Description

CIP-A302 is an automatic control system for the mobile Cleaning In Place system CIP-302. The automatization includes all functions necessary to perfect cleaning and sanitation of all containers and optionally also pipes and hoses in a brewery using a special program, sensors, motorized valves and PLC industrial computer with the no-touch display. This control system is compatible only with the CIP-302 machine.

The automatic control system includes :

I. Hardware

- PLC processor unit : IFM CR1140 Ecomat

- Display : IFM Ecomat display 4.3“ (no touch, with control buttons)

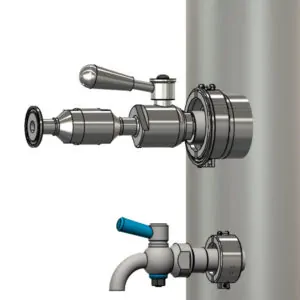

- Motorized valves – 7pcs of servovalve 1″ + 2pcs of servovalve 5/4″

- Thermo sensors – 1pc of IFM TA2135

- Conductivity sensor – IFM LDL200

- Full pipe sensor – IFM LMT100

- Level sensor – 2pcs of INDCOM SF141

- Induction flow meter – IFM SM8120

- IO link master – IFM AL1323

- IO link modul – IFM AL2334

- Emergency stop button

- Dosing peristatic pumps – 2pcs

- Cable set – IFM

- Holder of a storage canister with a concentrated chemical – 2pcs

II. Software (manual and automatic operations) :

Manual operations :

- Self cleaning of the CIP station (if the machine is equipped with the optional equipment for the self cleaning)

- Sludge removal from the CIP tanks

Automatic operations :

- Automatic keeping of the sanitizing solution level in the tanks

- Automatic dosing of the concentrated chemicals from canisters to the tanks

- Automatic keeping of the sanitizing solutions quality during the cleaning process

- Automatic heating and keeping the chemical solutions at required temperature

- Automatic rinsing cycle – with water (if a water hose is connected)

- Automatic cleaning cycle – with chemical solutions from the tanks

- Automatic venting when sanitizing solutions circulate

- Automatic flushing-through of the pipe system

- Automatic cleaning and sanitizing of the pipes and hoses (optionally, if the machine is equipped with the optional equipment for cleaning the hoses and pipe lines)

- Sensing and checking the quality of the sanitizing solution

Designed only for :

Reviews

There are no reviews yet.