Description

Stainless steel filter housing for three 30/3″ filtration candle elements is a tool used in the pre-bottling stage of a beverage production process.

It is necessary tool to achieve clean beer, wine, fruit juices or other food liquids. The structure of the filter housing includes a 30″ AISI 316 stainless steel housing for three 30″ filtration elements that guarantees maximum hygiene and safety in beverage filtration operations and ensures the removal of yeast cells and bacteria, minimising any alteration of the final product.

This filter housing has a working capacity from 800 L/h of up to 3000 L/h depending on beverage kind, pump capacity and clogging the filtration elements with captured yeast and other solid particles.

The housing is designed to operate with three 30″ CODE 7 type filter cartridges which are connected paralelly. Therefore all 3 filtration cartridges must be with the same porosity.

Compact and resistant even under harsh operating conditions, the materials used in the construction of the filter housing provide a high level of filtration quality.

In addition, the possibility of disassembling the various components simplifies the cleaning of the equipment after use.

Technical features and parameters :

- Material: AISI 316 stainless steel

- Liquid In / Out connections: 2x Butterfly valve DIN 11851 DN 25 male thread

- Filter cartridge connection type: 30″ CODE 7

- Drain: Ball valve BSP 1/4″ female

- Venting: 2x Ball valve BSP 1/4″ female

- Flow rate: 800-3000 L/h (depending on the filter cartridge clogging, cartridge type etc.)

- Pore size 0.1 – 10 µm (depending on the filter cartridge)

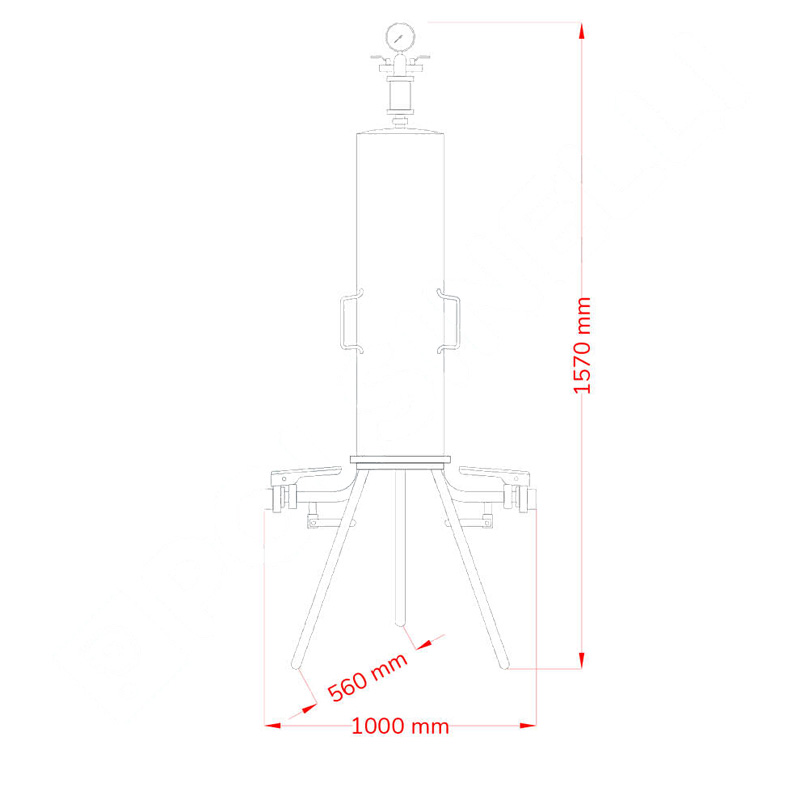

- Dimensions in mm: 1000 x 1000 x 1570 mm

- Weight: 35 kg

- Volume: 7.5 Litres

- Conforms to CE safety standards

- Filter cartridge not included

Dimensions :

We recommend you to purchase also :

FCSH-30C7 : Stainless steel housing for sterile storing 30/3″ filtration cartridge

Reviews

There are no reviews yet.