- Water filter and Victaulic connections included with the units

- Wide range model series: Unit available in cooling from 63kW to 1040kW1 en froid, and in heating from 59kW to 1050kW².

Available options

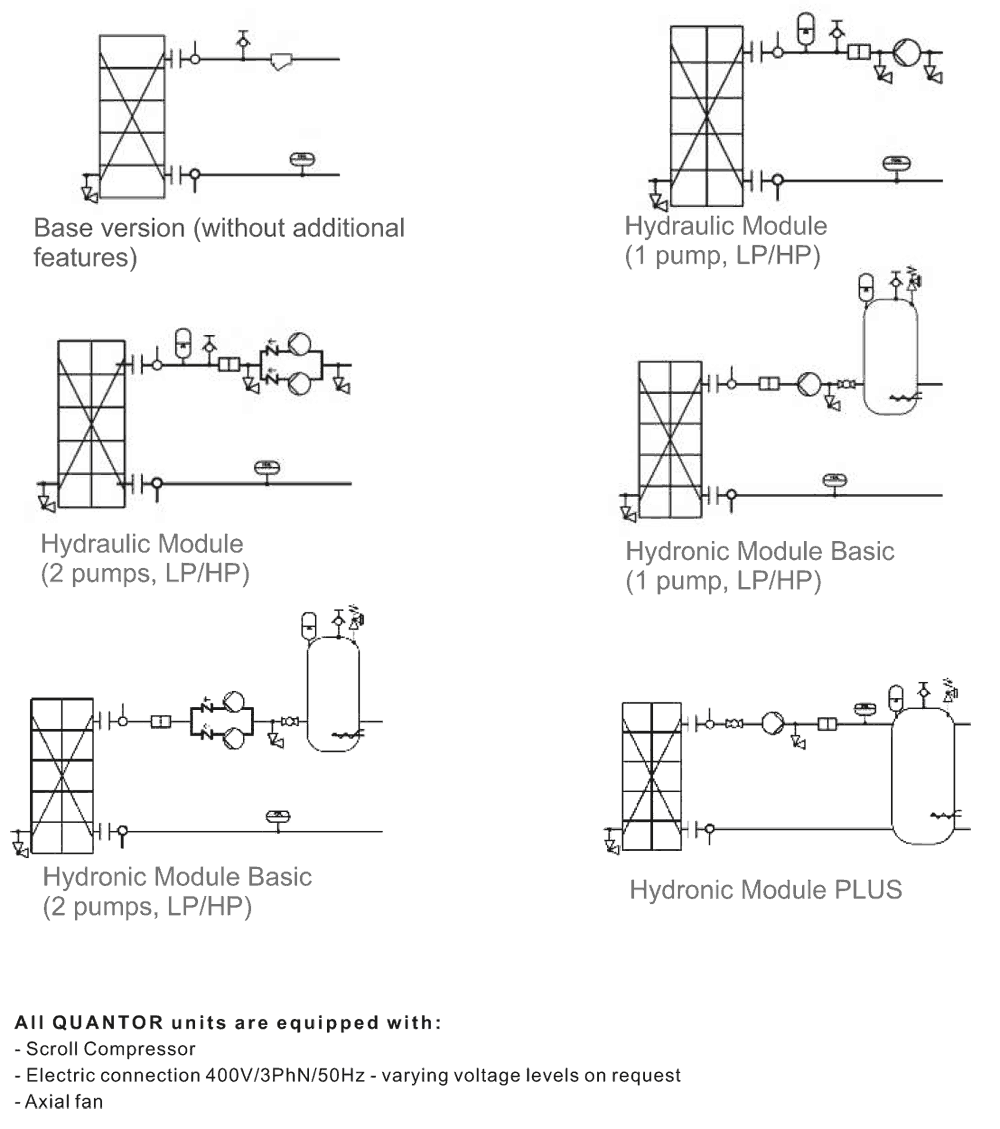

- Hydraulic Module (Pump, filtre, expansion vessel and safety components)

- Hydronic Module Basic (stainless steel buffer tank, pump, expansion vessel and safety components)

- Hydronic Module PLUS (stainless steel buffer tank as hydraulic flow-adaptation, pump, expansion vessel and safety components). No by-pass valve needed with this option

- Epoxy coating on the condenser

- Fans with frequency converter

- Fans with stronger air-thrust

- Heat recovery

- Remote control and / or Internet interface

- By models from Q1083, additional noise-reduction is possible. The lowest water temperature is then limited to +4°C .

- Soft-start for compressors

- Power Factor Correction (Cos Phi)

- Second pump

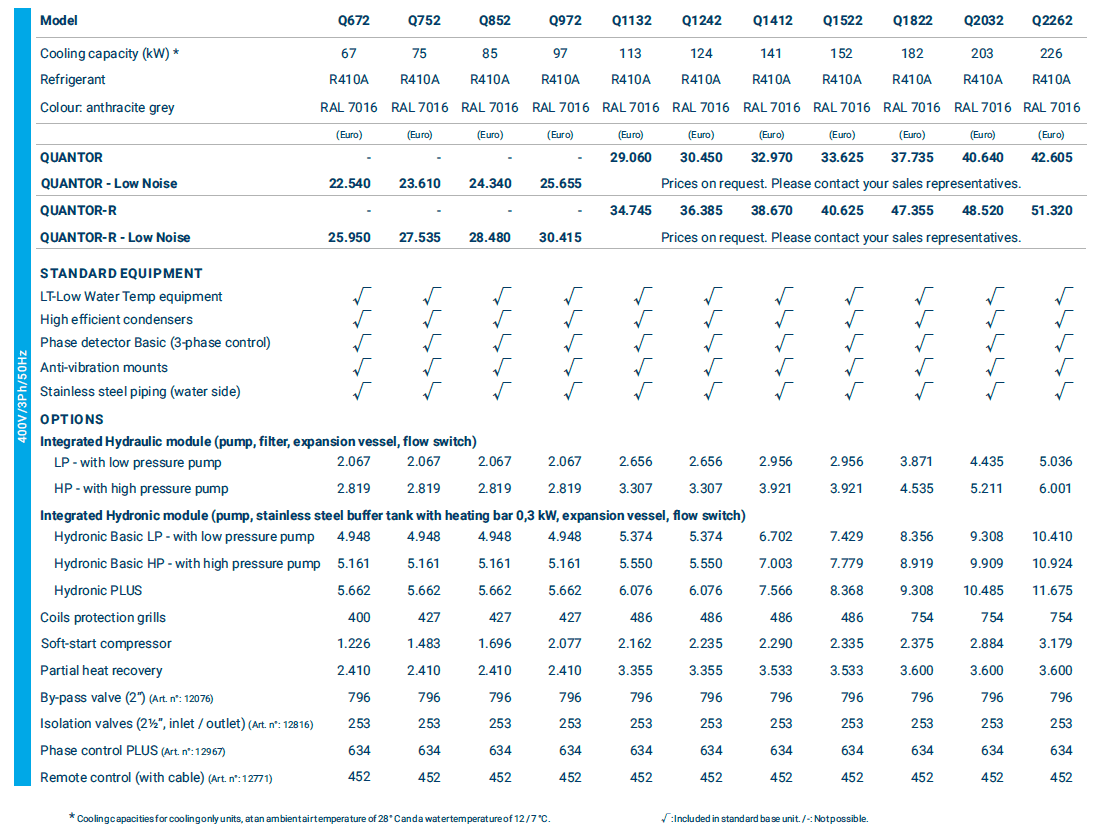

Technical details of all available models :

Standard and optional equipment :

Hydraulic system – options :

Notice :

Prices of the chillers for USA electric standard are available on demand.

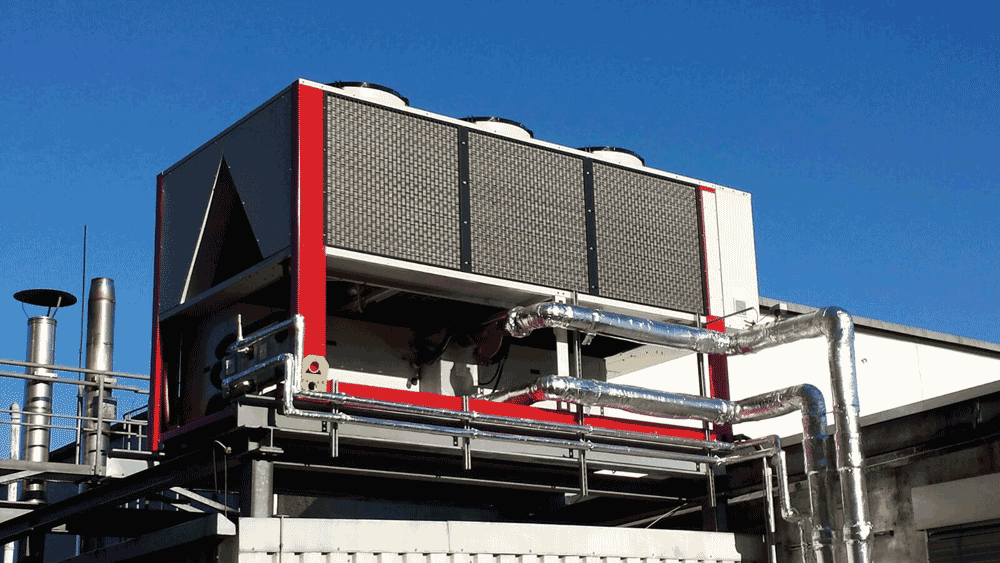

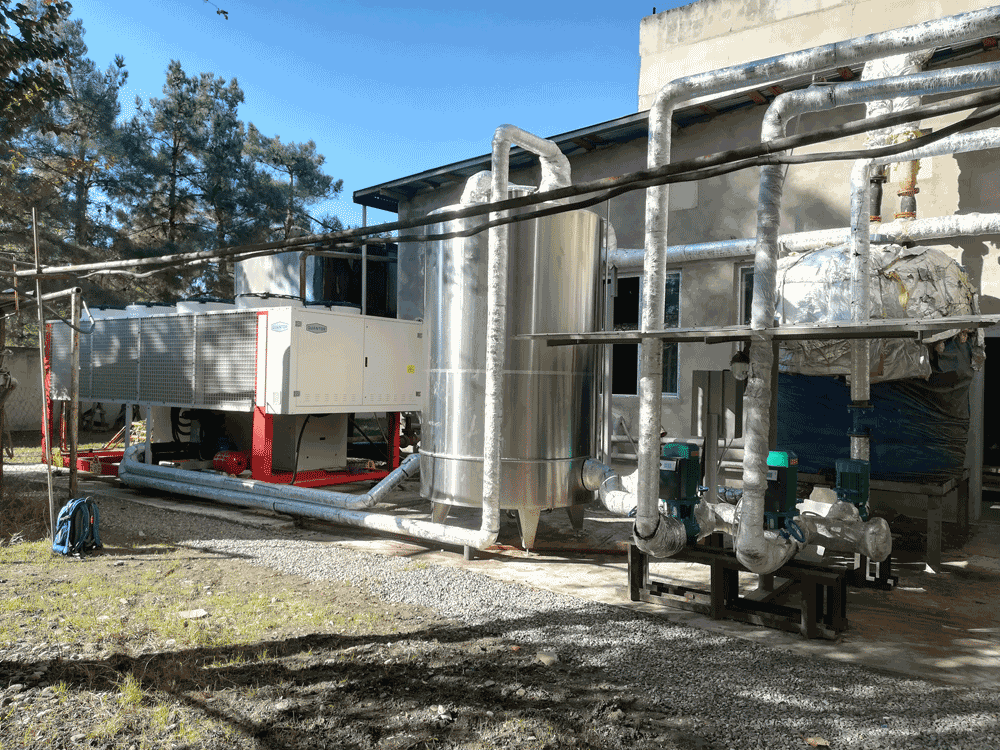

Example installations – Europe

Reviews

There are no reviews yet.